Assembly device for welding circuit board and heat sinking base plate and welding method thereof

A circuit board and heat sink technology, which is applied in the field of fixtures for solidification and welding of power amplifier module circuit boards and heat sink substrates, can solve the problem of damage to the core device of the amplifier-power tube, affecting the electrical conductivity and thermal conductivity of the heat sink substrate, and the deterioration of amplifier stability. and other problems, to achieve the effect of saving installation time, stabilizing electrical performance, and reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

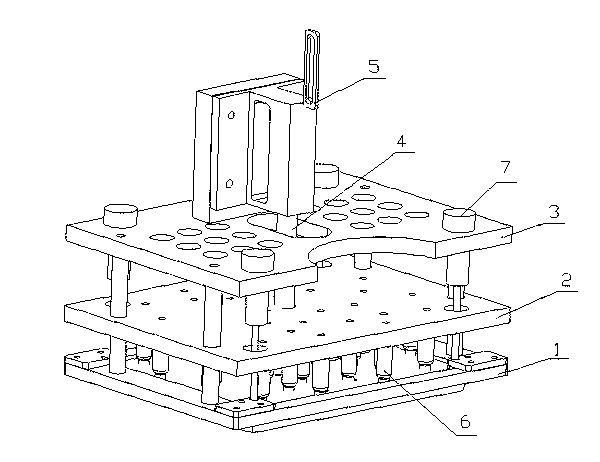

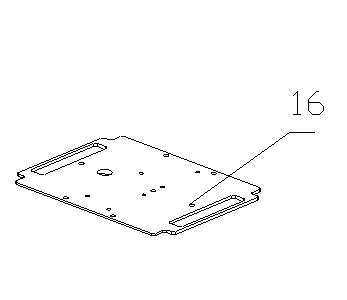

[0023] see figure 1 The tooling device of the present invention includes a plywood layer composed of a bottom plate 1, a middle plate 2 and a top plate 3 which are made of high-temperature-resistant phenolic resin plate material and are placed horizontally in sequence, and a clamping rod 4 located at the center of the plywood layer and penetrating through the three-layer plywood. The top of the tight rod 4 is a clamp handle 5 that can clamp or unclamp the three-layer plywood, and the four corners of the plywood layers are respectively provided with a fastening screw 7 that is used to fix the three-layer plywood. A weldment consisting of a power amplifier module circuit board 11 and a heat sink substrate 12 can be placed on the bottom plate 1, and a plurality of crimping posts 6 with compression spring devices are fixedly connected downwards under the middle plate 2, and each crimping post 6 The positions correspond to the crimping holes 13 on the power amplifier module circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com