Press-fit fixing terminal, and electronic component having the same terminal

一种固定端子、电子部件的技术,应用在固定连接、电气元件、电路等方向,能够解决上升、变形成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

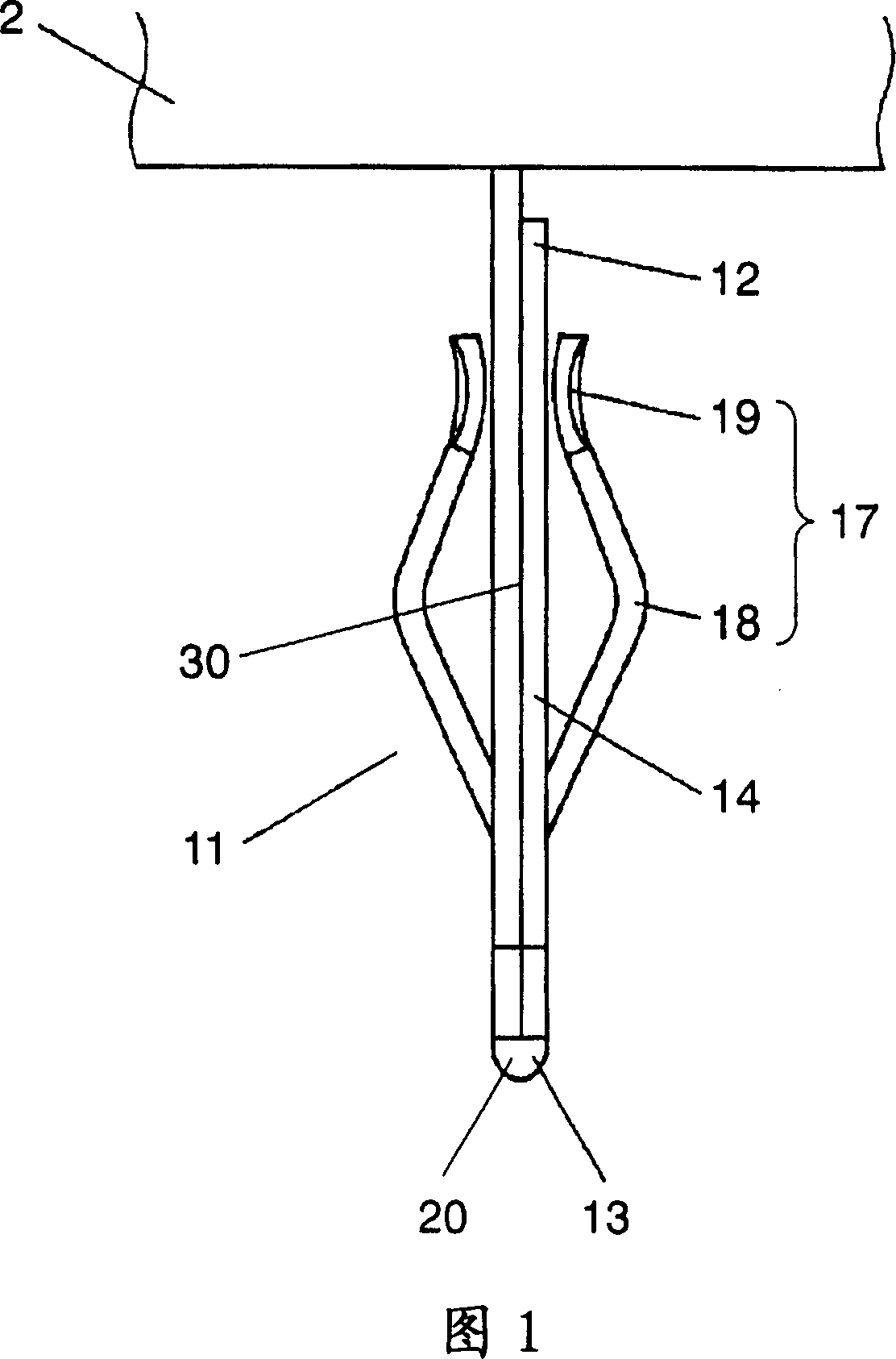

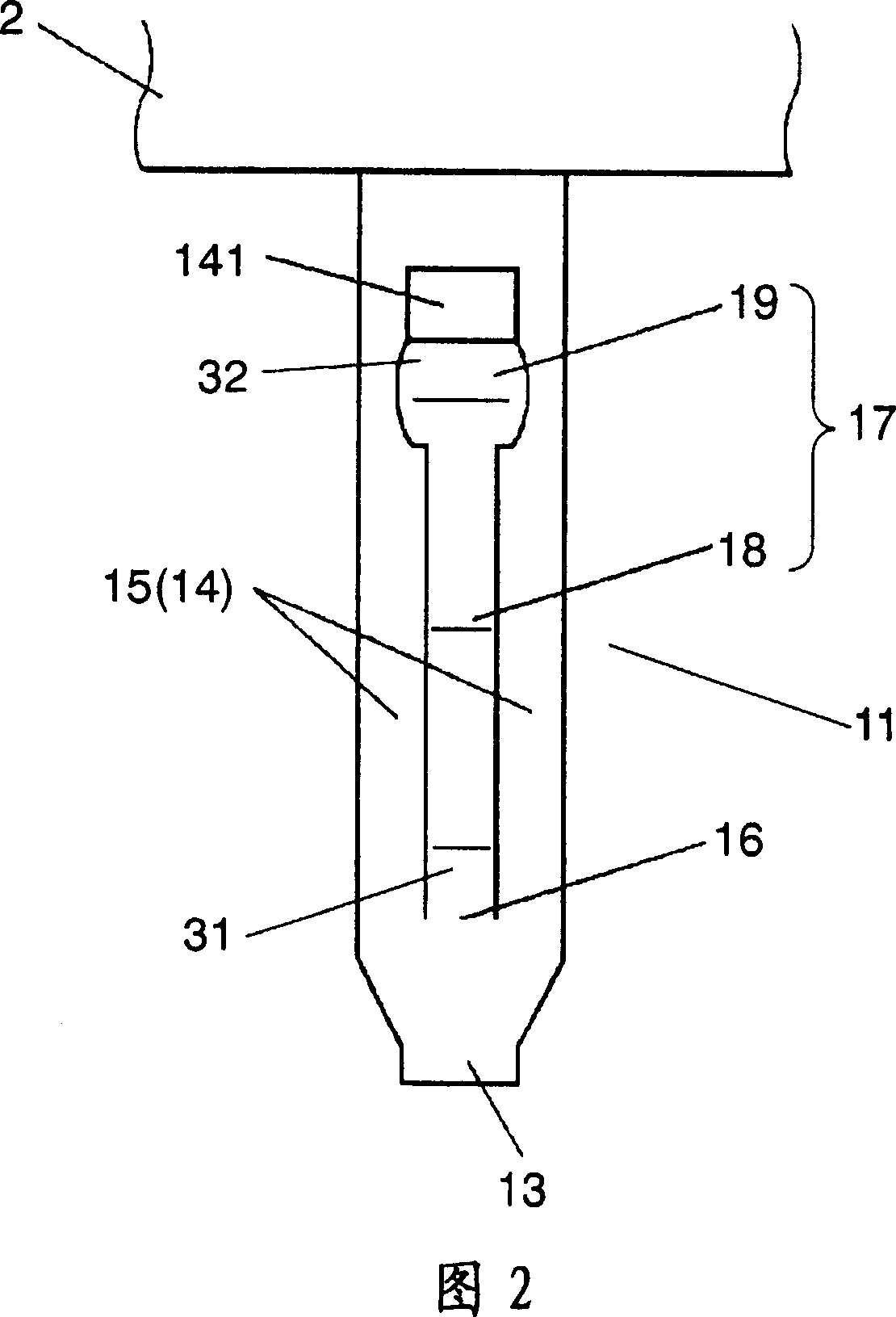

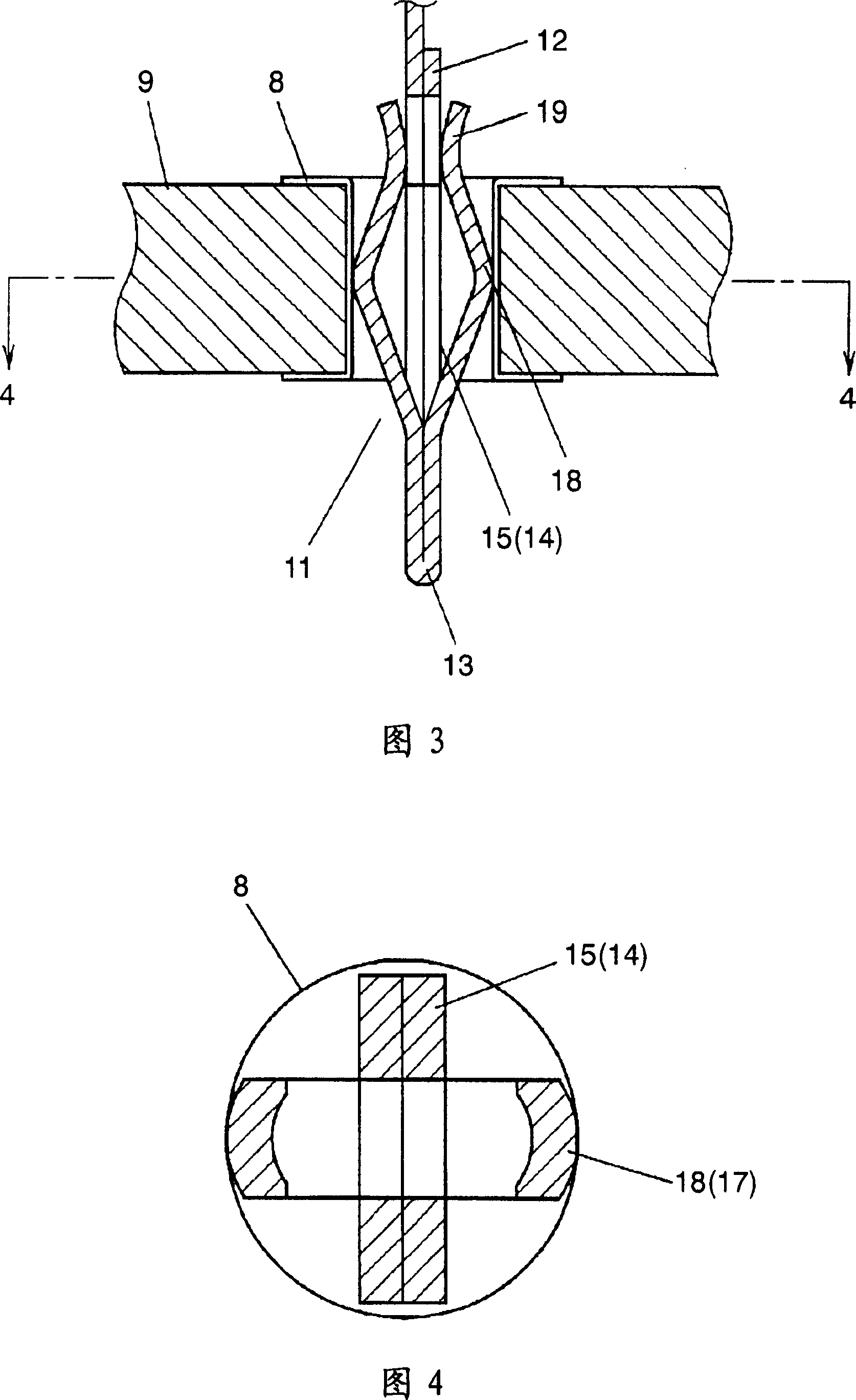

[0025] 1 is a front view of a press-fit terminal according to an embodiment of the present invention. FIG. 2 is a side view of the press-fit terminal shown in FIG. 1. FIG. The vertical sectional view under the state in the hole, Fig. 4 is the horizontal sectional view along line 4-4 shown in Fig. 3.

[0026] In FIGS. 1 and 2 , the press-fit terminal 11 of this embodiment can be inserted into a through hole of a wiring board for attachment and detachment, and includes a flat plate portion 14 and an elastic contact portion 17 .

[0027] The flat plate portion 14 is made of sheet metal, and its folded front end 12 is located at the root side, and the folded back portion 20 is folded to form an insertion front end 13 when inserted into the through hole. The elastic contact portion 17 is provided at symmetrical positions on both sides of the folded portion 30 of the flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com