A plastic-steel door and window assembly sealing strip installation crimping machine

A technology for plastic-steel doors and windows and sealing strips, which is applied in the field of plastic-steel doors and windows assembly and sealing strip installation and crimping machinery, which can solve the problem that the sealing strips of different sizes cannot be effectively crimped, the working length of the crimping mechanism is short, and the overall appearance of the sealing strips is affected. problem, to achieve the effect of small space occupation, convenient overall operation and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

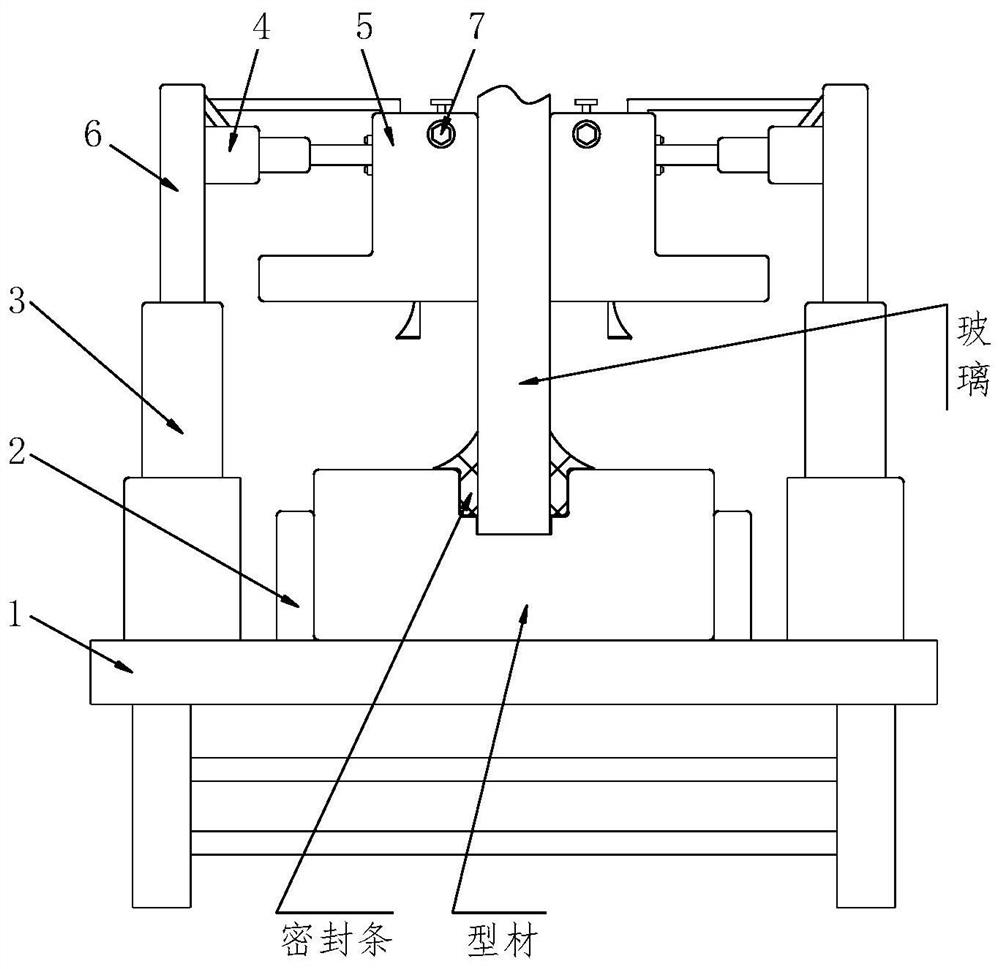

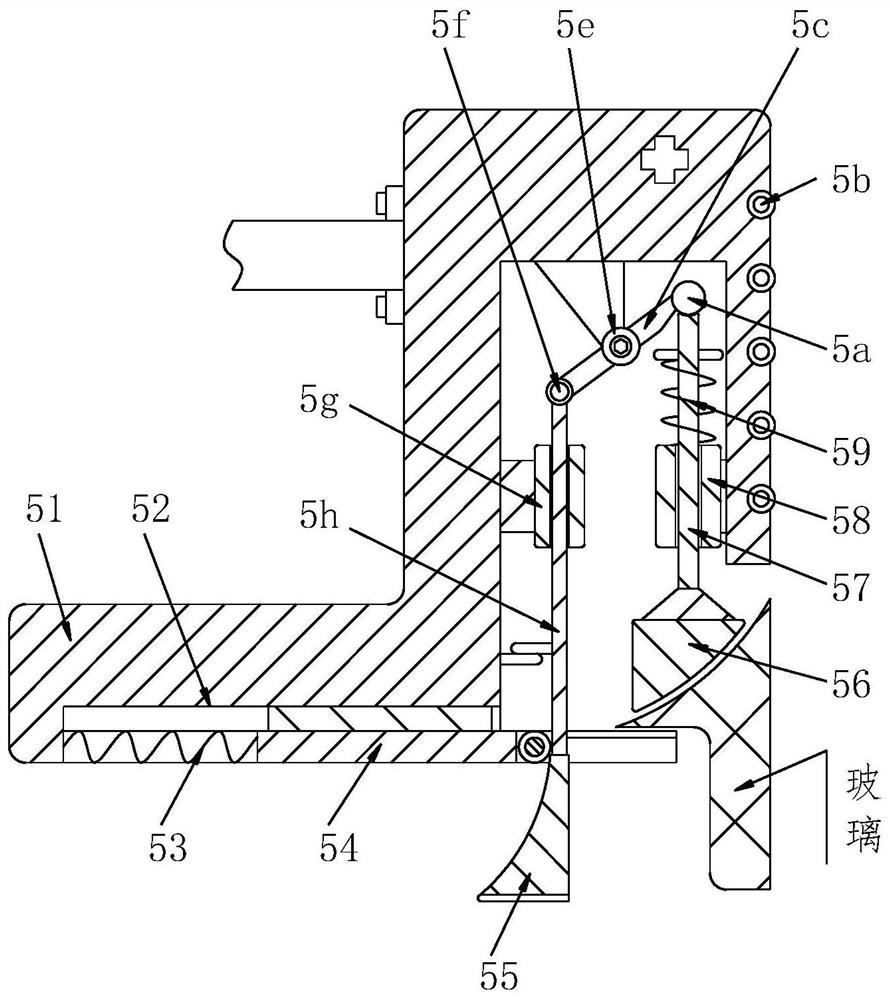

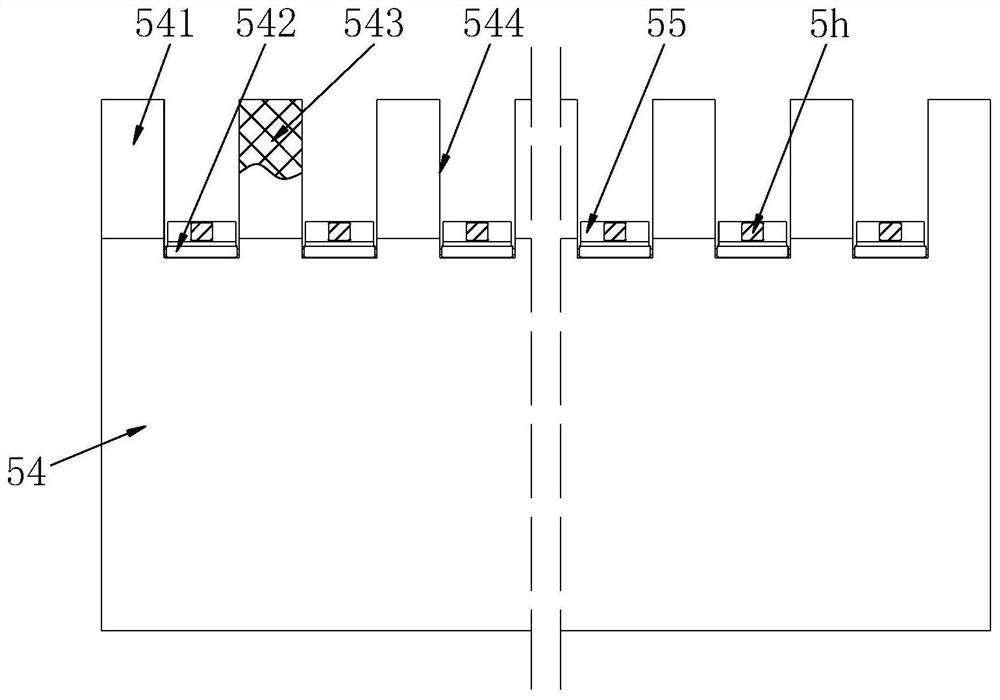

[0022] Such as Figure 1 to Figure 5 As shown, a plastic-steel door and window assembly sealing strip installation and crimping machine includes a workbench 1, a fixing frame 2, a first electric telescopic rod 3, a second electric telescopic rod 4, a crimping structure 5, a connecting column 6 and a splicing assembly 7 , the top center of the workbench 1 is fixed with a fixed frame 2 by bolts, the upper end surface of the workbench 1 and the symmetrical positions on both sides of the fixed frame 2 are equipped with a first electric telescopic rod 3, and the first electric telescopic rod 3 The top of the connecting column 6 is connected with a connecting column 6, and the outer wall of one side of the connecting column 6 is equipped with a second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com