Tubular knitted fabric having opening portion in knitting terminal side and knitting method

A technology of knitted fabrics and openings, which is applied to the field of tubular knitted fabrics with openings on the knitting terminal side and its knitting field, which can solve the problems of increased manufacturing costs and high prices, and achieve reduced opening area, good quality style, and reduced The effect of the opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

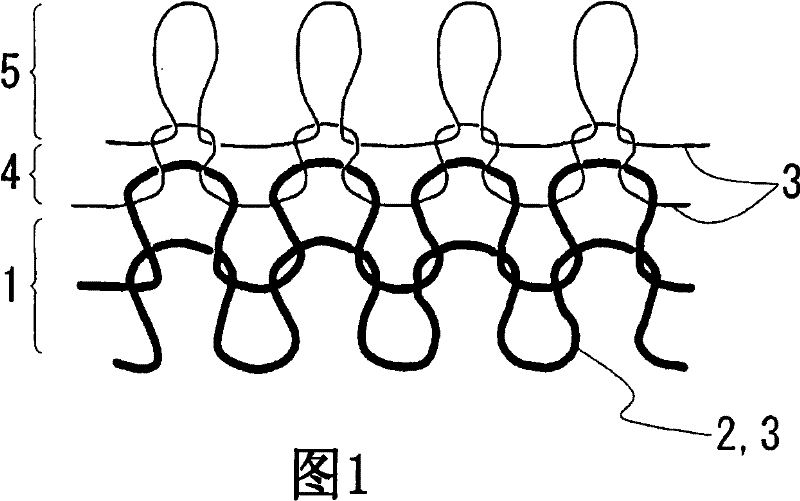

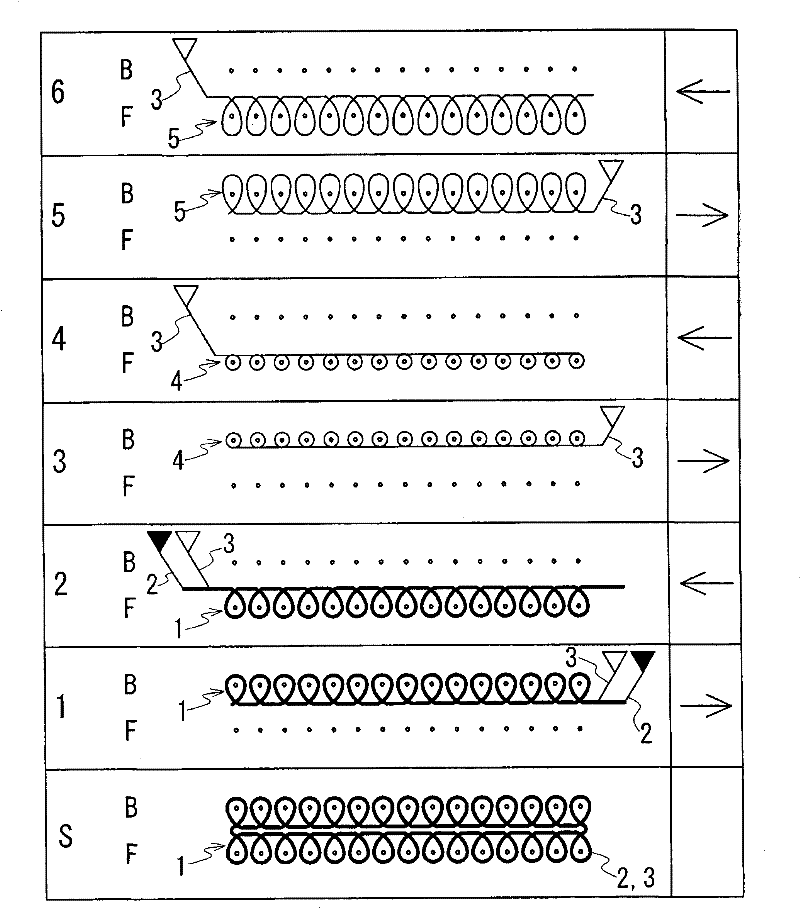

[0042] Fig. 1 is a plan view of a part of the opening end at the foot insertion opening of a sock. figure 2 A diagram showing a knitting process when knitting the opening end of the foot insertion opening of the sock according to the present embodiment.

[0043] In the loop diagrams and knitting process diagrams of the first embodiment and the second embodiment, the loops formed by plated knitting in which main yarns and plated yarns are overlapped are shown by thick lines, and the loops formed by plated yarns alone are shown by thin lines. formed coil.

[0044] exist figure 2 The weaving process diagram and the following Figure 4 with Figure 5 In the knitting process diagram, the numbers on the left indicate the steps of the knitting process, the F on the left indicates the front needle bed, B indicates the rear needle bed, and the arrow indicates the yarn feeding direction.

[0045] In the present embodiment, the knitted fabric main body 1 of the tubular knitted fabric...

no. 2 approach

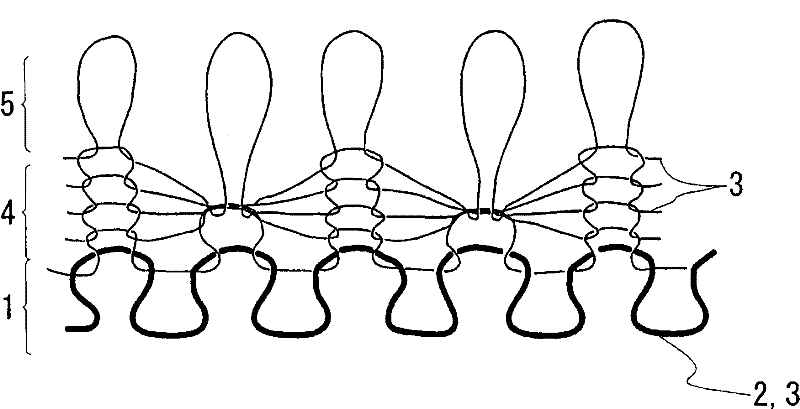

[0055] image 3 A planar loop diagram showing a part of the opening end at the foot insertion opening of the sock. Figure 4 with Figure 5 A diagram showing a knitting process when knitting the opening end of the foot insertion opening of the sock according to the present embodiment.

[0056] In the present embodiment as well, the knitted fabric main body 1 is knitted in a cylindrical shape by a plating knitting method using the main yarn 2 and the plating yarn 3 . At the opening end of the leg insertion opening formed on the knitting end side of the knitted fabric main body 1, there is formed a small loop knitted fabric portion 4 knitted using only the plating 3 following the courses knitted with the main yarn 2 and the plating 3 , and the final course portion 5 that is knitted next to the small loop knitted fabric portion 4 using only the plating 3 .

[0057] In the present embodiment, the bouclé knitted fabric portion 4 is formed by knitting four courses at a stitch den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com