Industrial oil smoke anti-pollution discharge equipment

An anti-pollution and oil fume technology, which is used in the removal of oil fume, lighting and heating equipment, and household heating, etc., can solve the problems of oil fume pollution and poor smoke exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

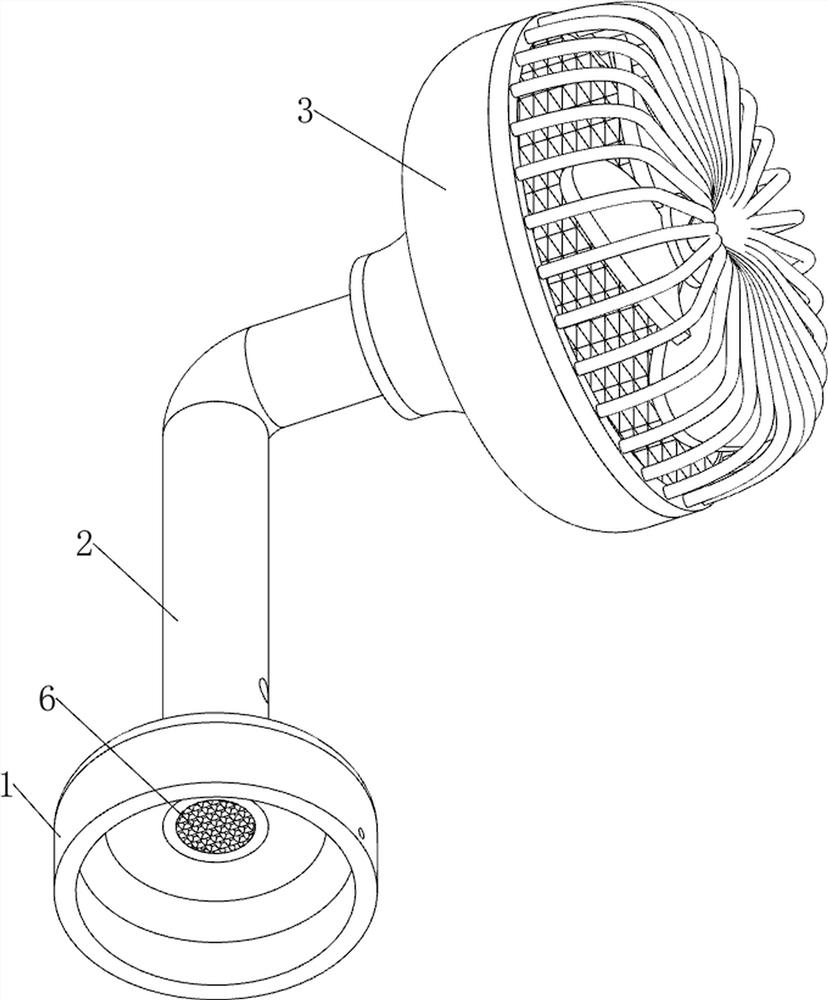

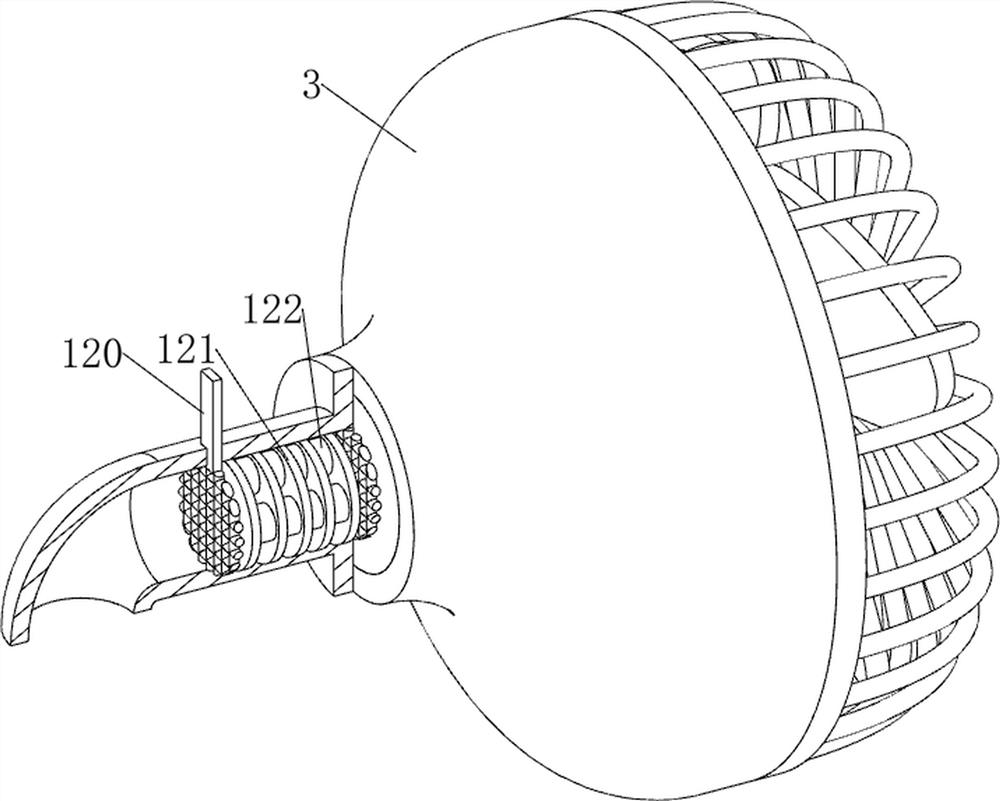

[0025] A kind of industrial oil fume anti-pollution discharge equipment, such as Figure 1-3 As shown, it includes a base 1, an exhaust pipe 2, a protective cover 3, a first turbofan 4, a first filter 5, a second filter 6, a fixing mechanism 7 and a driving mechanism 8, and the top of the base 1 is provided with an exhaust Pipe 2, the right side of the upper part of the exhaust pipe 2 is provided with a protective cover 3, the first turbofan 4 is rotatably connected in the protective cover 3, the left side of the protective cover 3 is provided with a first filter screen 5, the bottom of the exhaust pipe 2 and The upper right side is provided with a second filter screen 6 , the base 1 is provided with a fixing mechanism 7 , and the base 1 is provided with a driving mechanism 8 .

[0026] Fixing mechanism 7 comprises fixed plate 70, slide block 71, first spring 72, nut 73 and bolt 74, and base 1 three sides are all provided with fixed plate 70, and all sliding type is connected ...

Embodiment 2

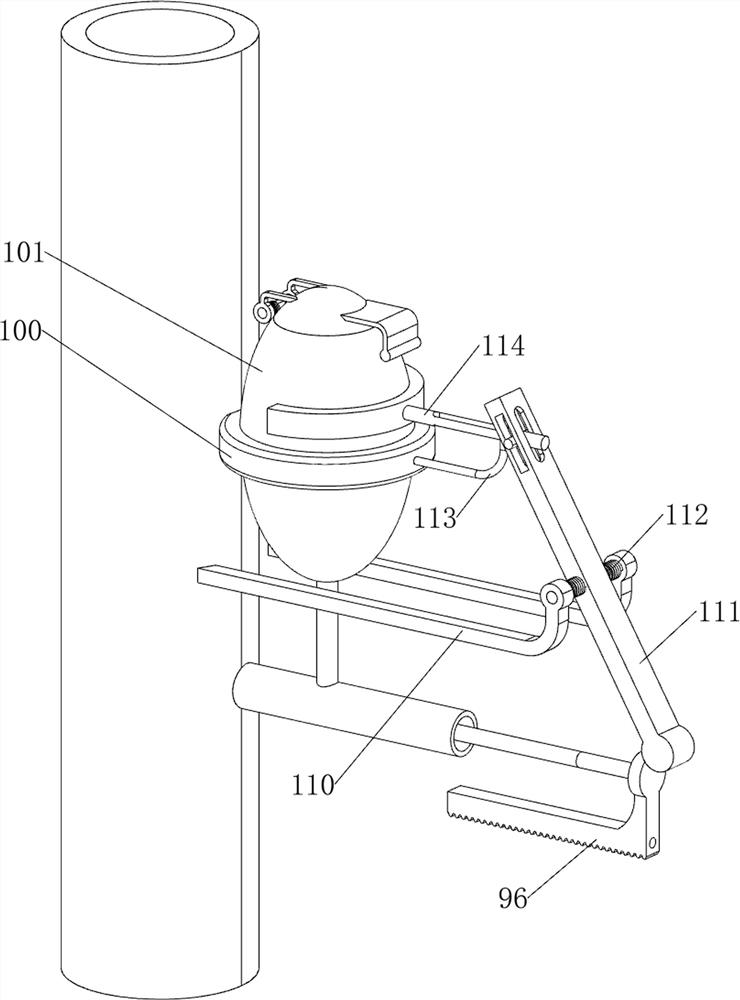

[0030] On the basis of Example 1, such as Figure 4-7 Shown, also include spraying mechanism 9, spraying mechanism 9 includes second bevel gear 90, transmission assembly 91, spur gear 92, guide rod 93, rack 94, rubber rod 95, spray nozzle 96 and second spring 97, install The left side of the lower part of the plate 80 is rotatably connected with a second bevel gear 90, the left front side of the top of the mounting plate 80 is rotatably connected with a spur gear 92, and a transmission assembly 91 is connected between the spur gear 92 and the second bevel gear 90, and the transmission assembly 91 consists of Composed of two pulleys and a belt, the two pulleys are respectively connected to the spur gear 92 and the second bevel gear 90, the belt is wound between the spur gear 92 and the second bevel gear 90, and the lower right side of the exhaust pipe 2 is provided with a guide Rod 93, the guide rod 93 is slidingly connected with a rack 94, the left side of the rack 94 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com