Charging gun terminal structure and rubber coating mode

A terminal structure and charging gun technology, applied in charging stations, electric vehicle charging technology, circuits, etc., can solve the problems of poor heat dissipation effect, sudden change in crimping position, and high labor cost, and achieve good compression ratio and volume ratio. Reduced gasket parts, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

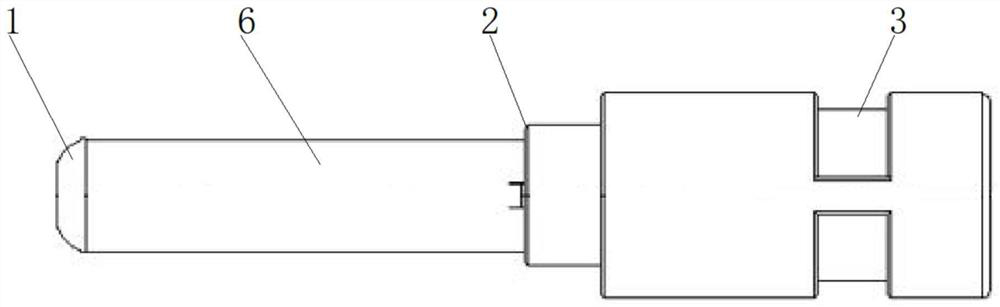

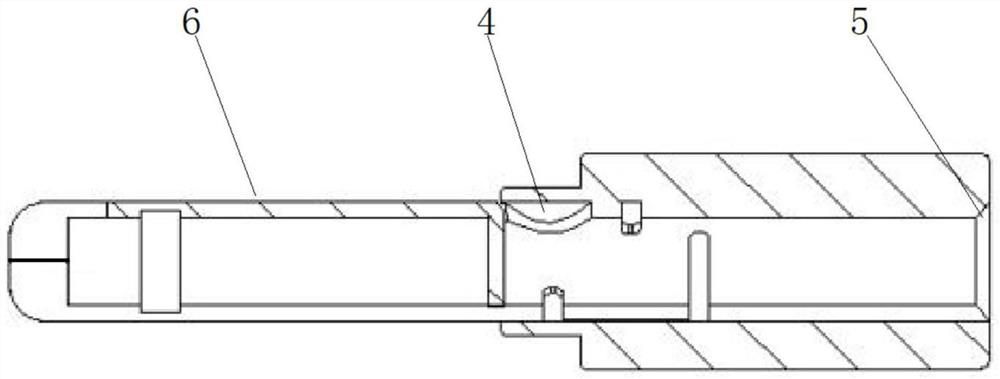

[0023] A charging gun terminal structure and encapsulation method, comprising a terminal main body 6, the inner end of the terminal main body 6 away from the chamfer 5 is provided with a pin, and the diameter of the pin is 6mm, and the 6mm pin is conductive for the main body of the charging gun to realize the charging function , one end of the terminal main body 6 is provided with a stamping terminal head chamfer 1, the position of the head chamfer meets the requirements of the insertion force, and the outer side of the terminal main body 6 is provided with a rubber-coated terminal 2, and the length of the rubber-coated terminal 2 is 25mm. For the effect of effective insulation, the outer side of the terminal body 6 is provided with a buckle position 3 on the side of the end point 2 of the rubber coating. There is a circular baffle 4 with an inner groove. The circular baffle 4 with an inner groove can better solve the problem of mold forming. One end of the terminal body 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com