Bathroom chassis and manufacturing method thereof

A chassis and bathroom technology, applied in bathtubs, showers, sanitary equipment, etc., can solve the problems of insufficient resin curing, burrs, rough reinforcement layers, etc. The effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

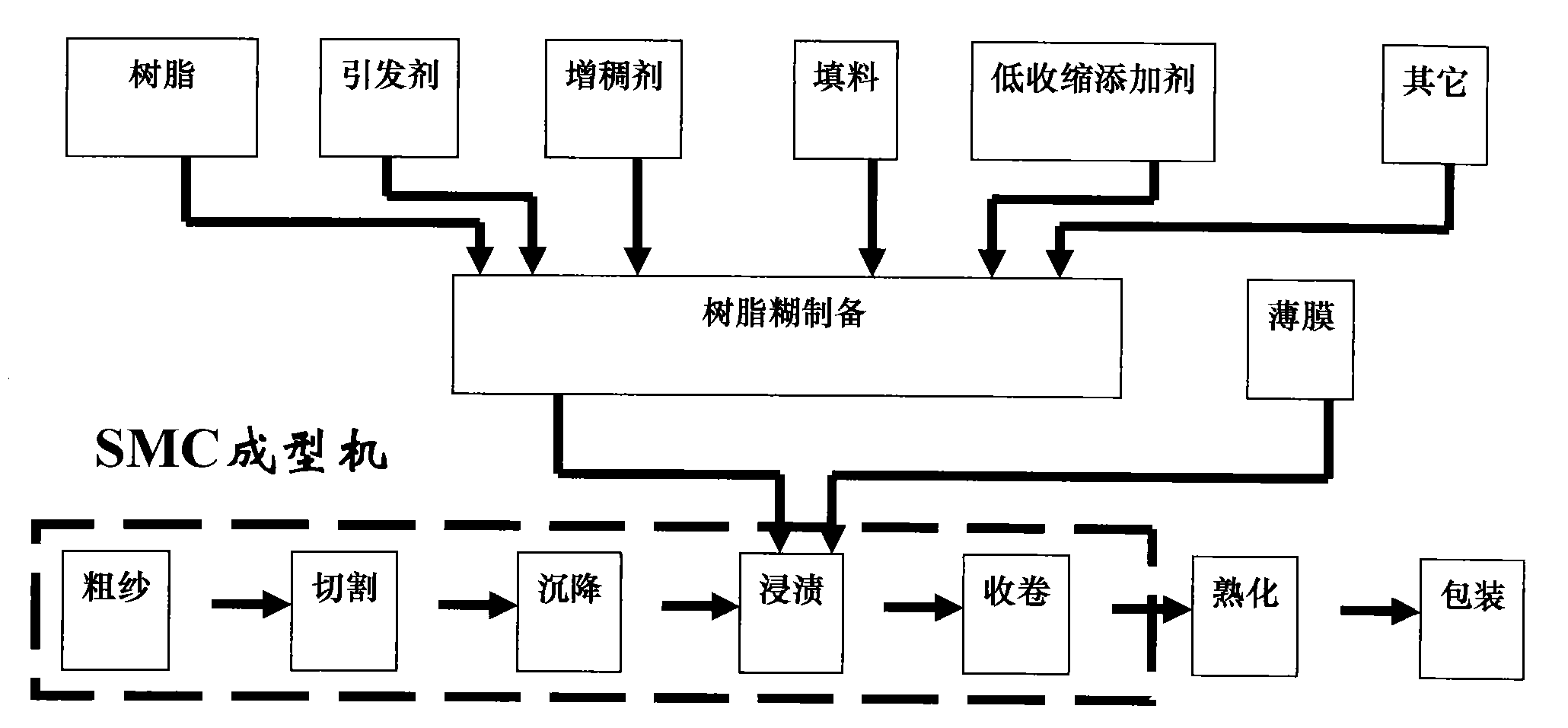

[0031] The bathroom chassis of the present invention is made of SMC material. SMC is the abbreviation of three English words for sheet molding compounds, translated as sheet molding compound, which is composed of unsaturated polyester resin, glass fiber, filler, curing agent, thickener, crosslinking agent, colorant, mold release It is composed of more than ten kinds of materials such as agent, and is made into a sandwich-like sheet on the SMC unit. After aging, it is placed on the mold, and it is molded with an SMC press at high temperature and high pressure.

[0032] Compared with the traditional acrylic and cast bathroom chassis, the SMC bathroom chassis has uniform internal quality, no pores, less volatilization of volatile organic compounds, accurate size, high surface quality, smooth back, light weight and high strength, not easy to crack, durable use Etc.

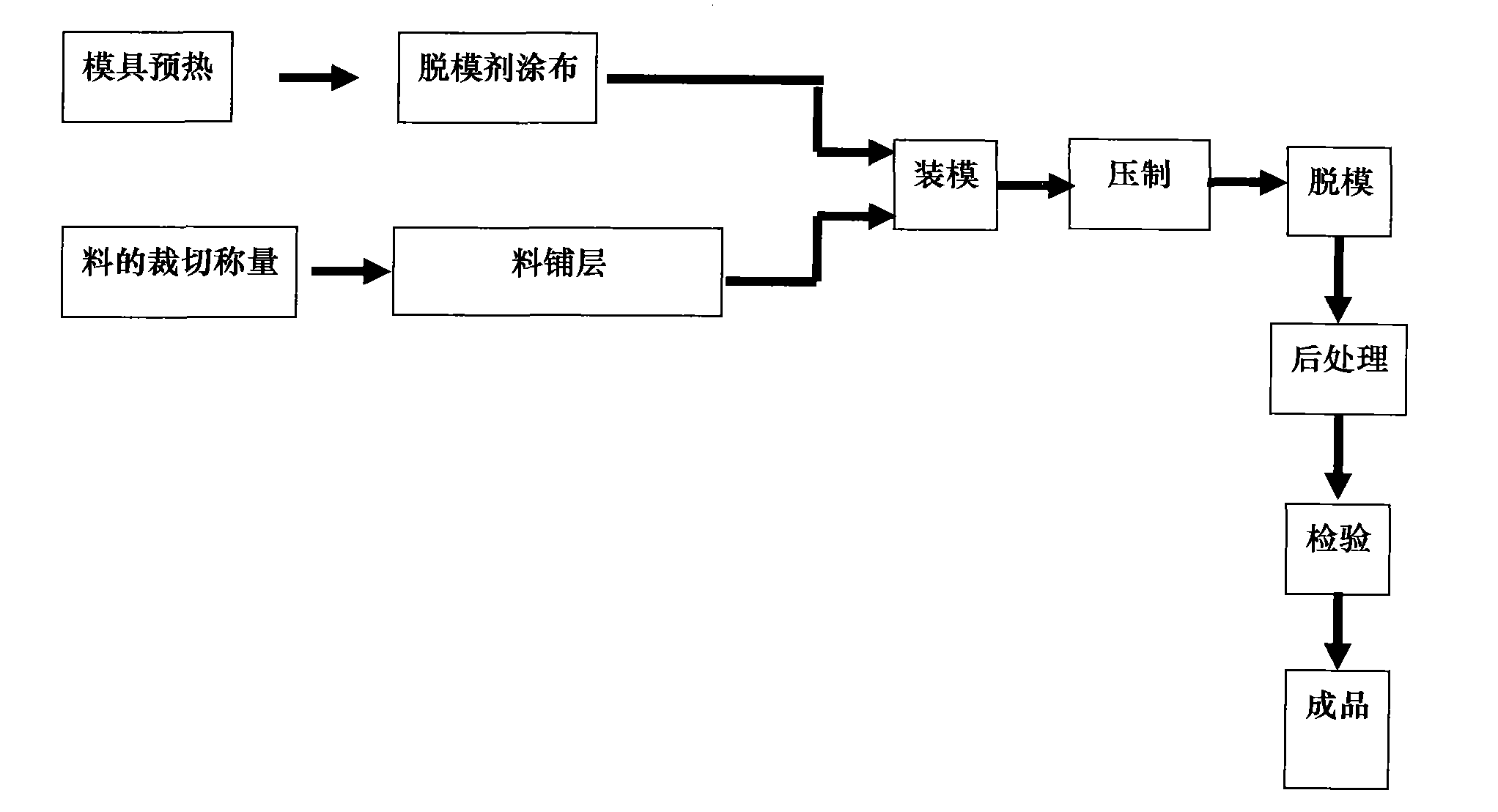

[0033] The production of SMC bathroom chassis includes two steps: first, the production of SMC sheet; second, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com