Cold roof prepared from PET modified film

A modification and roofing technology, which is applied to roofs, roofs using flat/curved panels, roof cladding, etc., can solve problems such as poor weather resistance and heat resistance, limited roof panel diversification, and poor thermal insulation performance. Achieve excellent weather resistance and heat resistance, not easy to embrittlement, fall off and yellowing, good heat insulation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

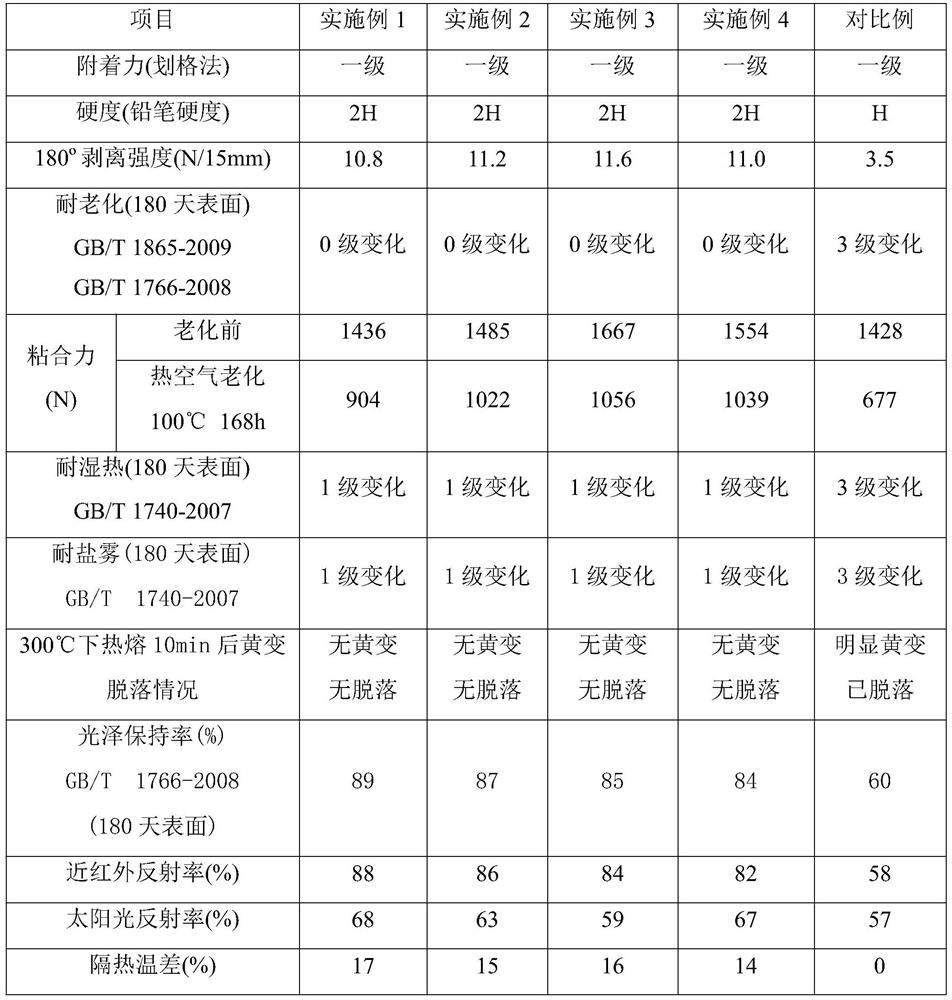

Examples

Embodiment 1

[0021] The preparation of a heat-reflecting roof panel prepared by a PET modified film comprises the following steps:

[0022] (1) Pre-treated aluminum foil board: the aluminum foil board is pickled and passivated, and then dried to obtain a pre-treated aluminum foil board;

[0023] (2) Pass SiO with a particle size of 6nm 2 Particle modified PET to obtain modified PET; the modified PET raw material is pre-crystallized and dried, and then enters the extruder to melt and plasticize, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; The adsorption device is pressed on the quenching wheel, rapidly cooled to form a cast sheet, and then stretched longitudinally and transversely in sequence (the longitudinal stretching ratio is 3.0, and the transverse stretching ratio is 3.4). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET modified film.

...

Embodiment 2

[0027] A kind of preparation of the cool roof that PET modified film prepares comprises the steps:

[0028] (1) Pretreated steel plate: the steel plate is subjected to alkali washing and passivation treatment, and then dried to obtain a pretreated steel plate;

[0029] (2) Pass SiO with a particle size of 12nm 2 Particle modified PET to obtain modified PET; the modified PET raw material is pre-crystallized and dried, and then enters the extruder to melt and plasticize, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; The adsorption device is pressed on the quenching wheel, rapidly cooled to form a cast sheet, and then undergoes longitudinal and transverse stretching in sequence (the longitudinal stretching ratio is 3.2, and the transverse stretching ratio is 3.6). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET modified film.

[0030...

Embodiment 3

[0033] A kind of preparation of the cool roof that PET modified film prepares comprises the steps:

[0034] (1) Pre-treated copper plate: the substrate plate is washed with water and passivated, and then dried to obtain a pre-treated copper plate;

[0035] (2) Pass SiO with a particle size of 20nm 2 Particle modified PET to obtain modified PET; the modified PET raw material is pre-crystallized and dried, and then enters the extruder to melt and plasticize, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; The adsorption device is pressed on the quenching wheel, rapidly cooled to form a cast sheet, and then stretched longitudinally and transversely in sequence (the longitudinal stretching ratio is 3.4, and the transverse stretching ratio is 3.8). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET modified film.

[0036] (3) Cover the PET ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com