Junction box for photovoltaic modules for easy crimping of bus bars

A photovoltaic module and junction box technology, applied in the field of double-glass photovoltaic power generation modules, can solve the problems affecting the normal use of the junction box, troublesome operation process, unstable connection method, etc., to achieve good connection effect, long service life, and spare parts less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

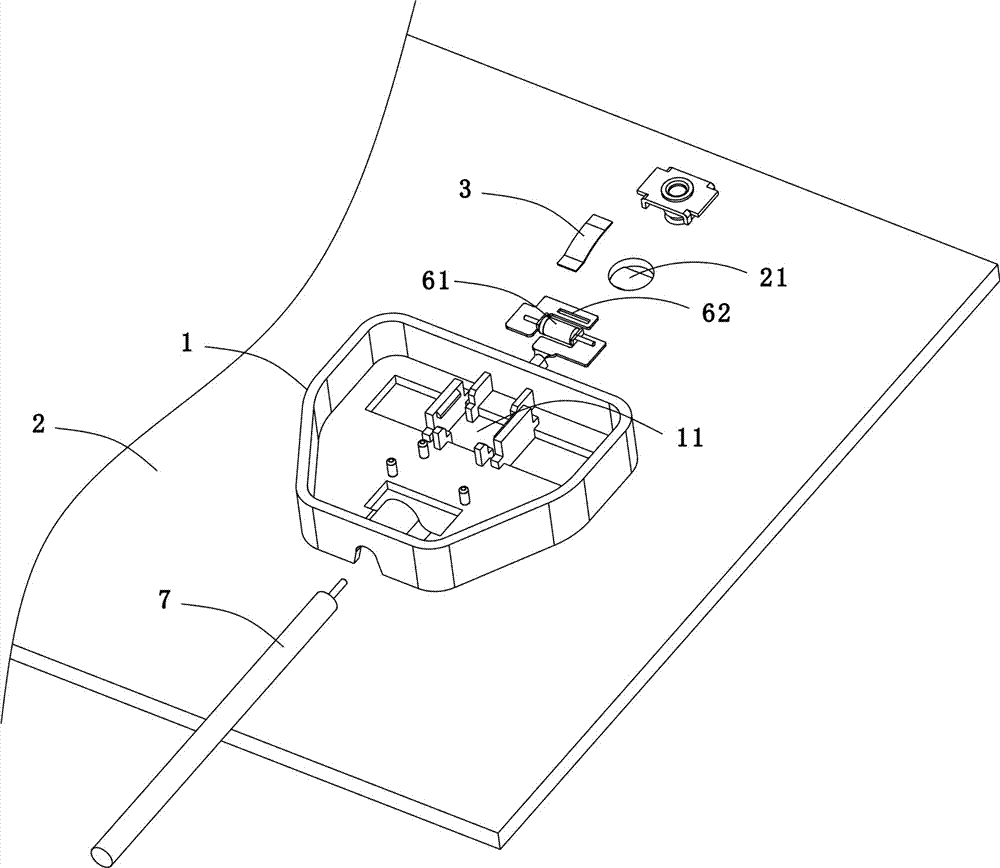

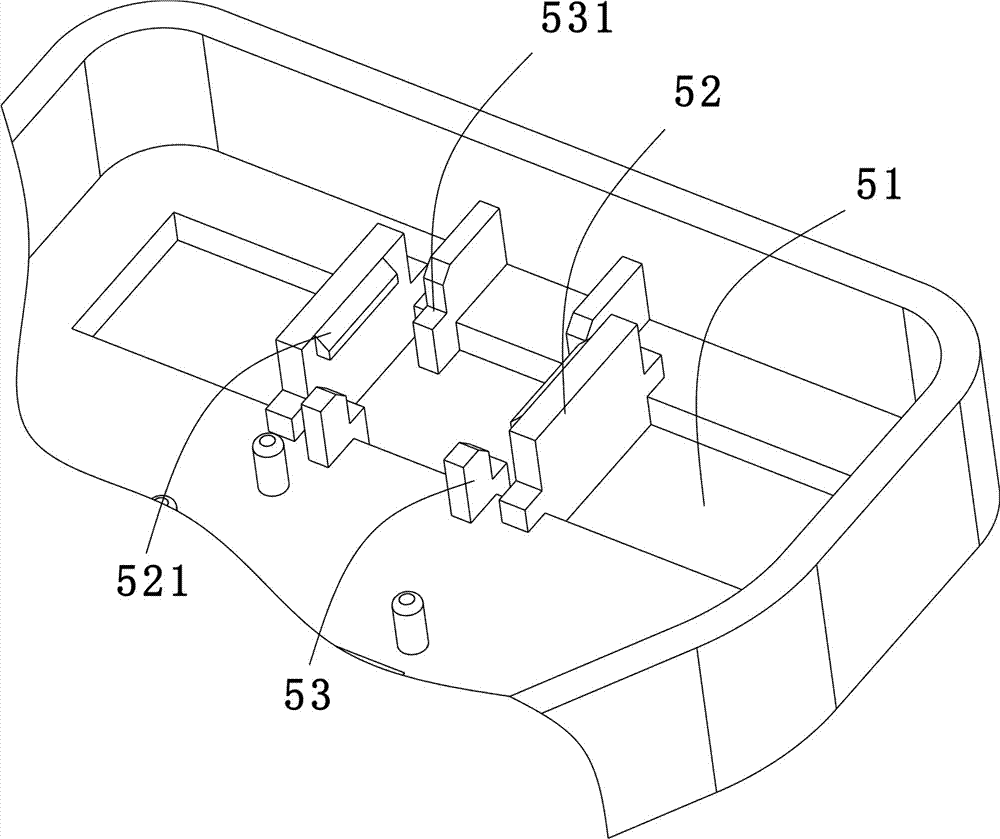

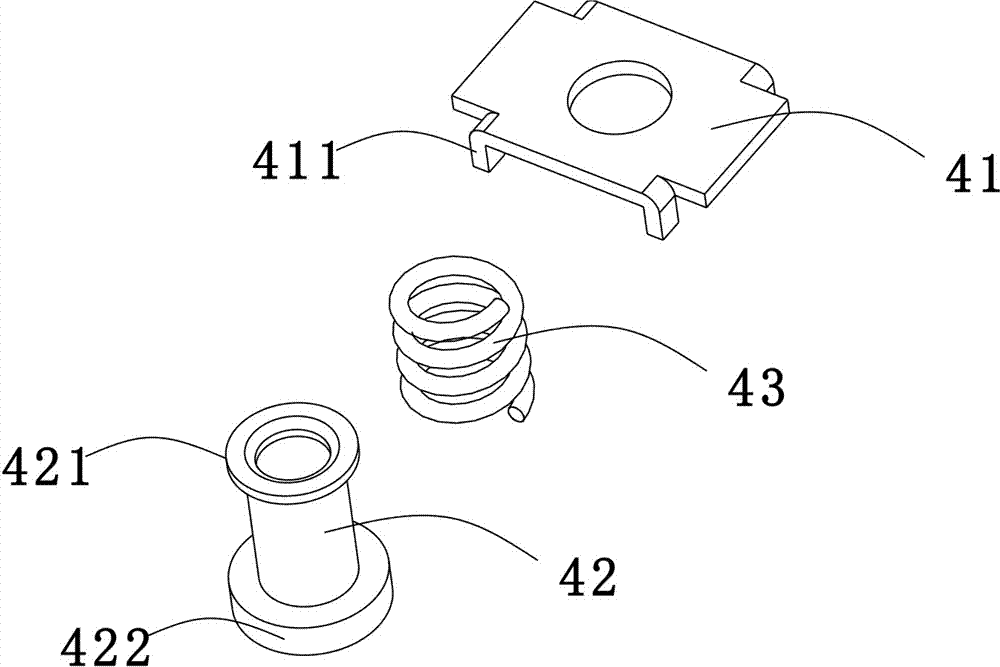

[0015] Such as Figure 1-3 As shown, a photovoltaic module junction box that is convenient for crimping bus bars includes a junction box body 1, a glass 2, a connecting cable 7 and an inner bus bar placed in the glass. The cable interface for cable insertion; the glass is provided with an opening 21, so that the inner bus bar in the glass can be exposed for the electrical connection of the junction box body 1; the bottom of the junction box body 1 is provided with a crimping groove 11, The crimping groove 11 is opposite to the opening; the junction box body 1 is provided with a diode assembly, a foreign exchange bar 3 and a crimping device, one end of the foreign exchange bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com