A flywheel housing and flywheel mounting sling and method of using the same

A flywheel housing and flywheel technology, applied in the field of flywheel housing and flywheel installation spreader, can solve the problems of difficult operation, hidden safety hazards, and high labor intensity of workers, achieve strong versatility, reduce labor intensity and operation difficulty, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

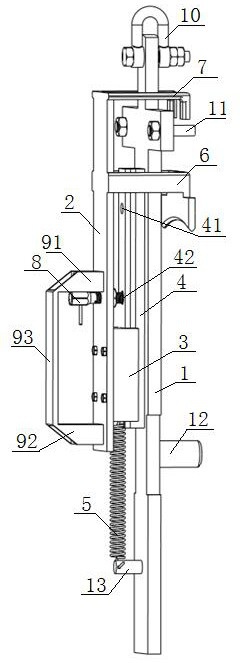

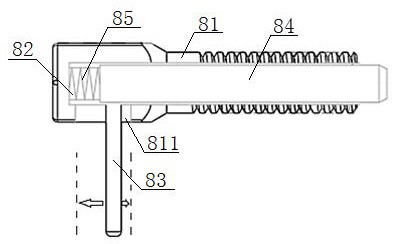

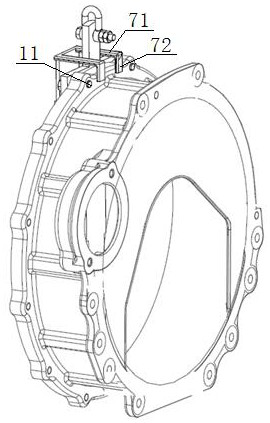

[0043] see figure 1 , figure 2 , a flywheel housing and a flywheel mounting sling, comprising a support plate 1, a limit plate 2, a slider 3, a latch 8, and the upper part of the front of the support plate 1 is provided with a flywheel that matches the fixing holes of the periphery of the flywheel shell The shell limit support pin 11, the middle part of the front of the support plate 1 is provided with the center limit pin 12 of the flywheel which is matched with the center through hole of the flywheel, the middle part and the lower part of the back of the support plate 1 are respectively provided with a longitudinal slideway 4 and a transverse connecting rod 13 , the longitudinal slideway 4 is provided with a hoisting positioning hole 41 and a locking hole 42, the lifting positioning hole 41 is located above the locking hole 42, and one side of the slider 3 is slidingly matched with the longitudinal slideway 4, The other side of the sliding block 3 is fixedly connected with...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] see figure 1 , the spreader also includes a handle 9 and a lifting ring 10. The handle 9 includes an upper connecting plate 91 located above the latch 8, a lower connecting plate 92 located below the latch 8, and a hand grip 93. The upper connecting plate 91, One end of the lower connecting plate 92 is fixedly connected to the back of the limiting plate 2, and the other ends of the upper connecting plate 91 and the lower connecting plate 92 are fixedly connected to the upper and lower ends of the handle bar 91 respectively, and the suspension ring 10 is an inverted U-shaped structure. , its lower end is fixedly connected with the top end of the support plate 1 through a locking nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com