Threading structure for urban electric power engineering construction

A power engineering and urban technology, applied in cable installation, cable laying equipment, electrical components, etc., can solve the problems of poor wire stability, inconvenient steering, inconvenient storage, etc., and achieve the effect of improving stability and anti-dropping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

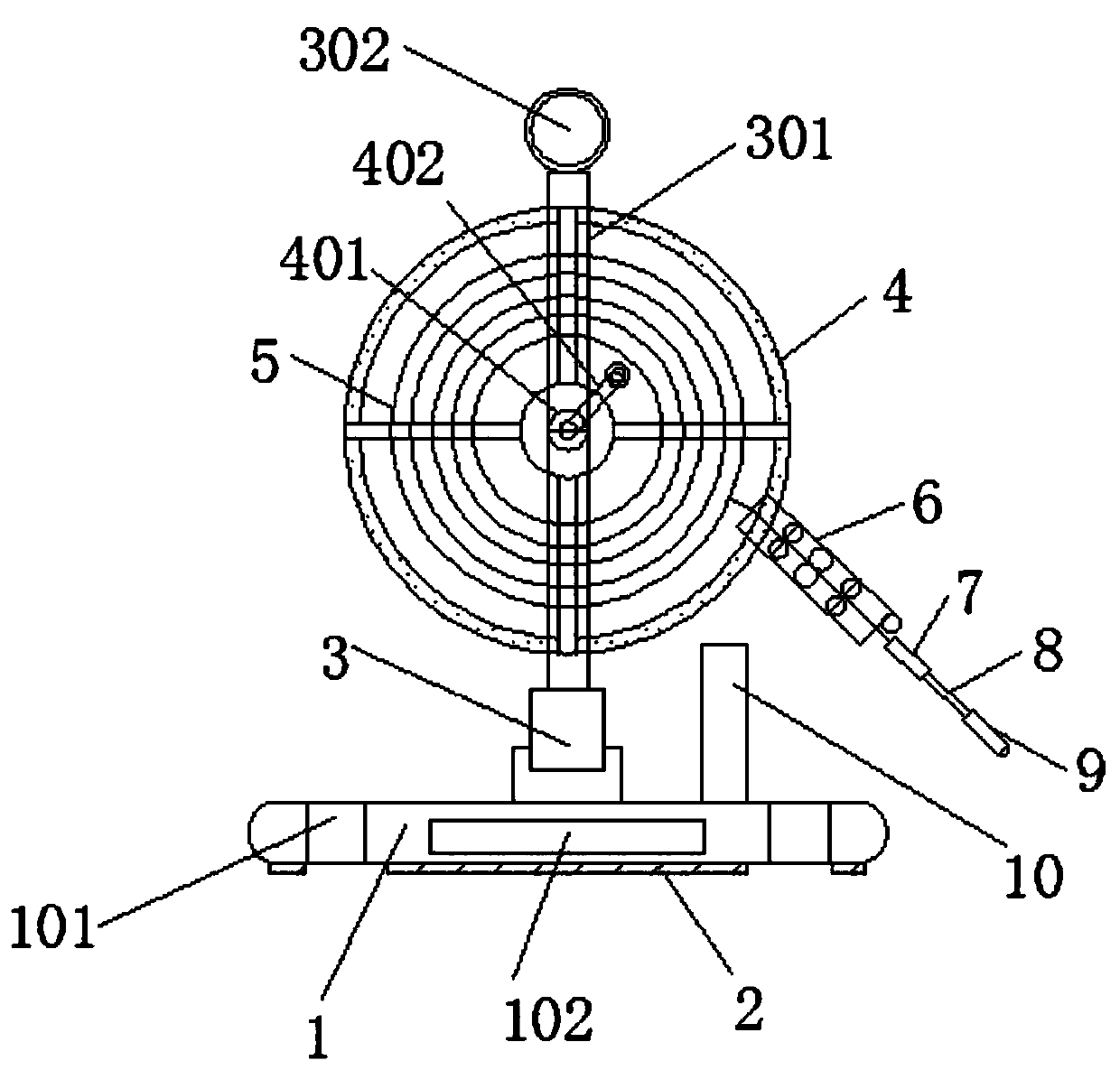

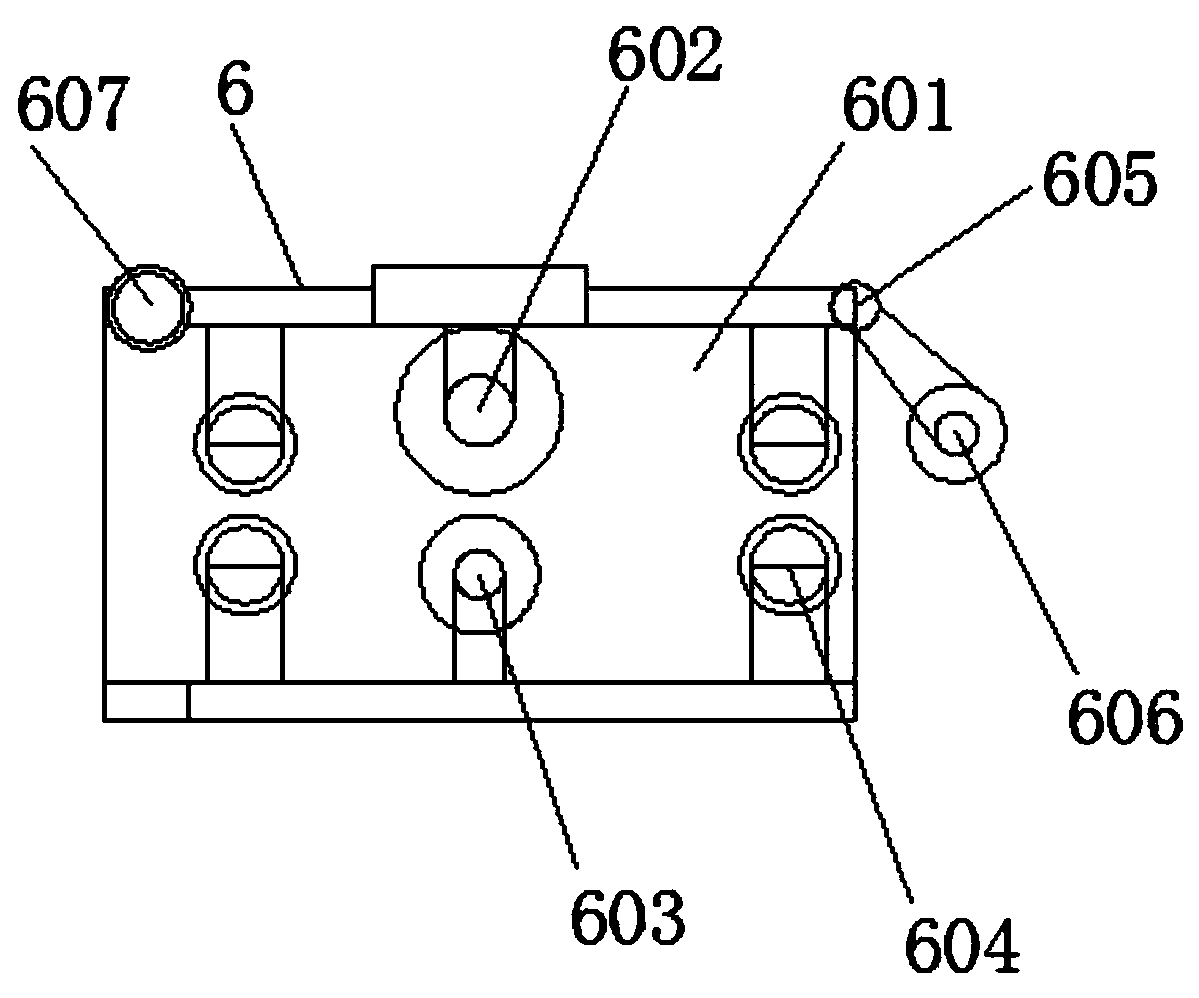

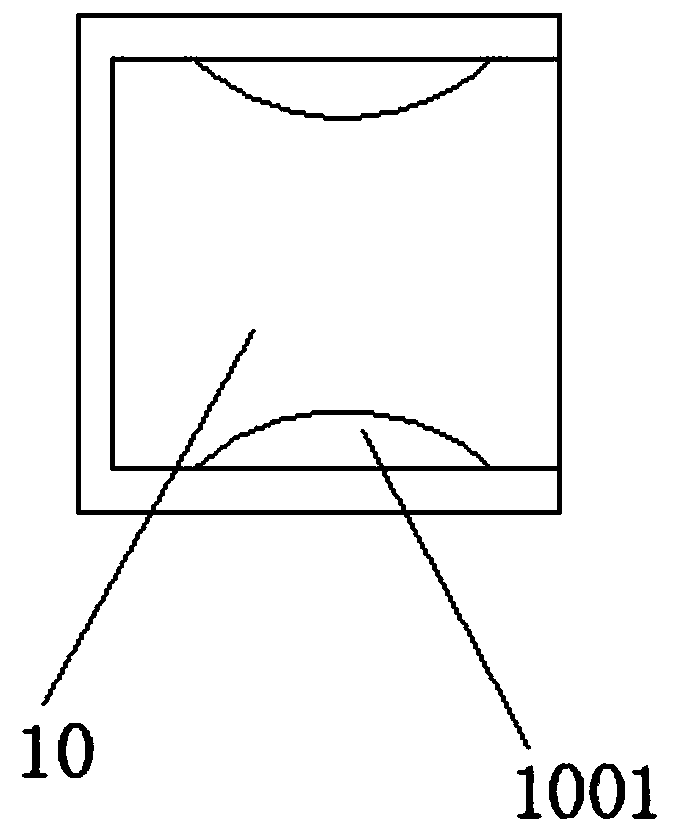

[0035] Such as Figure 1-7 As shown, the present invention provides a technical solution: a threading structure for urban electric power engineering construction, including a base 1, a supporting frame 301 is rotatably connected above the base 1, and a winding reel 4 is fixedly connected inside the supporting frame 301, A steel wire 5 is installed inside the winding reel 4 , one end of the steel wire 5 is fixedly connected to the guide head 9 through a traction head 7 and a spring 8 , and one side of the winding reel 4 is movably connected to the measuring device 6 through a locking wheel 11 .

[0036]The surface of the base 1 is symmetrically provided with threaded holes 101, the side wall of the base 1 is provided with a counterweight groove 102, the lower surface of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com