New process for modifying rabbit hair fiber grafted silk protein

A technology of fibroin and rabbit hair fiber, applied in fiber treatment, animal fiber, biochemical fiber treatment, etc., can solve the problems of restricting fabric color, changing fabric style, damaging fibers, etc., achieving good anti-pilling effect and reducing consumption , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

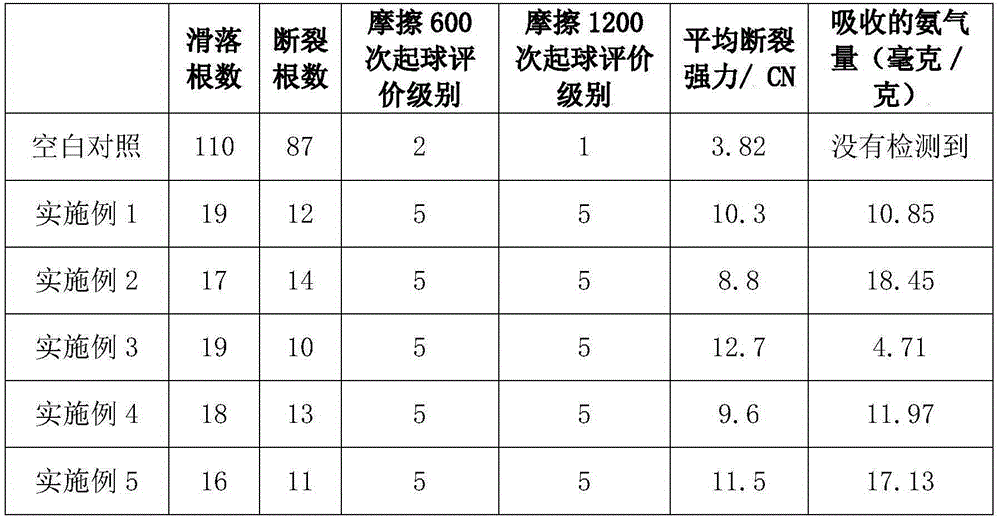

Examples

Embodiment 1

[0020] The process of grafting silk protein to modify rabbit hair fiber is as follows:

[0021] (1) Pretreatment:

[0022] Equipped with pretreatment solution: cellulase 0.9g / L, laccase 0.1g / L, silk protein 1g / L, fish skin collagen 0.5g / L, trehalose 0.5g / L;

[0023] The pretreatment process is: take the rabbit fur fabric soak in a water bath with a bath ratio of 1:30, put it into a constant temperature ultrasonic generator with an intensity of 10w / cm, keep it at a constant temperature of 40°C for 15 minutes, and then air dry.

[0024] (2) Silk protein grafting treatment:

[0025] Continue the grafting treatment on the pretreated rabbit fur fabric;

[0026] Equipped with finishing solution: 2% sucrose fatty acid ester, 2% silk protein, 2% flat plus O, pH value controlled at 6;

[0027] The treatment process is as follows: bath ratio is 1:50, put in a constant temperature ultrasonic generator, intensity of 6w / cm, water bath at 60℃ for 15min; 60℃ pre-drying for 20min, high temperature baking...

Embodiment 2

[0029] The process of grafting silk protein to modify rabbit hair fiber is as follows:

[0030] (1) Pretreatment:

[0031] Equipped with pretreatment solution: cellulase 0.9g / L, laccase 0.1g / L, silk protein 1g / L, fish skin collagen 0.5g / L, trehalose 0.5g / L;

[0032] The pretreatment process is: take the rabbit hair fabric soak in a water bath with a bath ratio of 1:30, put it into a constant temperature ultrasonic generator with an intensity of 12w / cm, keep it at a constant temperature of 40°C for 9 minutes, and then air dry.

[0033] (2) Silk protein grafting treatment:

[0034] Continue the grafting treatment on the pretreated rabbit fur fabric;

[0035] Equipped with finishing solution: 2% sucrose fatty acid ester, 2% silk protein, 2% flat plus O, pH value controlled at 8;

[0036] The treatment process is as follows: bath ratio is 1:50, put in a constant temperature ultrasonic generator, intensity of 6w / cm, water bath at 60℃ for 12min; pre-drying at 60℃ for 20min, high temperature bak...

Embodiment 3

[0038] The process of grafting silk protein to modify rabbit hair fiber is as follows:

[0039] (1) Pretreatment:

[0040] Equipped with pretreatment solution: cellulase 0.9g / L, laccase 0.1g / L, silk protein 1g / L, fish skin collagen 0.5g / L, trehalose 0.5g / L;

[0041] The pretreatment process is: take the rabbit hair fabric soak in a water bath with a bath ratio of 1:30, put it into a constant temperature ultrasonic generator with an intensity of 11w / cm, keep it at a constant temperature of 40°C for 13 minutes, and then air dry.

[0042] (2) Silk protein grafting treatment:

[0043] Continue the grafting treatment on the pretreated rabbit fur fabric;

[0044] Equipped with finishing solution: 2% sucrose fatty acid ester, 2% silk protein, 2% flat plus O, pH value controlled at 7;

[0045] The treatment process is as follows: bath ratio is 1:50, put in a constant temperature ultrasonic generator, intensity of 6w / cm, water bath at 60℃ for 14min; pre-drying at 60℃ for 20min, high temperature ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com