Large-diameter stainless steel stay cable and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of time-consuming, the appearance of the cable anchor head is not round enough, not tight enough, etc., and achieves good anti-drop performance, beautiful appearance, Strong crimping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

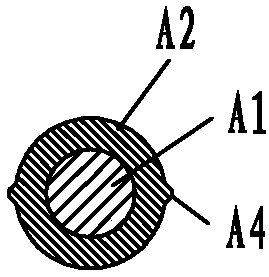

[0038] Embodiment 1: a kind of large-diameter stainless steel cable, such as Figure 4-Figure 8 As shown, it includes a stainless steel strand 1 and two pressure pipe joints 2. The pressure pipe joint has an inner hole 21, and the inner hole 21 of the pressure pipe joint is composed of an inclined hole 211 and an equal diameter hole 212. , the diameter of the inclined hole gradually decreases from the end to the middle, the minimum diameter of the inclined hole is the same as the diameter of the equal diameter hole, and a taper plug 3 is respectively set on the central wire 11 at both ends of the stainless steel strand, The two ends of the stainless steel stranded wire respectively penetrate into the inner hole of the pressure pipe joint and form an integral body with the pressure pipe joint through pressing. The diameter of the stainless steel stranded wire is 36-80 mm.

[0039] In this embodiment, the taper plug 3 is a circular truncated structure with a central hole 31, the...

Embodiment 2

[0040] Embodiment 2: a kind of manufacture method of the large-diameter stainless steel cable as described in embodiment 1, comprises the following steps:

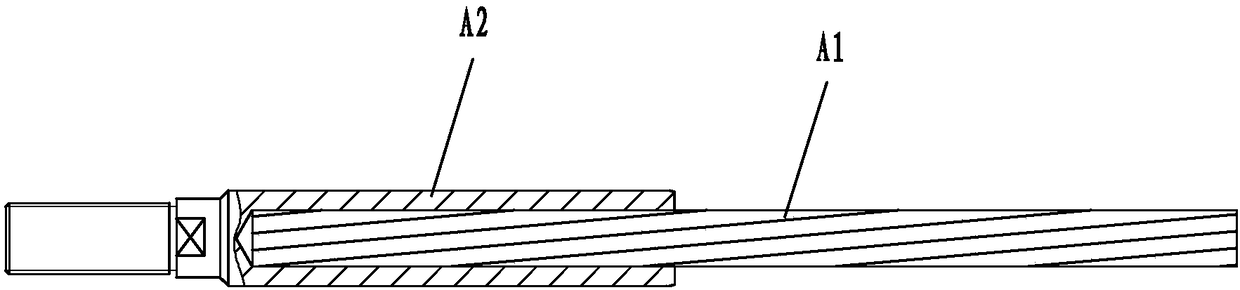

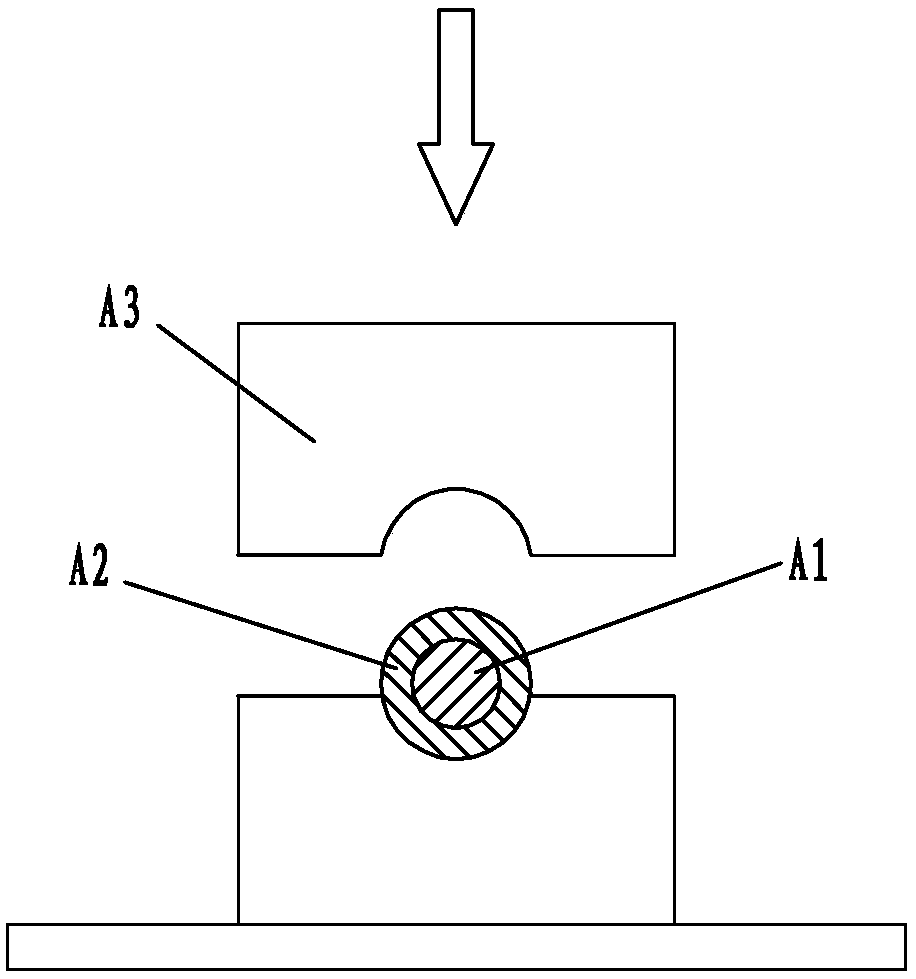

[0041] (1) Take a stainless steel strand 1 with a diameter of 36-80 mm, first insert the annular extrusion die 5 into the stainless steel strand, the middle part of the annular extrusion die is an extrusion forming hole 51, and the annular extrusion The length of the extruding hole 51 of mold is 75~85mm, preferably 80mm, and the extruding hole is made of tapered hole 511 and integral circular hole 512, and the length of tapered hole 511 and integral circular hole 512 is 40mm respectively Left and right, the tapered hole of the annular extrusion die faces the end of the stainless steel strand;

[0042] (2) Drive a taper plug 3 into the center wire 11 at one end of the stainless steel strand 2; the taper plug 3 is a circular truncated structure with a central hole 31, and the diameter of the large end of the taper plug is 1 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com