Antireflection coating plated on infrared glass and preparation method thereof

A technology of infrared glass and anti-reflection coating, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of high reflectivity and difficult adhesion of germanium selenium arsenic infrared glass, and achieve anti-shedding Good performance, good scratch resistance, high anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

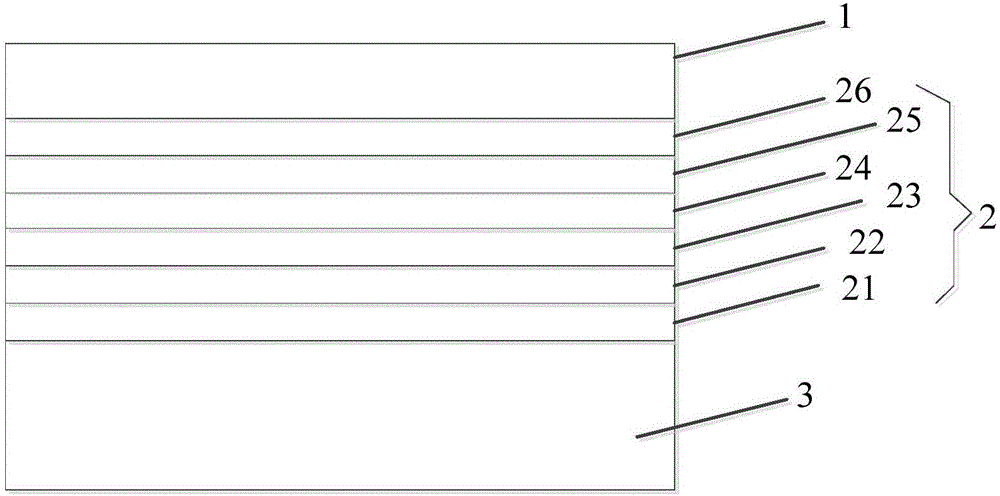

[0020] Such as figure 1 As shown, the present invention discloses an anti-reflection film coated on infrared glass, comprising a DLC film layer 1 and an adhesive layer 2, the DLC film layer 1 is bonded on the infrared glass substrate 3 through the adhesive layer 2, and the adhesive The bonding layer 2 includes a first ZnSe layer 21, a first Ge layer 22, a second ZnSe layer 23, a second Ge layer 24, a third ZnSe layer 25 and a third Ge layer 26 arranged alternately in sequence, and the first ZnSe layer 21 is located at Between the infrared glass substrate 3 and the first Ge layer 22 , the third Ge layer 26 is located between the third ZnSe layer 25 and the DLC film layer 1 .

[0021] The total thickness of the DLC film layer 1 and the adhesive layer 2 is between 8-12 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com