Anti-shedding tile

A technology of anti-shedding and ceramic tiles, which is applied in the field of ceramic tiles, can solve the problems of falling off, high transportation cost, and low adhesion, and achieve the effect of improving adhesion strength, low transportation cost, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

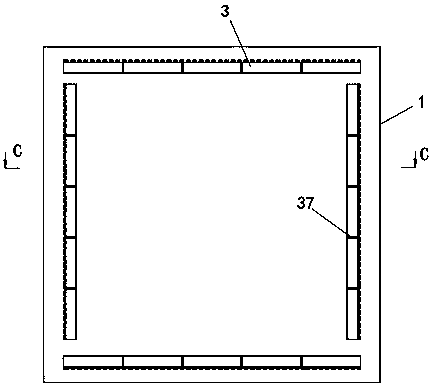

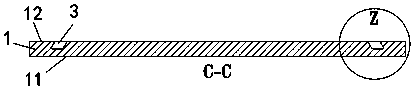

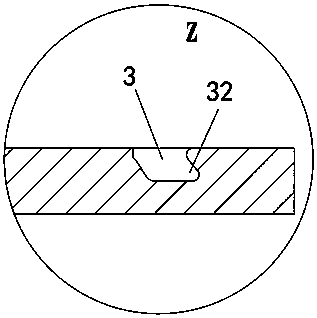

[0030] Such as Figure 1 to 3 As shown, the anti-falling ceramic tile includes a ceramic tile base 1. One side of the ceramic tile base 1 is a decorative surface 11 and the other is an adhesive surface 12. The adhesive surface 12 is provided with anti-drop grooves, which include two symmetrically arranged inclined grooves. 3. Two inclined grooves 3 form a figure eight structure with a cross section of a "eight" shape. The number of inclined grooves 3 is four. The four inclined grooves 3 are arranged perpendicular to each other and arranged in an "mouth" shape. The inclined direction of the inclined groove 3 It forms an acute bottom angle 32 with the bottom of the groove. The acute bottom corner 32 is a rounded corner. The four inclined grooves 3 are evenly provided with stiffeners 37. The stiffeners 37 fill the inclined groove 3, so that the stiffener 37 is partially inclined to the groove 3 and the ceramic tile base 1. The thickness is the same.

[0031] A total of four inclined...

Embodiment 2

[0035] Such as Figure 4 to 8 As shown, the anti-falling ceramic tile includes a ceramic tile base 1. One side of the ceramic tile base 1 is a decorative surface 11 and the other is an adhesive surface 12. The adhesive surface 12 is provided with anti-drop grooves, which include two symmetrically arranged inclined grooves. 3. Two inclined grooves 3 are connected symmetrically to form a figure-eight structure with a cross section of "eight". One side of the inclined groove 3 is provided with matching grooves 38 with the same number and symmetrically connected structure. The inclined groove 3 and the matching groove 38 constitute a cross section There are sixteen eight-shaped grooves 31 on the bonding surface 12, a total of sixteen inclined grooves 3 and sixteen matching grooves 38, four eight-shaped grooves 21 form a straight edge, four The straight edges constitute a "mouth" shape, and a circular groove 33 and a filling chute group 35 are uniformly provided in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com