Lightweight, high strength, inexpensive and heat insulated rowlock wall masonry method

A hollow wall, high-strength technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of unsuitable expansion bolts, inconvenient construction, time-consuming and laborious, etc., to improve self-insulation effect, convenient masonry, and ensure smoothness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

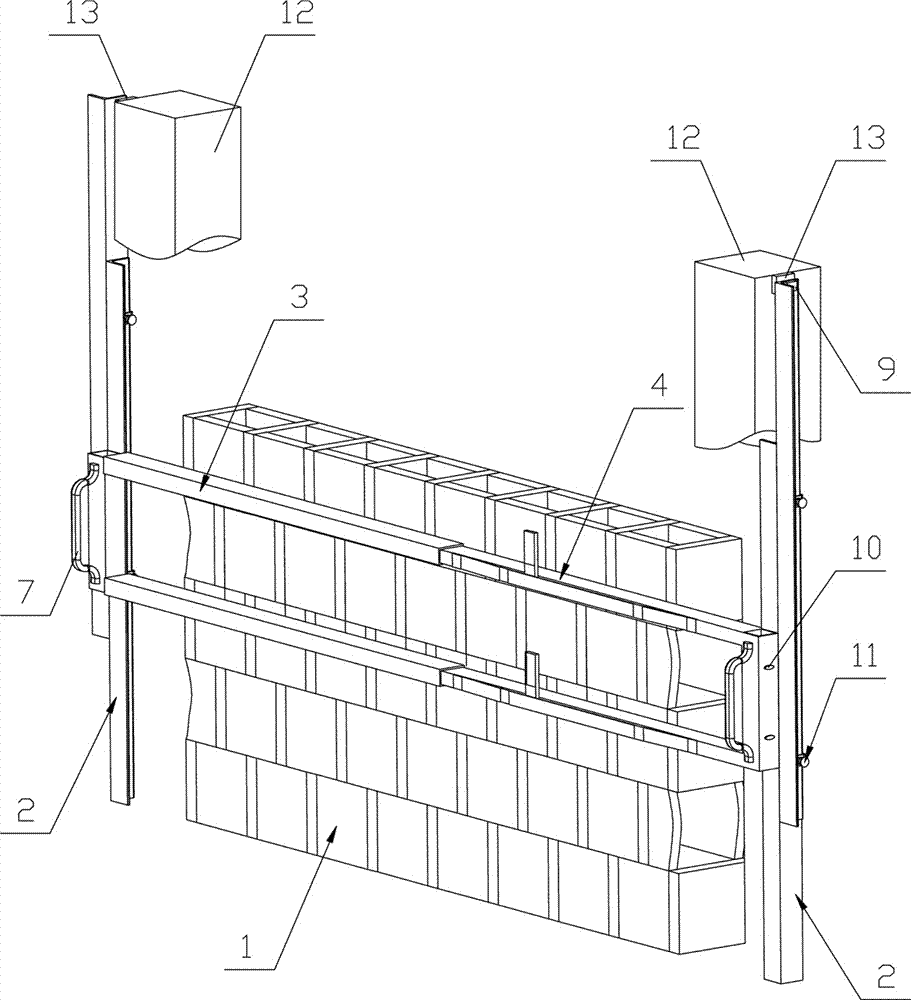

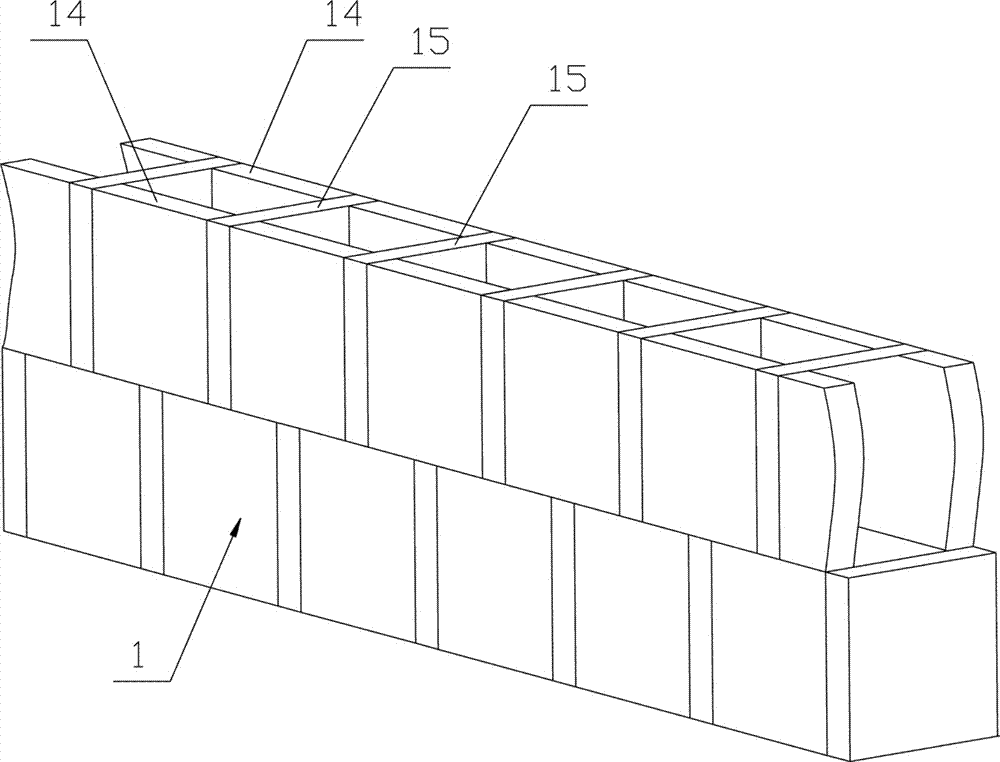

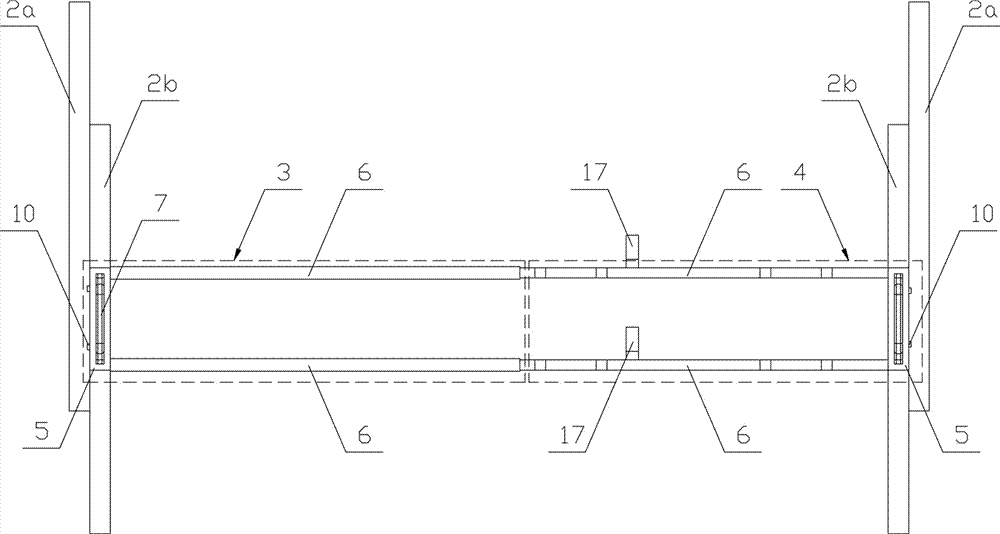

[0028] See Figure 1-5 , A light-weight, high-strength, low-cost, heat-insulating empty bucket wall masonry method, including the following masonry steps:

[0029] (1) Equipped with several autoclaved aerated bricks of the same specification;

[0030] (2) According to the direction of the empty bucket wall 1 to be built, the profiling mechanism is constructed; the profiling mechanism is composed of two iron pillars 2 on the left and right, and the left profiling 3 and the right profiling 4; the post 2 is telescopic The column is composed of an upper angle steel 2a and a lower angle steel 2b, and the two angle steels are fastened and connected by a fixing card 11; the left profile 3 and the right profile 4 are each composed of a longitudinally arranged positioning edge 5 and two horizontally arranged supports The mold side 6 constitutes a semi-closed rectangular frame structure, and a handrail 7 is provided on the positioning side 5; a magnetic seat A8 with a switch knob 10 is inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com