Ultrasonic flowmeter support

A flowmeter and ultrasonic technology, applied in the field of brackets, can solve the problems of easy dust absorption, inconvenient reading, unclear reading, etc., and achieve the effect of convenient operation, easy installation and disassembly, and easy observation of detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

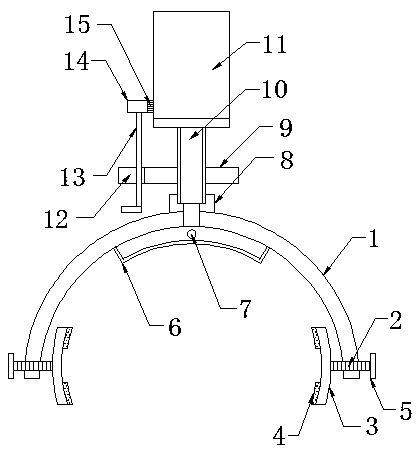

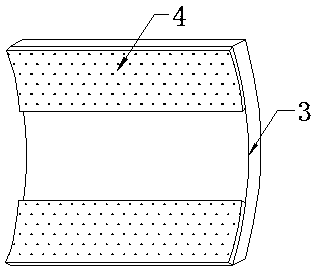

[0024] Such as figure 1 and image 3 As shown, it includes an arc-shaped fixing plate 1, the two sides of the arc-shaped fixing plate 1 are provided with locking mechanisms, the center of the bottom end of the arc-shaped fixing plate 1 is fixedly connected with an arc-shaped wire box 6, and the side wall of the arc-shaped wire box 6 A threading hole 7 is excavated in the middle of the ultrasonic flowmeter, which can collect the wires of the ultrasonic flowmeter, thereby protecting the wires and reducing the probability of corrosion and damage. It includes four screw rods 2 and four holding plates 5, the four screw rods 2 are threadedly connected with both sides of the arc-shaped fixed plate 1, the four holding plates 5 are respectively fixedly connected with one end of the four screw rods 2, and the four screw rods 2 The other end is fixedly connected with an arc-shaped splint 3, which can clamp pipes of different diameters and is convenient for clamping adjustment. The top a...

Embodiment 2

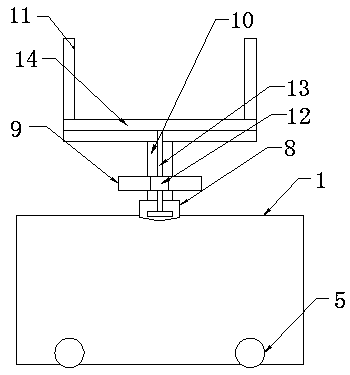

[0026] On the basis of Example 1, such as figure 2 As shown, the top of the connecting seat 8 is rotatably connected with a rotary tube 10, and the top of the rotary tube 10 is fixedly installed with a U-shaped clip 11, which can fix the meter head of the ultrasonic flowmeter and facilitate rotation at the same time. The middle part of the rotary tube 10 is fixed Connected with the grip ring 9, the grip ring 9 is convenient to hold and rotate, the side wall of the grip ring 9 is fixedly connected with the limit block 12, the inside of the limit block 12 is slidably connected with the transmission rod 13, and the top of the transmission rod 13 is fixedly connected with a fixed Bar 14, the side wall of the fixed bar 14 is fixedly connected with a brush bar 15, the brush bar 15 can wipe off the dust on the surface of the meter head, which is convenient for the operator to clearly observe the detection data, and the bottom end of the transmission rod 13 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com