Wall decorative panel assembly

A technology for wall decoration and decorative panels, which is applied to the parts, lighting devices, lighting devices and other directions of lighting devices, can solve the problem of lack of decorative panels that can hide the outer corner lines, etc., to improve the appearance and comfort, and the installation method is simple. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

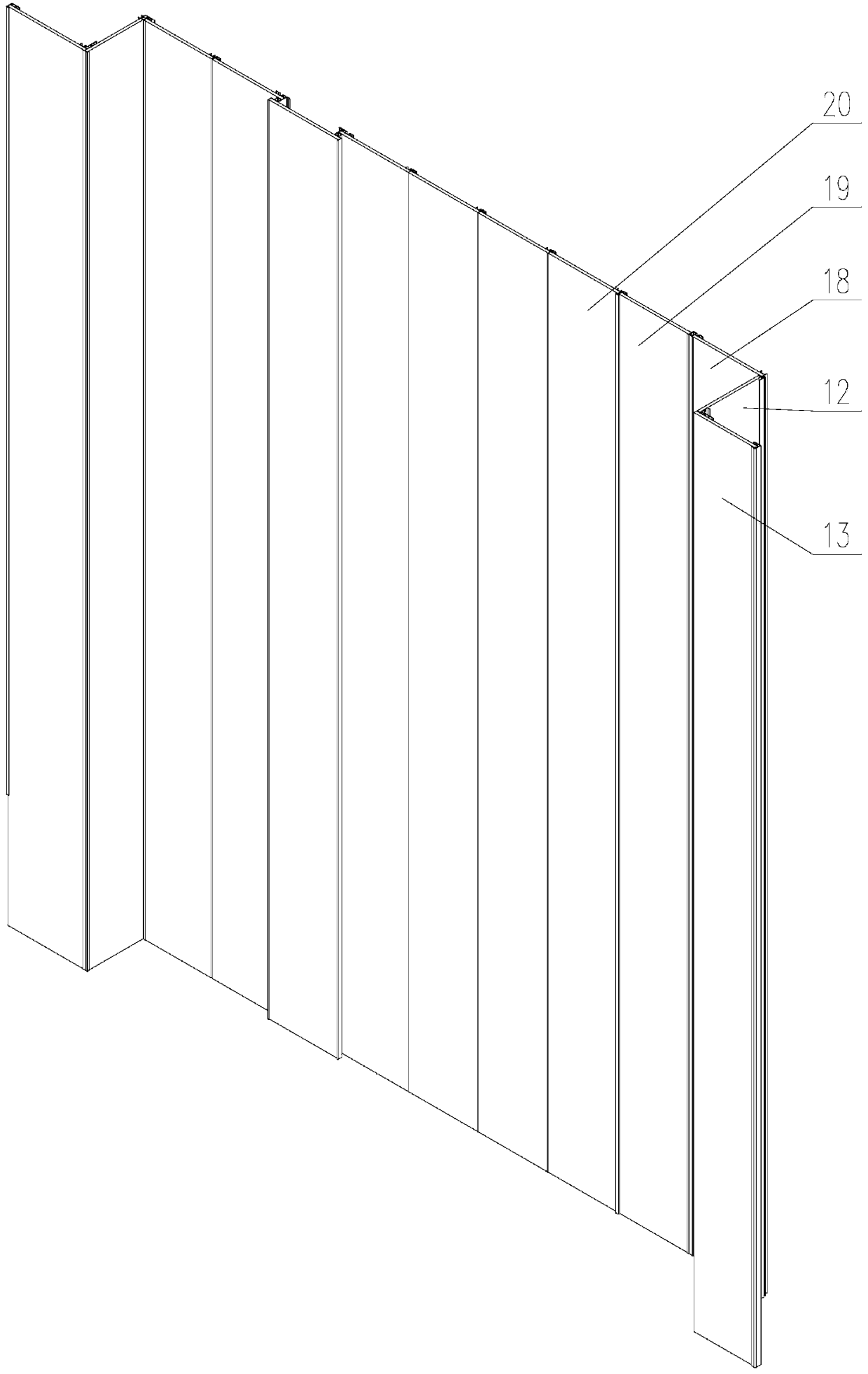

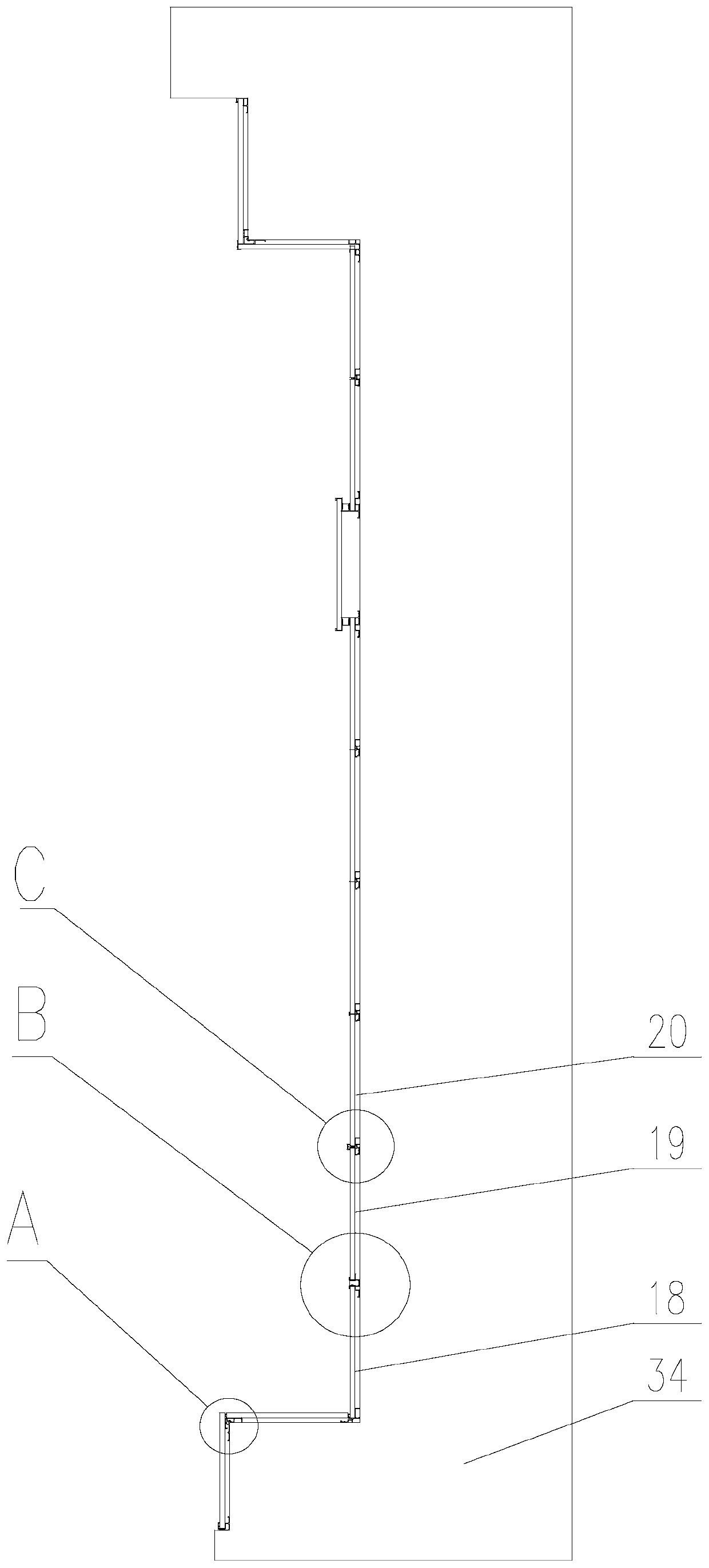

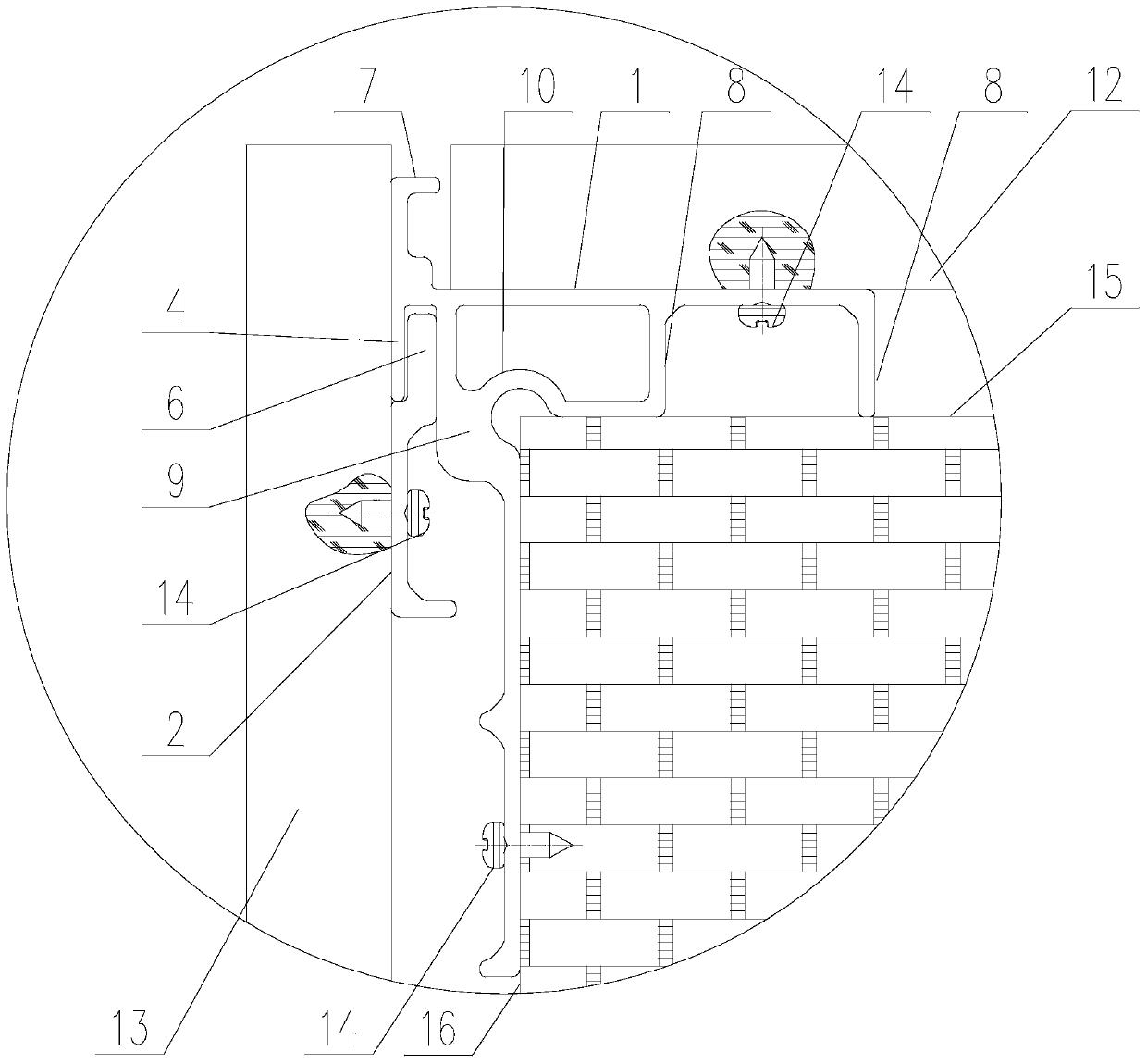

[0041] Such as Figure 1 to Figure 8 As shown, a wall decorative panel assembly of the present invention includes two decorative panels installed at the external corner of the wall, and the two walls at the external corner of the wall are respectively the external corner surface A15 and the external corner surface B16, and The corresponding two decorative panels are the external corner decorative panel A12 and the external corner decorative panel B13 respectively, the external corner decorative panel A12 is connected with the external corner decorative panel B13 through the external corner line assembly, and the external corner line assembly includes a connecting strip Plate A1 and the connecting strip B2 and the fixed strip 3 located on the same side of the connecting strip A1, the long sides of the connecting strip A1, the connecting strip B2 and the fixed strip 3 are parallel to each other, and the connecting strip B2 and the board faces of the fixed strips 3 are all perpen...

Embodiment 2

[0049] This embodiment is based on the embodiment 1, and describes the implementation of the plug-in structure.

[0050] Such as Figure 3 ~ Figure 6 As shown, in the present invention, a clamping strip 4 is provided on the end of the connecting strip A1 close to the male corner decorative panel B13, and one side of the clamping strip 4 is connected to the end of the connecting strip A1 , the other side of which is in contact with the back of the male corner decorative board B13, and the long side line of the clamping strip 4 is parallel to the long side line of the connecting strip A1, forming a gap between the clamping strip 4 and the fixed strip 3 For the female port 5 to be plugged in, the end of the connecting strip B2 close to the connecting strip A1 protrudes to form a male plug 6 for plugging in, and the male plug 6 is inserted into the female port 5 .

Embodiment 3

[0052] This embodiment is based on the above-mentioned embodiments, and describes the structure of the present invention when matching requires external corner lines for decoration.

[0053] Such as Figure 3 ~ Figure 6 As shown, in the present invention, a first decorative strip 7 is provided on the surface of the connecting strip A1 opposite to the fixed strip 3 and on the left side, and the axis of the first decorative strip 7 Parallel to the long edge of the connecting strip A1.

[0054] The shape of the cross section of the decorative strip 7 is not limited. For example, the cross-section of the decorative strip 7 is L-shaped, one side of which is connected to the connecting strip A1, and the leftmost part of the decorative strip 7 is coplanar with the left side of the connecting strip B2, that is, in contact with the back side of the decorative panel B, The side of the decorative strip 7 away from the connecting strip A1 is a decorative end, which is used to be exposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com