Wall decorative material with Chinese art paper texture and application

A decorative material and texture technology, applied in coating, construction, building structure, etc., can solve problems such as easy cracking of wallpaper joints, poor environmental protection, diatom mud not resistant to scrubbing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: leveling substrate + primer + latex paint + special fiber mesh + surface coating material

[0066] (1) The base material is leveled with leveling putty or mortar, and ground to a smooth surface.

[0067] (2) Apply primer to strengthen the base material and improve the bonding force between the special fiber mesh felt and the base material.

[0068] (3) Apply latex paint, lay a special fiber mesh felt, and flatten it with a plastic scraper.

[0069] (4) Apply one layer of surface coating material, and after the surface is dry, apply a second layer of surface coating material to form a fiber decorative wall material with clear lines.

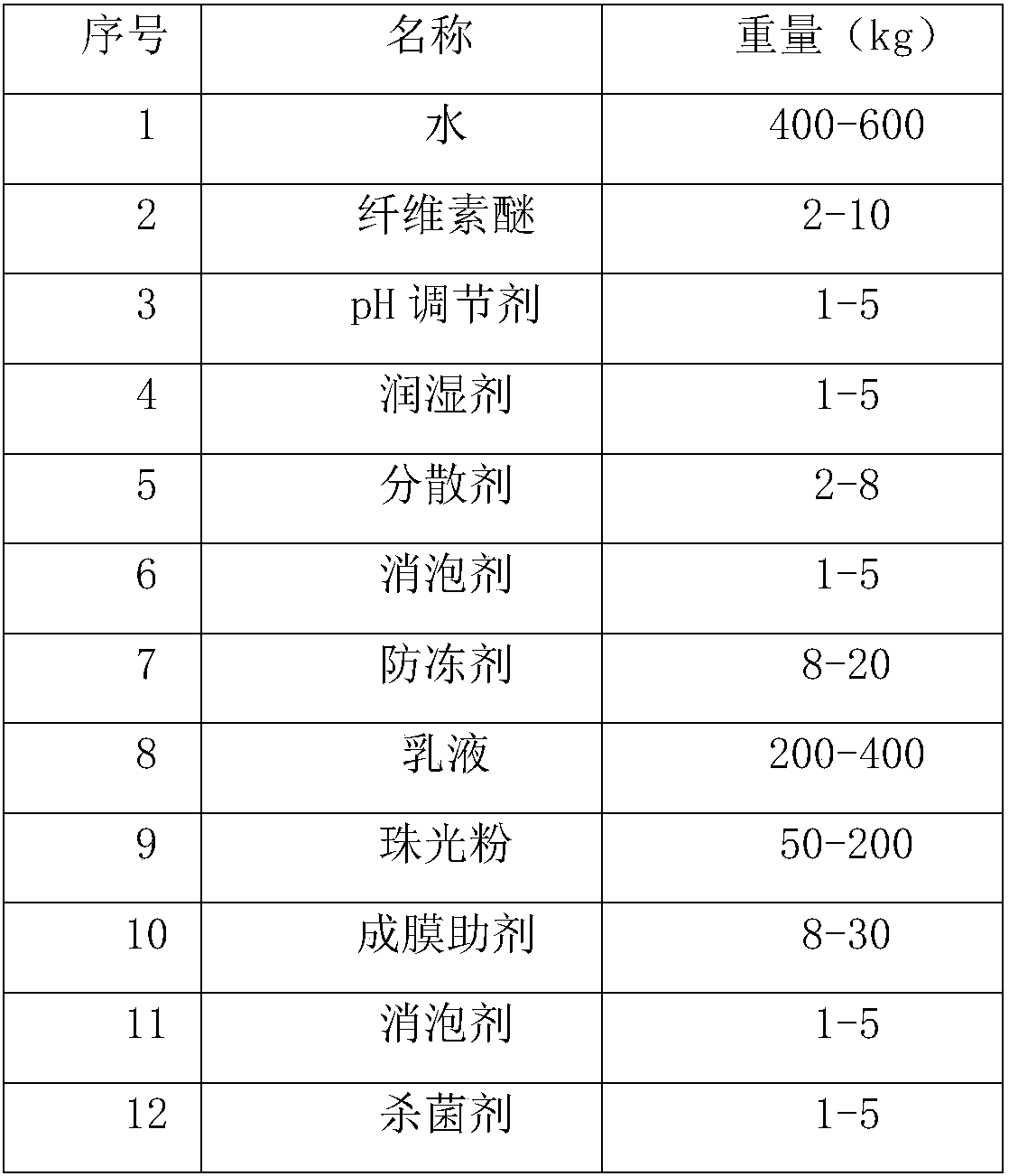

[0070] Components and parts by mass of the surface coating material:

[0071]

[0072]

[0073] The method of surface coating material, add water to the reaction vessel, start the mixer, adjust the speed to 600-800 rpm, add cellulose ether, disperse for 5 minutes; add pH regulator, wetting agent, dispersant, defoamer AMP -...

Embodiment 2

[0075] Example 2: leveling substrate + primer + latex paint + special fiber mesh + surface coating material

[0076] (1) The base material is leveled with leveling putty or mortar, and ground to a smooth surface.

[0077] (2) Apply primer to strengthen the base material and improve the bonding force between the special fiber mesh felt and the base material.

[0078] (3) Apply latex paint, lay a special fiber mesh felt, and flatten it with a plastic scraper.

[0079] (4) Brush the first layer of surface coating material, and when the surface layer is dry, use a plastic scraper to flatten it horizontally and then vertically.

[0080] (5) Apply the second layer of surface coating material. After the surface layer is dry, use a plastic scraper to flatten it horizontally and then vertically to form a high-grade luxury decorative wall material with distinct layers and strong texture.

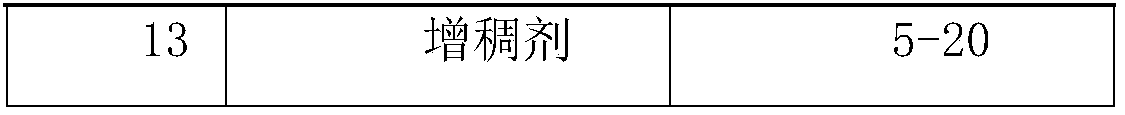

[0081] The components and parts by mass of the surface coating material are:

[0082]

[008...

Embodiment 3

[0086] Embodiment 3: embodiment 1 or embodiment 2+water-based pearlescent paint embellishment

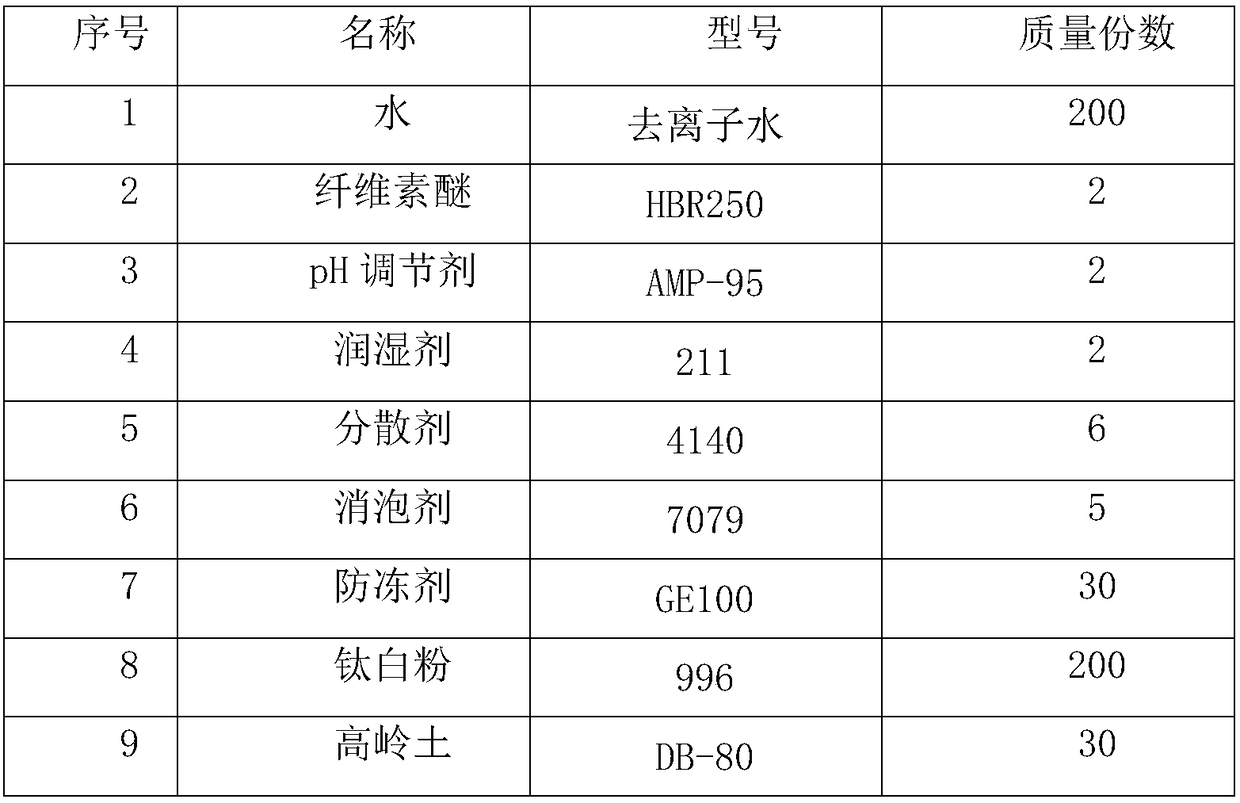

[0087] Components and parts by mass of water-based pearlescent paint:

[0088]

[0089]

[0090] On the basis of Example 1 or Example 2, use natural seaweed sponge to slap water-based pearlescent paint to embellish to form a decorative wall material with illusion effect.

[0091] Add water, start the mixer, adjust the speed to 600-800 rpm, add cellulose ether, and disperse for 5 minutes; add pH regulator, wetting agent, dispersant, 4 parts of defoamer 7079, antifreeze, and disperse for 15 minutes , add emulsion, disperse for 5 minutes; add pearl powder, disperse for 15 minutes, add film-forming aid, defoamer, bactericide and disperse for 5 minutes; add thickener, stir for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com