PCB (polychlorinated biphenyl) smear removal drug liquid filtration recycling equipment and smear removal drug liquid filtration recycling method thereof

A technology of glue residue and liquid medicine, which is applied in the field of PCB filtration and reuse equipment for removing glue residue and liquid medicine, can solve the problems of increasing enterprise cost, unreliable connection, and unsmooth signal connection of multi-layer boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

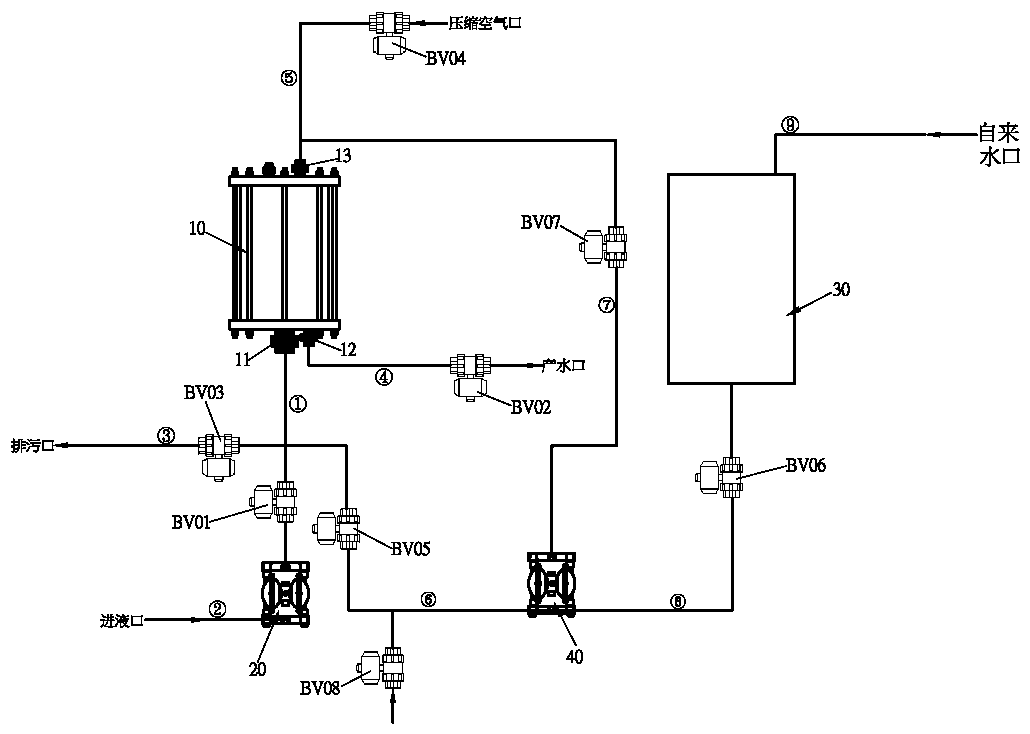

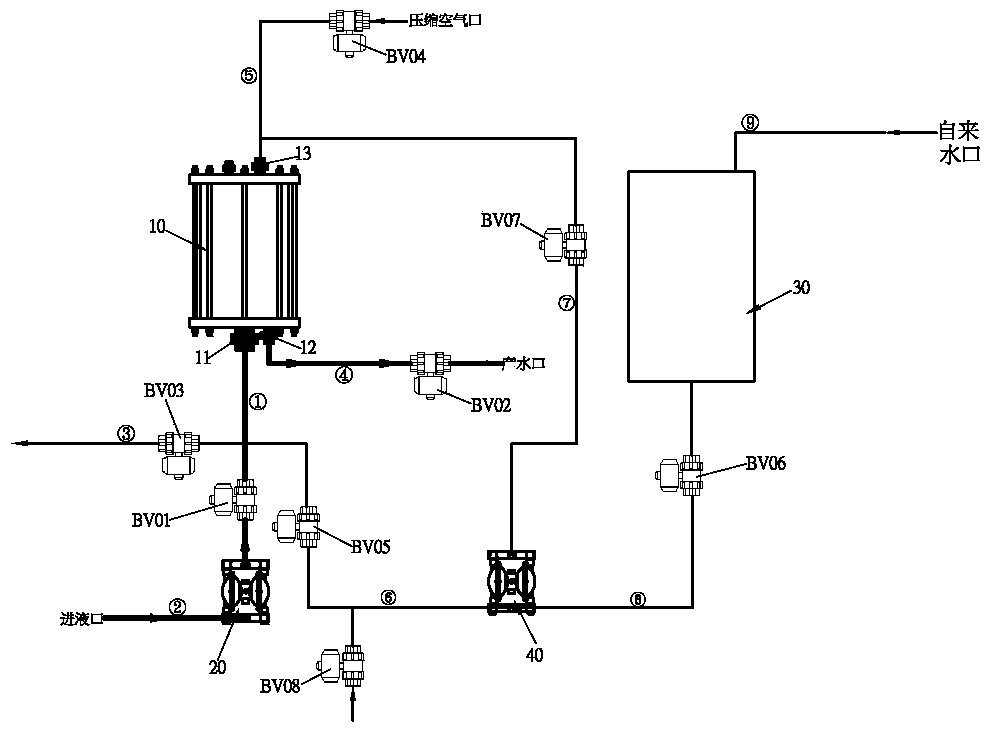

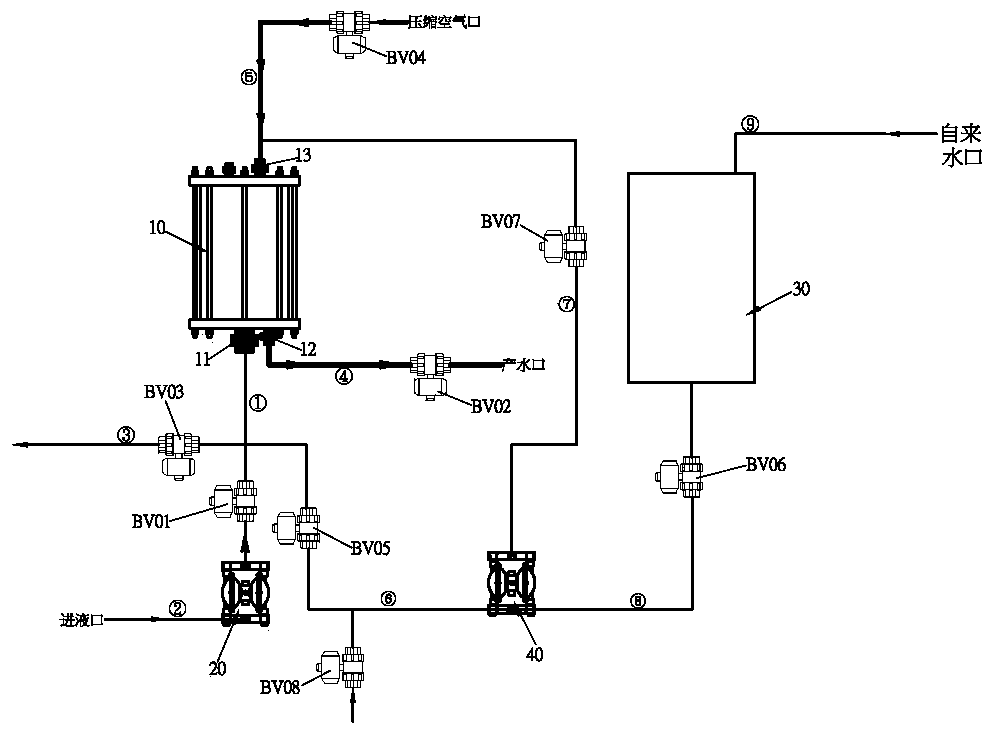

[0053] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention, including filter membrane module 10, filter pump 20, cleaning bucket 30, cleaning pump 40, liquid inlet, sewage outlet, water production port, compressed air port and tap water mouth.

[0054] Wherein: the filter membrane module 10 is built with multiple sets of filter membranes (not shown in the figure), and the filter membrane module 10 has a water inlet 11, a water outlet 12 and an air inlet 13;

[0055] The water inlet 11 of the filter membrane module 10 communicates with the outlet of the filter pump 20 through the first pipeline ①, the inlet of the filter pump 20 communicates with the second pipeline ② one end, the second pipeline ② communicates with the liquid inlet, and the first A pipeline ① is provided with a water inlet valve BV01. The waste water flows into the filter membrane module 10 through the liquid inlet, the second pipeline ②,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com