Functionally-gradient diamond-like carbon film and preparing method and product of functionally-gradient diamond-like carbon film

A functional gradient, diamond technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the decorative needs such as affecting the surface quality of DLC film decorative layer, high process cost, ignoring high surface finish and color And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

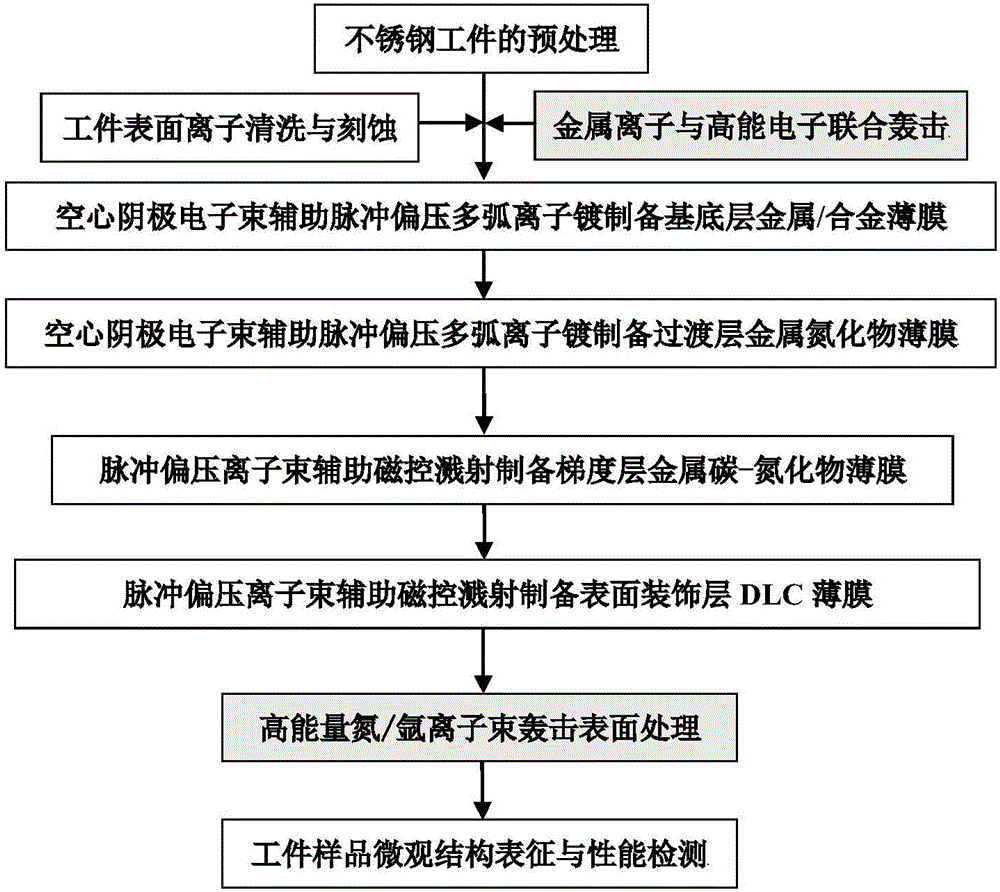

[0117] A method for preparing a functionally graded diamond-like carbon film in this embodiment, the flow chart is shown in figure 1 , including the following steps:

[0118] 1) Pretreatment of stainless steel workpieces: at room temperature, place polished stainless steel watch appearance workpieces in an ultrasonic cleaner filled with an environmentally friendly water-based metal cleaning solution for surface cleaning and degreasing (according to conventional methods); into ethanol solution and dried after dehydration.

[0119] 2) Ion cleaning and etching on the surface of the workpiece: (1) Place the polished stainless steel watch appearance workpiece in the reaction furnace and keep the vacuum degree in the reaction furnace at 5.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 70A after the Ta-HCD electron gun arcs, and the plasma arc of the Ta-HCD source directly irradiates the surface of the workpiece until t...

Embodiment 2

[0132] A method for preparing a functionally graded diamond-like carbon film in this embodiment comprises the following steps:

[0133] 1) Pretreatment of stainless steel workpieces: at room temperature, place polished stainless steel watch appearance parts in an ultrasonic cleaner filled with an environmentally friendly water-based metal cleaning solution for surface cleaning and degreasing; then put the cleaned workpieces into ethanol solution for dehydration After drying.

[0134] 2) Ion cleaning and etching on the surface of the workpiece: (1) Place the polished stainless steel watch appearance workpiece in the reaction furnace and keep the vacuum degree in the reaction furnace at 2.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 120A after the Ta-HCD electron gun arcs, and the plasma arc of the Ta-HCD source directly irradiates the surface of the workpiece until the temperature in the vacuum chamber reaches 20...

Embodiment 3

[0147] A method for preparing a functionally graded diamond-like carbon film in this embodiment comprises the following steps:

[0148] 1) Pretreatment of stainless steel workpieces: at room temperature, place polished stainless steel watch appearance parts in an ultrasonic cleaner filled with an environmentally friendly water-based metal cleaning solution for surface cleaning and degreasing; then put the cleaned workpieces into ethanol solution for dehydration After drying.

[0149] 2) Ion cleaning and etching on the surface of the workpiece: (1) Place the polished stainless steel watch appearance workpiece in the reaction furnace and keep the vacuum degree in the reaction furnace at 2.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 150A after the Ta-HCD electron gun arcs, and the Ta-HCD source plasma arc directly irradiates the surface of the workpiece until the temperature in the vacuum chamber reaches 120 ° C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com