Nano composition with hair loss preventing, hair growing, hair fixing and hair blackening functions as well as preparation method and application thereof

A nano-composition, a technology for preventing hair loss and regrowth, which are applied to a nano-composition with black hair function and its preparation, fix hair, have the field of preventing hair loss and regrowth, and can solve the problems of poor use effect, difficult adsorption, and insufficient efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of the nano composition described in the above technical scheme, comprising the following steps:

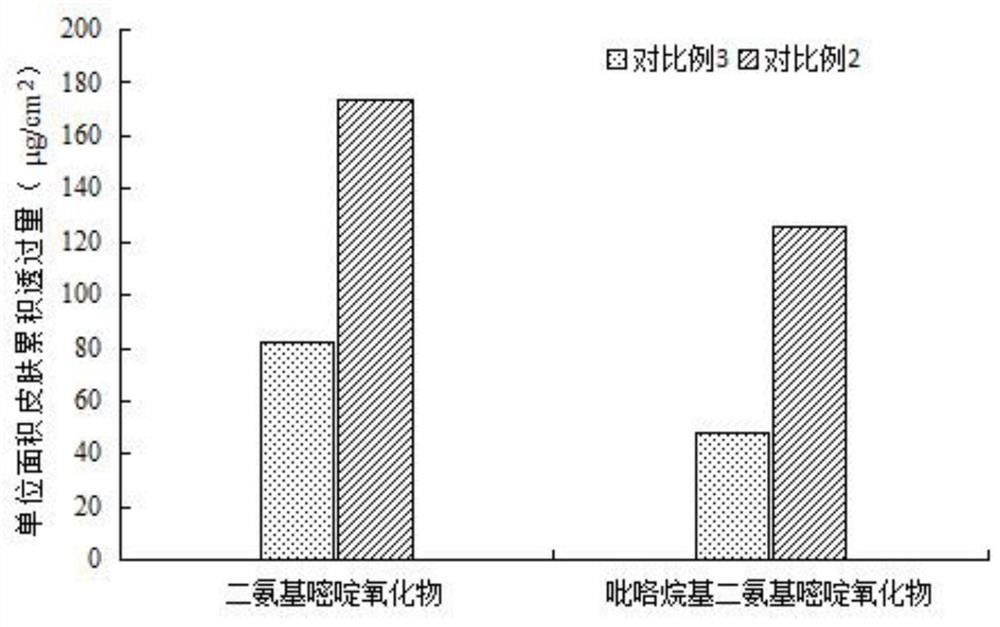

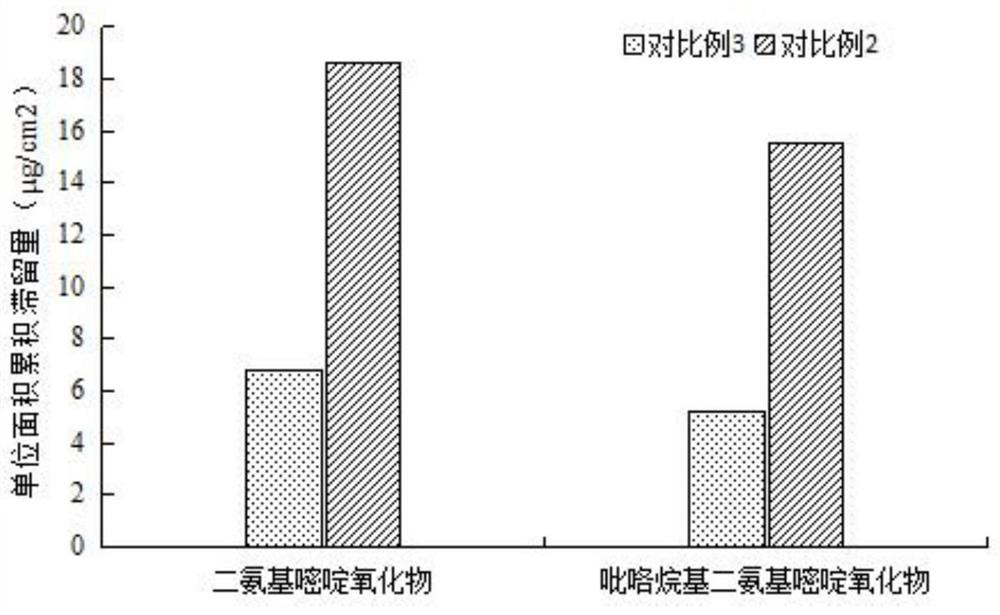

[0060] (1) The fat-soluble components in the phospholipid, cholesterol, cell penetrating agent, polyol, diaminopyrimidine oxide, pyrrolidinyl diaminopyrimidine oxide and hair growth peptide, hair-fixing peptide, black hair peptide are mixed, Dissolving at 20-60°C to obtain the first mixture;

[0061] (2) Mix the water-soluble ingredients in the hair growth peptide, hair-fixing peptide, and black hair peptide, polyhydric alcohol, vitamin E polyethylene glycol succinate and water, and dissolve at 20-60° C. to obtain the second mixture;

[0062] (3) adding the second mixture obtained in step (2) dropwise to the first mixture obtained in step (1), and then performing shear emulsification treatment to obtain a micron-scale dispersion;

[0063] (4) The micron-scale dispersion obtained in the step (3) is subjected to high-...

Embodiment 1

[0075] 5% soybean lecithin, 1% hydrogenated soybean lecithin, 0.5% cholesterol, 2% hydroxypropyl trimethyl ammonium chloride hydrolyzed soybean protein, 1% soybean oil trimethyl ammonium chloride, 20% propylene glycol, 5 % 1,2-pentanediol, 4% diaminopyrimidine oxide, 2% pyrrolidinyl diaminopyrimidine oxide and 0.1% palmitoyl hexapeptide-25 were mixed, heated and dissolved in a 35°C water bath to obtain the first mixture;

[0076] 0.1% Octapeptide-2, 0.1% Acetyl Tetrapeptide-3, 0.1% Biotin Tripeptide-1, 0.2% Acetyl Hexapeptide-1, 5% Glycerin and 3% Vitamin E Polyethylene Glycol Succinate Add it into 50.9% purified water, heat and dissolve in a water bath at 35°C to obtain the second mixture;

[0077] Add the second mixture dropwise to the first mixture and keep stirring. After the mixing is completed, high-speed shear emulsification is carried out at a speed of 5000 rpm for 8 minutes to obtain a micron-sized dispersion;

[0078] The micron-scale dispersion was subjected to hig...

Embodiment 2

[0081] 7% egg yolk lecithin, 1% cholesterol, 4% hydroxypropyltrimethylammonium chloride hydrolyzed soybean protein, 2% polyquaternium-51, 15% propylene glycol, 15% 1,2-hexanediol, 5 % diaminopyrimidine oxide, 2.5% pyrrolidinyl diaminopyrimidine oxide and 0.05% palmitoyl tripeptide-1 were mixed, heated and dissolved in a water bath at 40°C to obtain the first mixture;

[0082] Add 0.05% myristoyl pentapeptide-17, 0.05% myristoyl pentapeptide-16, 0.05% decapeptide-10, 0.1% copper peptide, 5% butanediol and 4% vitamin E polyethylene glycol succinate into 39.2% purified water, heated and dissolved in a 40°C water bath to obtain the second mixture;

[0083] Add the second mixture dropwise to the first mixture and keep stirring. After the mixing is completed, perform high-speed shear emulsification at a speed of 7000 rpm for 6 minutes to obtain a micron-sized dispersion;

[0084] The micron-scale dispersion was subjected to high-pressure homogenization treatment at a pressure of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com