Patents

Literature

36results about How to "Crimp firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

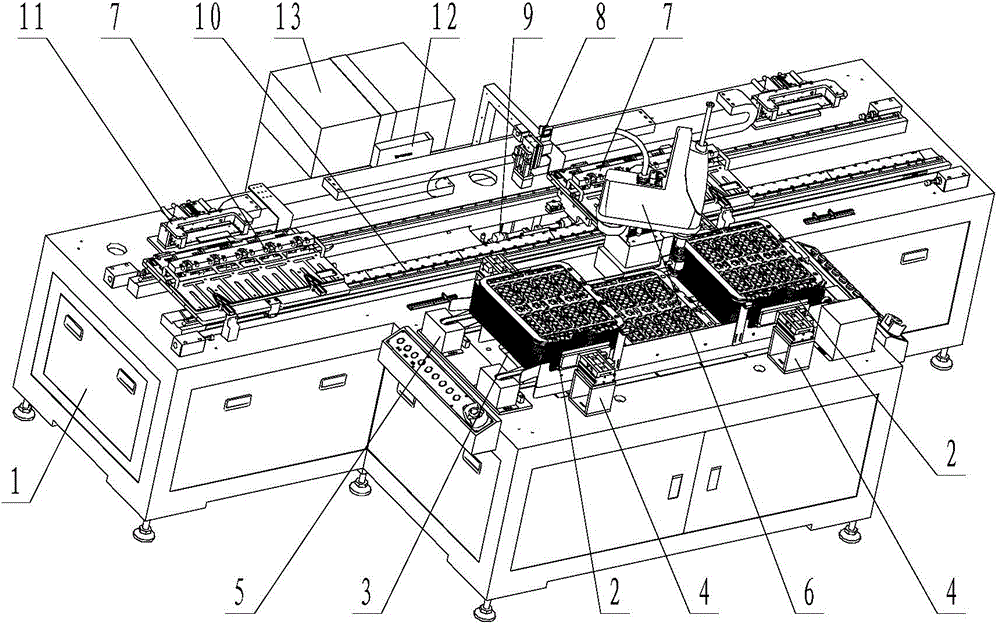

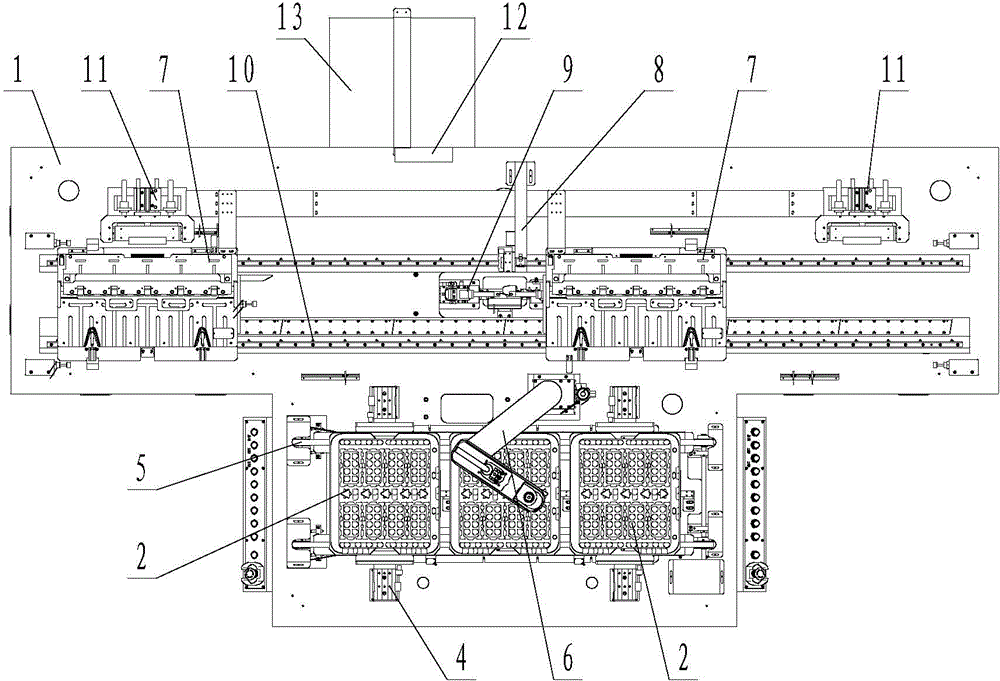

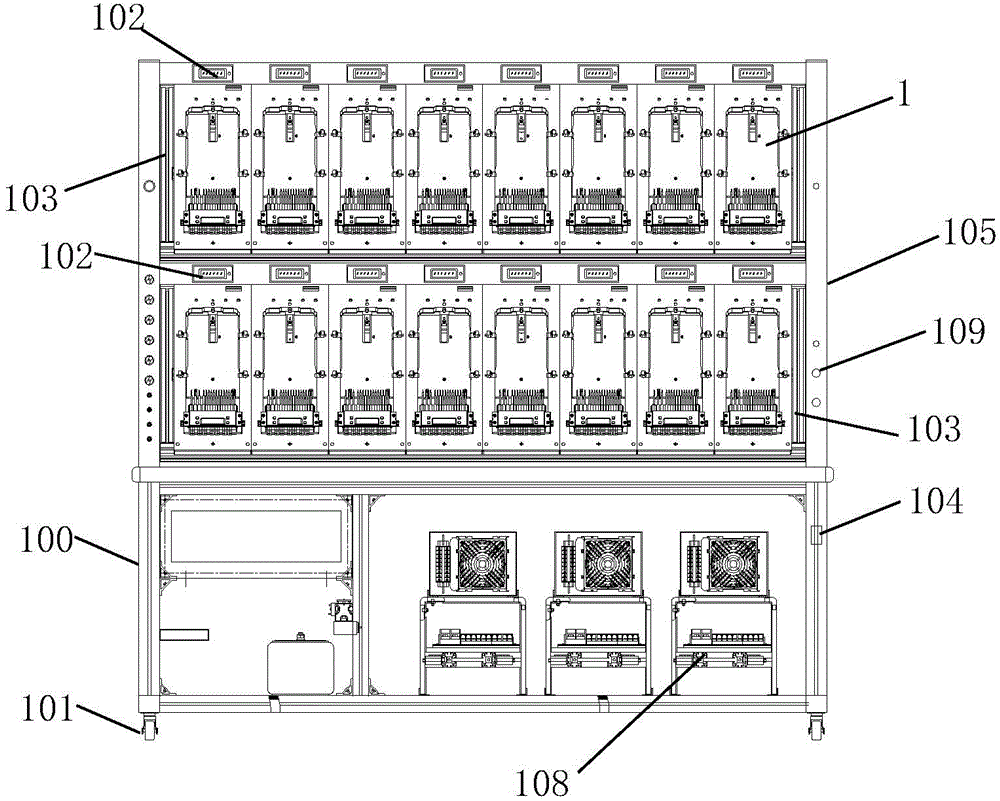

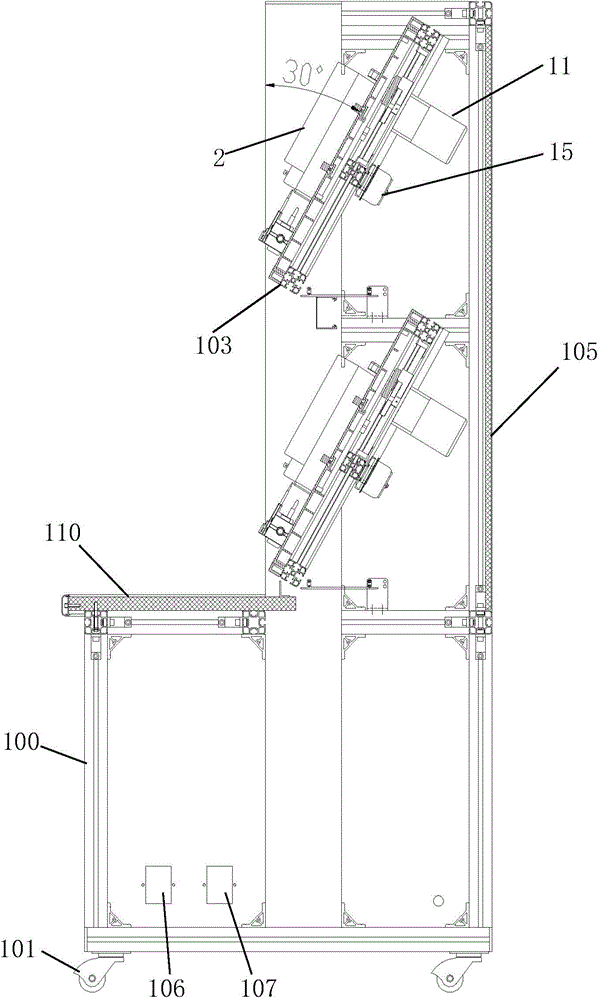

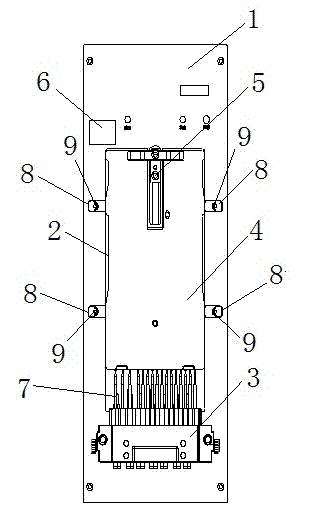

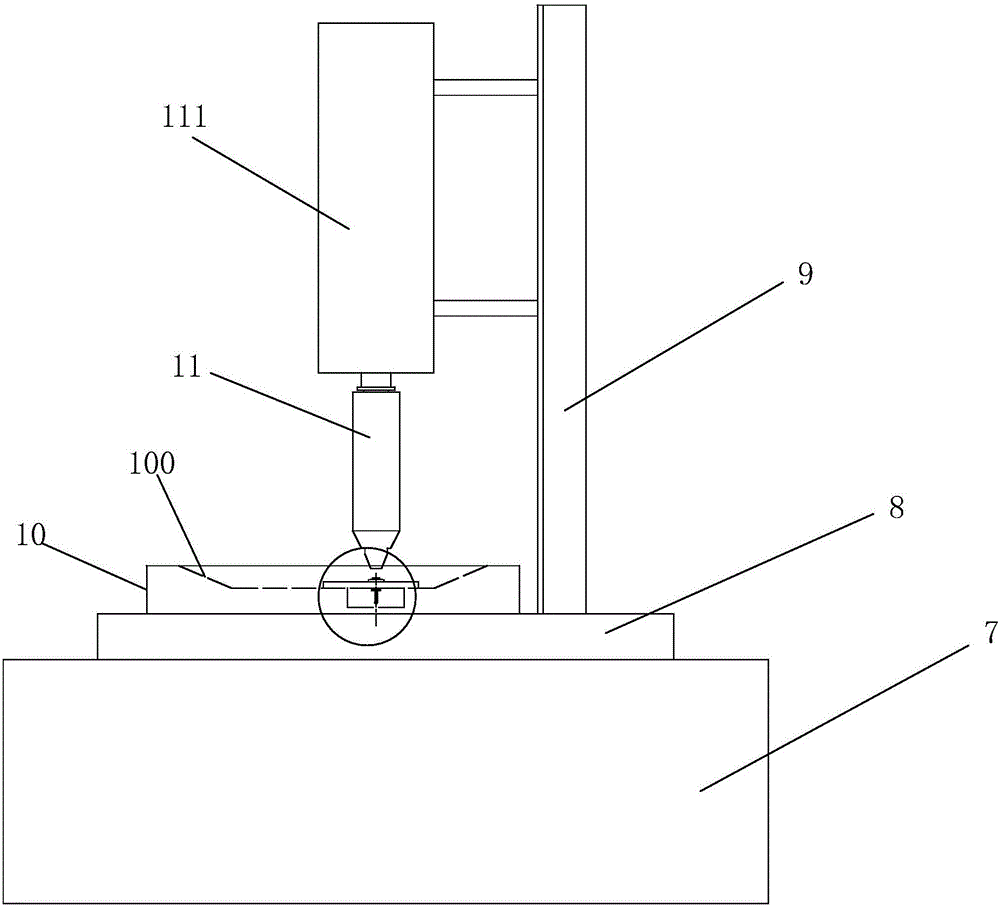

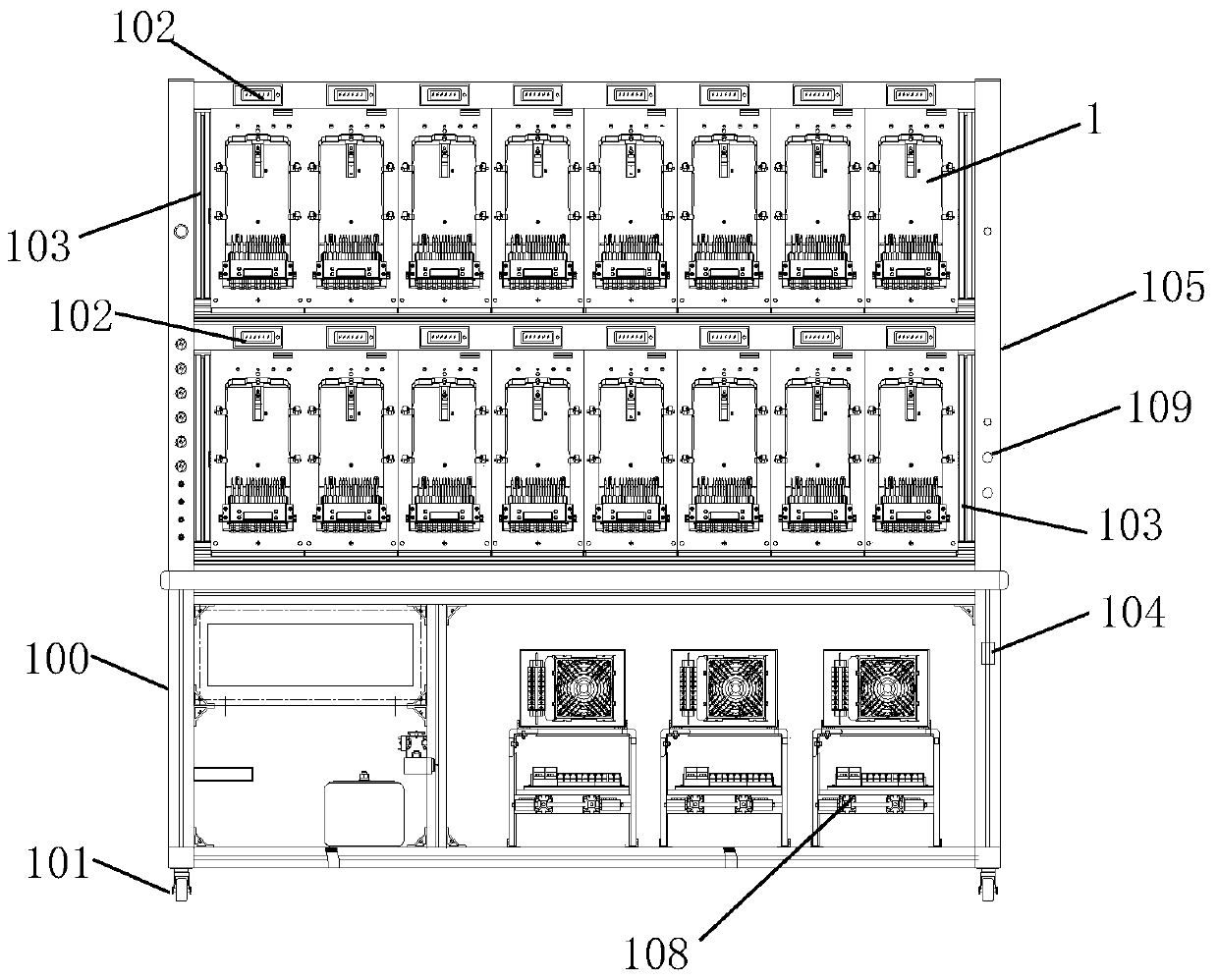

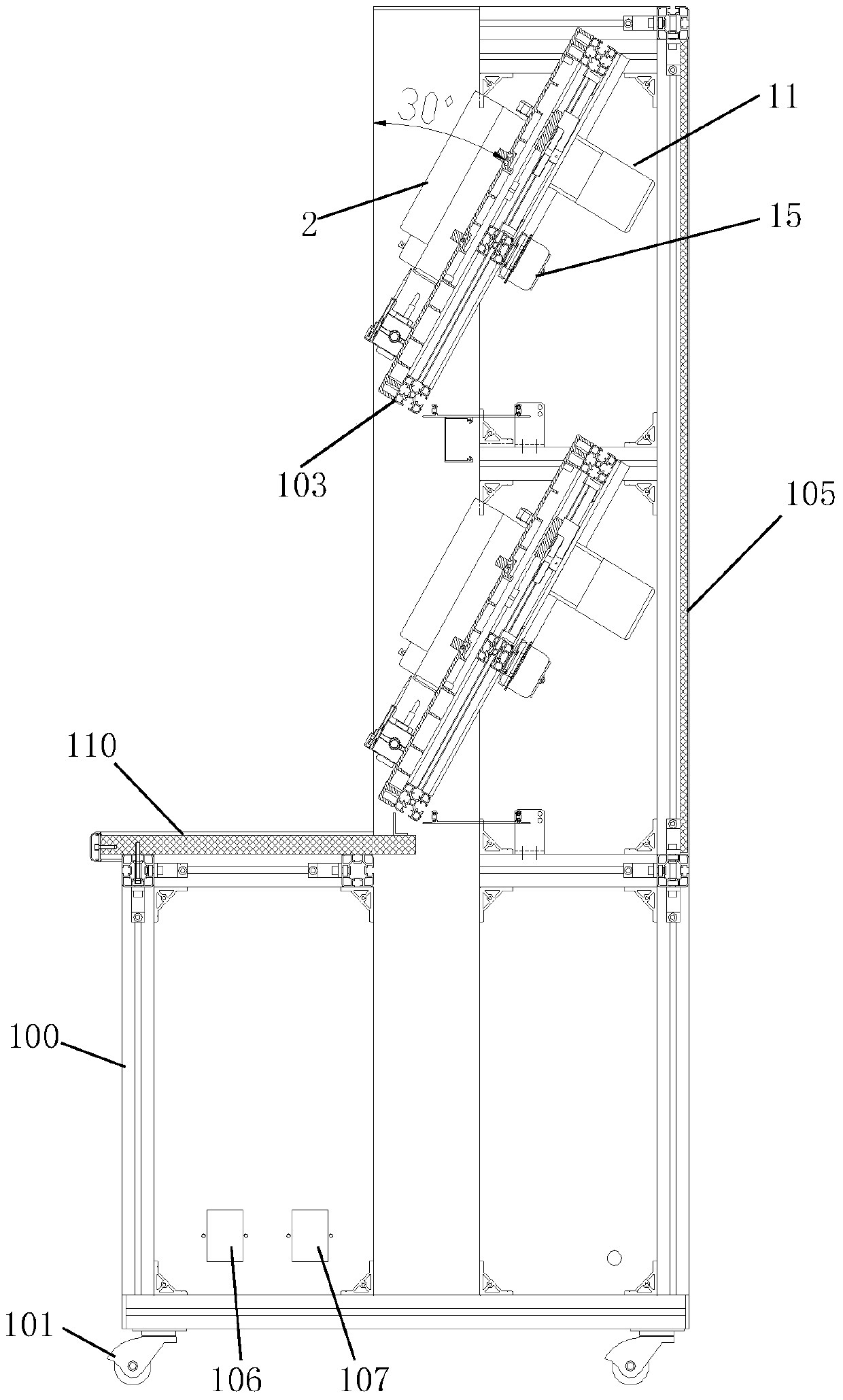

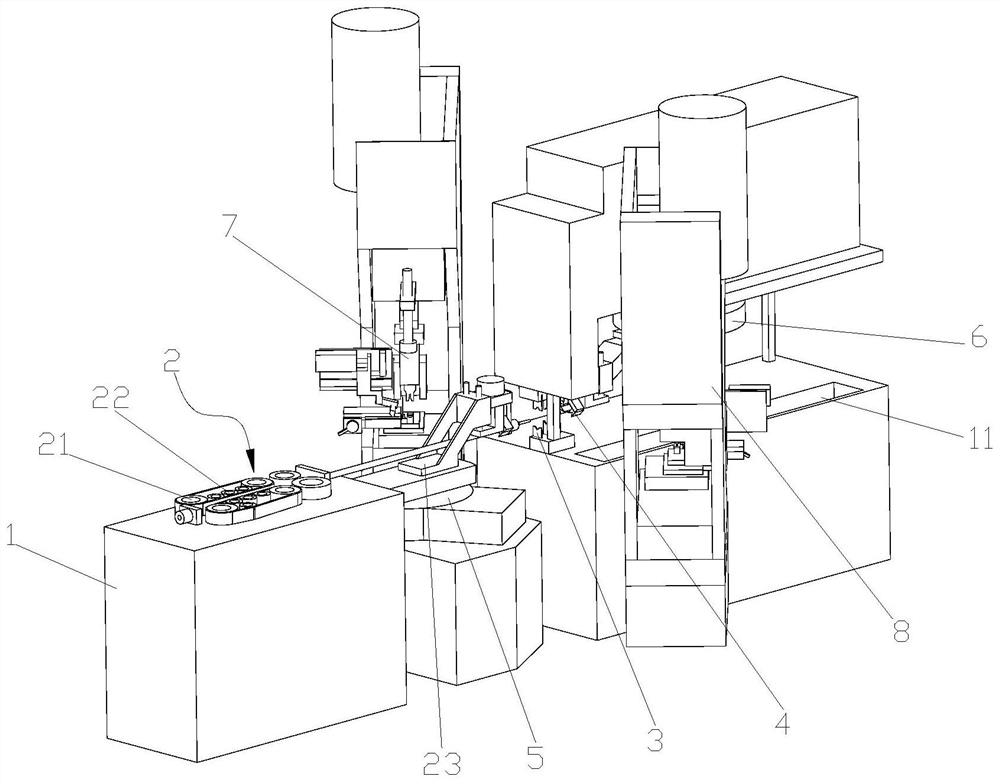

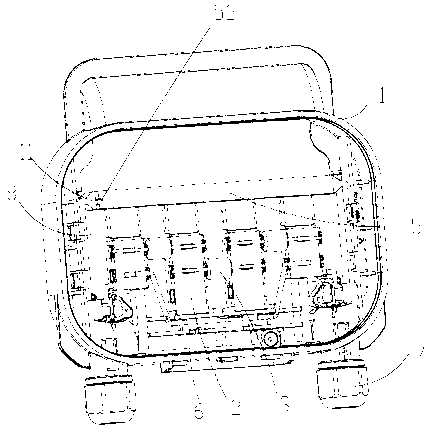

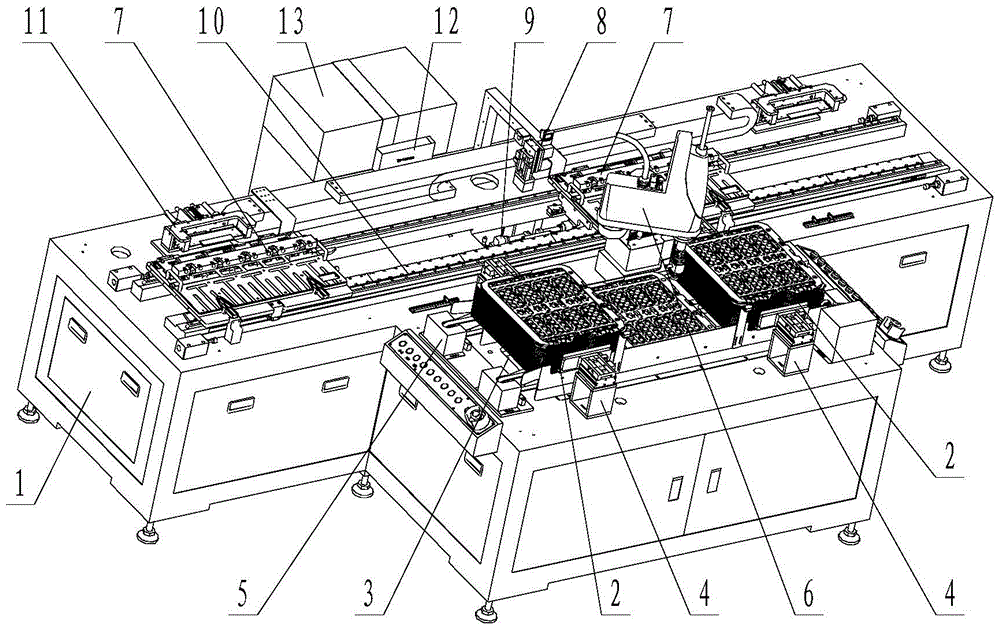

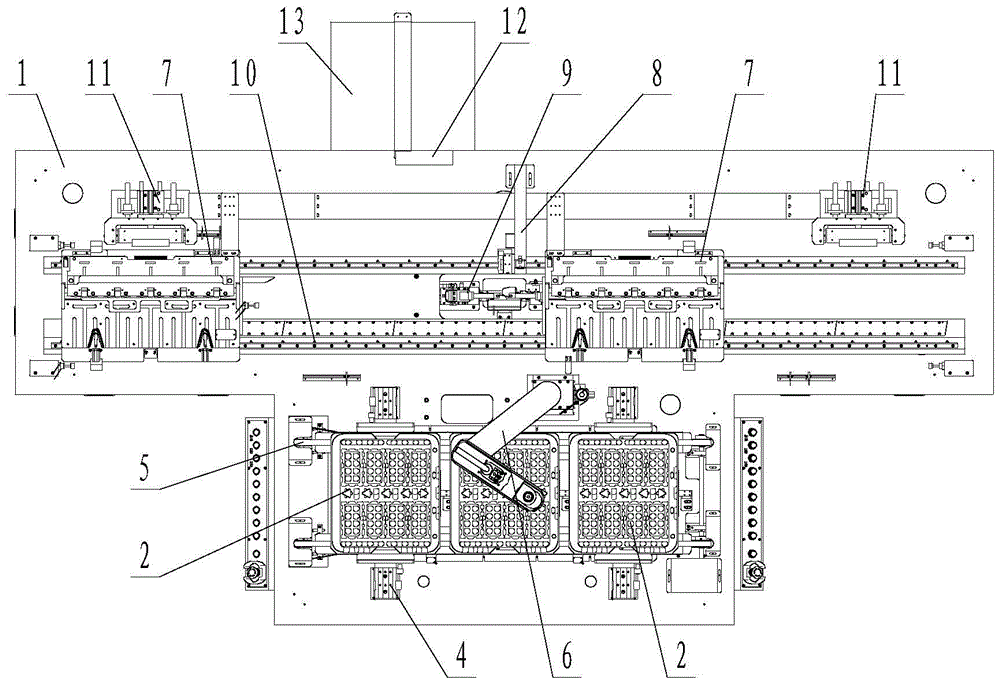

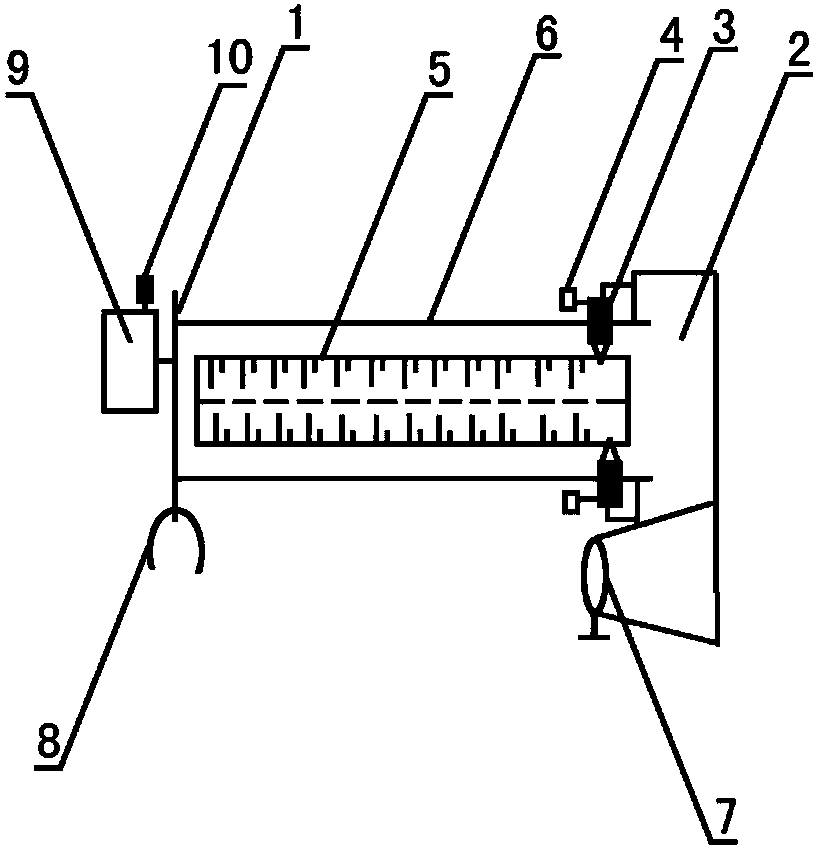

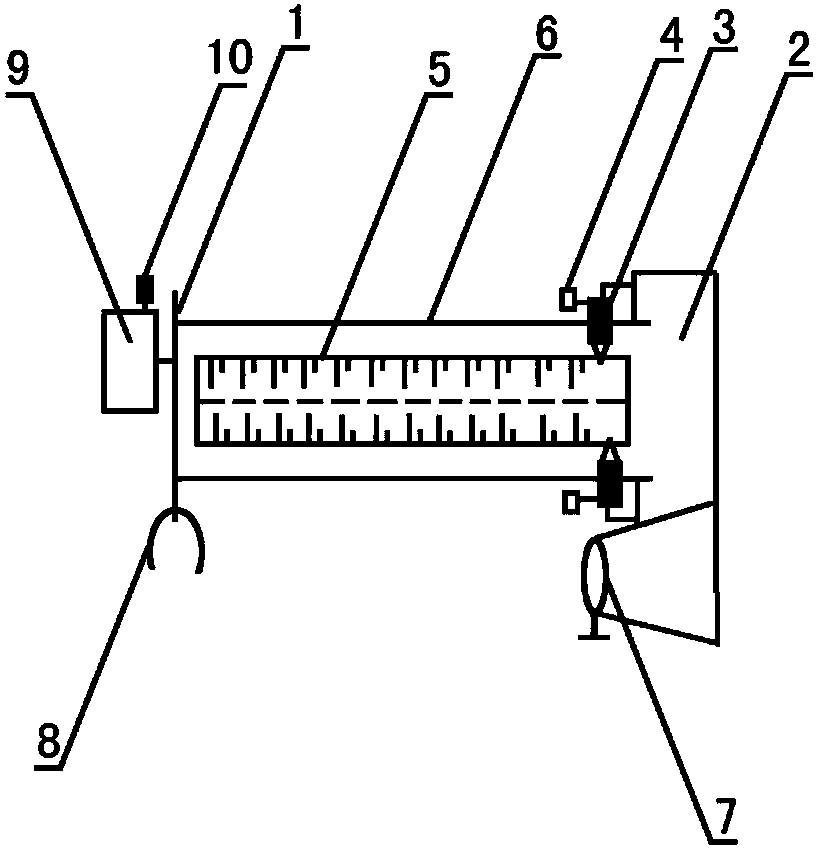

OLED panel test device

ActiveCN104391206ARealize point screen test controlHigh degree of automationElectrical testingTest efficiencyEngineering

The invention belongs to the technical field of OLED panel test, and specifically relates to an OLED panel test device. The OLED panel test device comprises a machine frame, a support tray, a support tray lifting device, support tray clamping devices, a support tray moving device, a conveying device, a pressure jointing fixture, a pressing device, an aligning device, a linear moving device, a port connecting device, an image signal generator which is mounted on the machine frame, and a control terminal; the support tray is placed in a support tray moving position and arranged at the top of the support tray lifting device; the support tray clamping devices are arranged at bilateral sides of the tray; the conveying device is located between the support tray moving device and the linear moving device; the pressure jointing device is mounted on a slide platform of the linear moving device; the aligning device is located below the pressure jointing device; both the pressing device and the port connecting device are arranged at one side of the linear moving device. The OLED panel test device achieves screen-lightening test of OLED panel, the whole process is highly automated, the operation is simple, and the test efficiency is high.

Owner:KUSN JINGXUN ELECTRONICS TECH

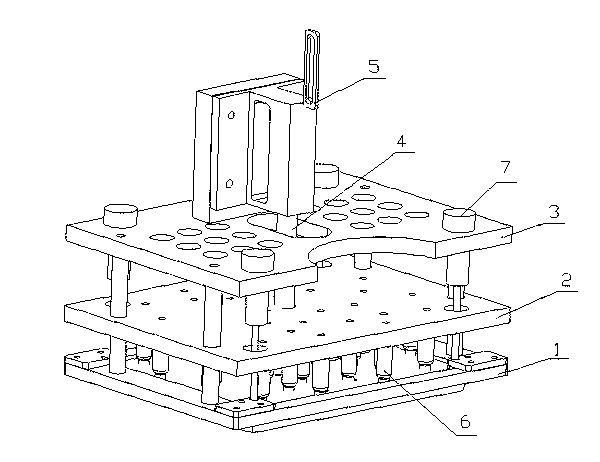

Assembly device for welding circuit board and heat sinking base plate and welding method thereof

InactiveCN102837099AReliable crimpingCrimp firmlySoldering auxillary devicesAudio power amplifierManufacturing technology

The invention discloses an assembly device for welding a circuit board and a heat sinking base plate and a welding method of the assembly device, relating to the emitting and manufacturing technical field of a radio and a television. The assembly device comprises clamping board layers consisting of a bottom board, a middle board and a top board which are horizontally arranged in sequence, and a clamping rod which is arranged on the centers of the clamping plate layers and penetrates through the three layers of the clamping plates, wherein a clamp handle capable of clamping or loosening the three layers of the clamping plates is arranged on the top end of the clamping rod; and bolts for fixing the three layers of the clamping plates are respectively arranged on four corners of the clamping plate layers. A welding piece consisting of a power amplifier module circuit board and the heat sinking base plate can be arranged on the bottom board; a plurality of pressing columns with pressure spring devices are fixedly connected below the middle board vertically; and a position of each pressing column is in one-to-one correspondence with the power amplifier module circuit board and a pressing hole on the heat sinking base plate respectively. Compared with the prior art, the assembly device can effectively ensure the power amplifier module circuit board to reliably connect with the heat sinking base plate for a long time, so as to achieve good electrical conductivity and thermal conductivity, and improve working stability and reliability of an amplifier.

Owner:BEIJING TONGFANG GIGAMEGA TECH

Rapid three-phase electronic type electric energy meter calibration crimp connection device and calibration method thereof

ActiveCN104569530AImprove test efficiencyImprove accuracyElectrical measurementsElectric machineryElectrical control

The invention belongs to the technical field of three-phase electronic type electric energy meter automation, and particularly relates to a rapid three-phase electronic type electric energy meter calibration crimp connection device and a calibration method thereof. Wheels are arranged at the bottom of the crimp connection device, a workbench is arranged on an electric control box supported through the wheels, a meter rack is vertically arranged on the workbench, multiple layers of meter hanging plates are arranged on the meter rack in an inclined mode, multiple unit meter plates are arranged on the surface of each meter hanging plate, left blocks and right blocks are arranged on the edges of the left side and the right side of each unit meter plate, and a control motor is arranged on the back face of each unit meter plate; a hollow plane groove is formed in the surface of each unit meter plate, a sliding floor is arranged in the hollow plane groove, and a three-phase electronic type electric energy meter is arranged on the surface of the sliding floor; left sliding grooves are formed between the sliding floor and the left blocks, right sliding grooves are formed between the sliding floor and the right blocks, a device meter bracket is arranged between the bottom edge of the unit meter plate and the bottom edge of the hollow plane groove, and crimp terminals are arranged on the device meter bracket.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU +1

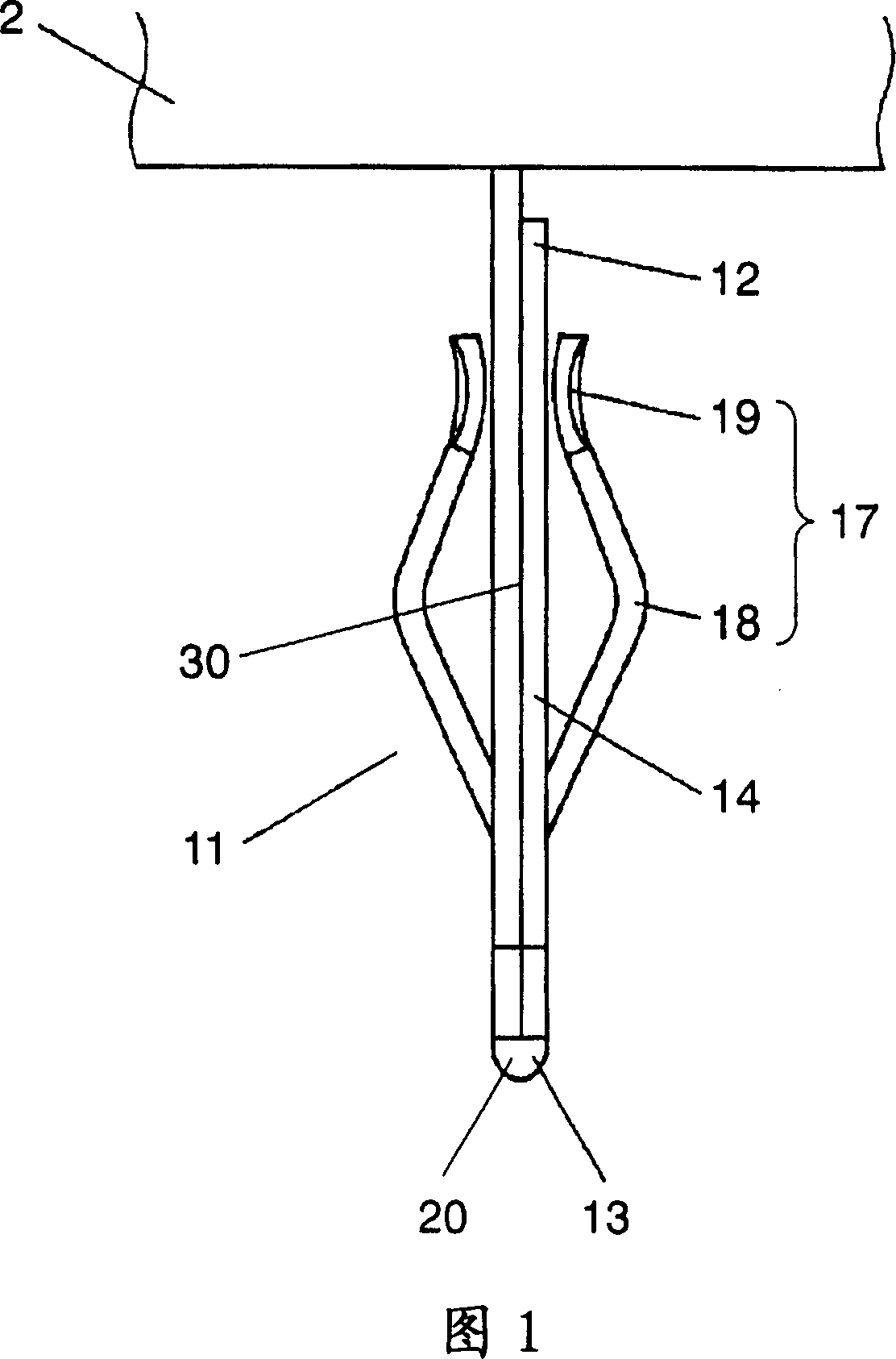

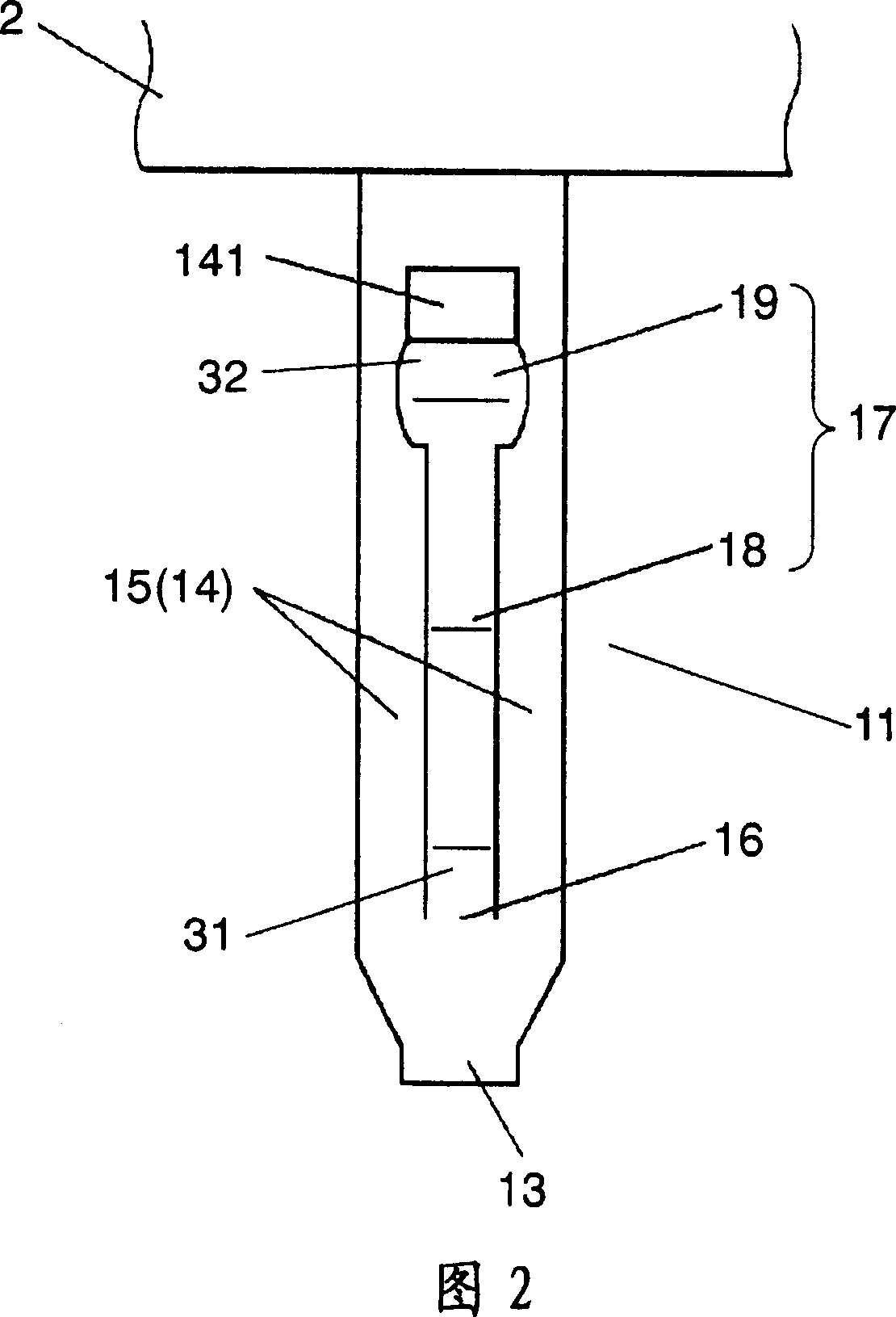

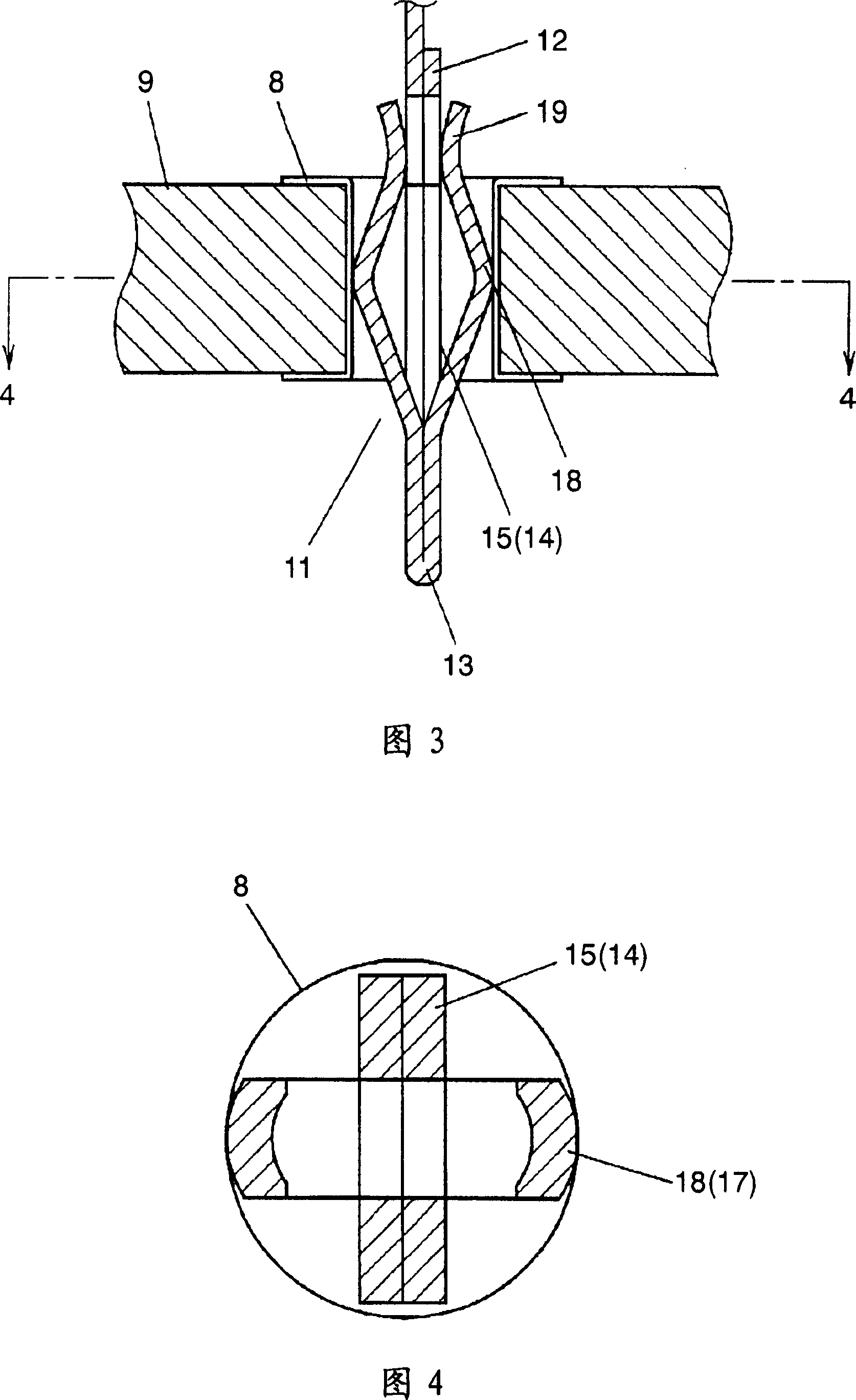

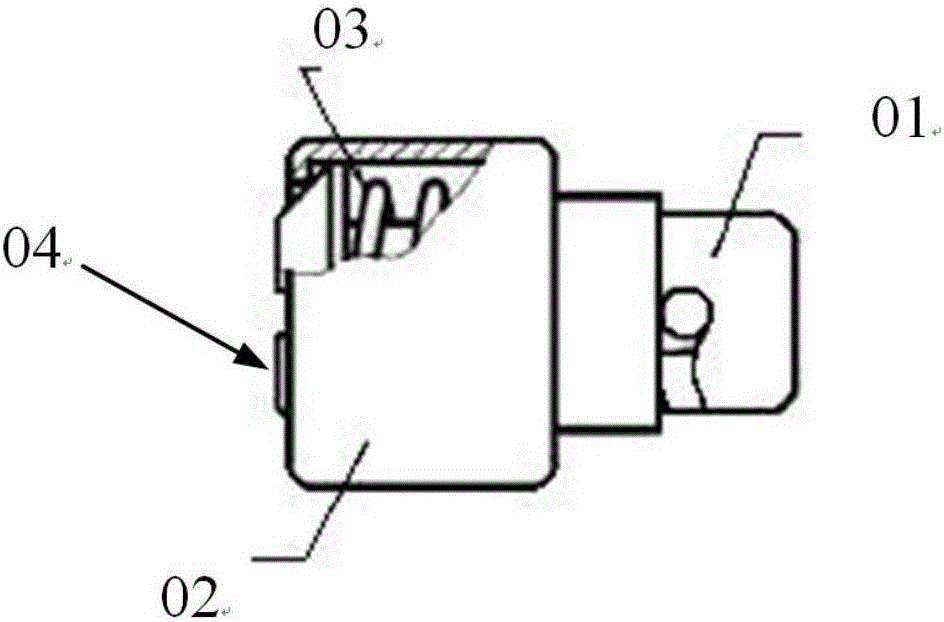

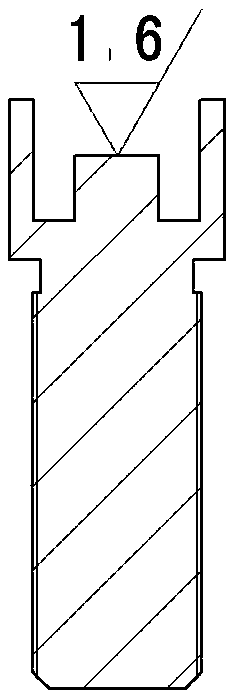

Press-fit fixing terminal, and electronic component having the same terminal

InactiveCN1964140ANot prone to plastic deformationCrimp firmlyPrinted circuit aspectsPrinted circuit manufactureEngineeringElectronic component

A press-fit fixing terminal is mountable to a wiring board by being inserted into a through-hole of the wiring board, and includes a flat plate section and a resilient contacting section. The flat plate section is made of metal thin plate and double-backed such that an end of the flat plate section is placed on a root side and a bent point works as an insertion tip when the terminal is inserted into the through-hole. The resilient contacting sections sandwich the double-backed portion of the flat plate section such that they are placed symmetrically with respect to the double-backed portion and both of the ridges of the resilient contacting section face outward viewed from the double-backed portion, so that each one of the resilient contacting sections forms a V-shape including an obtuse angle.

Owner:PANASONIC CORP

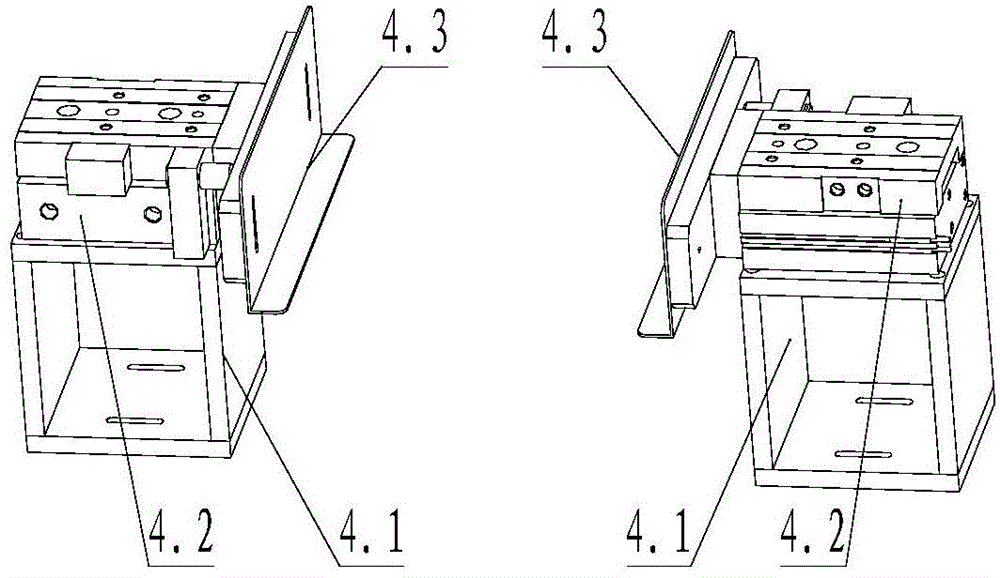

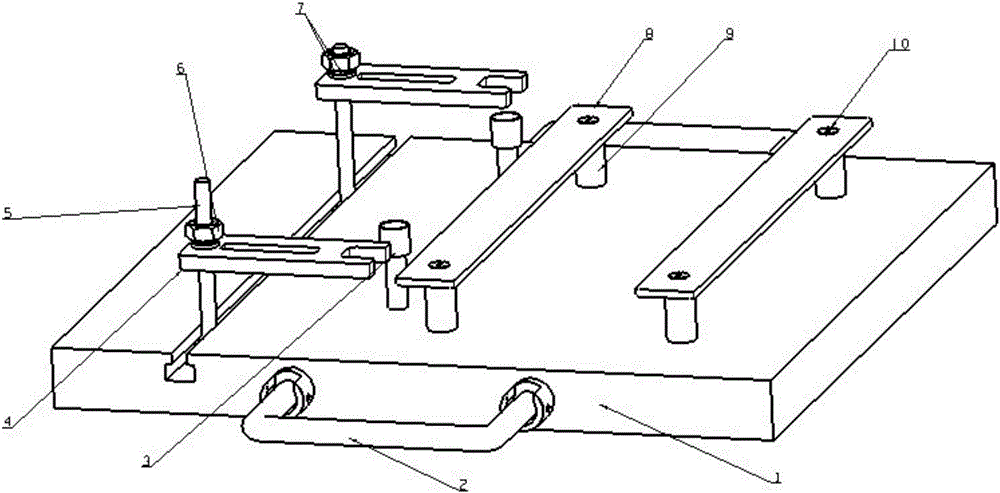

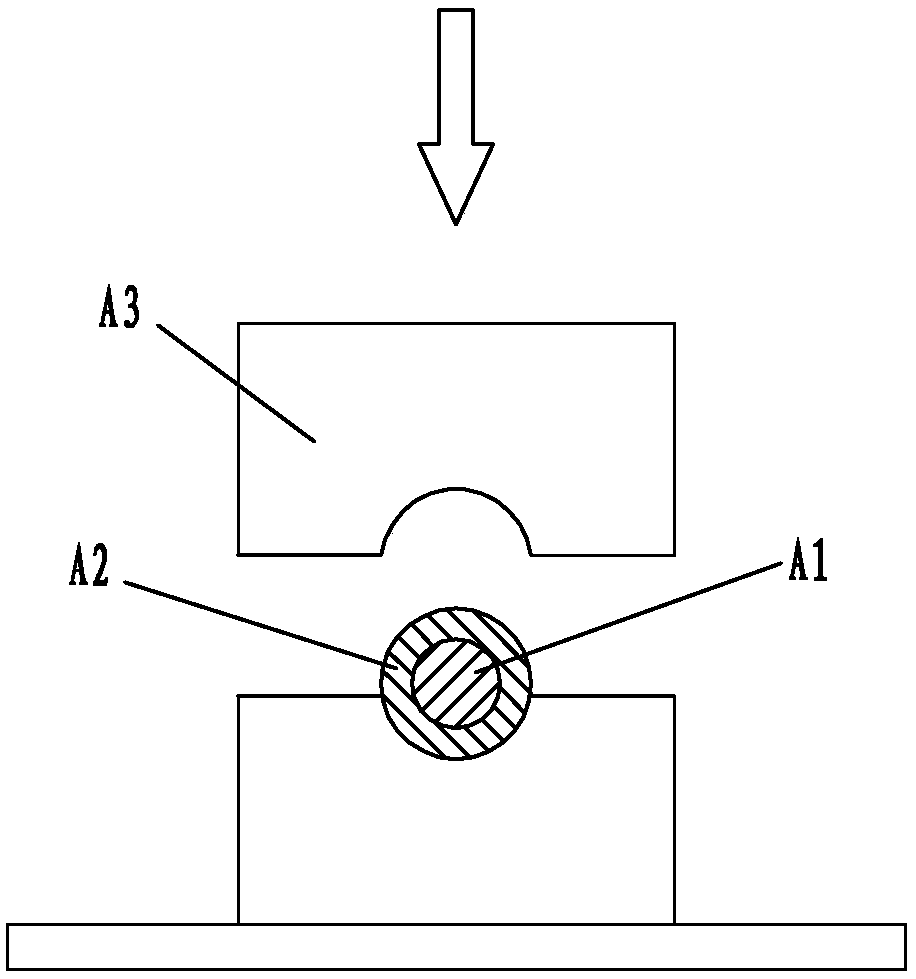

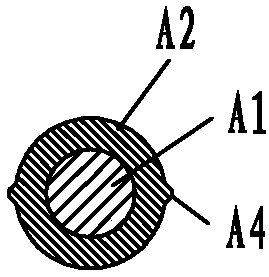

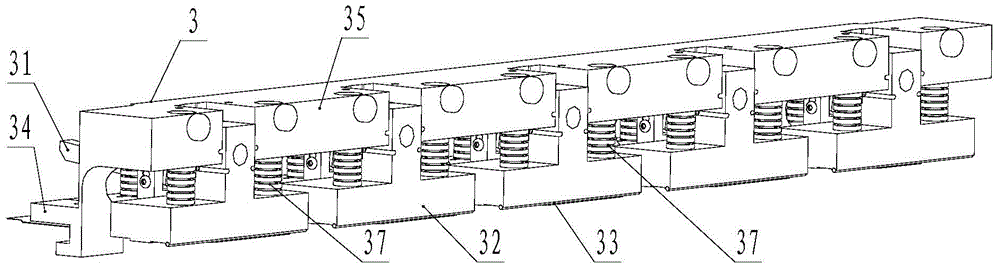

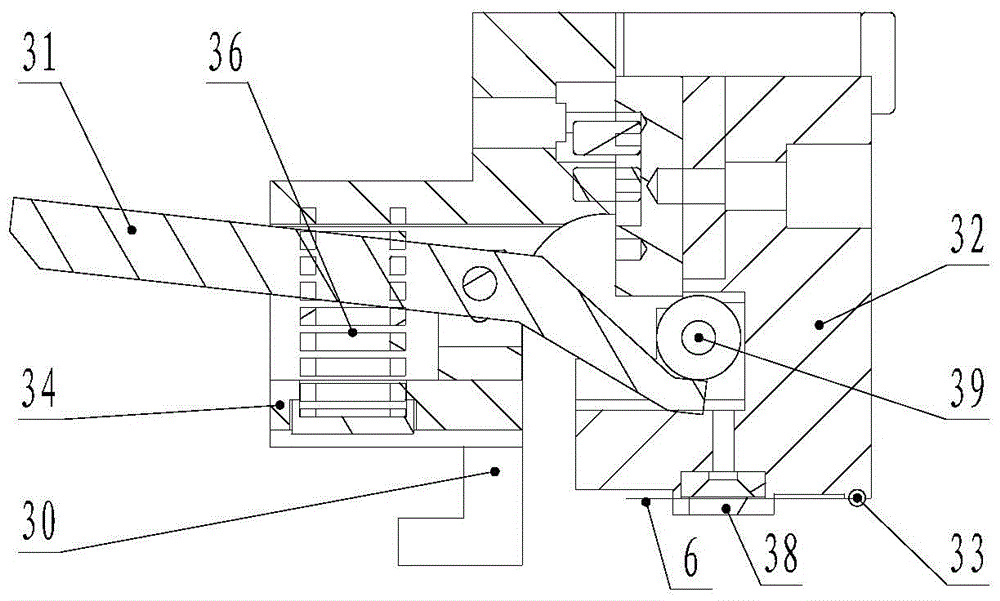

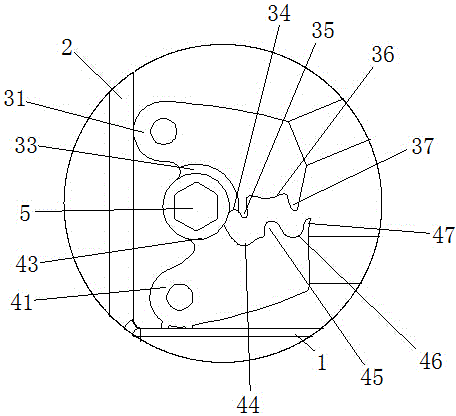

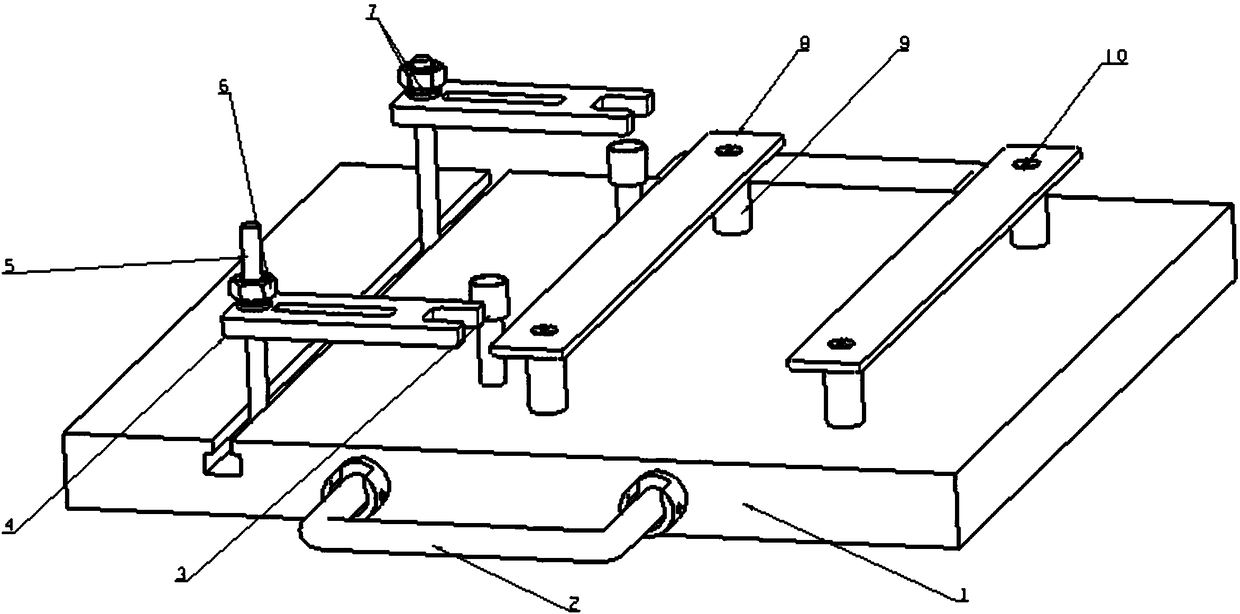

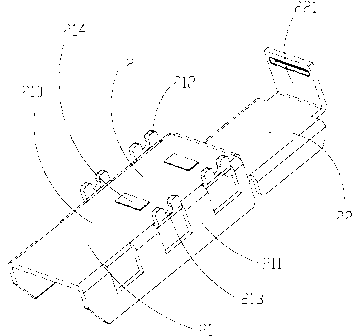

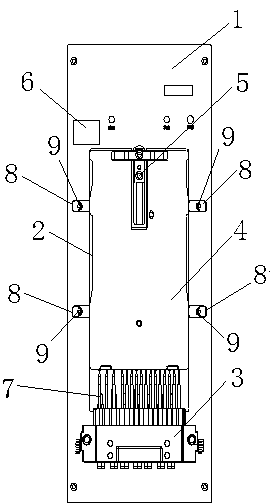

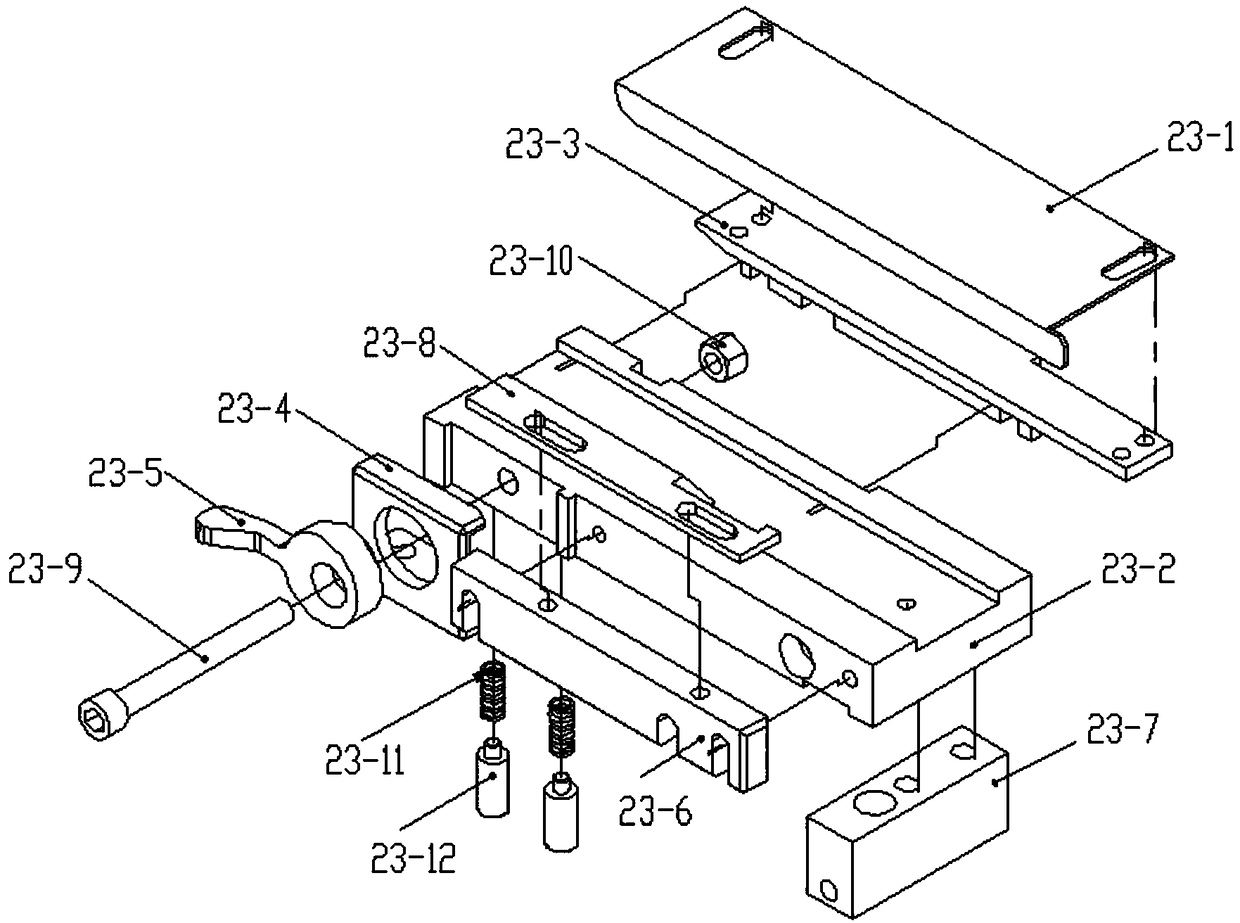

Automatic positioning and crimping device and automatic positioning and crimping method of binding post of intelligent electric energy meter

ActiveCN102928807ACrimp firmlyStable stitch removalElectrical measurementsEngineeringManufacturing enterprises

The invention discloses an automatic positioning and crimping device and an automatic positioning and crimping method of a binding post of an intelligent electric energy meter. An upper surface of a base plate is provided with a sliding bottom plate which can automatically slide; two slide grooves respectively and outwardly extend on left and right sides of the sliding bottom plate; each slide groove is internally provided with a sliding rolling bead for positioning an intelligent electric energy meter to be detected to realize the function of automatically guiding and positioning the intelligent electric energy meter; the detection efficiency and the detection accuracy are greatly improved; the rapid crimping and clearing of the binding post of the stable, high-efficiency and high-reliability intelligent electric energy meter are realized; the crimping success rate of automatically detecting the binding post of the electric energy meter is improved and technical guarantees are provided for the reliable operation of an automatic detection system of the electric energy meter; and the automatic positioning and crimping device and the automatic positioning and crimping method can be widely applied to the automatic detection system of the electric energy meter in other electric power companies, electric energy meter manufacturing enterprises and related fields, and have a good application prospect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

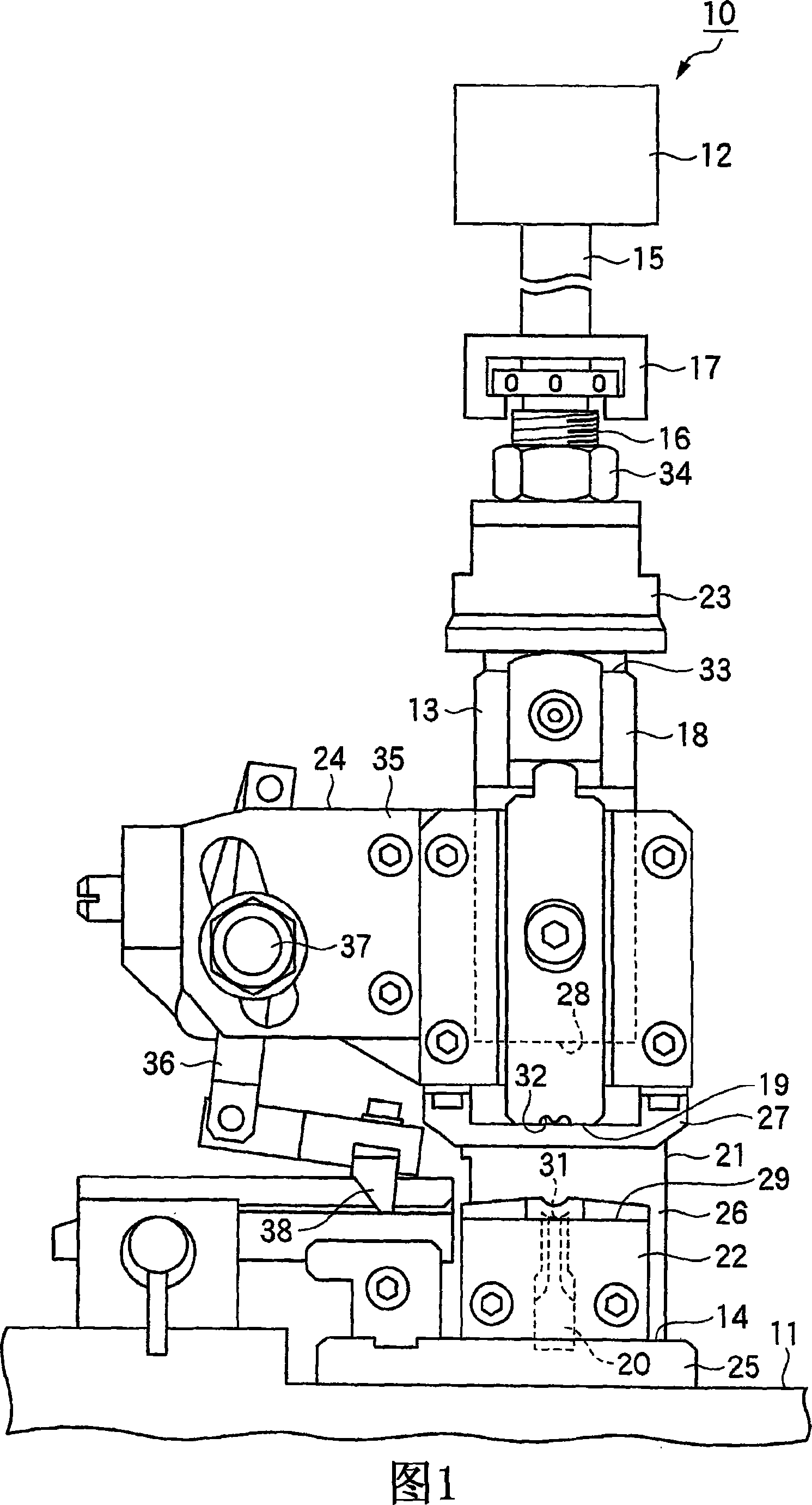

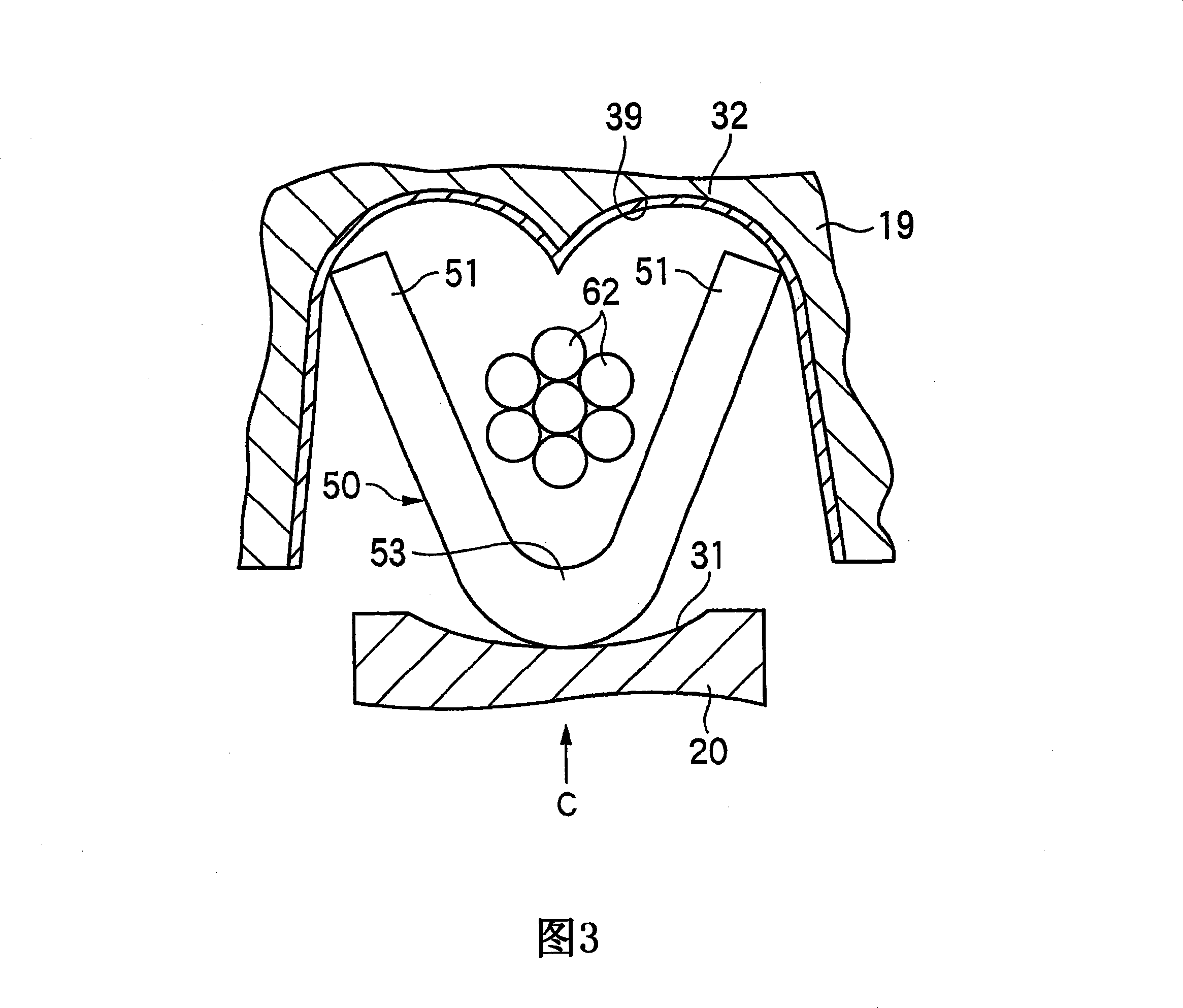

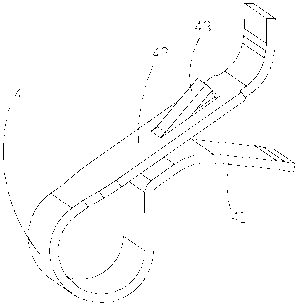

Crimping apparatus

InactiveCN101227054ACrimp firmlyImprove mechanical propertiesLine/current collector detailsEngineeringMechanical engineering

A crimping device comprising an anvil for supporting a metal terminal including a base plate portion for mounting an electric wire thereon, and a pair of crimping crimps respectively extending upward from opposite sides of the base plate portion. a tab part; and a crimping device, the crimping device has a pressing and fixing part for pressing and fixing the crimping piece part. The anvil cooperates with the pressing and fixing part of the crimper to press and fix the crimping piece part, which is used for crimping the crimping piece part to the electric wire installed on the metal terminal. Mirror-finishing is performed on the press-fixed portion.

Owner:YAZAKI CORP

Quick-release spiral lock catch riveting tooling

The invention discloses a quick-release spiral lock catch riveting tooling. The quick-release spiral lock catch riveting tooling comprises a supporting part and a riveting tool, wherein the supporting part comprises a base, and height-adjustable base plates are arranged on the base and used for supporting box boards; movable screws are also arranged on the base, and height-adjustable press plates are mounted on the screws; a height-adjustable cushion block is further arranged between each screw and the corresponding base plate, a groove with an inverted U-shaped cross section is formed in the top of the cushion block, and the size of the cushion block is matched with that of a lock nut of a quick-release spiral lock catch; an U-shaped opening is formed in one end, close to the corresponding cushion block, of each press plate; the riveting tool comprises a lengthening bar and riveting punches detachably connected with the lengthening bar, inner grooves are formed in tops of the riveting punches, outer edges are chamfered, lock pins are sleeved with the inner grooves in the tops, and flanging operation of riveting is realized under the chamfering action by the aid of external force. The quick-release spiral lock catch riveting tooling is firm in compression joint and high in practicability; if manual pressing is replaced with tooling pressing, manpower and working hours can be saved, and meanwhile, the qualification rate of riveting is increased.

Owner:TIANJIN JINHANG COMP TECH RES INST

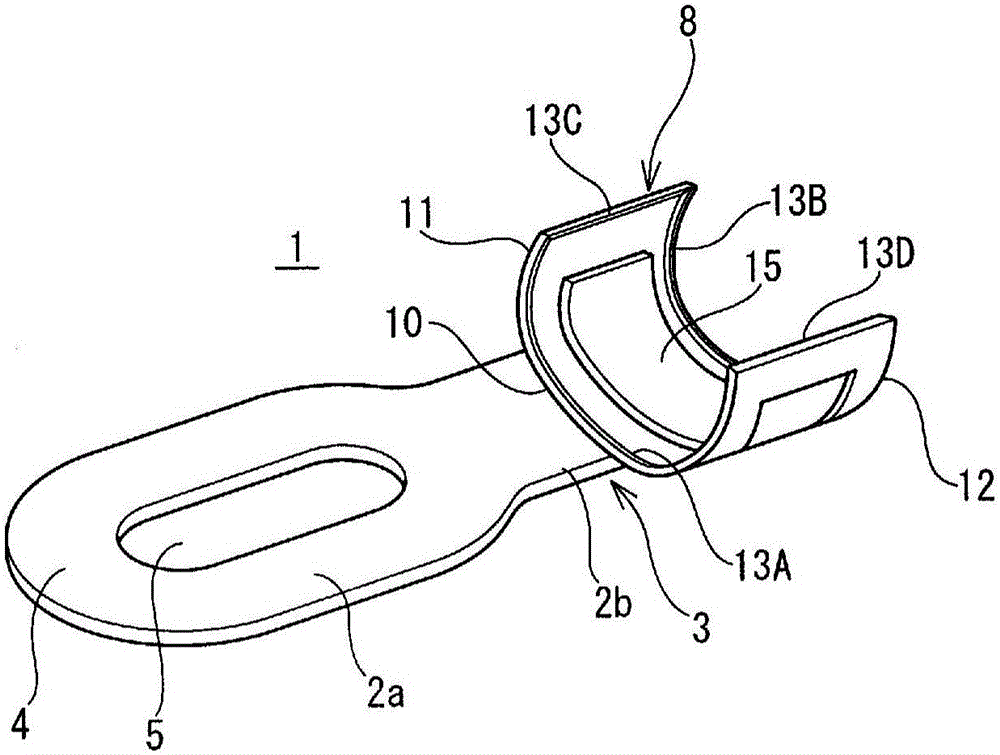

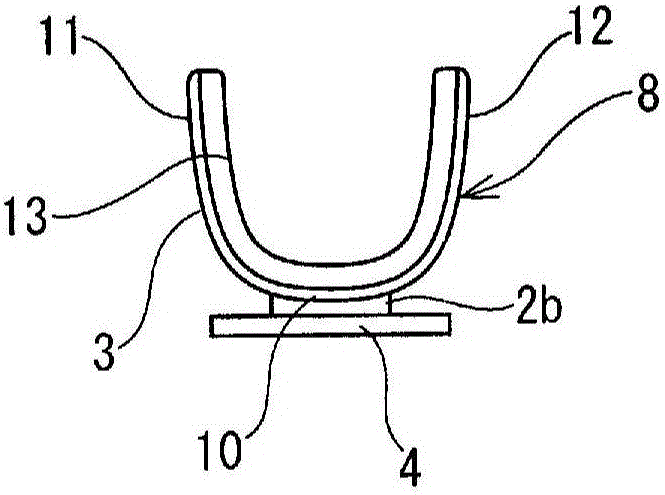

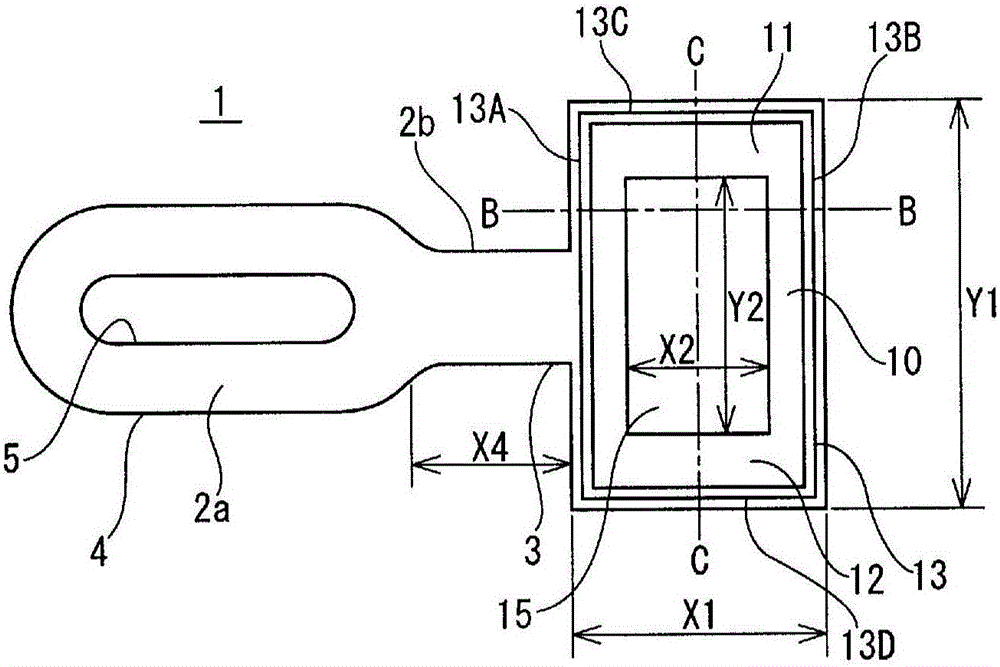

Terminal for electrical wire connection and electrical wire connection structure of said terminal

InactiveCN106165200APrevent floodingImprove electrical connection reliabilityLine/current collector detailsConnections effected by permanent deformationEngineeringStructural engineering

The present invention is provided with a partially stripped section (21) in which a core wire is partially exposed by peeling away an insulating coating at a position separated by a required dimension from the end of an electrical wire but leaving a part of the insulating coating in the circumferential direction. The present invention is further provided with a terminal (1) connecting to the partially stripped section, wherein an electrical wire connection section (3) is equipped with one crimped section (8) from which left and right barrels (11, 12) protrude from both sides in the width direction of a central section that comprises a substrate (2b). The electrical wire connection section is provided, along the outer peripheral edge of the crimped section, with ribs (13A, 13B, 13C, 13D) in a square frame shape protruding inwards and is provided with a core wire contact section (15) which protrudes inwards in a stepped shape in a portion surrounded by the ribs, the size of said core wire contact section corresponding to the partially stripped section of the electrical wire. The protrusion dimension of the core wire contact section (15) corresponds to the thickness of the insulating coating (20b) of the electrical wire to be connected.

Owner:SUMITOMO WIRING SYST LTD

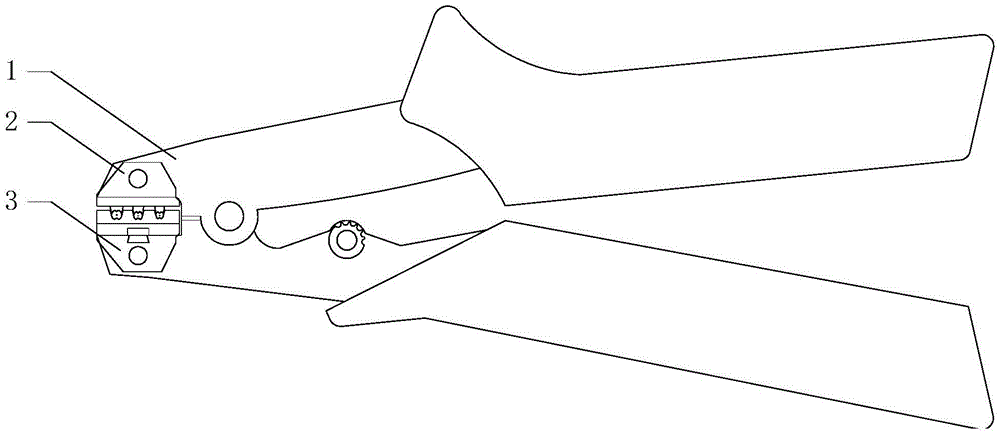

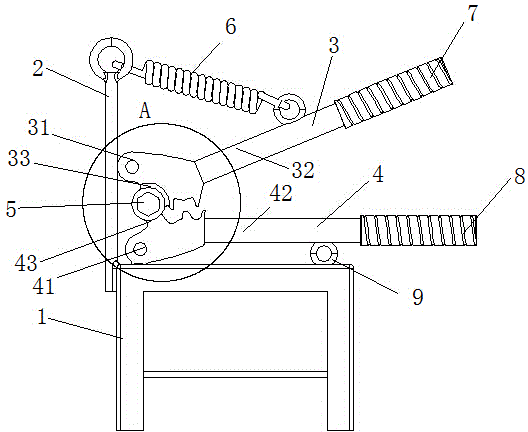

Novel crimping tool and using method

InactiveCN105479357ALow labor intensity for crimpingCrimp firmlyLine/current collector detailsClampsTransverse grooveEngineering

The invention relates to a novel crimping tool and a using method. The crimping tool mainly comprises a plier body which is provided with an upper plier head and a lower plier head, the upper plier head is fixedly connected with an upper jaw, and the lower plier head is fixedly connected with the lower jaw; the upper jaw is provided with plier protrusions, and the lower jaw is provided with plier concavities used for containing the plier protrusions; each plier protrusion is provided with a circular-arc through groove which is internally provided with an upper protrusion part; transverse grooves are formed in the side faces of the plier protrusions and penetrate through the circular-arc through grooves to form multiple crimping heads. According to the novel crimping tool and the using method, by means of the improvement on the jaw structures, efficient crimping can be conducted on a wire and an insertion hole of an O-shaped inner cavity, positioning can be conducted through a positioning unit, and the insertion hole is not prone to slipping in the crimping process.

Owner:济南无线电十厂有限责任公司

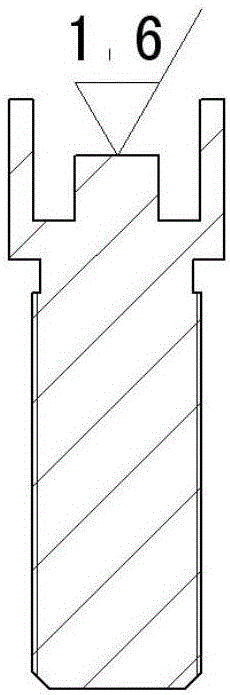

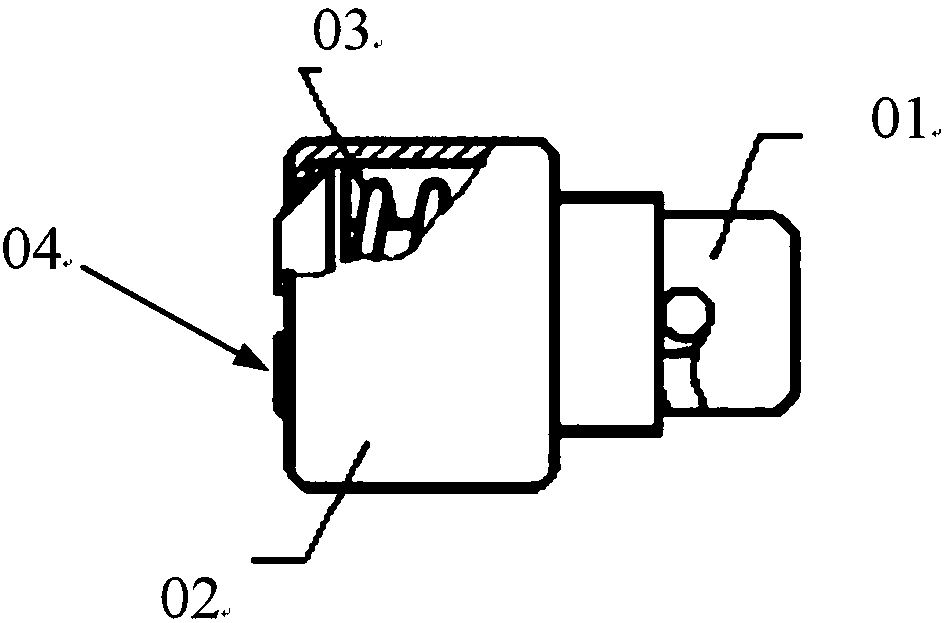

Connecting plug hole copper rivet pressing connection tool

The invention provides a connecting plug hole copper rivet pressing connection tool which is simple in structure and capable of improving the working efficiency and saving time. The pressing connection tool comprises an air cylinder, an inner lining mole core, a pin, an outer lining mode sleeve and a spring. The outer lining mode sleeve is provided with a stepped hole. The upper portion of the outer lining mode sleeve is provided with a pair of slide holes communicating with a large hole body of the stepped hole. The spring is arranged on the inner lining mole core in a sleeving mode and located in the large hole body of the stepped hole of the outer lining mode sleeve. The upper portion of the inner lining mole core is provided with a pin hole. The pin is arranged in the pin hole. The two ends of the pin are located in the slide holes. The pin is located over the spring. According to the connecting plug hole copper rivet pressing connection tool, pressing connection is easy, and a copper rivet is not prone to being flattened or damaged; and pressing connection is stable, the pre-riveting production step is eliminated, and the product manufacturing period is greatly shortened.

Owner:YANGZHOU LIANGCHENG AUTO PARTS

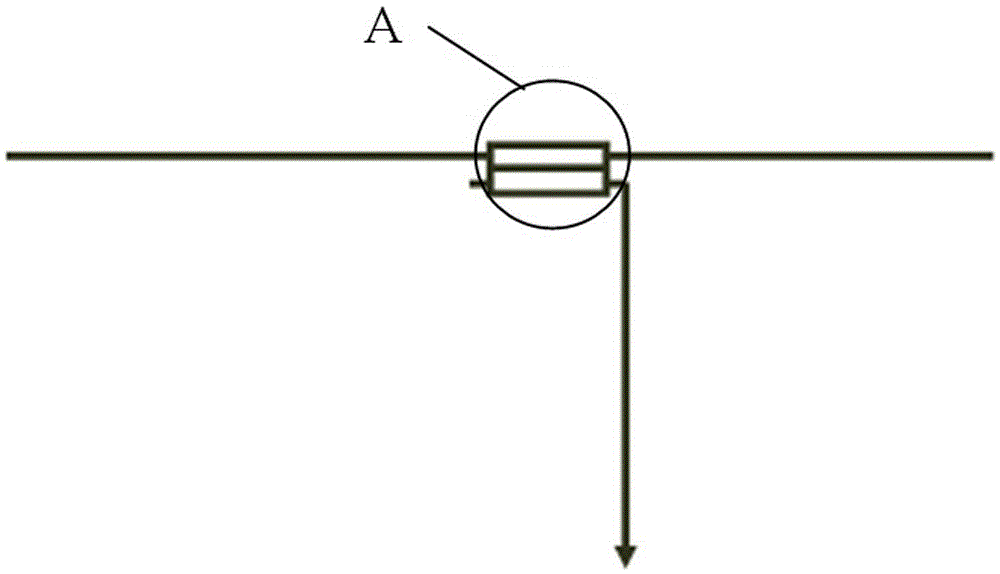

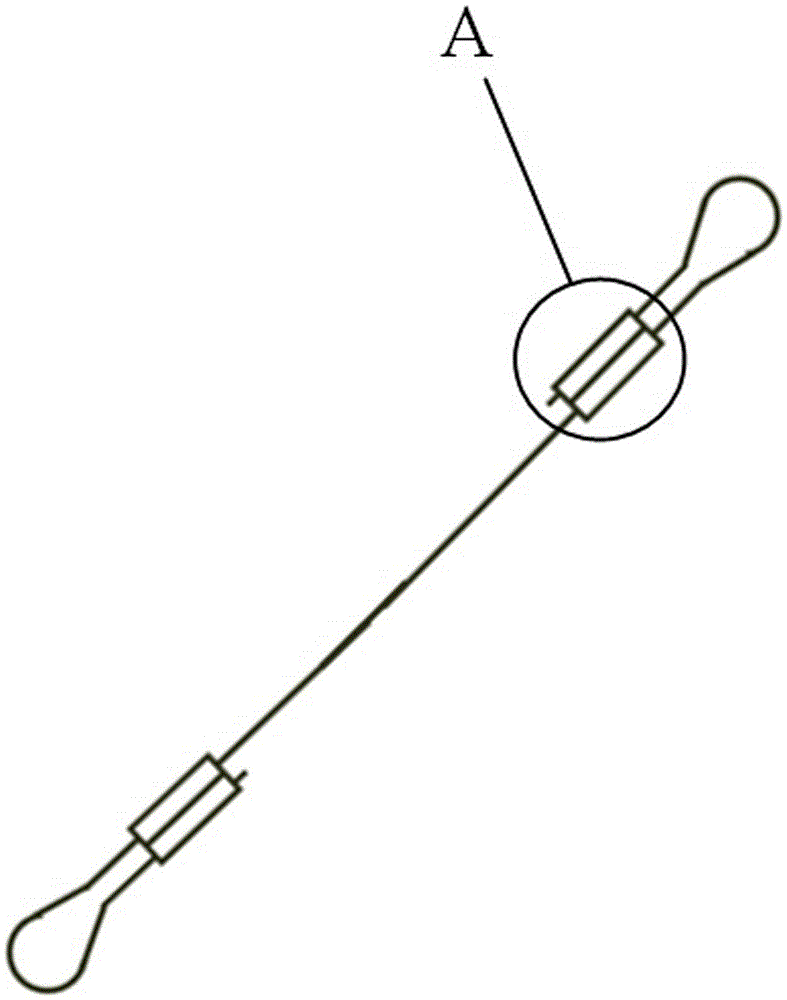

Compression-connecting pipe applied to parallel connection of cables and applications thereof

InactiveCN105406207ACrimp firmlyFirmly connectedConnections effected by permanent deformationElectric connection basesFailure rateEngineering

The invention discloses a compression-connecting pipe applied to parallel connection of cables and applications thereof. The compression-connecting pipe comprises a main body, and also comprises a main body cover, wherein the main body is provided with at least two slots, the upper portion of the main body is provided with a cable inlet, and the main body cover can be inserted into the inlet after cables are placed into the slots, for executing compression-connecting. With applications of the compression-connecting pipe in fixation of tail wires of stay wires of overhead power lines and shunting of overhead power lines, the problems that in the prior art bolts are easy to loosen and corrode and binding by iron wires is high in maintenance cost are overcome; the compression-connecting pipe is stable in performance, firm in connection, long in service life and low in failure rate.

Owner:STATE GRID CORP OF CHINA +2

M-shaped welding process for electric resistance wires and high temperature wires

InactiveCN106825970AEasy to operateFunctionalMetal working apparatusWelding apparatusElectrical resistance and conductanceEngineering

The invention discloses an M-type welding process between a resistance wire and a high-temperature wire, which comprises the following steps: A. Do a good job of cleaning the surface of the resistance wire and the high-temperature wire, and clean the metal sleeve; B. Break the resistance wire into an M-type ; C. Peel the high-temperature wire, and the wire exposed after peeling is in the same plane as the M-shaped resistance wire; D. Cover the M-shaped resistance wire and the high-temperature wire with the metal sleeve, and the M-shaped resistance wire and the high-temperature wire end The part is exposed to the outside of the metal casing; E, the metal casing is crimped, and the M-shaped resistance wire, the high-temperature wire, and the metal conduit are fixed to form a welding surface; F, the welding surface of the end of the metal conduit is welded. The invention has the advantages of simple operation, time saving and labor saving, practical function, safety and reliability, and can effectively prolong the service life.

Owner:艾克森(江苏)节能电热科技有限公司

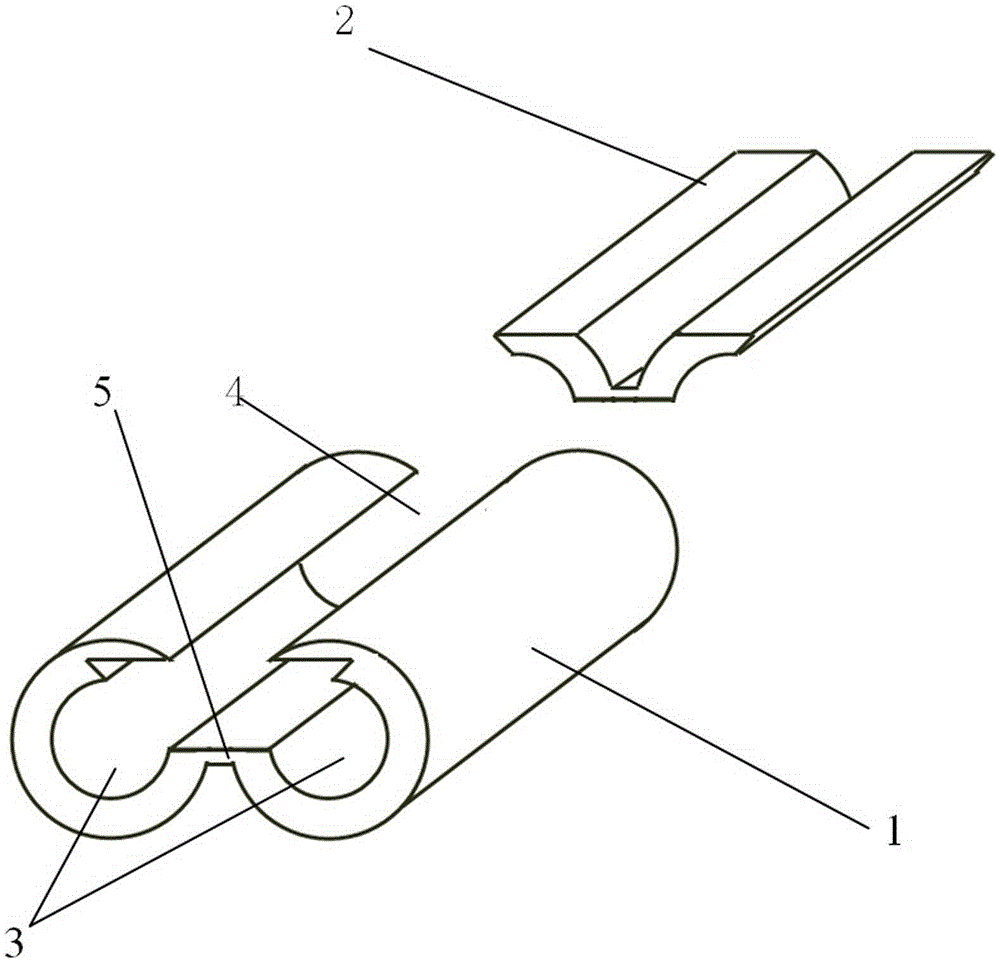

Large-diameter stainless steel cable and method of making the same

ActiveCN108262410BGood shedding resistanceCrimp firmlySlide fastenersStructural engineeringSS - Stainless steel

Owner:柳州豪姆机械有限公司

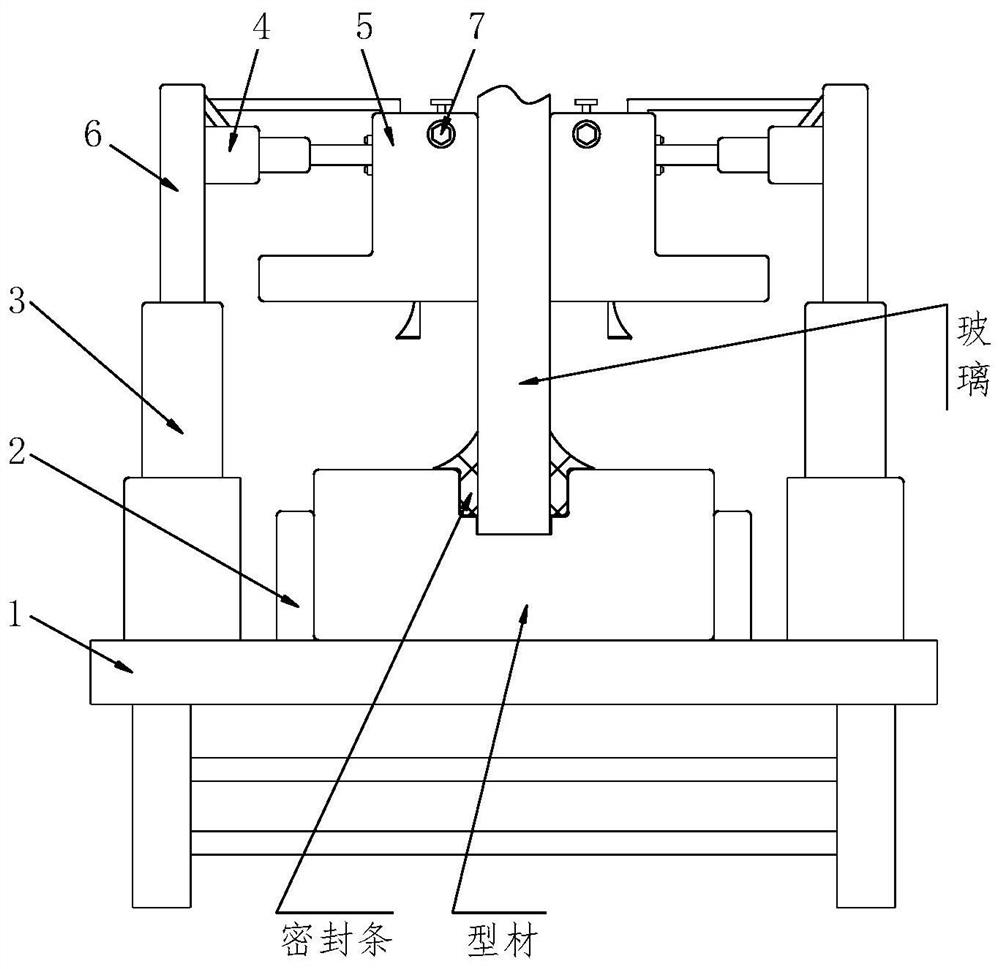

A plastic-steel door and window assembly sealing strip installation crimping machine

The invention relates to a plastic-steel door and window assembly sealing strip installation and crimping machine, including a workbench, a fixed frame, a first electric telescopic rod, a second electric telescopic rod, a crimping structure, a connecting column and a splicing assembly, characterized in that: The center position of the top of the workbench is fixed with a fixed frame by bolts. The upper end of the workbench and the symmetrical positions on both sides of the fixed frame are installed with the first electric telescopic rod. The top of the first electric telescopic rod is connected with a connecting column. The connecting column A second electric telescopic rod is installed on one side of the outer wall through bolts, and the end of the second electric telescopic rod is provided with a crimping structure, and a plurality of crimping structures are connected by splicing components, and the inside of the crimping structure is connected to the splicing component. There is a cross-shaped hole at the joint. The present invention can quickly complete the crimping work of the sealing strip and ensure the integrity of the crimping of the sealing strip. It can also be adjusted by splicing components and is applicable to the sealing strips of different sizes of plastic-steel doors and windows. Crimp work.

Owner:徐州坤达门窗有限公司

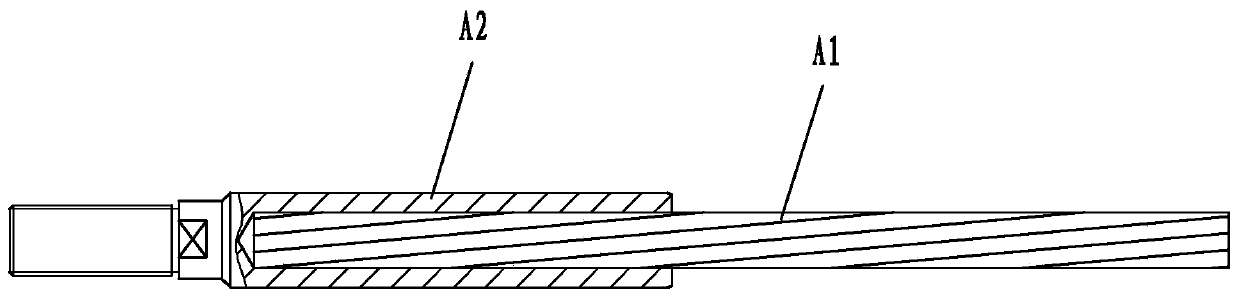

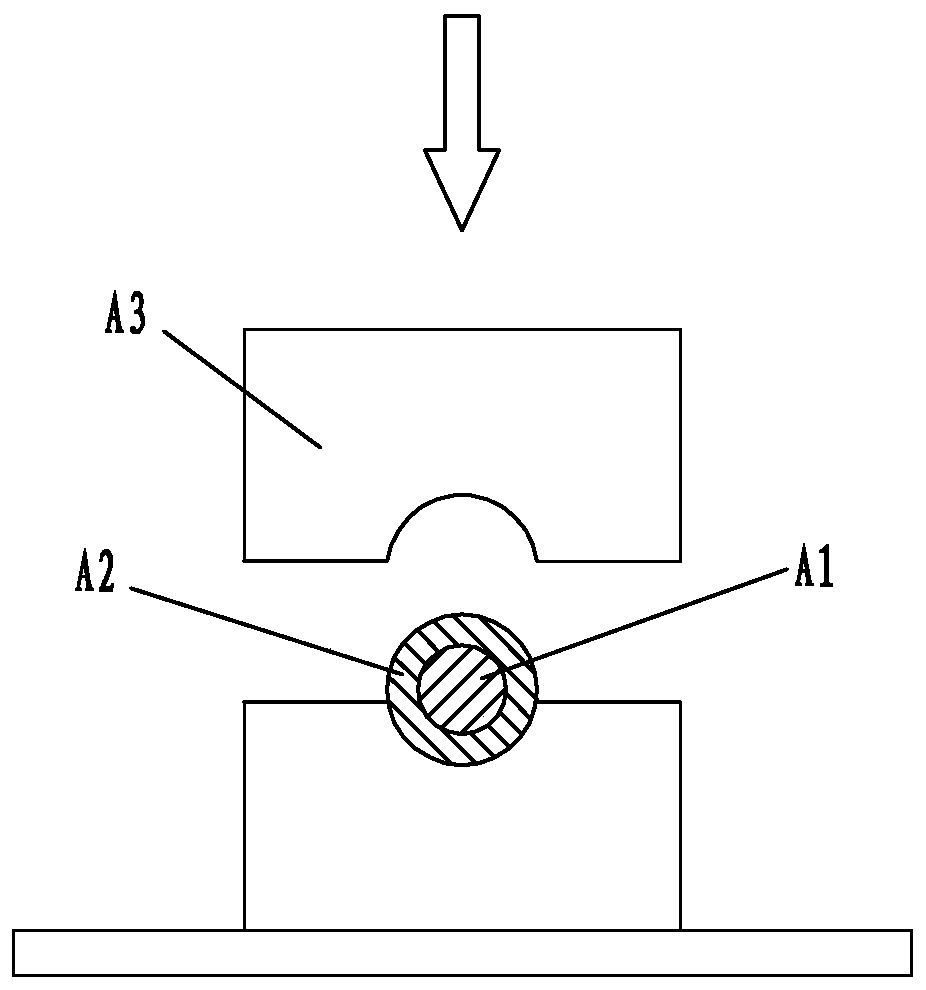

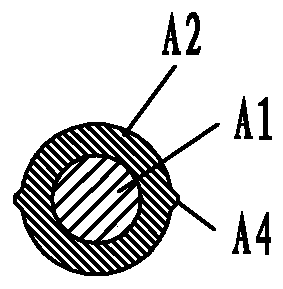

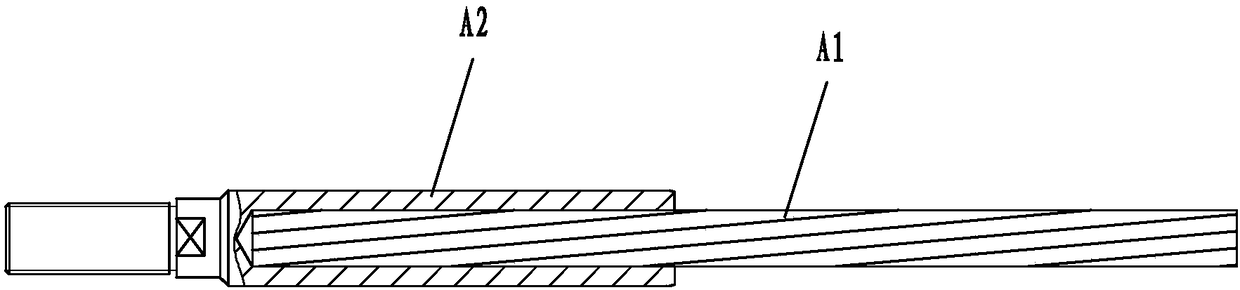

Large-diameter stainless steel stay cable and manufacturing method thereof

The invention relates to a large-diameter stainless steel stay cable and a manufacturing method thereof. The large-diameter stainless steel stay cable comprises a stainless steel stranded wire and twopressure pipe joints, wherein an inner hole is formed in the pressure pipe joints, and the inner hole of the pressure pipe joints is composed of an inclined hole and an equal-diameter hole; the diameter of the inclined hole is gradually reduced from the end part to the middle, and the minimum diameter of the inclined hole is the same as the diameter of the equal-diameter hole; center wires at thetwo ends of the stainless steel stranded wire are correspondingly sleeved with conical plugs, the two ends of the stainless steel stranded wire correspondingly penetrate into the inner hole of the pressure pipe joints and are formed into one body with the pressure pipe joints through compression, and the diameter of the stainless steel stranded wire is 36-80 mm. According to the large-diameter stainless steel stay cable, a novel production process is adopted so that the pressing type large-diameter stainless steel stay cable with the diameter of 36-80 mm can be machined, the product parameters such as the minimum breaking tensile force and the like meet relevant regulations, furthermore, the appearance is round, and the appearance is more attractive.

Owner:柳州豪姆机械有限公司

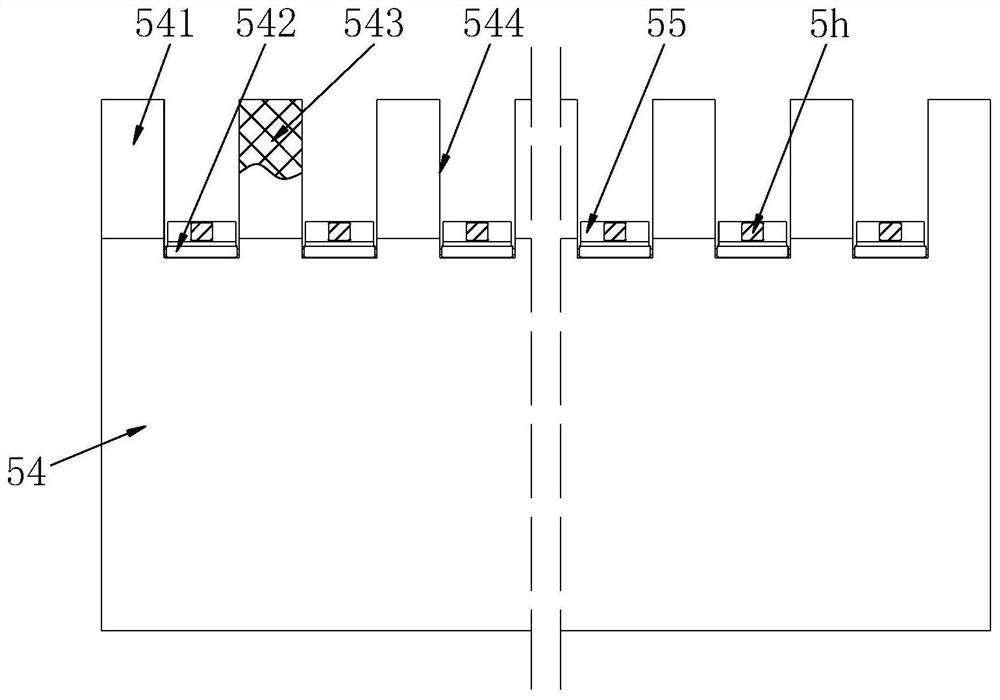

A fast three-phase electronic electric energy meter verification crimping device and verification method thereof

ActiveCN104569530BImprove test efficiencyImprove accuracyElectrical measurementsSurface mountingElectric machine

The invention belongs to the technical field of automation of three-phase electronic electric energy meters, and in particular relates to a rapid three-phase electronic electric energy meter verification crimping device and a verification method thereof. The bottom end of the crimping device is provided with wheels, and an electric control box supported by the wheels There is a workbench on the top, and a watch frame is installed vertically on the workbench. Several layers of hanging watch boards are installed obliquely on the workbench. Several unit watch boards are installed on the surface of the hanging watch board. There are left stoppers, right stoppers and control motors installed on the back of the left and right sides. There are also recessed plane grooves on the surface of the unit panel. A sliding bottom plate is arranged in the concave plane groove. The upper surface of the sliding bottom plate A three-phase electronic watt-hour meter is installed, a left chute and a right chute are arranged between the sliding bottom plate and the left block and the right block, and a device is also provided between the lower edge of the unit meter plate and the lower edge of the depressed plane groove. A table holder, the device is provided with crimping terminals on the table holder.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU +1

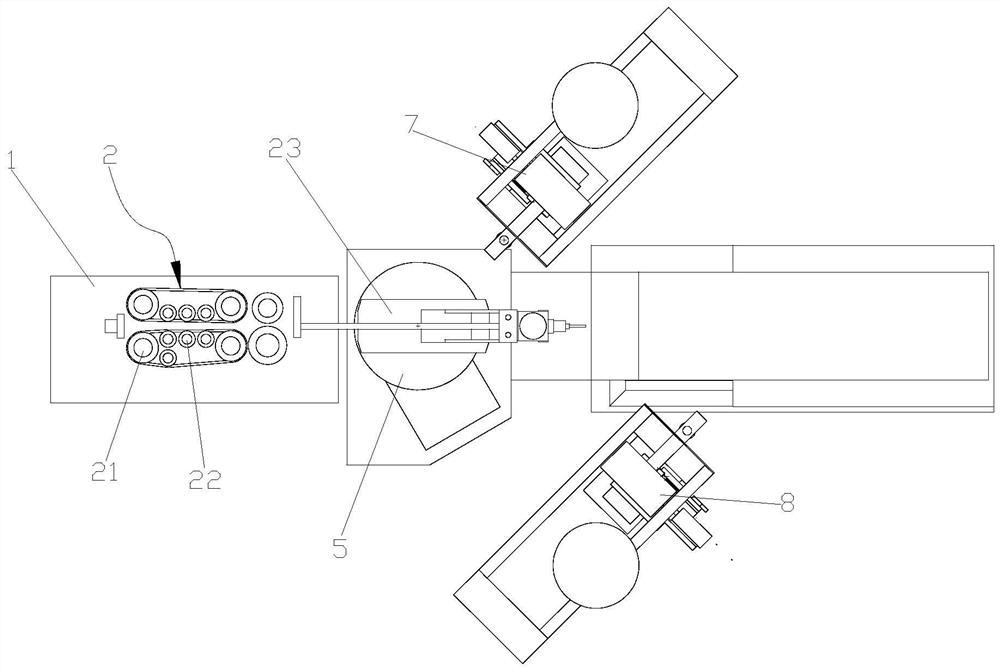

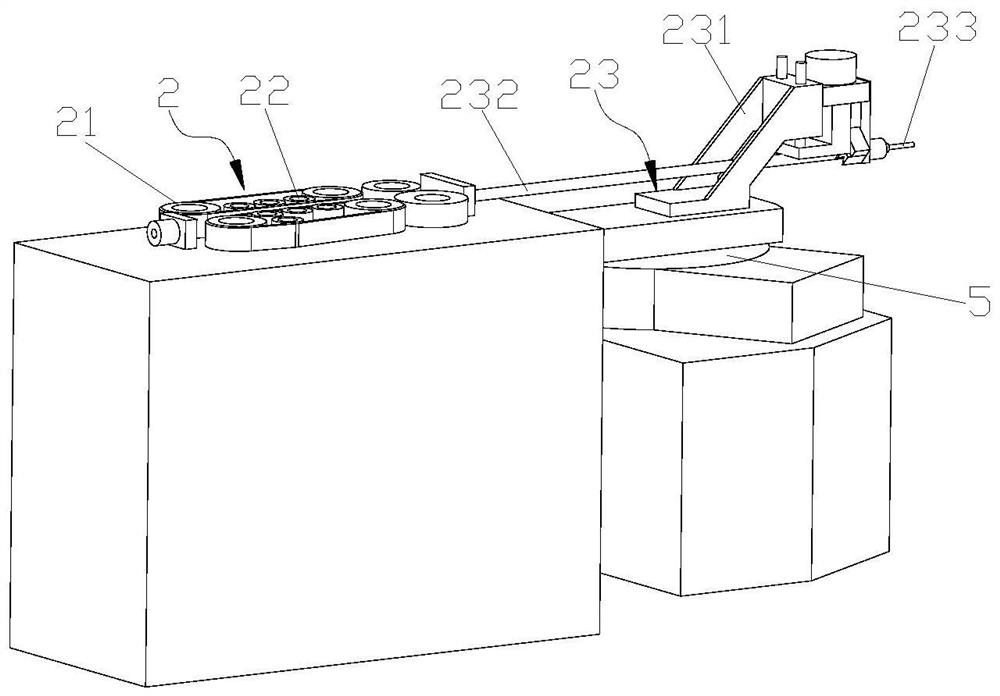

A double-head crimping terminal machine for wire harness

ActiveCN113381261BImprove crimping process efficiencyAccurate crimping positionLine/current collector detailsEngineeringTransfer line

The disclosure relates to a double-head crimping terminal machine for wire harnesses, including a frame and a wire harness feeding module, a cutting module, a clamping module, a first swinging module, a second swinging module, a first crimping terminal module, The second pressing terminal module and control module; the wiring harness module is used to transport the wiring harness; the cutting module is set in the middle of the wiring harness delivery path; the clamping module is set in the rear section of the wiring harness delivery path; the first pressing terminal module is set beside the wiring harness seat side; the first swinging module is linked with the harness seat; the second crimping terminal module is arranged on the side of the clamping module; the second swinging module is linked with the clamping module; the control module is respectively connected with the wire harness module, the cutting module, the clamping module, The first swing module, the second swing module, the first press terminal module, and the second press terminal module are connected for signals. The present disclosure can quickly complete the processing of crimping terminals at both ends of the wire harness, can effectively improve the efficiency of terminal crimping processing, simplify manual operations, and improve the degree of automation of equipment.

Owner:广州新李汽车零部件有限公司

Charging gun terminal structure and rubber coating mode

PendingCN114597685ALow costIncrease productivityVehicle connectorsContact member manufacturingStructural engineeringMachining

The invention discloses a charging gun terminal structure and a rubber coating mode, and relates to the field of charging gun accessories, the charging gun terminal structure comprises a terminal main body, one end of the terminal main body is provided with a stamping terminal head chamfer, the outer side of the terminal main body is provided with a rubber coating end point, and the outer side of the terminal main body is provided with a buckling position on one side of the rubber coating end point. An inner groove circular baffle plate is arranged on the inner side of the rubber coating end point in the terminal main body, and a chamfer is arranged at one end in the terminal main body. Compared with a machining terminal, after the stamping terminal is formed, the cost is greatly reduced by more than 50%, the production efficiency is improved by 100%, the test heat dissipation effect is good, the heat dissipation effect is 5 DEG C lower than that of an existing machining terminal, sealing gasket parts are reduced, the stamping terminal is made of a copper alloy material and is easy to form, the material hardness reaches more than 180 degrees, the requirement for 10000 times of plugging and unplugging is met, and the service life of the stamping terminal is prolonged. After the terminal is encapsulated, the internal space is in a sealed state, the test reaches IP68 waterproof and dustproof grade, and the wiring mode is B-type crimping, so that the terminal is more stable, and the compression ratio plot ratio is better.

Owner:WORKERSBEE ELECTRONICS TECH HLDG SUZHOU CO LTD

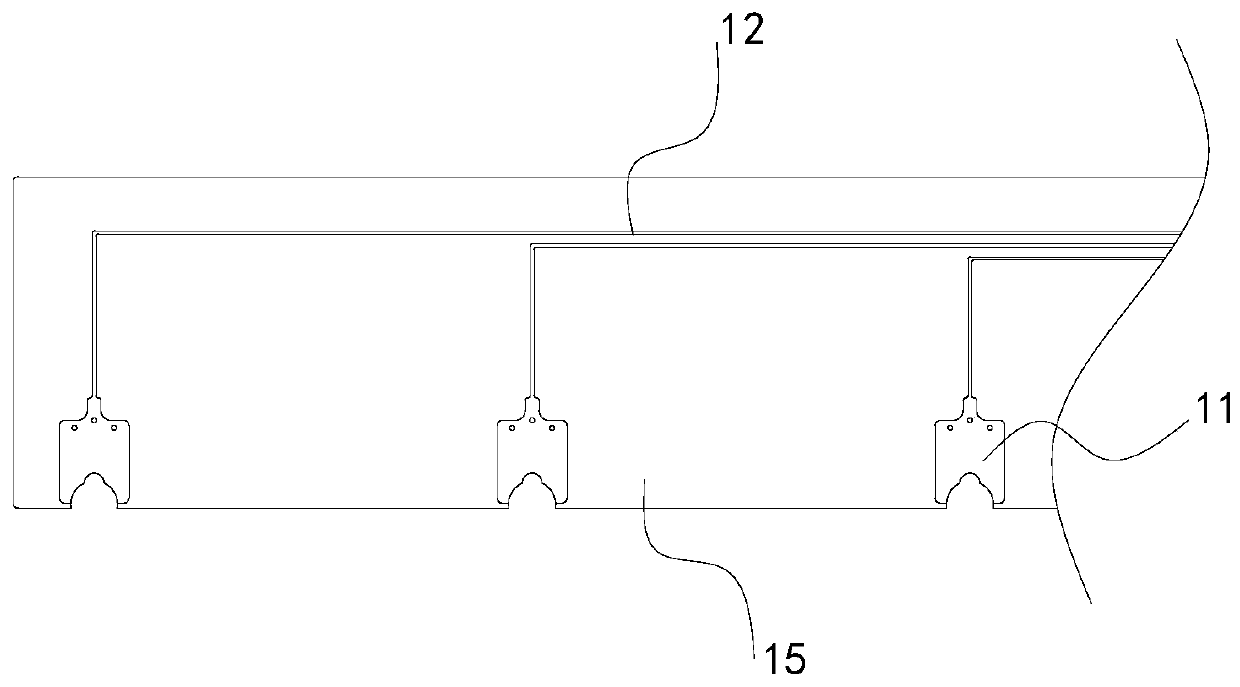

Flexible circuit board, capacitive screen and flexible circuit board processing method

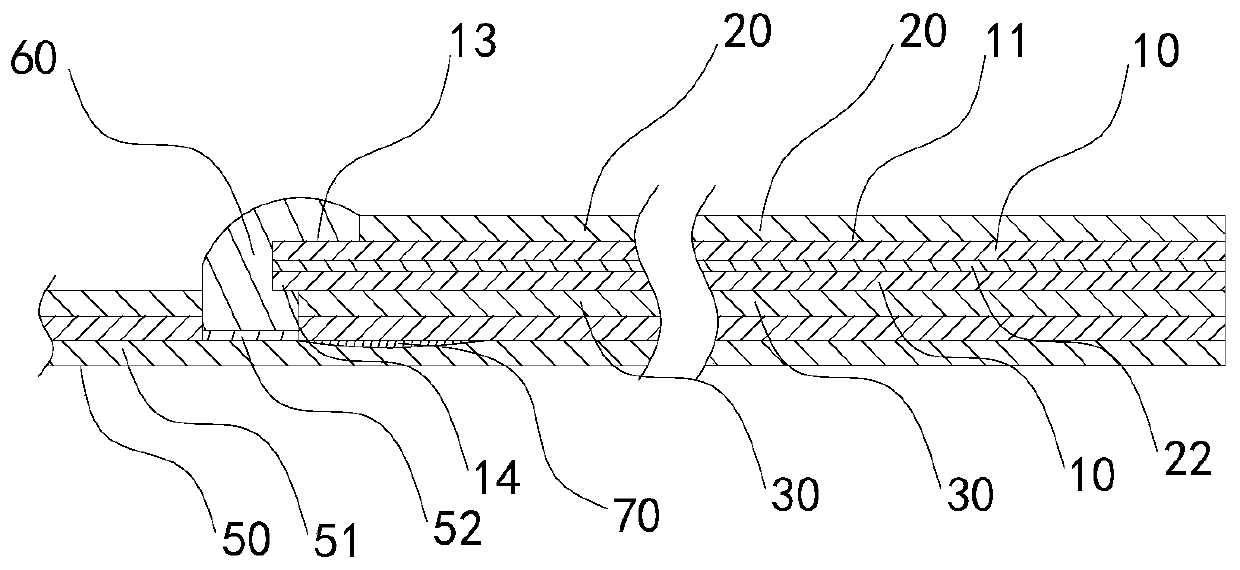

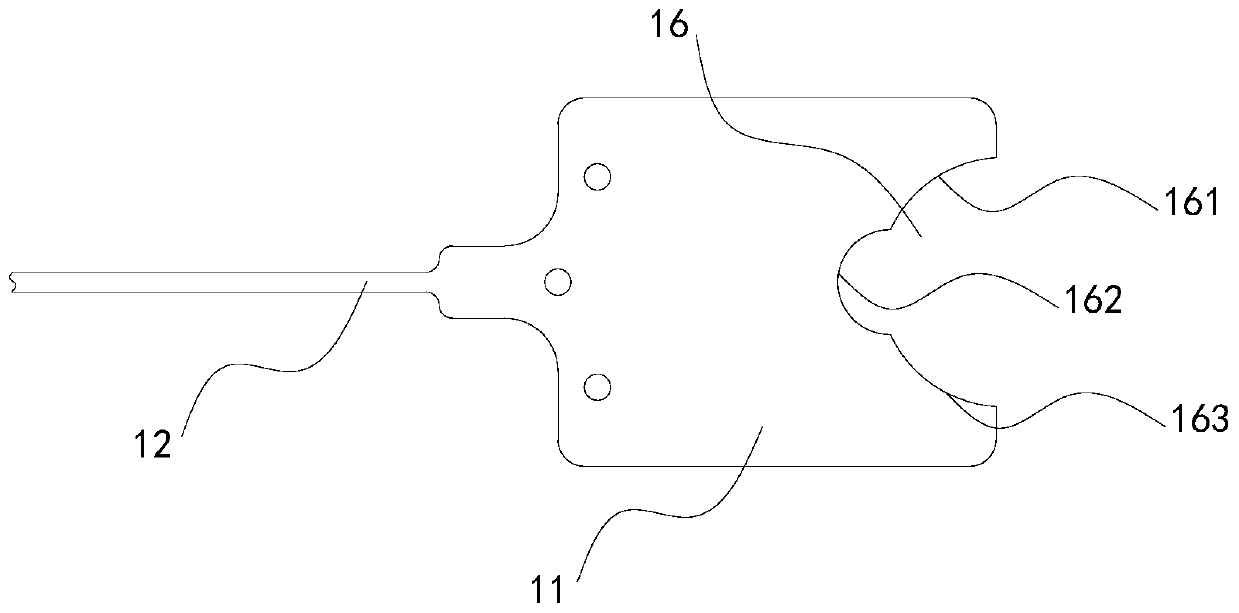

ActiveCN109757031BIncrease contactAvoid breakingElectrical connection printed elementsInput/output processes for data processingCapacitanceFlexible circuits

Disclosed are a flexible circuit board, a capacitance screen (50), and a method for machining the flexible circuit board. The flexible circuit board comprises a base layer (22), and a conductive layer (10), wherein the conductive layer (10) is attached to the base layer (22); the conductive layer (10) is at least provided with a conductive sheet (11) and a conductive wire (12); the conductive sheet (11) and the conductive wire (12) are mutually electrically connected; the conductive sheet (11) is located at a conductive connection side, and a first avoidance notch (16) is provided on the conductive sheet (11); and the opening width of the first avoidance notch (16) gradually reduces from the outside to the inside. The conductive connection structure is stable; the problems of poor contact and binding an open circuit in the flexible circuit board can be solved; process flow time for machining the conductive sheet is short; and a drilling operation is easily carried out, and the structure is more stable and reliable.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

A universal crimping tool for cable lugs

ActiveCN104092080BFast crimping speedCrimp firmlyLine/current collector detailsLower limitMechanical engineering

Owner:STATE GRID CORP OF CHINA +2

Junction box for photovoltaic modules for easy crimping of bus bars

ActiveCN105811873BSave materialReduce manufacturing costPhotovoltaicsPhotovoltaic energy generationEmbedded systemJunction box

Owner:ZHEJIANG FORSOL ENERGY

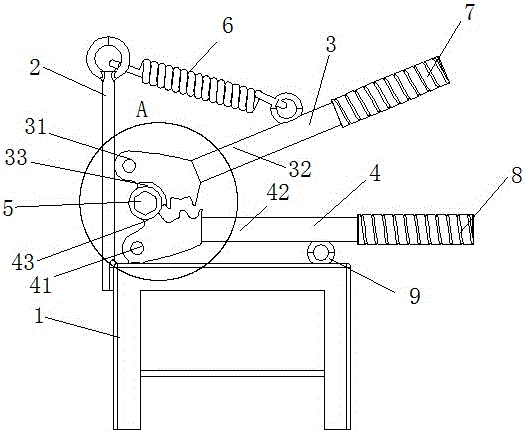

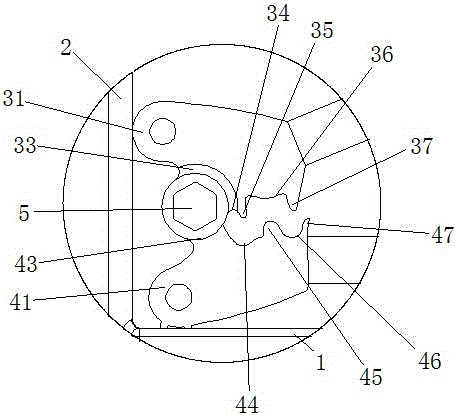

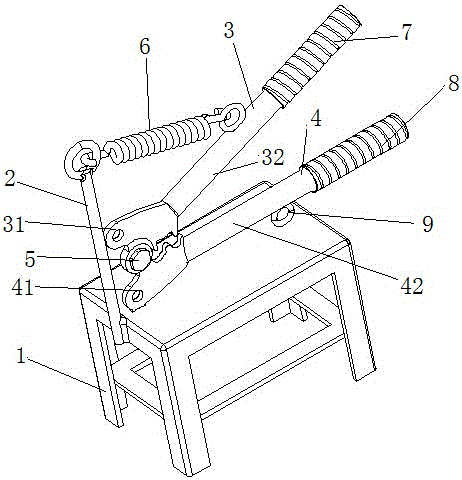

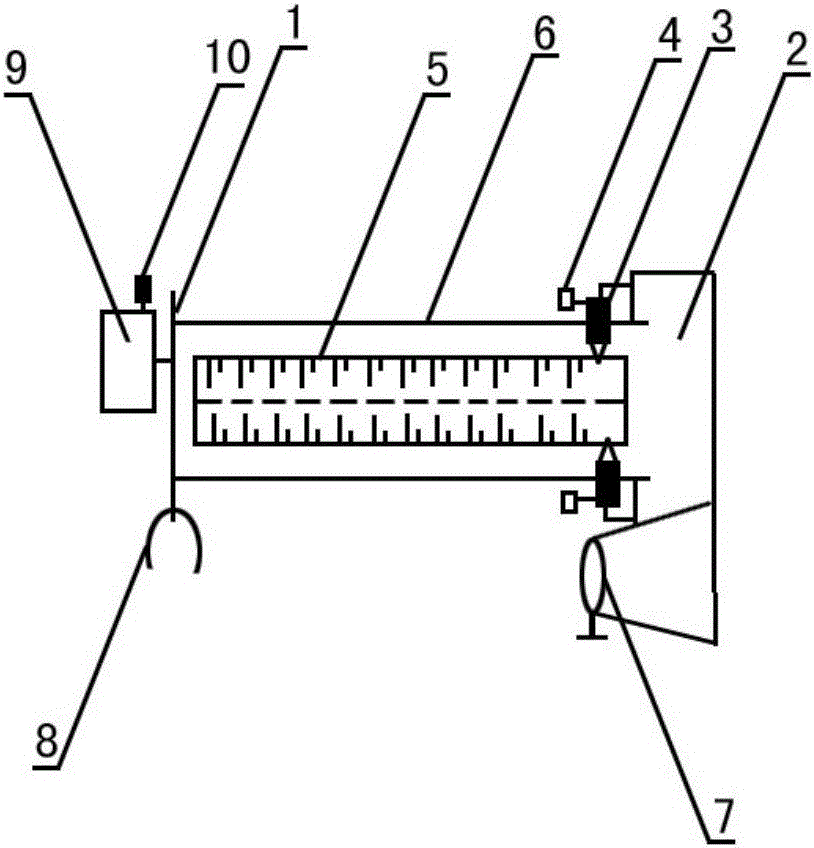

Compressional-type length monitoring device of riveter

ActiveCN105823453ASimplify functional designCrimp firmlyMeasurement devicesDisplay deviceEngineering

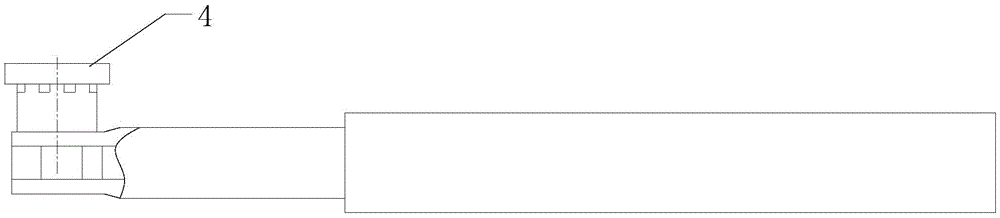

A compressional-type length monitoring device of a riveter comprises a frame body (1), wherein the overall frame body (1) has long structural design; a compression chamber device (2), a movable slide block (3) and a reader (4) are disposed at the front end; a length marking device (5) and a hanging support (6) are disposed symmetrically and vertically at the middle part; a round positioning device (7) is located under the compression chamber device (2); during use, the frame body (1) is placed above the riveter by a sleeving structure (8), the positioning device (7) sleeves the riveter hole end and carries out linkage compression according to an operational state, and a read value is directly uploaded to a display device (9) according to a code; and a prompt device (10) is disposed on the frame body (1) and can send out relevant prompts when a pull riveting operation is completed. The device has the advantages that functions are added; the design is simple; original functions are not influenced, and the riveting degree can be determined according to length data; compression connection stability is ensured; intelligent monitoring is carried out; and practicability is high.

Owner:沧州恒光试验仪器科技有限公司

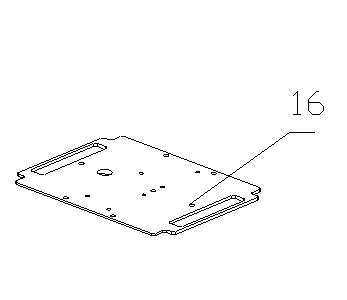

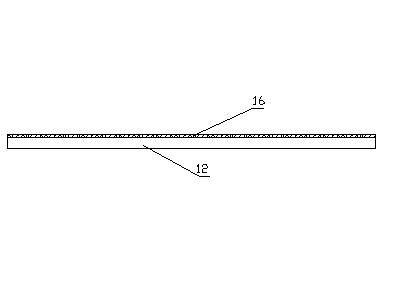

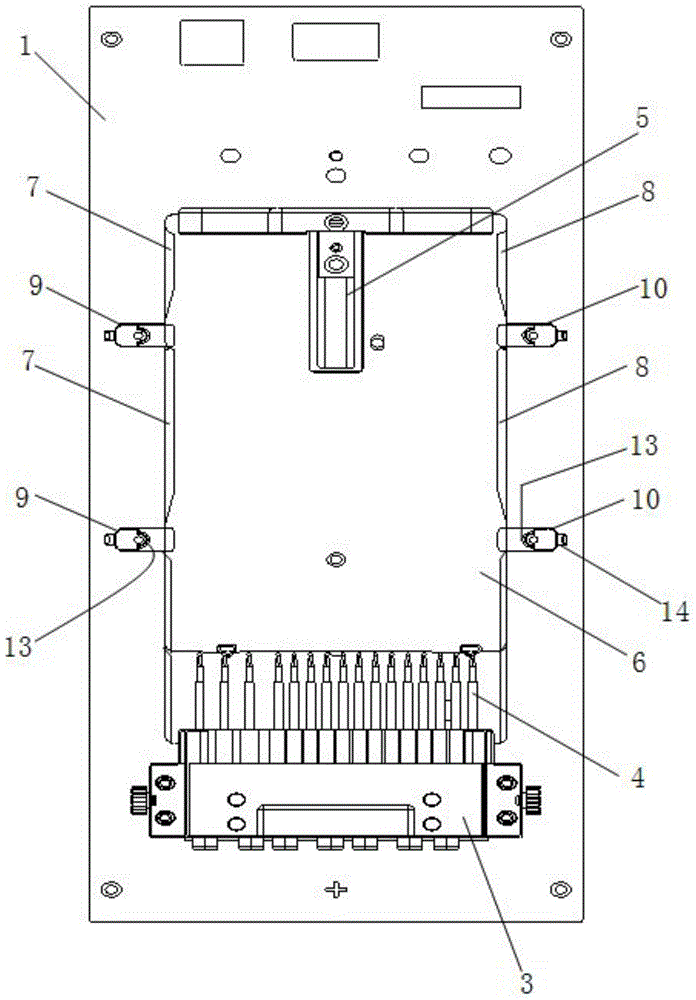

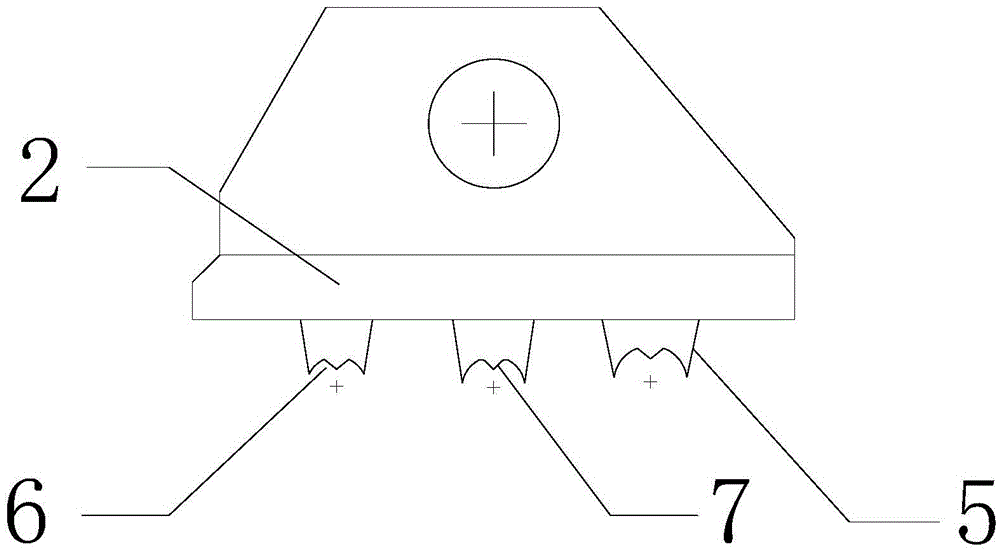

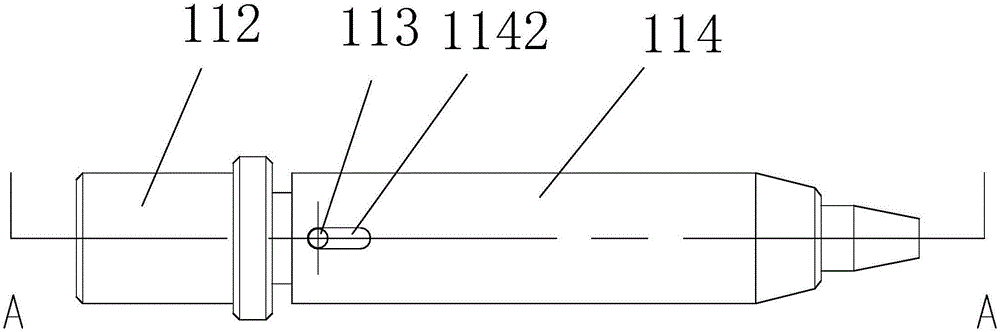

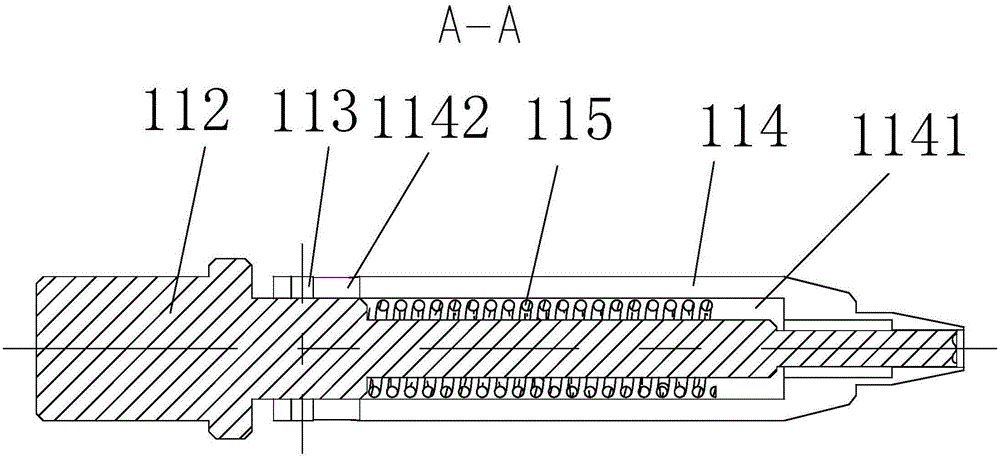

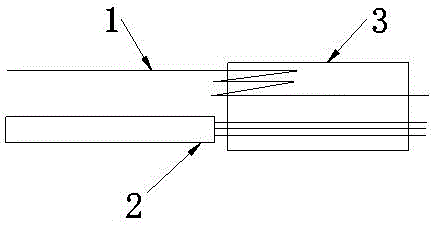

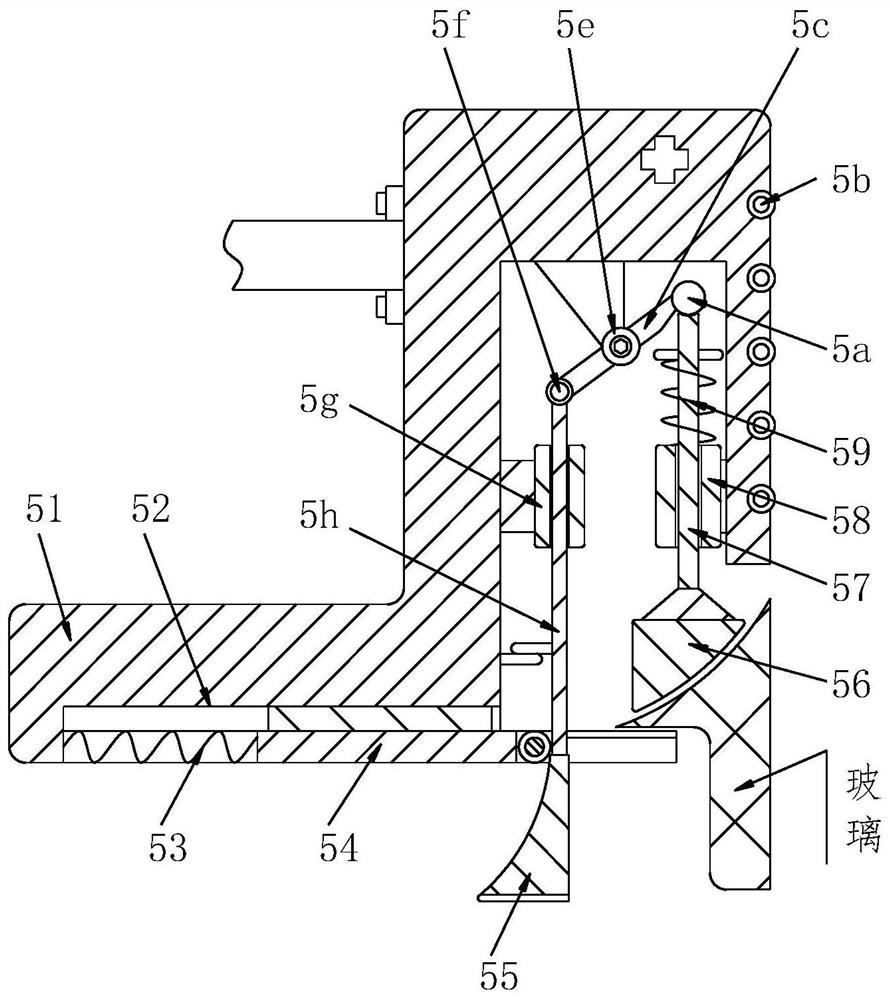

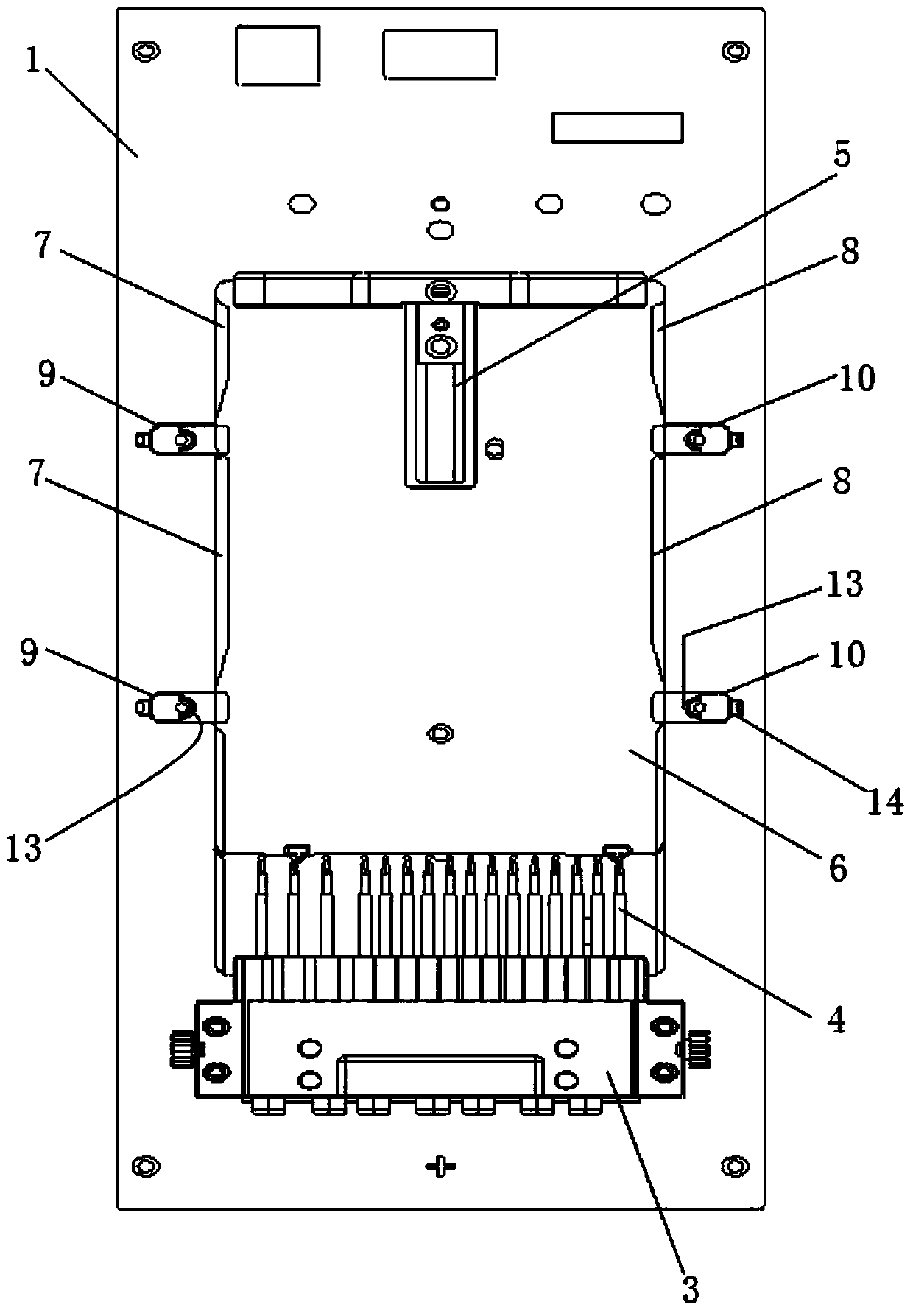

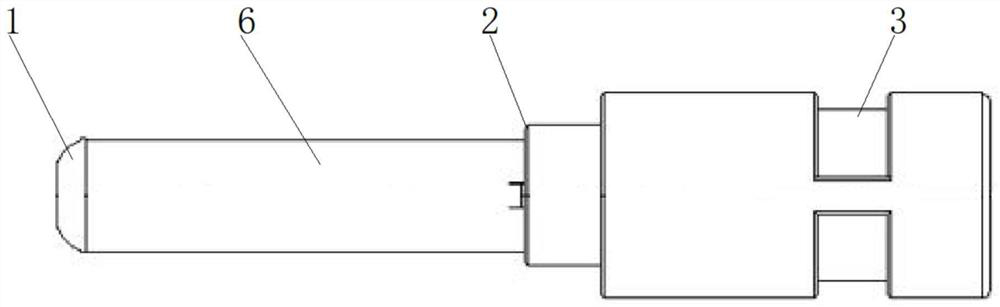

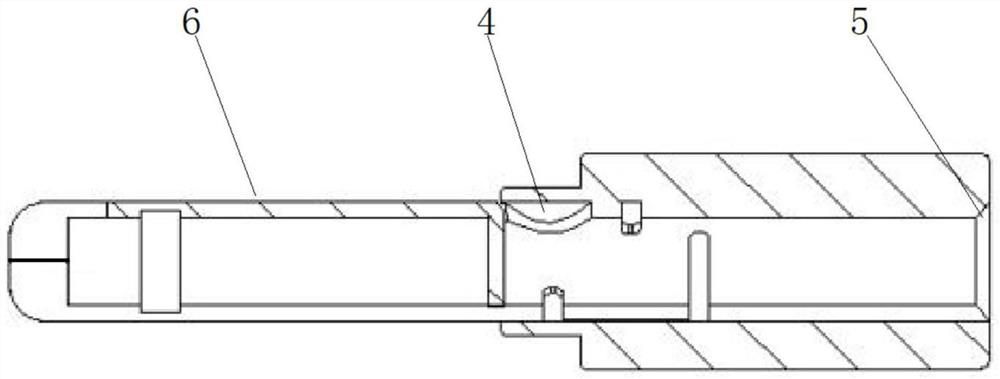

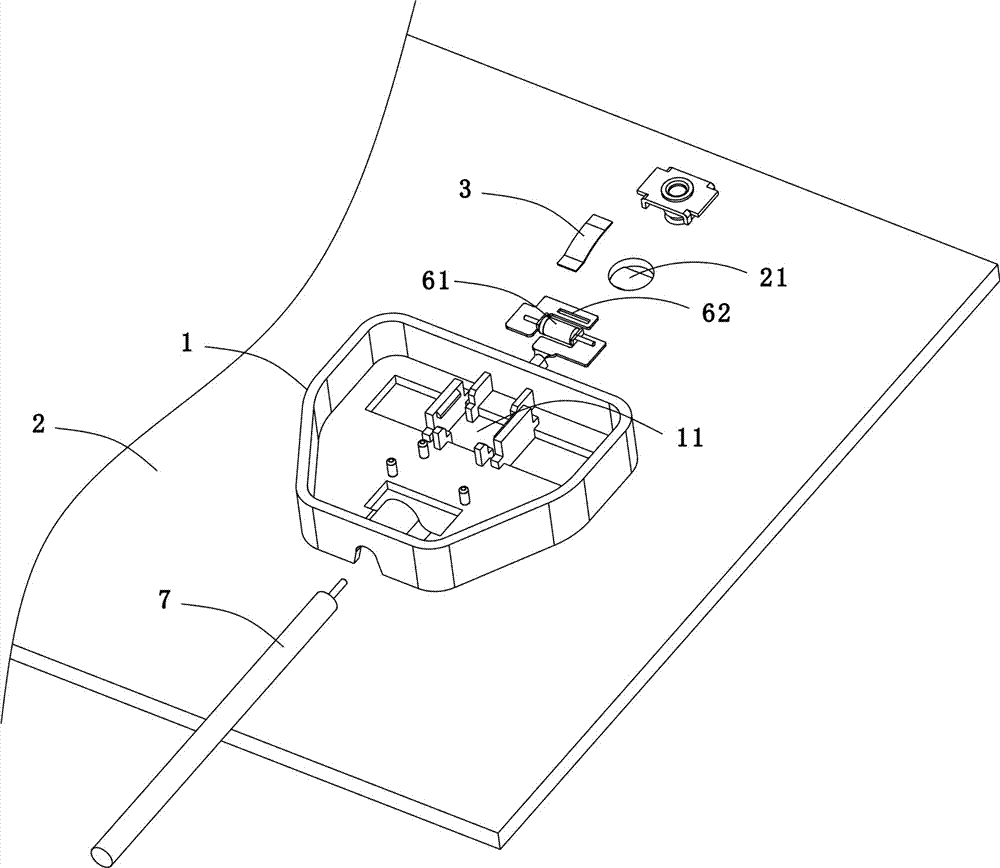

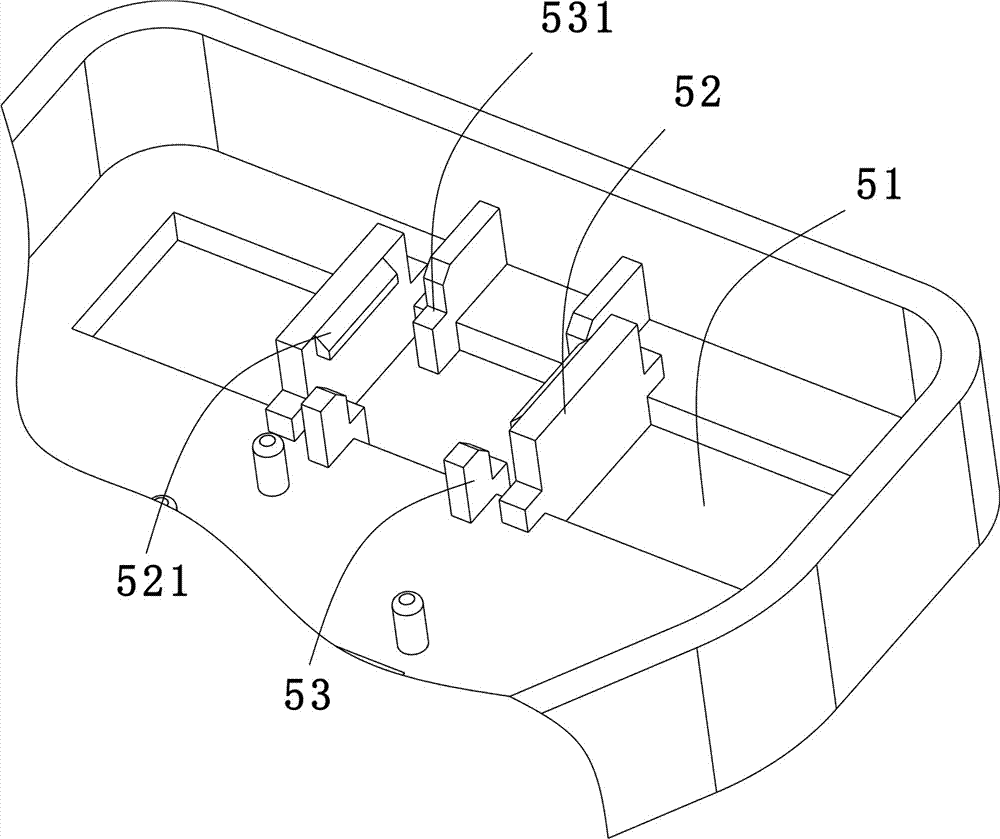

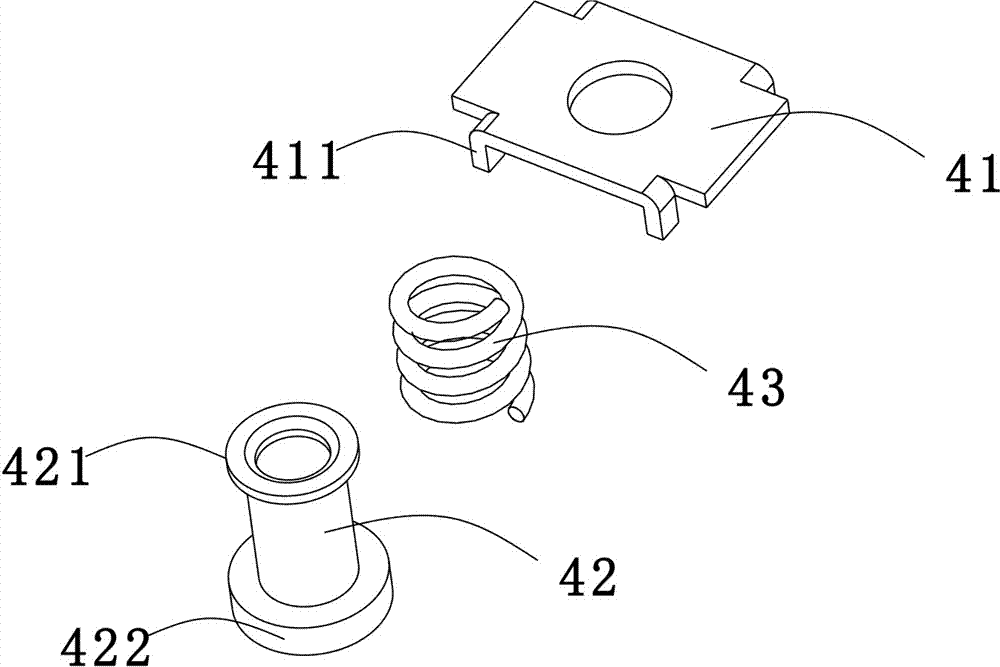

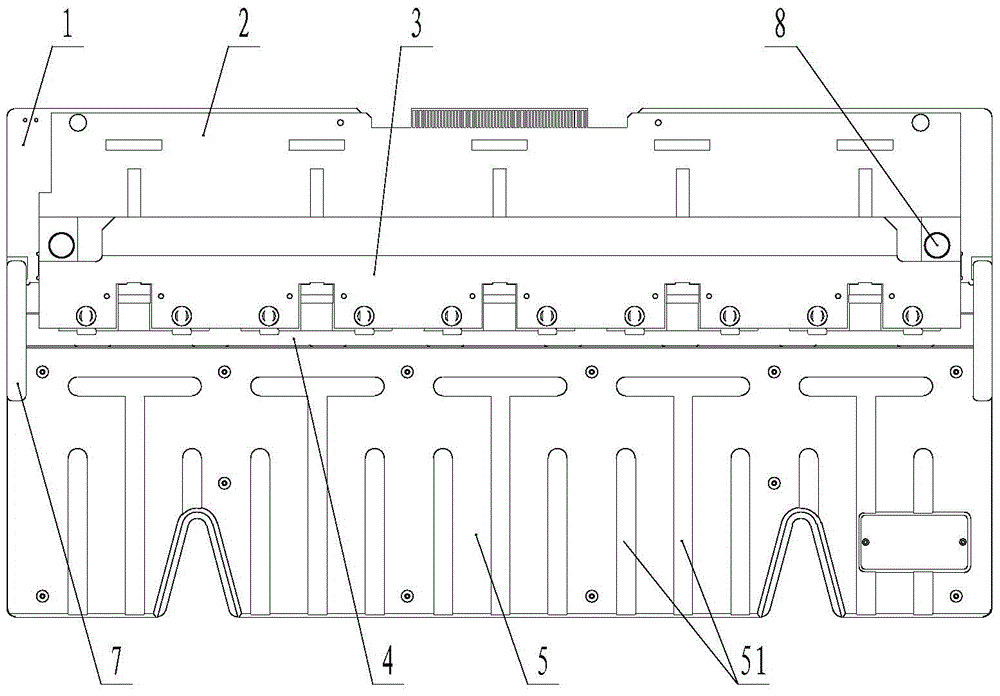

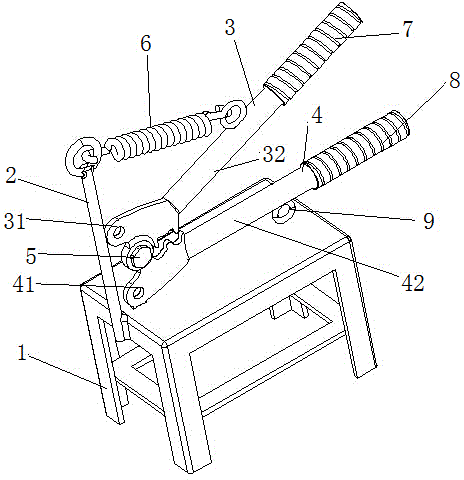

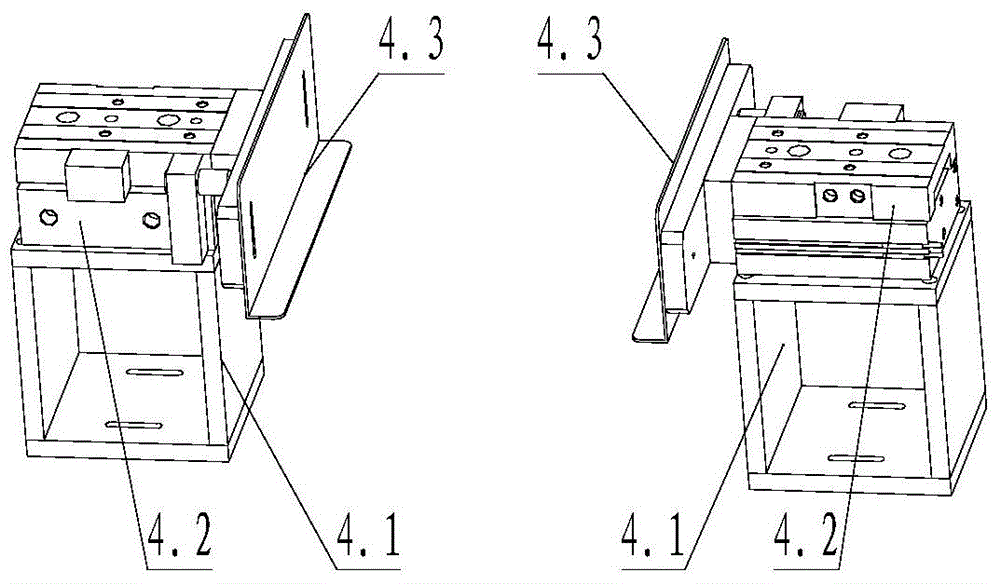

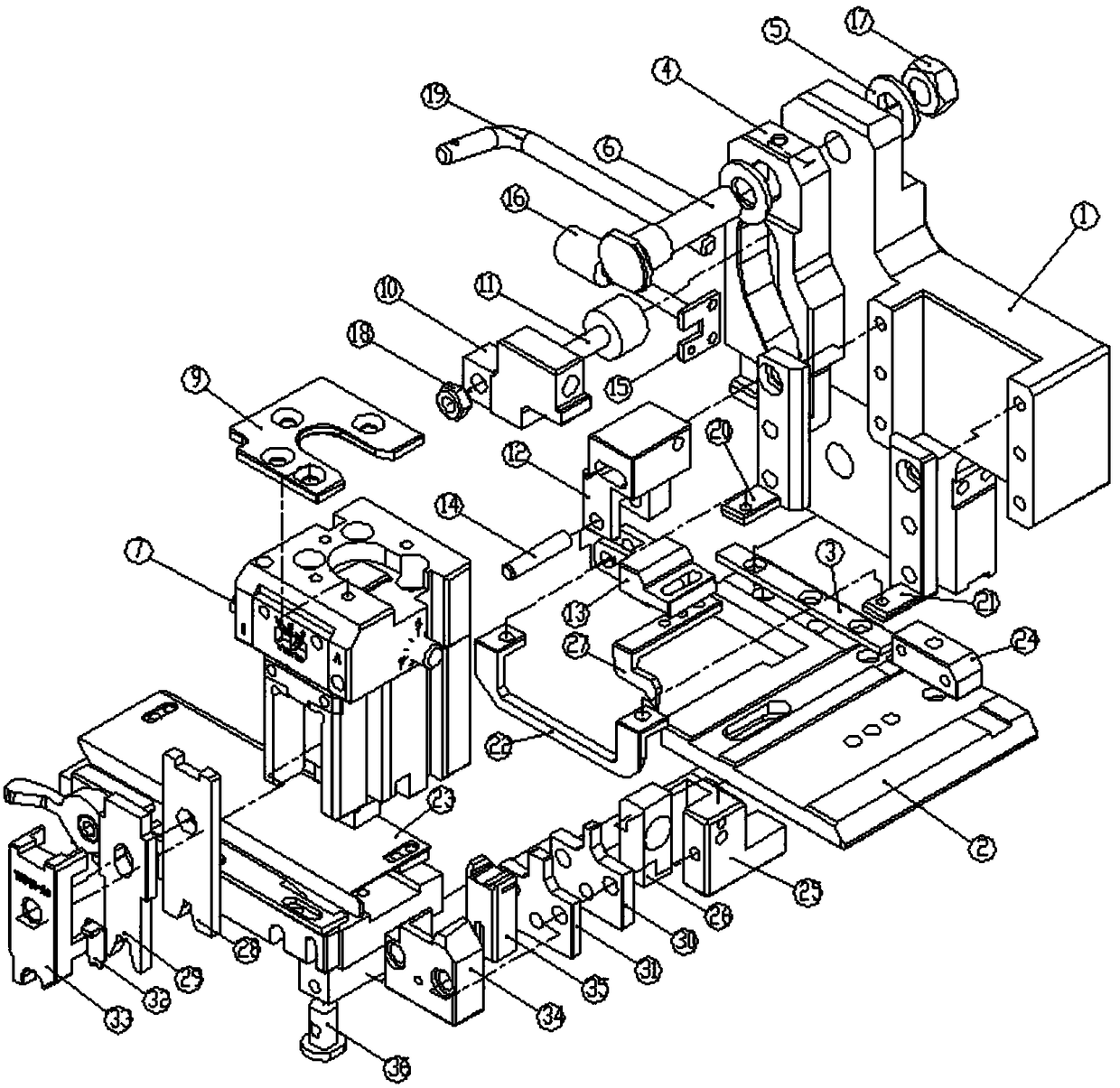

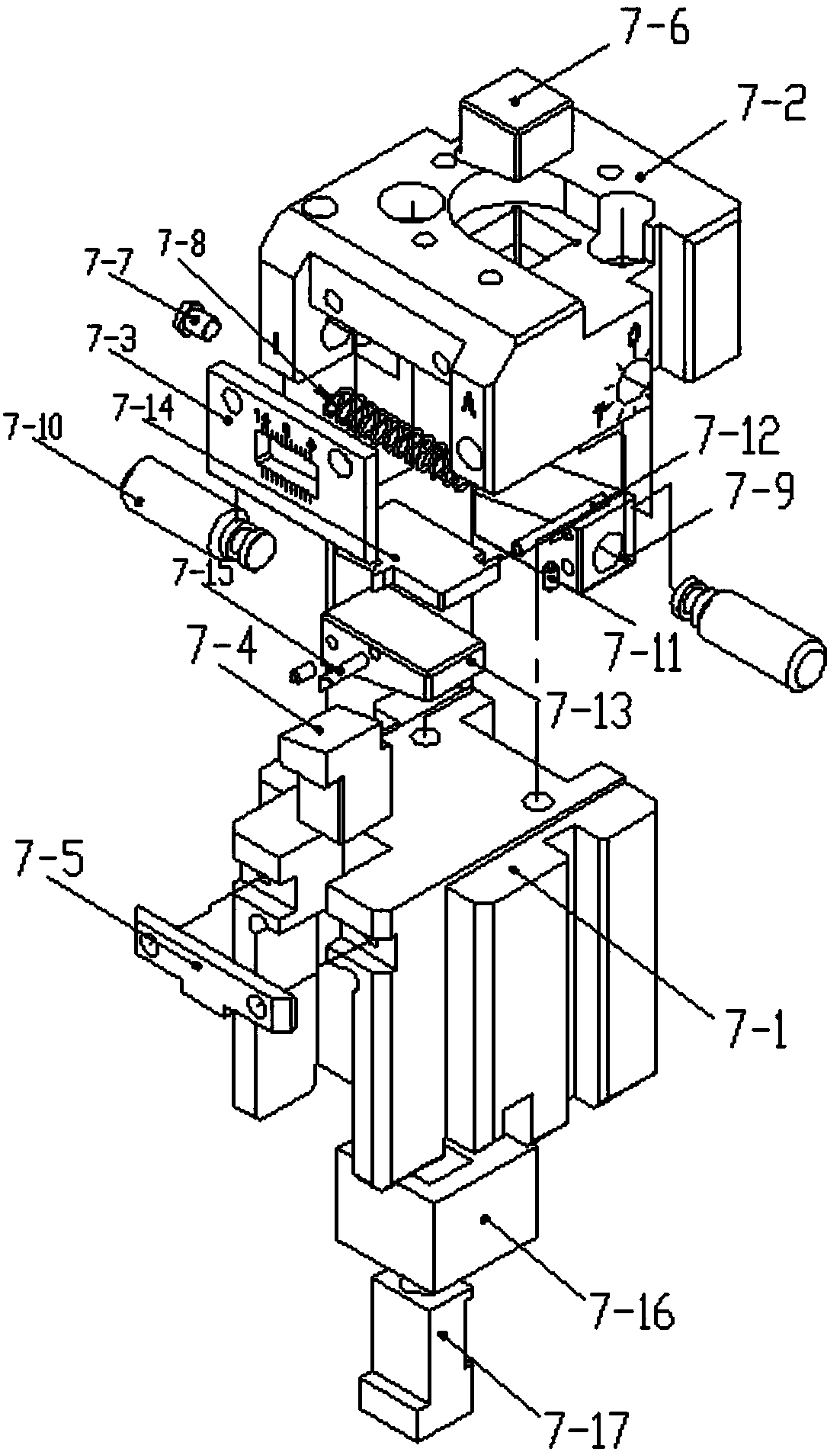

A crimping fixture for oled panels

ActiveCN104464582BSimple structureEasy to operateStatic indicating devicesFlexible circuitsEngineering

The invention belongs to the technical field of OLED panel testing, and particularly relates to a pressed connection jig for an OLED panel. The pressed connection jig comprises a supporting plate, a PCB, a pressed connection device, an OLED panel containing plate and flexible circuit boards. The pressed connection device comprises a support, pressing rods and pressing blocks, wherein the middle of each pressing rod is hinged to the support, one end of each pressing rod protrudes out of one side of the support, the upper surface of the other end of each pressing rod makes contact with the bottom of a transverse shaft inside the corresponding pressing block, the pressing blocks are installed on the other side of the support and can slide up and down along the support through the pressing rods, and a pressing head is arranged on the edge of each pressing block. The flexible circuit boards are fixed to the bottoms of the pressing bocks, one end of each flexible circuit board is electrically connected with the PCB, the other end of each flexible circuit board is connected with the corresponding pressing head, hole grooves are formed in the portions, located at the bottoms of the pressing heads, of the supporting plate, and transparent structures are arranged in the hole grooves. Pressed connection is conducted on the flexible circuit boards and the OELD panel through the cooperation of the lever type pressing rods and the pressing blocks on the pressed connection device, the structure is simple, operation is convenient, and the pressed connection is uniform and stable.

Owner:KUSN JINGXUN ELECTRONICS TECH

Universal crimping tool used for cable lugs

ActiveCN104092080AFast crimping speedCrimp firmlyLine/current collector detailsStructural engineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +2

Quick release screw lock riveting tooling

The invention discloses a quick-release spiral lock catch riveting tooling. The quick-release spiral lock catch riveting tooling comprises a supporting part and a riveting tool, wherein the supporting part comprises a base, and height-adjustable base plates are arranged on the base and used for supporting box boards; movable screws are also arranged on the base, and height-adjustable press plates are mounted on the screws; a height-adjustable cushion block is further arranged between each screw and the corresponding base plate, a groove with an inverted U-shaped cross section is formed in the top of the cushion block, and the size of the cushion block is matched with that of a lock nut of a quick-release spiral lock catch; an U-shaped opening is formed in one end, close to the corresponding cushion block, of each press plate; the riveting tool comprises a lengthening bar and riveting punches detachably connected with the lengthening bar, inner grooves are formed in tops of the riveting punches, outer edges are chamfered, lock pins are sleeved with the inner grooves in the tops, and flanging operation of riveting is realized under the chamfering action by the aid of external force. The quick-release spiral lock catch riveting tooling is firm in compression joint and high in practicability; if manual pressing is replaced with tooling pressing, manpower and working hours can be saved, and meanwhile, the qualification rate of riveting is increased.

Owner:TIANJIN JINHANG COMP TECH RES INST

Intelligent junction box

InactiveCN103137738AContact stabilityCrimp firmlyPhotovoltaicsPhotovoltaic energy generationMetal sheetEngineering

The invention provides an intelligent junction box. The intelligent junction box comprises a box body which is provided with a containing cavity, wherein a plurality of cooling fins and diodes are arranged in the containing cavity, the cooling fins are arranged in an abreast mode, the diodes are arranged between every two adjacent cooling fins, each diode is provided with a pin which contacts the adjacent cooling fins, and one end of each cooling fin is connected with a metal sheet. The intelligent junction box further comprises a plastic block, wherein the plastic block is connected with the metal sheet in a press mode, and is clamped with the side portion of the box body. Due to the facts that the plastic block is connected with the metal sheet in the press mode, and is clamped with the side portion of the box body, firm crimping can be guaranteed, and contact between the metal sheet and the cooling fins are enabled to be stable.

Owner:QC SOLAR SUZHOU CORP

An oled panel testing device

ActiveCN104391206BRealize point screen test controlHigh degree of automationElectrical testingTest efficiencyEngineering

Owner:KUNSHAN JINGXUN ELECTRONICS TECH CO LTD

Automatic positioning and crimping device and automatic positioning and crimping method of binding post of intelligent electric energy meter

ActiveCN102928807BCrimp firmlyQuick crimpElectrical measurementsEngineeringManufacturing enterprises

The invention discloses an automatic positioning and crimping device and an automatic positioning and crimping method of a binding post of an intelligent electric energy meter. An upper surface of a base plate is provided with a sliding bottom plate which can automatically slide; two slide grooves respectively and outwardly extend on left and right sides of the sliding bottom plate; each slide groove is internally provided with a sliding rolling bead for positioning an intelligent electric energy meter to be detected to realize the function of automatically guiding and positioning the intelligent electric energy meter; the detection efficiency and the detection accuracy are greatly improved; the rapid crimping and clearing of the binding post of the stable, high-efficiency and high-reliability intelligent electric energy meter are realized; the crimping success rate of automatically detecting the binding post of the electric energy meter is improved and technical guarantees are provided for the reliable operation of an automatic detection system of the electric energy meter; and the automatic positioning and crimping device and the automatic positioning and crimping method can be widely applied to the automatic detection system of the electric energy meter in other electric power companies, electric energy meter manufacturing enterprises and related fields, and have a good application prospect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

A compression type length monitoring device for a riveting gun

ActiveCN105823453BSimplify functional designCrimp firmlyMeasurement devicesDisplay deviceEngineering

A compressional-type length monitoring device of a riveter comprises a frame body (1), wherein the overall frame body (1) has long structural design; a compression chamber device (2), a movable slide block (3) and a reader (4) are disposed at the front end; a length marking device (5) and a hanging support (6) are disposed symmetrically and vertically at the middle part; a round positioning device (7) is located under the compression chamber device (2); during use, the frame body (1) is placed above the riveter by a sleeving structure (8), the positioning device (7) sleeves the riveter hole end and carries out linkage compression according to an operational state, and a read value is directly uploaded to a display device (9) according to a code; and a prompt device (10) is disposed on the frame body (1) and can send out relevant prompts when a pull riveting operation is completed. The device has the advantages that functions are added; the design is simple; original functions are not influenced, and the riveting degree can be determined according to length data; compression connection stability is ensured; intelligent monitoring is carried out; and practicability is high.

Owner:沧州恒光试验仪器科技有限公司

Lateral mechanical terminal crimping die

PendingCN108199244AFirmly connectedCrimp firmlyLine/current collector detailsMechanical engineeringPositioning system

A lateral mechanical terminal crimping die comprises a die frame assembly, a sliding block assembly, a positioning assembly and a feeding assembly, and is characterized in that the die frame assemblyand the sliding block assembly are fixedly connected through a sliding block left pressing plate and a sliding block right pressing plate; the positioning assembly is connected with the die frame assembly, through a positioning block front and rear adjusting block, a lower die positioning block and a vertical adjusting block; and the feeding assembly is fixedly connected with the die frame assembly through a travel arm bolt. The die has the advantages of reasonable structure, simple processing technology, strong mobility, high performance, low cost and easy operation.

Owner:天津市科美通科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com