Forging and pressing die

A mold and forging technology, applied in the field of forging molds, can solve the problems of excessive size deviation of forgings, plastic deformation of mold cavity, easy cracking, etc., and achieve the effect of not easy plastic deformation, less follow-up processing and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

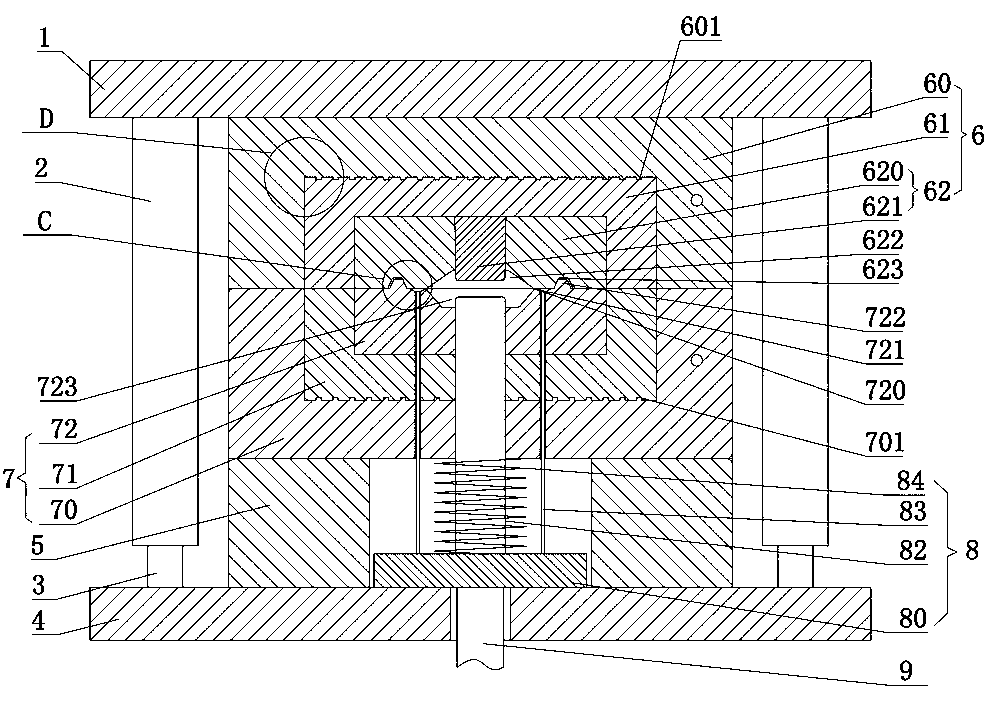

[0034] The present invention will be further described below in conjunction with the drawings and specific embodiments:

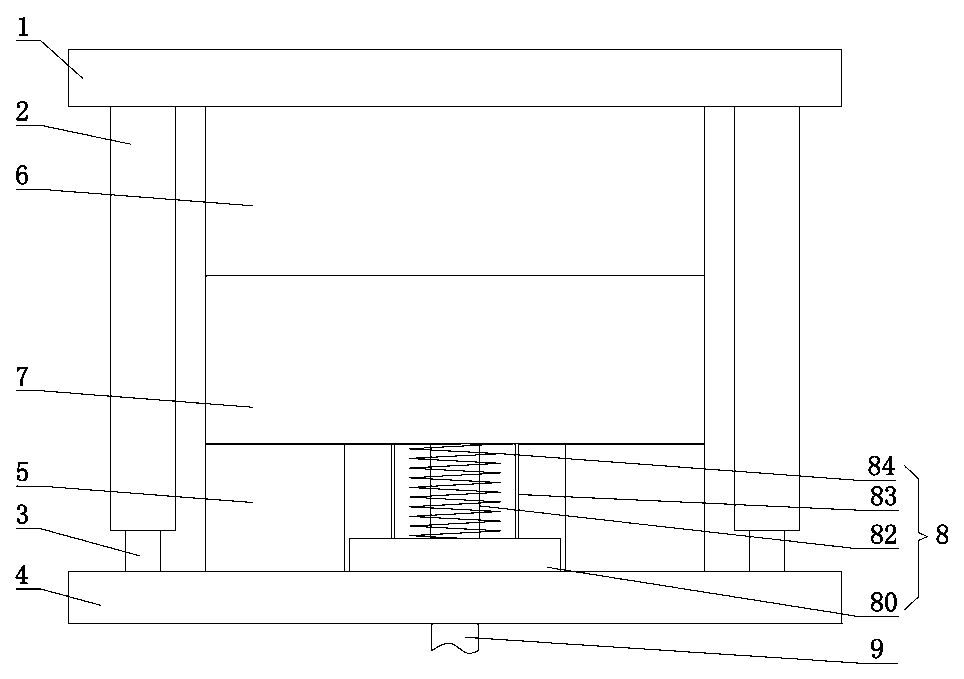

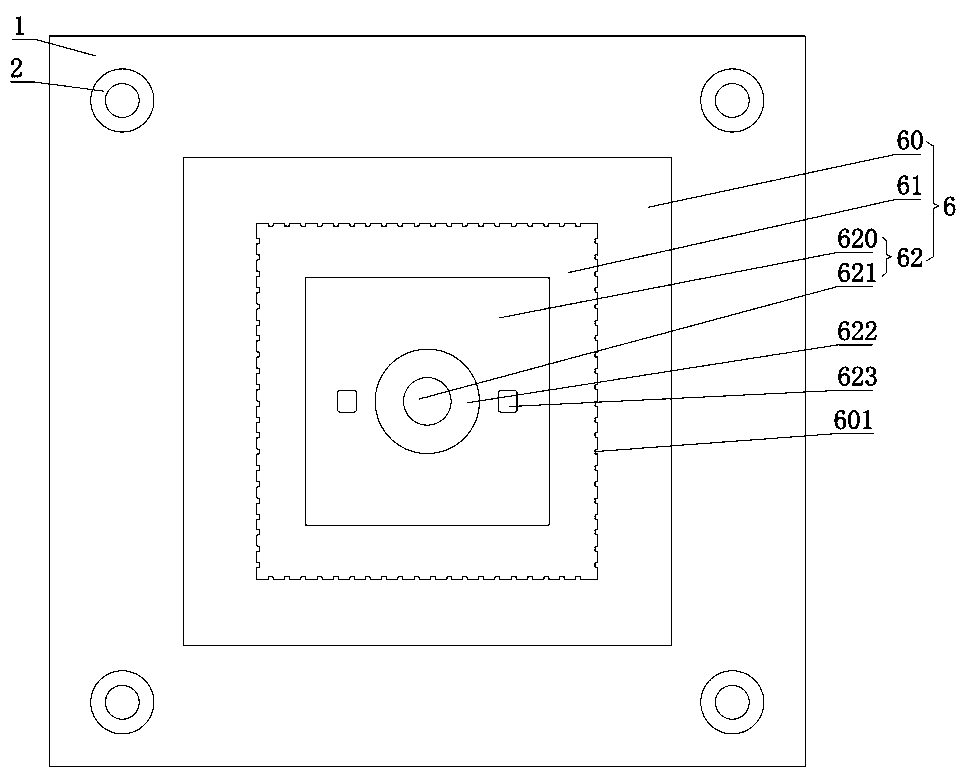

[0035] Such as Figure 1 ~ Figure 7 As shown, a forging die includes a horizontal plate type upper die seat 1, a vertical guide sleeve 2 is provided on the bottom surface of the upper die seat, a guide post 3 is inserted in the guide sleeve, and the bottom of the guide post 3 is fixed on a horizontal plate type On the lower mold base 4, the center of the lower mold base 4 is provided with a through hole, and the ejector rod 9 is movably penetrated into the through hole. It also includes a fixed plate 5, an upper combined mold 6, a lower combined mold 7 and an ejection device 8. The upper mold seat The materials of 1 and the lower mold base 4 are 45 steel, and the guide post 3 and the guide sleeve 2 are the guide post and guide sleeve of Shenzhen Hengtongxing Technology Co., Ltd.

[0036] The left and right sides of the top surface of the lower mold base 4 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com