A crimping fixture for oled panels

A panel and fixture technology, applied in the direction of instruments, static indicators, etc., can solve the problems of low test efficiency, crimping alignment deviation, crimping instability, etc., to achieve high test efficiency, uniform crimping, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

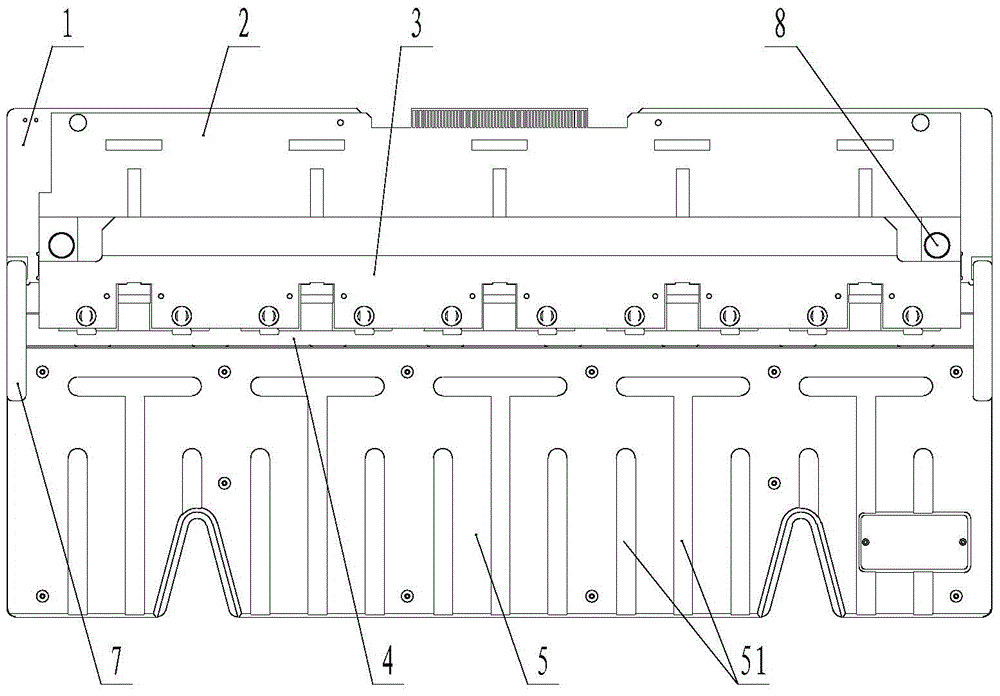

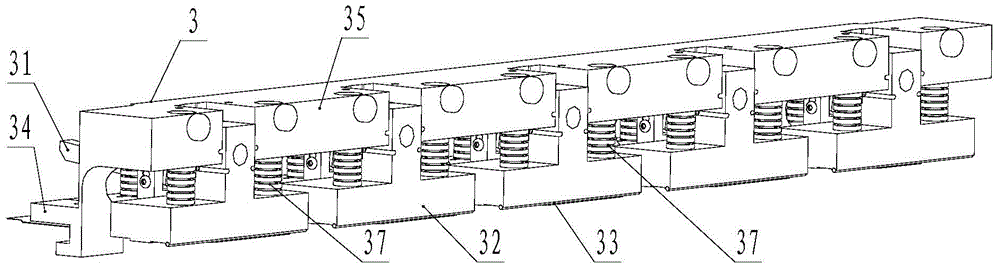

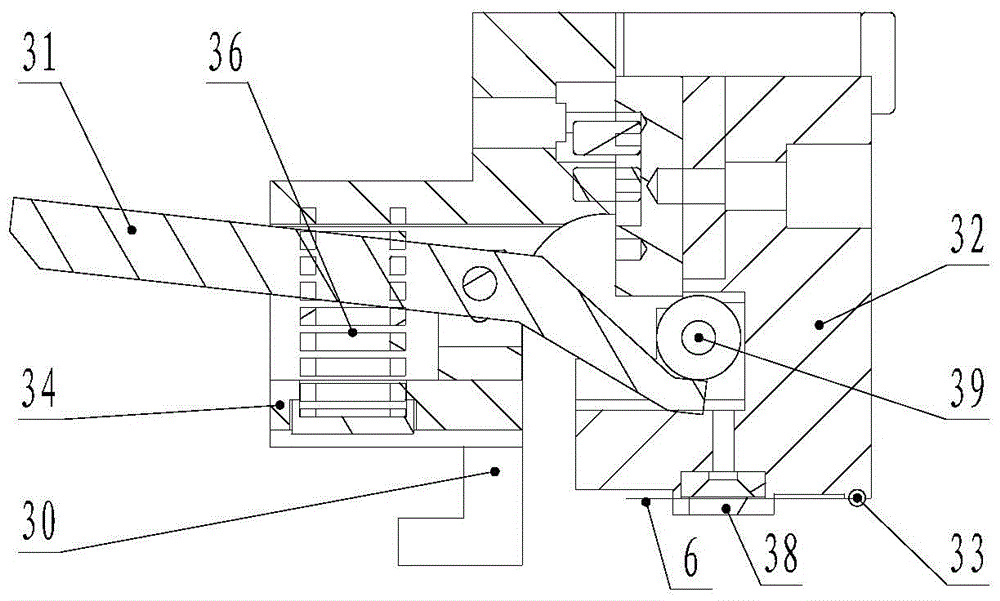

[0018] Such as Figure 1-3 As shown, the present invention includes a support board 1, a PCB board 2, a crimping device 3, an OLED panel placement board 5 and a flexible circuit board 6, and the PCB board 2 and the OLED panel placement board 5 are respectively fixed on both sides of the support board 1, The crimping device 3 is installed on the support plate 1 between the PCB board 2 and the OLED panel placement plate 5; the crimping device 3 includes a bracket 30, a pressing rod 31 and a pressing block 32, and the middle part of the pressing rod 31 is connected to the The bracket 30 is hinged, one end of the pressing rod 31 protrudes from one side of the bracket 30 , and the upper surface of the other end contacts the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com