Method for preparing tungsten carbide coating on surface of roller for lithium battery production

A technology of tungsten carbide coating and roll surface, which is applied in the direction of coating, roll, metal rolling, etc., can solve problems such as high precision requirements for replacement and grinding, complicated grinding for roll change, and degradation of roll surface quality, and achieve the goal of coating The effect of high layer densification, increased coating adhesion, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing a tungsten carbide coating on the surface of a roll for lithium battery production, comprising the following steps:

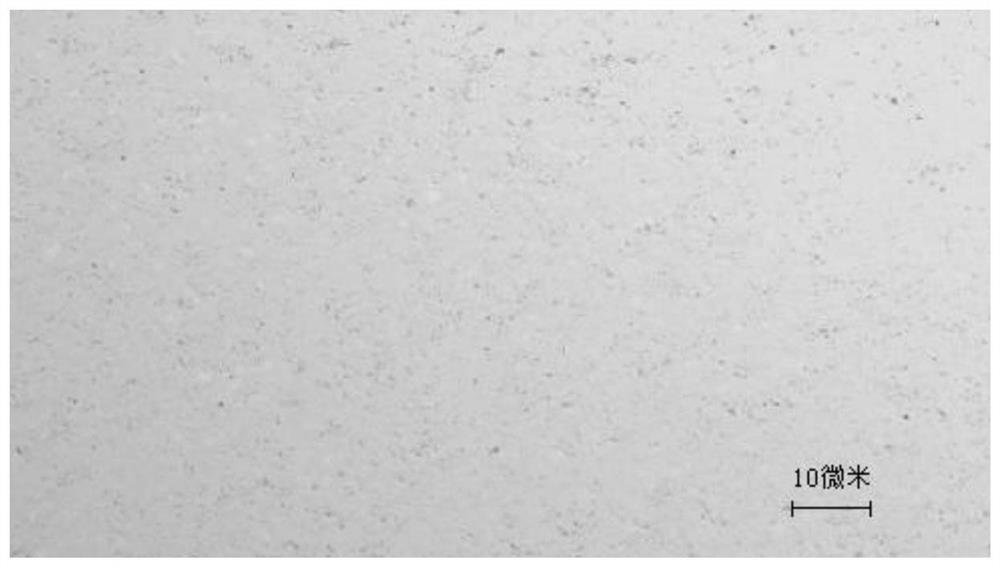

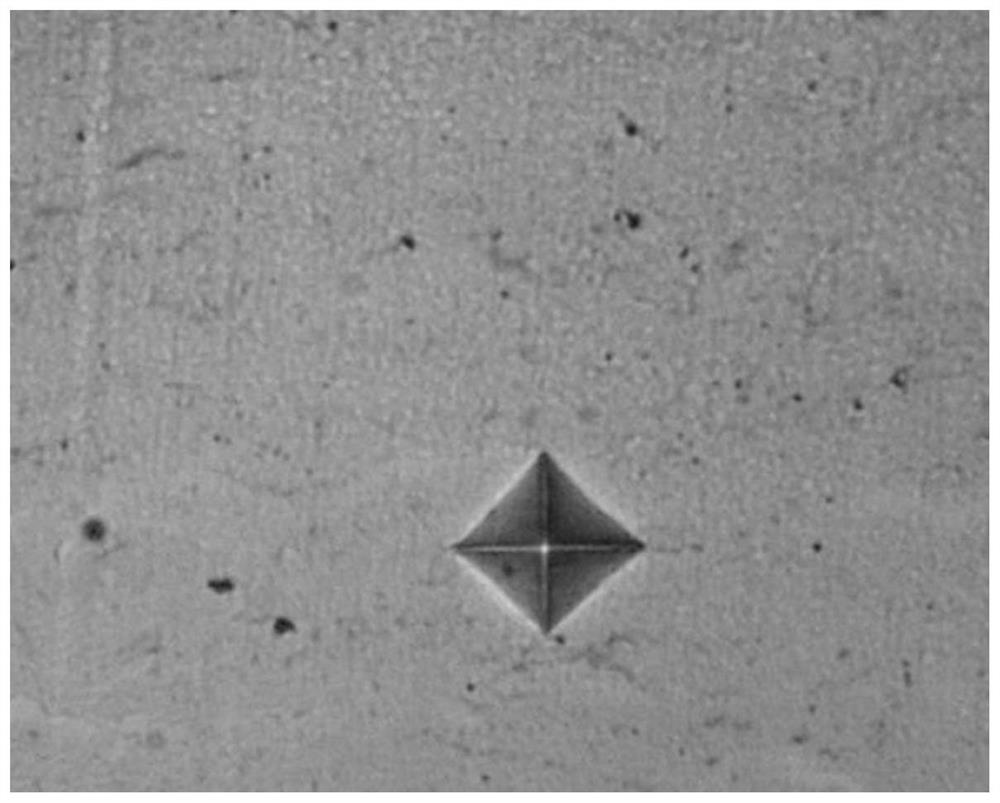

[0061] (1) Carry out visual inspection and magnifying glass inspection on the surface of the roll for lithium battery production to ensure that there are no scratches, holes or inclusions on the surface of the roll;

[0062] (2) Use acetone, gasoline or alcohol to thoroughly scrub the surface of the roll 3 times to remove oil and impurities, and then use a rough polisher to roughen the surface of the roll;

[0063] (3) adopt high temperature resistant adhesive tape and frock to carry out protective treatment to the non-spraying surface of roll two ends after rough grinding, obtain the roll to be sprayed;

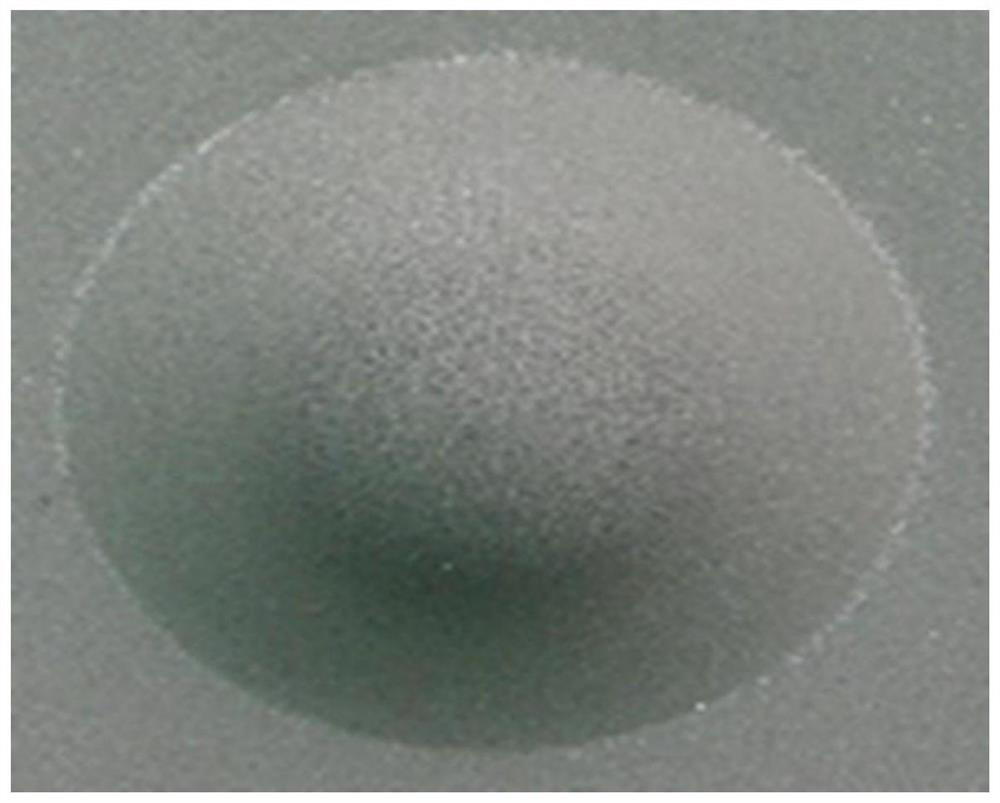

[0064] (4) Liquid-phase propane is used as the main combustion gas, compressed air is used as the combustion-supporting gas, and nitrogen is used as the carrier gas and powder-feeding gas. Each gas is input into the combustion ch...

Embodiment 2

[0071] A method for preparing a tungsten carbide coating on the surface of a roll for lithium battery production, comprising the following steps:

[0072] (1) Carry out visual inspection and magnifying glass inspection on the surface of the roll for lithium battery production to ensure that there are no scratches, holes or inclusions on the surface of the roll;

[0073] (2) Use acetone, gasoline or alcohol to thoroughly scrub the surface of the roll 3 times to remove oil and impurities, and then use a rough polisher to roughen the surface of the roll;

[0074] (3) adopt high temperature resistant adhesive tape and frock to carry out protective treatment to the non-spraying surface of roll two ends after rough grinding, obtain the roll to be sprayed;

[0075] (4) Liquid-phase propane is used as the main combustion gas, compressed air is used as the combustion-supporting gas, and nitrogen is used as the carrier gas and powder-feeding gas. Each gas is input into the combustion ch...

Embodiment 3

[0082] A method for preparing a tungsten carbide coating on the surface of a roll for lithium battery production, comprising the following steps:

[0083] (1) Carry out visual inspection and magnifying glass inspection on the surface of the roll for lithium battery production to ensure that there are no scratches, holes or inclusions on the surface of the roll;

[0084] (2) Use acetone, gasoline or alcohol to thoroughly scrub the surface of the roll 4 times to remove oil and impurities, and then use a rough polisher to roughen the surface of the roll;

[0085] (3) adopt high temperature resistant adhesive tape and frock to carry out protective treatment to the non-spraying surface of roll two ends after rough grinding, obtain the roll to be sprayed;

[0086] (4) Liquid-phase propane is used as the main combustion gas, compressed air is used as the combustion-supporting gas, and nitrogen is used as the carrier gas and powder-feeding gas. Each gas is input into the combustion ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com