Glazed tile with anti-slip and anti-slip effects and preparation method of glazed tile

A glazed tile and anti-slip technology, applied in the field of glazed tile and its preparation, can solve the problems of dark tone, poor hand touch, lack of vividness, etc., and achieve the effect of delicate and soft glaze, hygienic and clean, convenient and clear texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

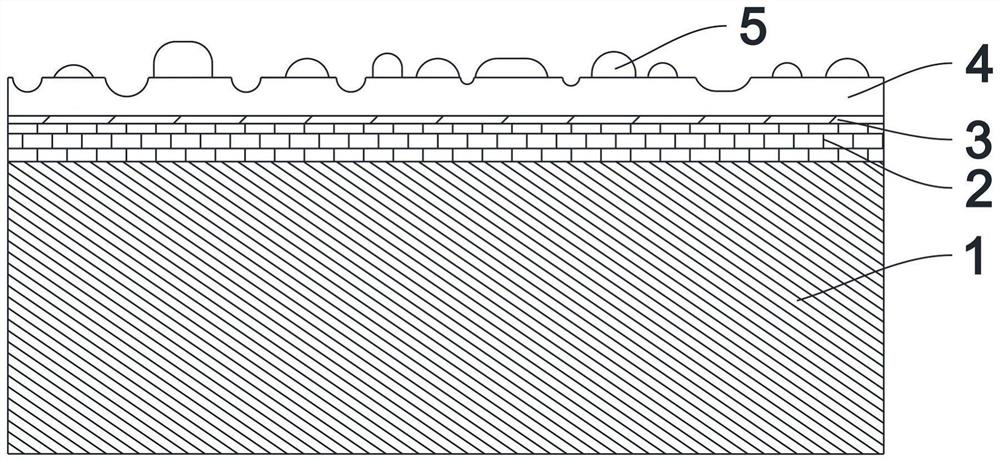

[0055]A glazed tile with anti-slip and anti-slip effects, characterized in that, from bottom to top, it comprises: a green body layer 1, a surface glaze layer 2, a color texture layer 3, a protective glaze layer 4 and a pattern layer 5; the pattern layer 5; Layer 5 is formed by printing and dyeing a printing glaze through a rubber roller, and the printing glaze includes high temperature convex powder, anti-slip glaze powder and printing paste; lines are engraved on the surface of the rubber roller.

[0056] First, by mass percentage, add 38% quartz, 22% feldspar, 8% hard clay to 25% plastic clay, stir evenly, add 7% nepheline powder and mix evenly, then ball mill In addition to iron, the fineness reaches 250 mesh sieve: 2.0%, and the slurry density reaches 1.70 ~ 1.75g / cm 3 . Then, powder with moisture content of 5% to 7% is formed by spray drying and other processes, and is formed into a green body by a press with a pressure of 450 bar, and dried at 150° C. for 15 minutes to...

Embodiment 2

[0061] A glazed tile with anti-slip and anti-slip effects, characterized in that, from bottom to top, it comprises: a green body layer 1, a surface glaze layer 2, a color texture layer 3, a protective glaze layer 4 and a pattern layer 5; the pattern layer 5; Layer 5 is formed by printing and dyeing a printing glaze through a rubber roller, and the printing glaze includes high temperature convex powder, anti-slip glaze powder and printing paste; lines are engraved on the surface of the rubber roller.

[0062] First, by mass percentage, add 40% quartz, 25% feldspar, and 5% hard clay to 25% plastic clay, stir evenly, then add 5% nepheline powder and mix evenly, then ball mill In addition to iron, the fineness reaches 250 mesh sieve: 2.0%, and the slurry density reaches 1.70 ~ 1.75g / cm 3 . Then, powder with moisture content of 5% to 7% is formed through spray drying and other processes, and is formed into a green body by a press with a pressure of 500 bar, and dried at 200° C. fo...

Embodiment 3

[0067] A glazed tile with anti-slip and anti-slip effects, characterized in that, from bottom to top, it comprises: a green body layer 1, a surface glaze layer 2, a color texture layer 3, a protective glaze layer 4 and a pattern layer 5; the pattern layer 5; Layer 5 is formed by printing and dyeing a printing glaze through a rubber roller, and the printing glaze includes high temperature convex powder, anti-slip glaze powder and printing paste; lines are engraved on the surface of the rubber roller.

[0068] First, by mass percentage, 43% of quartz, 20% of feldspar, and 8% of hard clay were added to 22% of plastic clay, stirred evenly, and then added 7% of nepheline powder, mixed evenly, and then ball milled. In addition to iron, the fineness reaches 250 mesh sieve: 2.0%, and the slurry density reaches 1.70 ~ 1.75g / cm 3 . Then, through spray drying and other processes, a powder with a moisture content of 5% to 7% is formed, which is formed into a green body by a press with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com