Connector for cold cathode tube

A cold cathode and connector technology, which is applied to devices for connecting, joining/disconnecting connecting components, discharge tubes, etc., can solve the problems of lengthening electrode wires, bending and deformation of electrode wires, complicated structure of connecting terminals, etc., and achieves safe clamping Easy to maintain and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

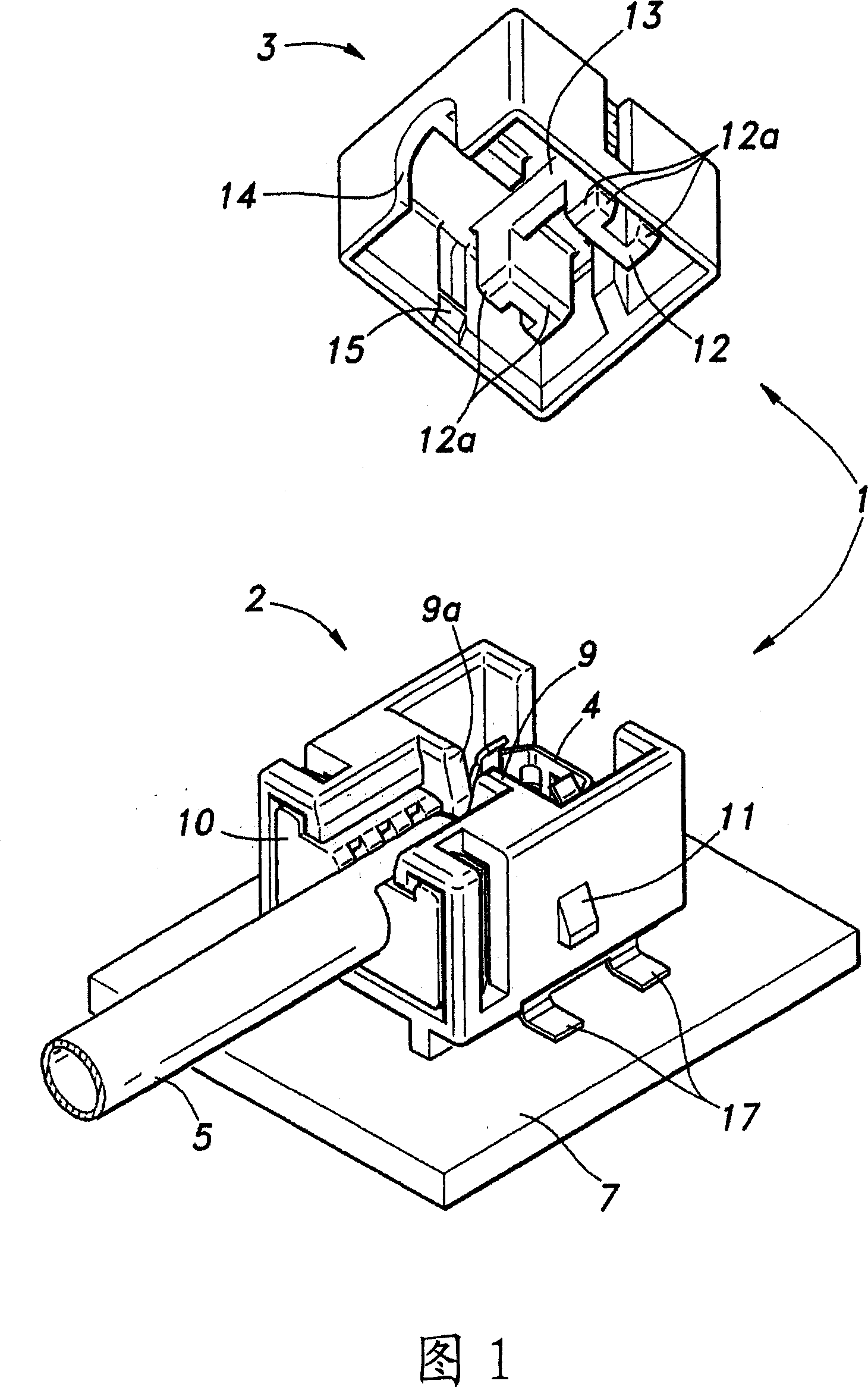

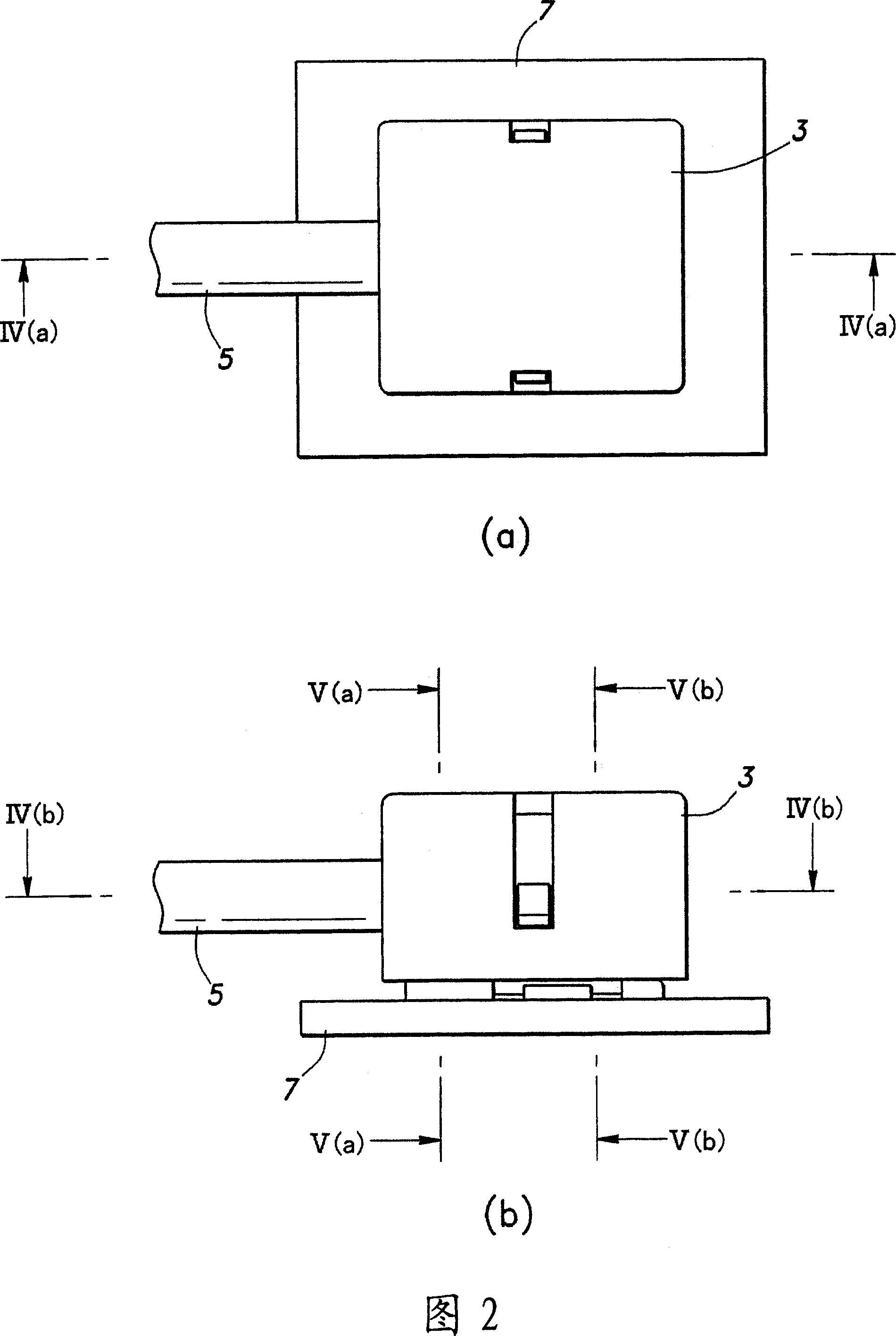

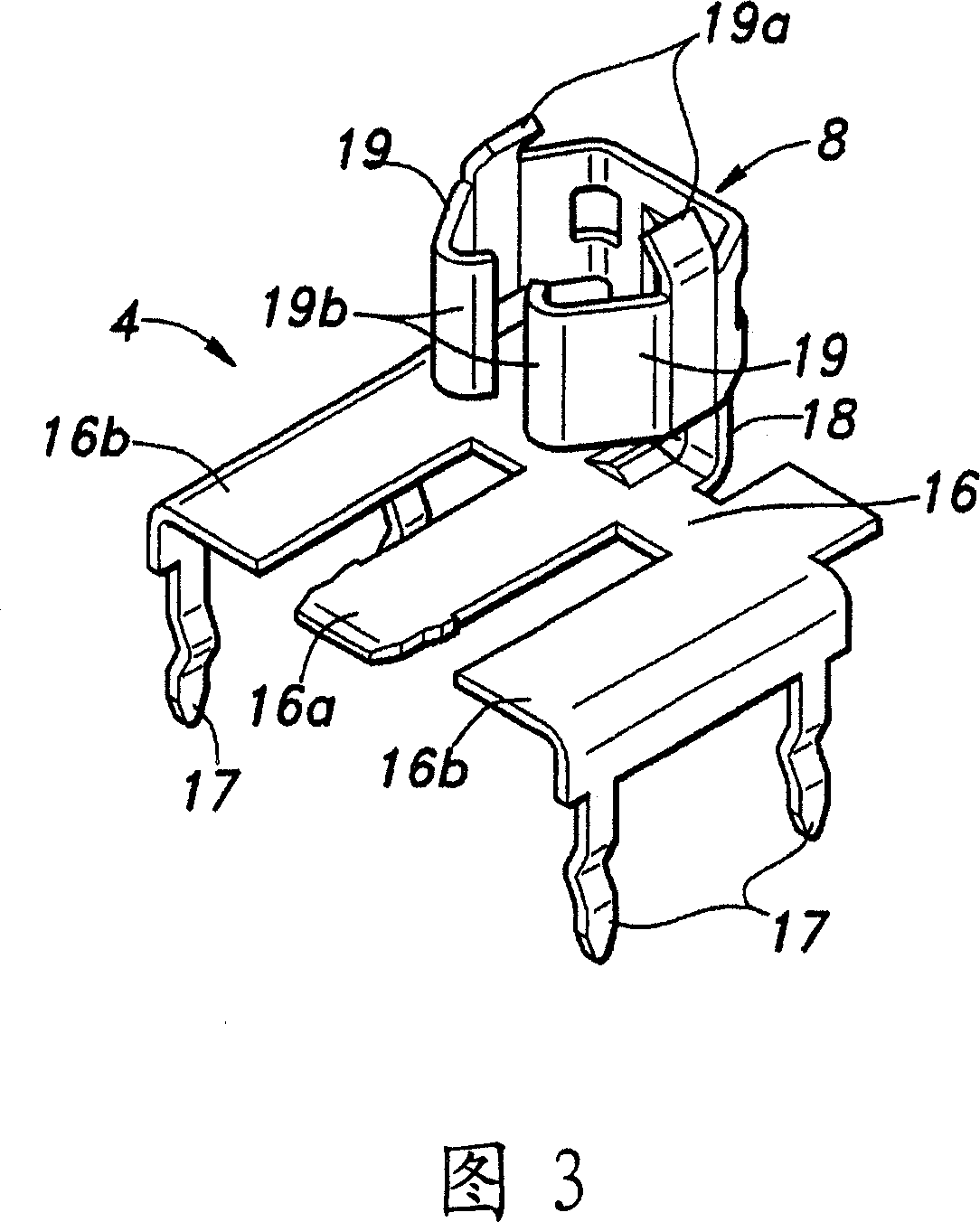

[0081] The connector for cold cathode fluorescent tubes according to the present invention will be described in detail based on the drawings showing the best mode to which the present invention is applied. FIGS. 1 to 6 show a first embodiment applied to a board-mounted type for connecting a connection terminal to a printed circuit board. 7 to 8 show modifications of the first embodiment applied to the substrate mount type. 9 to 13 show a second embodiment of the lead wire type applied to connecting the connection terminal to the lead wire. 14 to 16 show modifications of the second embodiment applied to the lead type.

[0082] The first embodiment will be described. FIG. 1 is a perspective view showing a CCFL connector 1 mounted on a substrate before a top cover is mounted. Fig. 2 shows the state after the top cover is attached, (a) is a plan view, and (b) is a side view. FIG. 3 is a perspective view showing a connection terminal built in the CCFL connector 1 . Fig. 4 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com