Connecting plug hole copper rivet pressing connection tool

A plug hole and copper rivet technology, applied in the field of crimping tooling, can solve the problems of wasting time, low tooling efficiency, low production efficiency, etc., and achieve the effect of canceling production steps, shortening manufacturing cycle, and stable crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention as Figure 1-7 As shown, the wiring plug hole 2 is located on the metal flange 1, and the top of the wiring plug hole 2 is provided with a metal terminal 3 and a plastic gasket 4 in sequence from top to bottom, and a plastic cover 5 is provided at the bottom. The rivets 6 are used to connect metal terminals, plastic gaskets, metal flanges and plastic covers to make them connected as a whole;

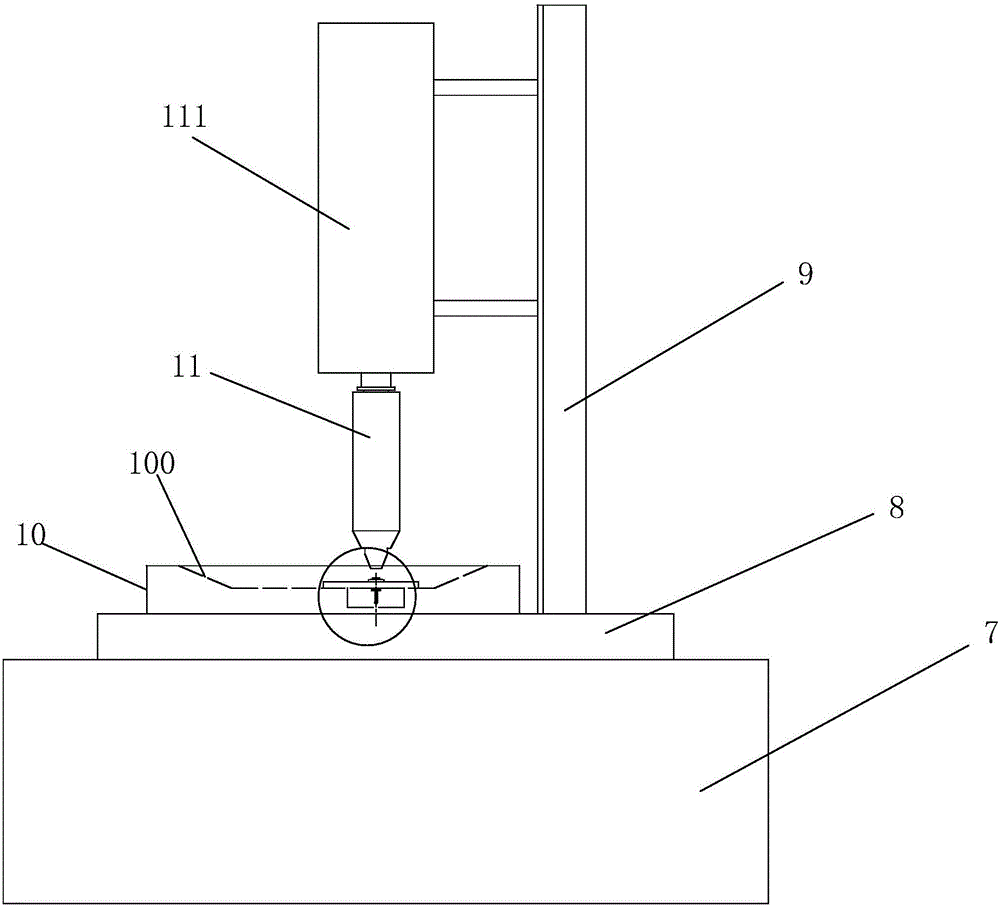

[0026] The crimping tool 11 is located above the workbench 7, the workbench 7 is provided with a base 8, the base 8 is provided with a sliding seat 9 and a support seat 10, and the crimping tooling is movably connected to the sliding seat Up and down, and lift (can be manually operated, push rod operation, etc.), the crimping tool is located directly above the support seat,

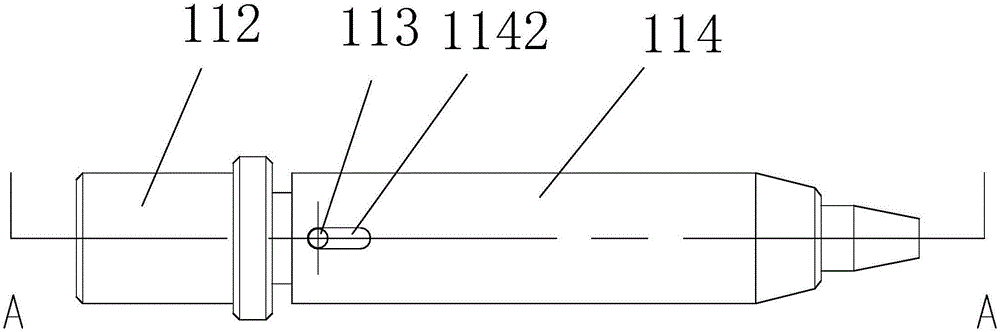

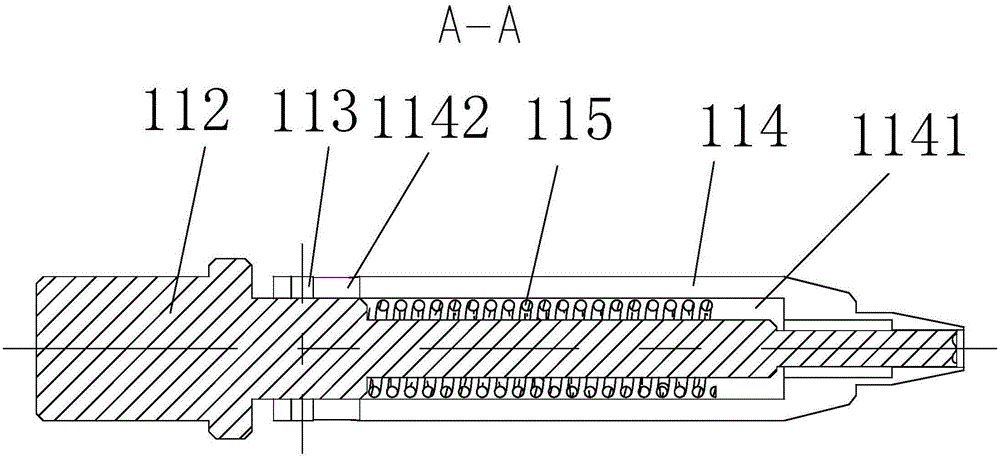

[0027] The crimping tooling 11 comprises a cylinder 111, a lining mold core 112, a pin 113, an outer lining mold cover 114 and a spring 115, and the cylinder comprises a cylinder body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com