Compression-connecting pipe applied to parallel connection of cables and applications thereof

A technology for crimping pipes and cables, applied in the direction of permanent deformation, electrical connection sockets, etc., can solve the problems of short service life, burnt equipment, increased contact resistance, etc., to achieve long service life, convenient connection, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

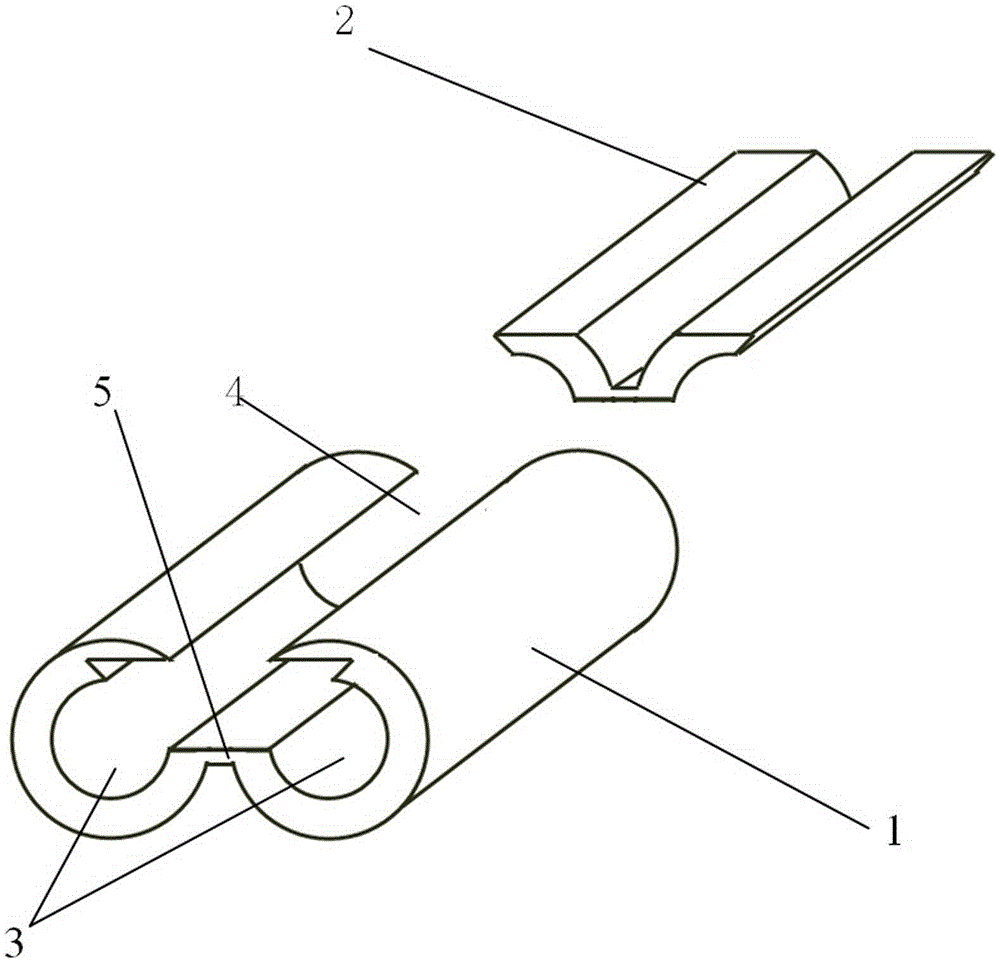

Method used

Image

Examples

Embodiment approach 2

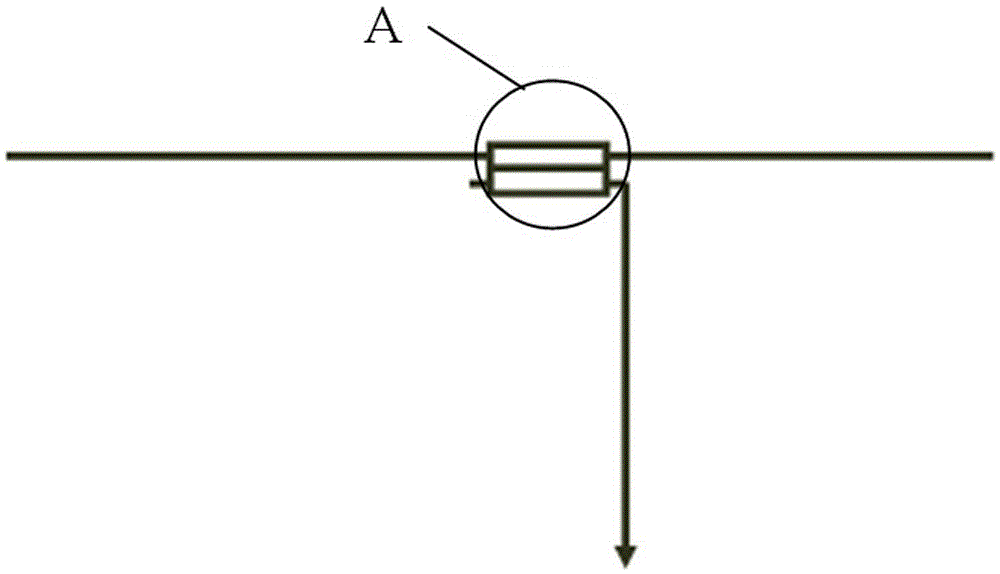

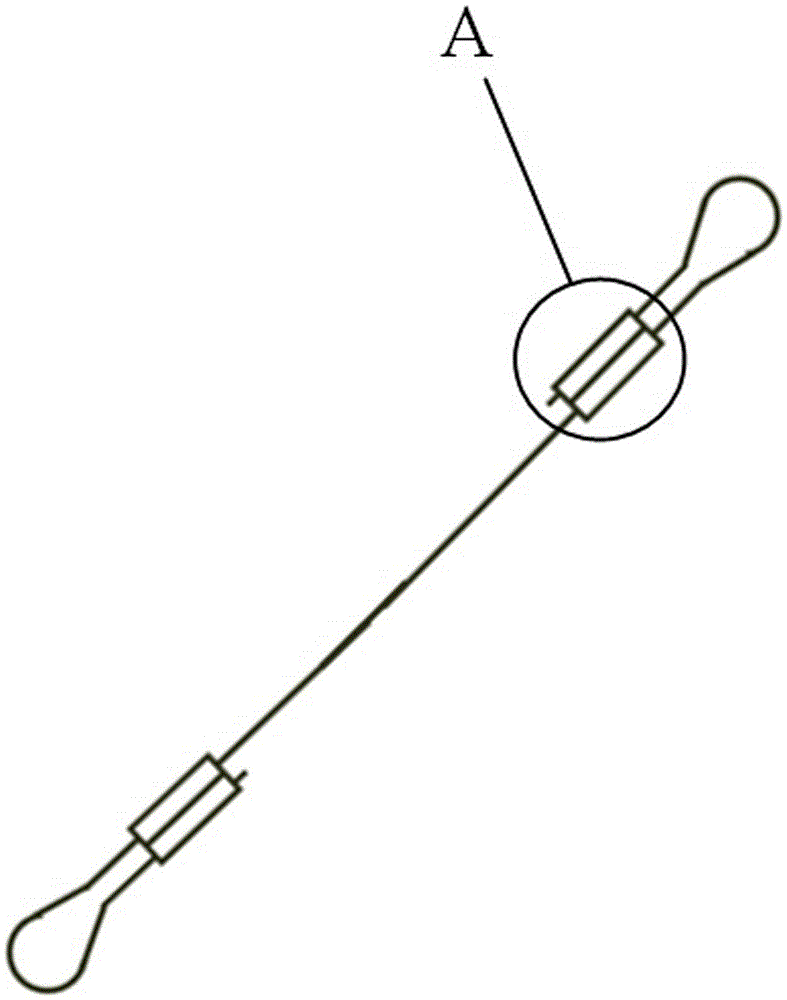

[0022] Implementation mode two: see image 3 with Figure 4 .

[0023] This is an embodiment of the present invention for fixing the tail end of the pole and tower stay wire.

[0024] from image 3 with Figure 4 It can be seen that the present invention is used for fixing the tail ends of pole and tower stay wires. The guy wire and tail wire are actually one cable, so the wire diameter is the same. Fix the tail end of the pull wire on the pull wire, and respectively put the end of the pull wire of the pull wire box into the two wire slots from the cable inlet 4. The two wire slots use the same radius, and the others are the same as in Embodiment 1. The cables are placed , After the body cover is inserted into the seal, crimping can be carried out. The invention is not only suitable for fixing the tail end of the newly installed stay wire, but also can use the crimping tube of the invention when the circuit structure still using the prior art needs to be maintained. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com