LED point light source lamp

A technology of LED lamp beads and point light source, applied in the direction of point light source, light source, electric light source, etc., can solve the problems of cumbersome adjustment, troublesome installation, increase installation and maintenance costs, etc., to meet the needs of decoration, convenient and free adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

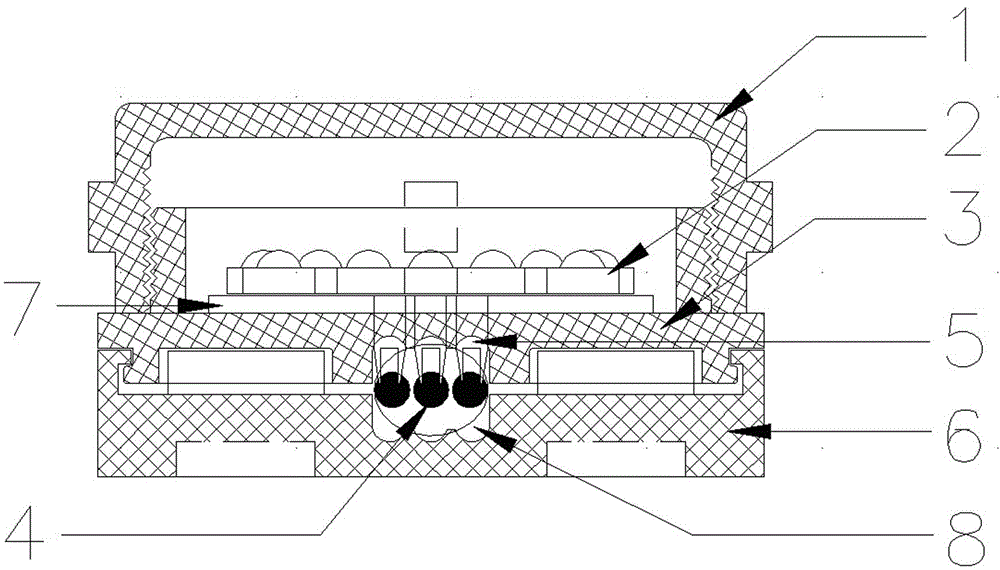

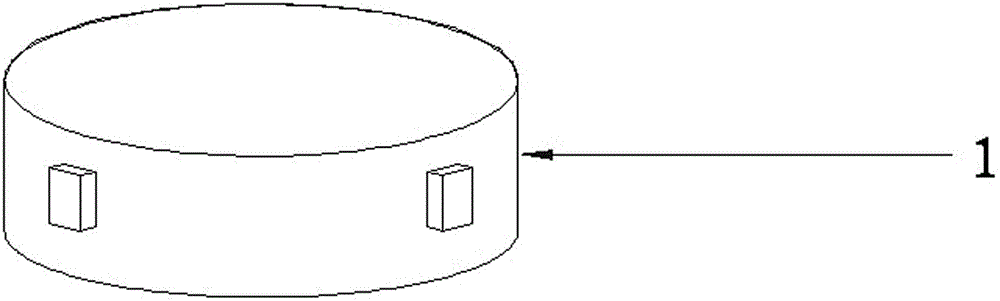

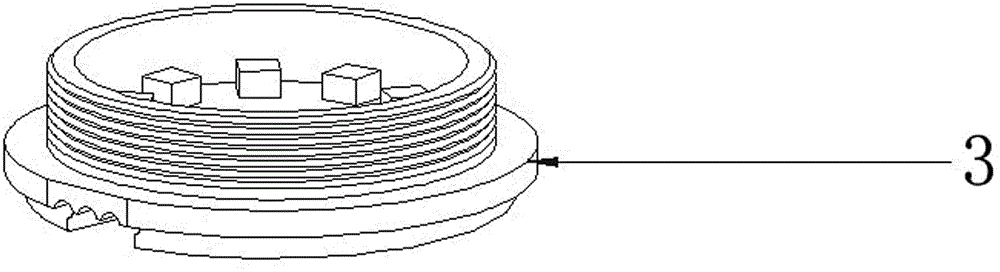

[0022] See Figure 1 to Figure 4 , the present invention includes lampshade 1, LED lamp bead 2, lamp body 3, wire 4, electrode 5, base 6, light source board 7, wire slot 8 and internal driving circuit. The LED lamp bead 2 is electrically connected to the light source board 7, and the bottom of the light source board 7 is electrically connected to an electrode 5, and the electrode 5 is embedded in the lamp body 3, and the light source board 7 will be fixed on the lamp body 3 at the same time, and the electrode 5 is embedded After the lamp body 3, the electrode 5 enters the wire slot 8; the wire 4 is placed in the wire slot of the base 6; the lampshade 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com