Production process of run-resistant anti-snagging underwear, and seamless underwear

A production process and anti-snagging technology, which is applied to underwear, corsets, yarns, etc., can solve problems affecting the appearance and service life of underwear, snagging and loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

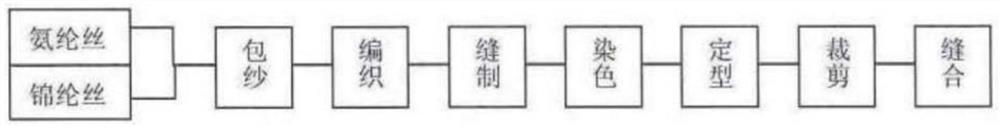

Method used

Image

Examples

Embodiment 1

[0033] Step 1, wrapped yarn

[0034] First, adjust the workshop temperature to 25°C and relative humidity to 65%, and use nylon and spandex yarns to wrap on a high-speed wrapping machine to make wrapped yarns suitable for weaving. Among them, spandex yarn is selected from model 15D-60D, and 20D special spandex is used in this embodiment, and nylon yarn is selected from FDY / DTY8D-70D, and DTY12 / 7 model is used in this embodiment. Among them, the draft ratio of wrapping is 2.7, the twist is 1600T / M, and the overfeed is 94%. Veil nylon yarn adopts FDY40 / 4 and DTY44 / 36 models (other models can also be selected according to needs).

[0035] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0036] 2. Weaving

[0037] Adjust the temperature of the weaving workshop to 25°C and the relative humidity to 65%. Put the required covered yarn in the weaving workshop to balance for five days, and then send it t...

Embodiment 2

[0056] 1. Wrapped yarn

[0057] Adjust the temperature of the workshop to 20°C and the relative humidity to 60%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is made of special spandex of model 15D, the nylon yarn is made of FDY / DTY 8D model, the draft ratio of wrapping is 3.0, the twist is 1700T / M, and the overfeed is 94.5%. 15D anti-loosening spandex is used as the inner wrapping yarn, and DTY / FDY 8D nylon is used as the outer wrapping yarn to ensure the aesthetics and breathability of underwear when the textile material is made into underwear.

[0058] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0059] 2. Weaving

[0060] Adjust the workshop temperature to 20°C and the relative humidity to 60%, send the covered yarn to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com