Patents

Literature

90results about How to "Not easy to crack and fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shell, manufacturing method thereof and electronic equipment

ActiveCN110582176ANot easy to fall offNot easy to crack and fall offVacuum evaporation coatingCasings/cabinets/drawers detailsMetallurgyElectronic equipment

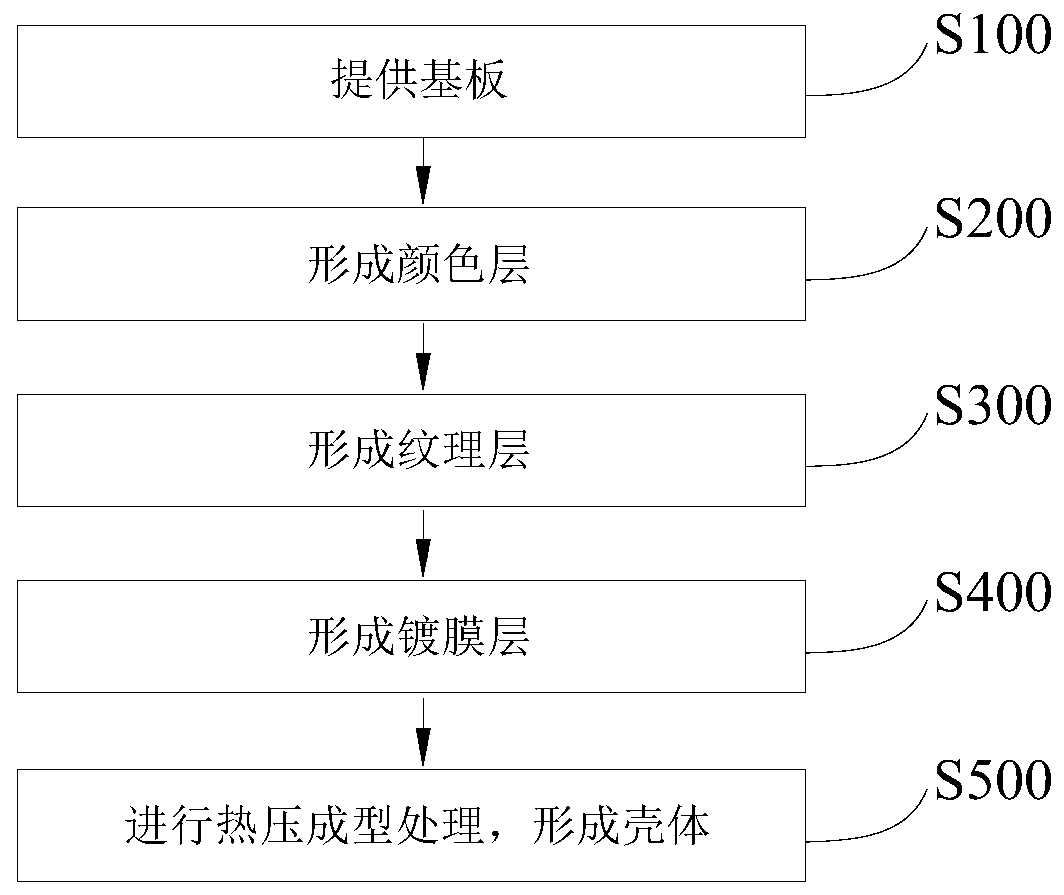

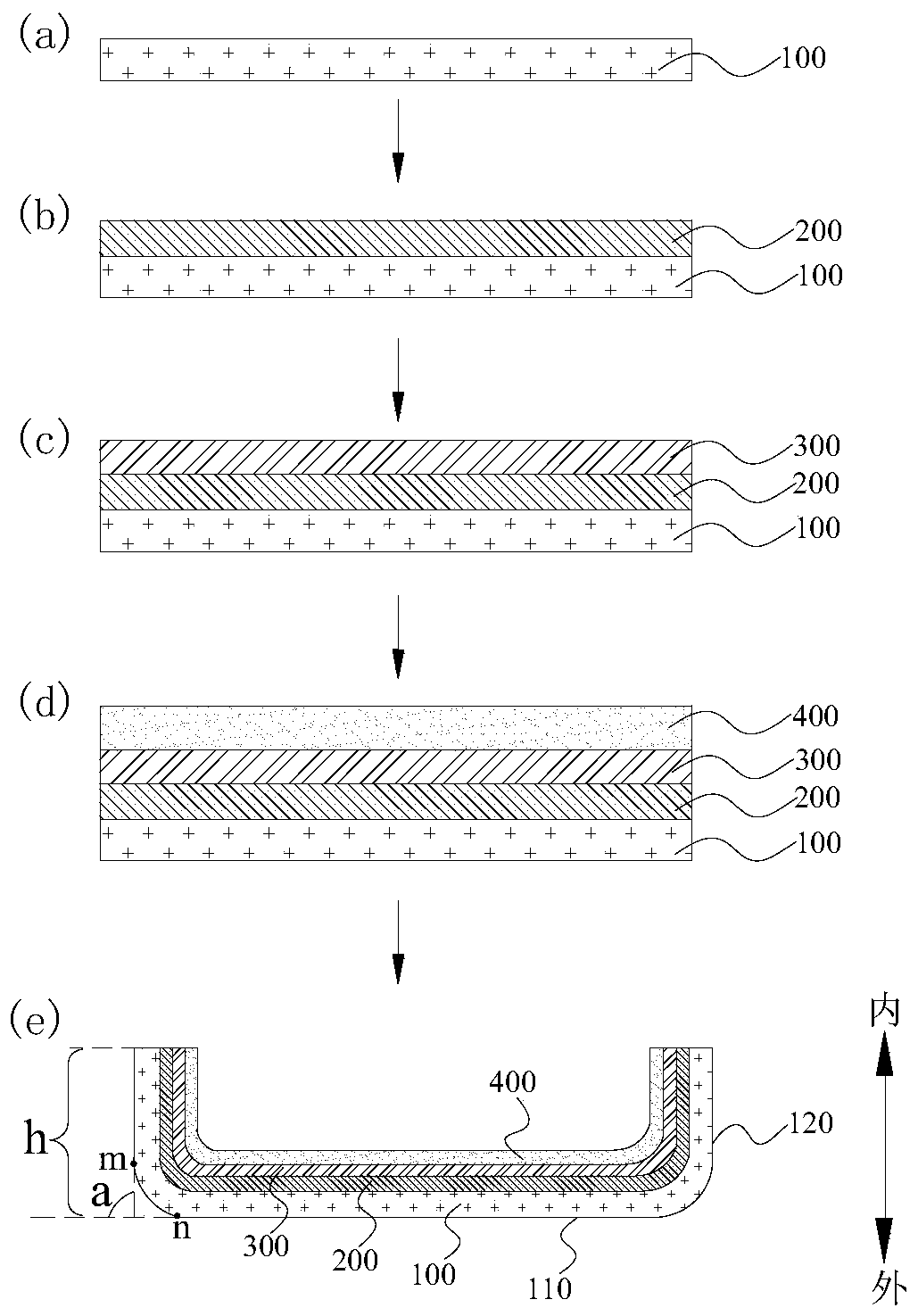

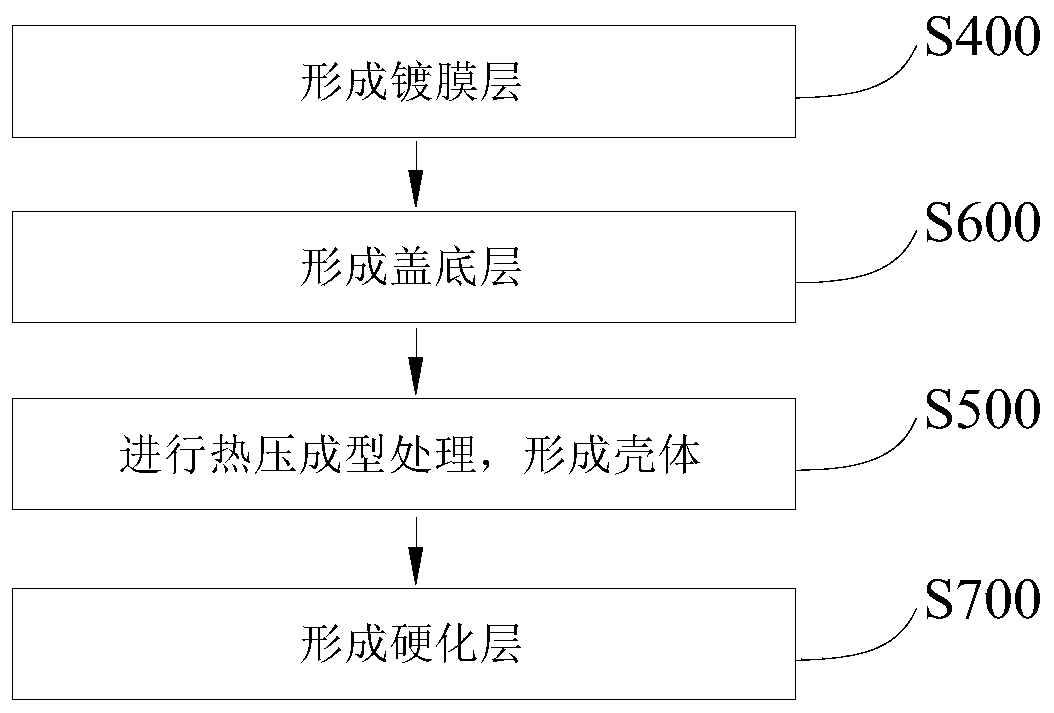

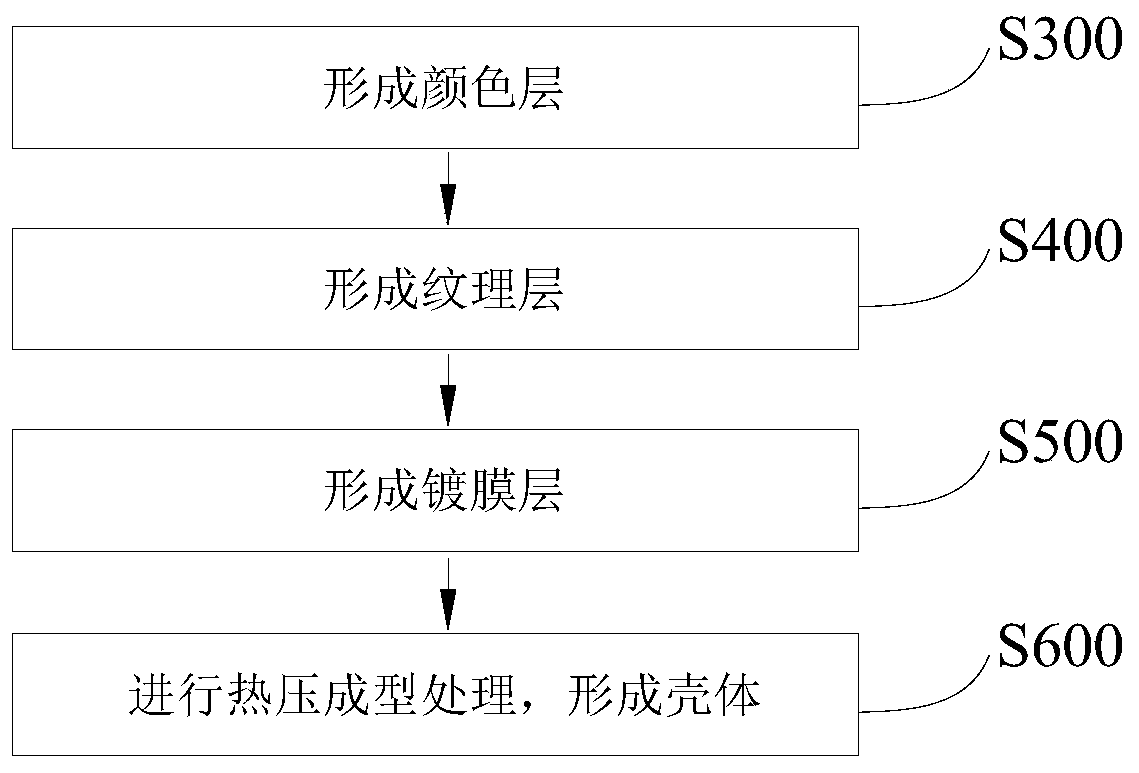

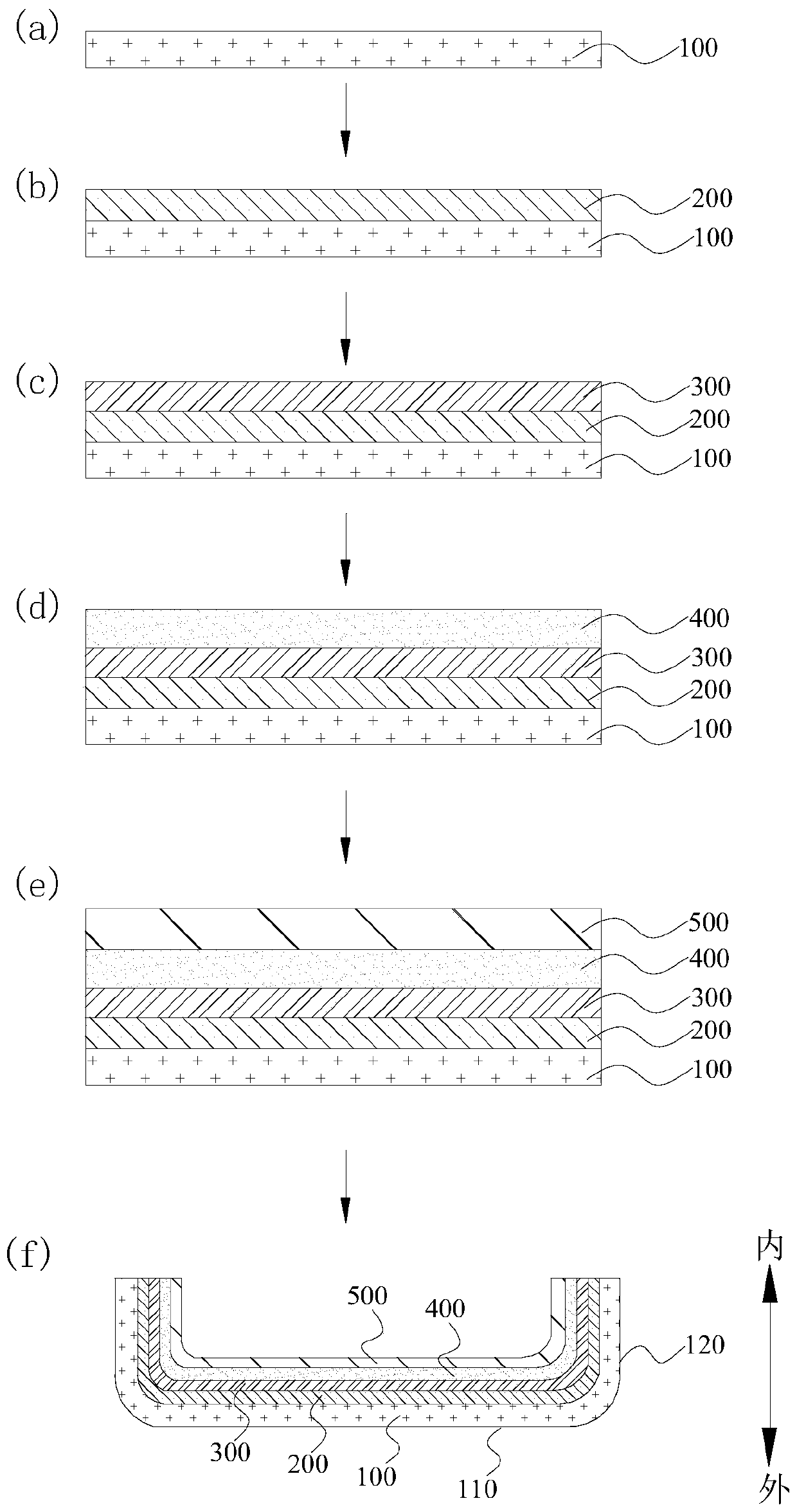

The invention discloses a shell, a manufacturing method thereof and electronic equipment. Specifically, the invention provides a method for manufacturing a shell, and the method comprises the steps: providing a substrate; forming a color layer on one side of the substrate, wherein the elongation at break of the color layer is greater than 100%; forming a texture layer on one side, far away from the substrate, of the color layer; forming a coating layer on one side, far away from the color layer, of the texture layer; and carrying out hot press molding treatment on the substrate on which the coating film layer is formed so as to form the shell, the shell is provided with a bottom surface and a side wall connected with the bottom surface, and a bending angle between the side wall and the bottom surface is greater than 70 degrees. Therefore, the method can be used for simply and conveniently preparing the large-angle bent shell, the color layer and the like of the shell are firmly combined with the substrate and are not easy to crack or fall off, and the shell prepared by the method is good in appearance effect and strong in product expressive force.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Shell, manufacturing method thereof and electronic equipment

InactiveCN110730581AWide variety of colorsIncrease productivityCasings/cabinets/drawers detailsPattern printingColor gradientHot press

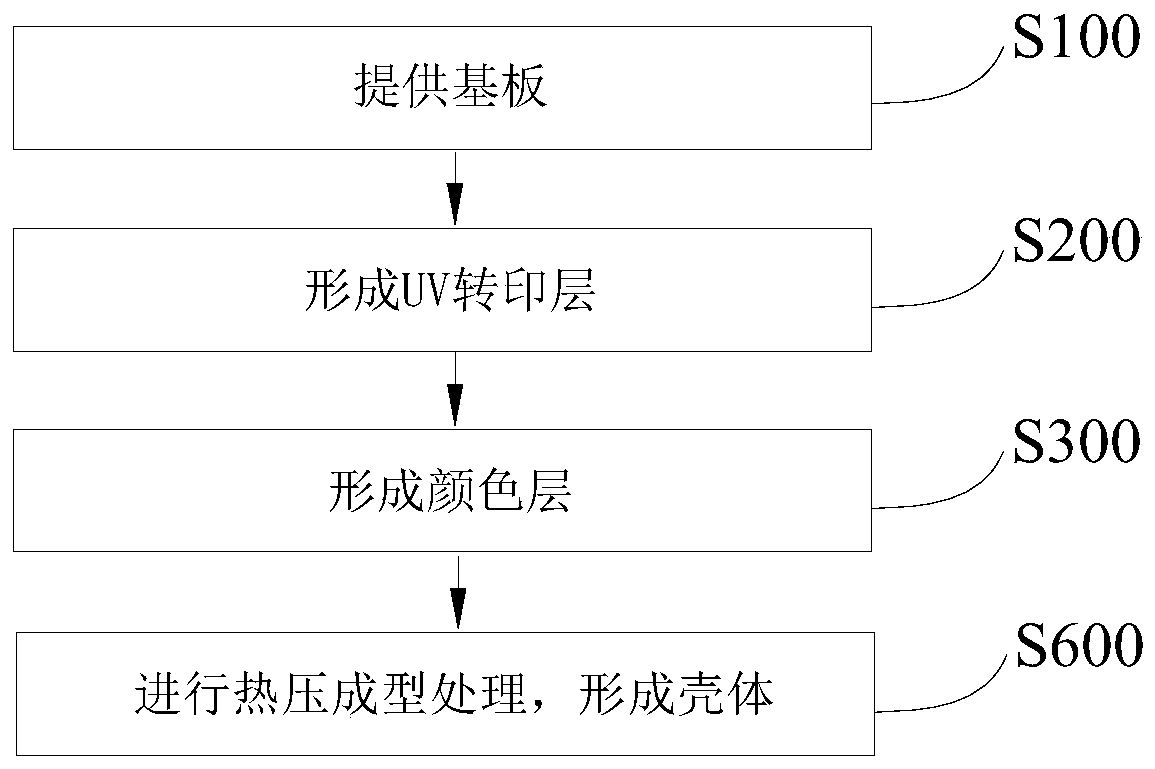

The invention discloses a shell, a manufacturing method thereof and electronic equipment. The method for manufacturing the shell includes the following steps that: a substrate is provided; a first UVadhesive is transferred at one side of the substrate so as to form a UV transfer layer; mixed ink is sprayed and printed on one side, far away from the substrate, of the UV transfer layer so as to form a color layer; and the substrate with the color layer is subjected to hot press molding treatment so as to form the shell, and the shell is provided with a bottom surface and side walls connected with the bottom surface. Therefore, the color layer and the substrate of the shell prepared through the method are firmly combined; the color layer is not prone to cracking or falling off in hot-press forming treatment and use processes; the shell has rich color gradient change forms; the appearance effect of the shell is good; and the product can be very expressive.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Titanium blank colored enamel product and manufacturing method

InactiveCN105313572ANot easy to crack and fall offNot easy to oxidize and rustDecorative surface effectsSpecial ornamental structuresTitanium oxideBorax

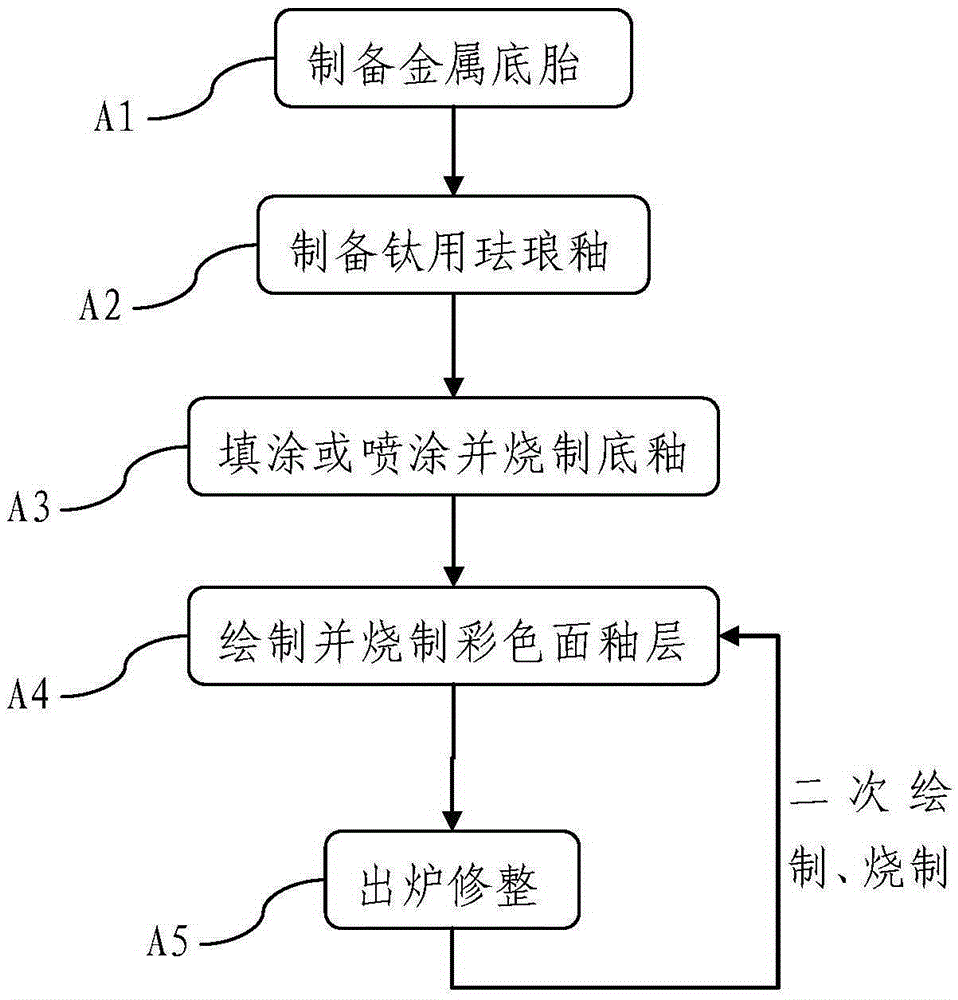

The invention relates to a titanium blank colored enamel product and a manufacturing method. The titanium blank colored enamel product comprises a metal bottom blank and a titanium enamel glaze layer, wherein the metal bottom blank is manufactured by using industrial pure titanium with the purity of more than 99%; a ground glaze layer of the titanium enamel glaze layer is prepared from 10% of titanium oxide, 35% of high-purity quartz, 32% of borax, 3.5% of barium oxide, 4% of zinc oxide, 3.2% of calcium oxide, 3% of magnesium oxide, 4.3% of aluminum oxide and 5% of lead oxide; a colored cover glaze layer is prepared from the mixture of 5% of the titanium oxide, 38% of the high-purity quartz, 34% of the borax, 2.5% of the zinc oxide, 3.2% of the calcium oxide, 6.5% of potassium oxide, 3.8% of the aluminum oxide and 7% of the lead oxide, and a coloring agent type metal oxide at the weight ratio of 100 to (0.5-12); and the titanium blank colored enamel product prepared by the steps of preparing the metal bottom blank and titanium enamel glaze, firing the ground glaze layer and the colored cover glaze layer, discharging from a furnace and trimming can be firmly glazed, has the bright and flat glaze and high rigidity and intensity, and is not easy to oxidize and get rusty.

Owner:杨仲华

High-temperature-resistant anti-oxidation paint for common steel and use method of high-temperature-resistant anti-oxidation paint

The invention discloses a high-temperature-resistant anti-oxidation paint for common steel and a use method of the high-temperature-resistant anti-oxidation paint. The high-temperature-resistant anti-oxidation paint and the use method aim at solving the problems that existing high-temperature-resistant anti-oxidation paint for common steel is poor in chemical stability and likely to crack and shed. The high-temperature-resistant anti-oxidation paint for common steel is prepared from, by weight, 30-50 parts of Al2O3-SiAlON-SiC powder, 3-5 parts of Cr2O3, 20-30 parts of a composite adhesive, 0.5-1.5 parts of potassium fluoborate and 0.5-1.5 parts of boron carbide. By adopting the Al2O3-SiAlON-SiC material as filler of the high-temperature-resistant anti-oxidation paint for common steel, the high temperature resistance and chemical stability of the high-temperature-resistant anti-oxidation paint for common steel are improved; by adopting a phthalocyanine resin prepolymer to prepare the composite adhesive, the stability and adhesiveness of the adhesive at a high temperature are improved, a coating is not likely to crack or shed, and the high temperature oxidation resisting capability of the coating is improved. The high-temperature-resistant anti-oxidation paint for common steel can be sprayed and brushed on the surface of billet steel at the room temperature to 500 DEG C; after processing is finished, the coating can shed naturally in the cooling process, and the dephosphorization difficulty is lowered.

Owner:浙江钜安拓新材料有限公司

Biodegradable lentinus edodes strain stick coating liquid and preparation method thereof

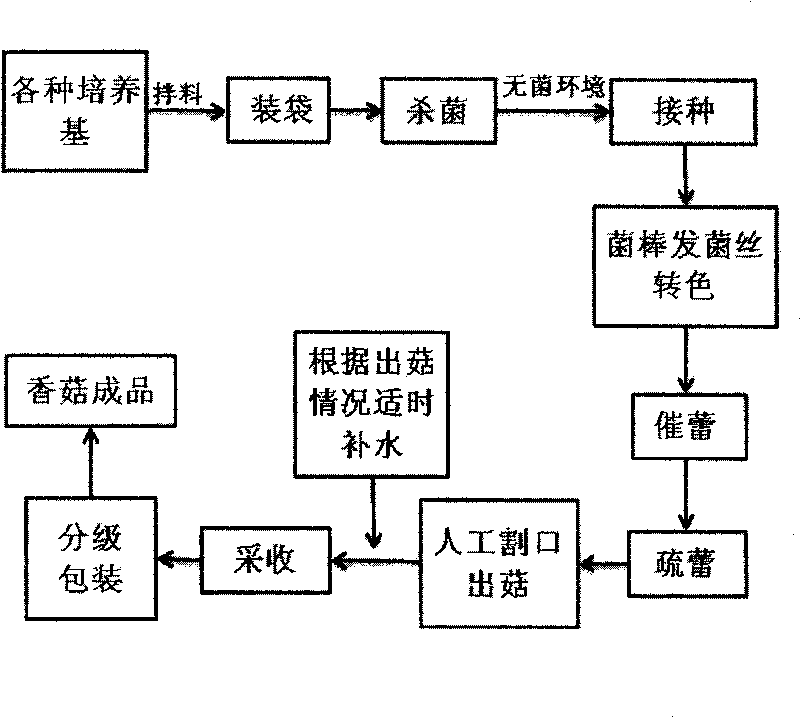

InactiveCN101691465AGuaranteed normal growthIncrease productionStarch coatingsHorticulturePolyvinyl alcoholBud

The invention discloses a biodegradable lentinus edodes strain stick coating liquid and preparation method thereof, which relates to a culture technique of lentinus edodes and comprises the following components, by mass percent, 10-12% of polyvinyl alcohol, 8-10% of starch, 2-4% of stearic acid, 3-5% of water retention agent, and the balance distilled water. When the product is used for culturing the lentinus edodes, the coating liquid is coated on the strain stick removing a plastic bag, so as to form a uniform and stable water retaining film with appropriate thickness. The film is flexible, moist and ventilative, and can prevent the loss of nutrient substances effectively; and the lentinus edodes bud can burst the water retaining film itself, without artificial incision. The fruiting body deformation can be avoided, thereby reducing the workload of bud sparseness and artificial incision. The popularization and application of the product can improve the quality and yield of lentinus edodes on the one hand, and on the other hand can save resource and labor force, decrease white pollution, develop recycling economy, thereby having good application prospect.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

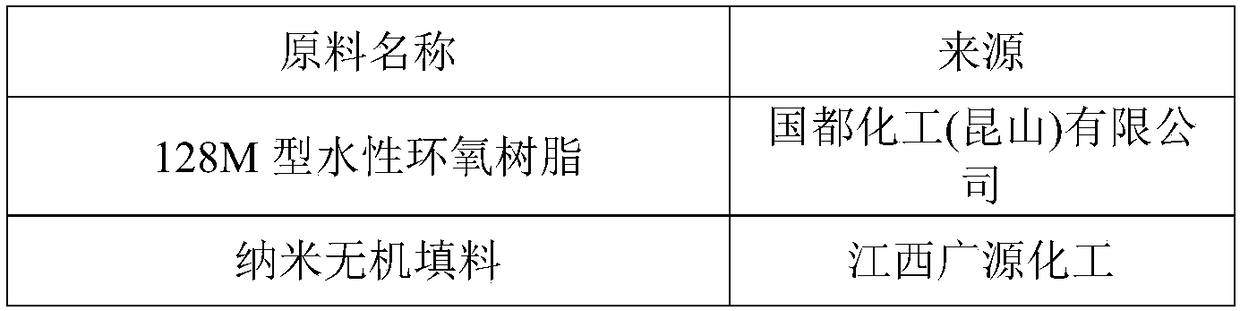

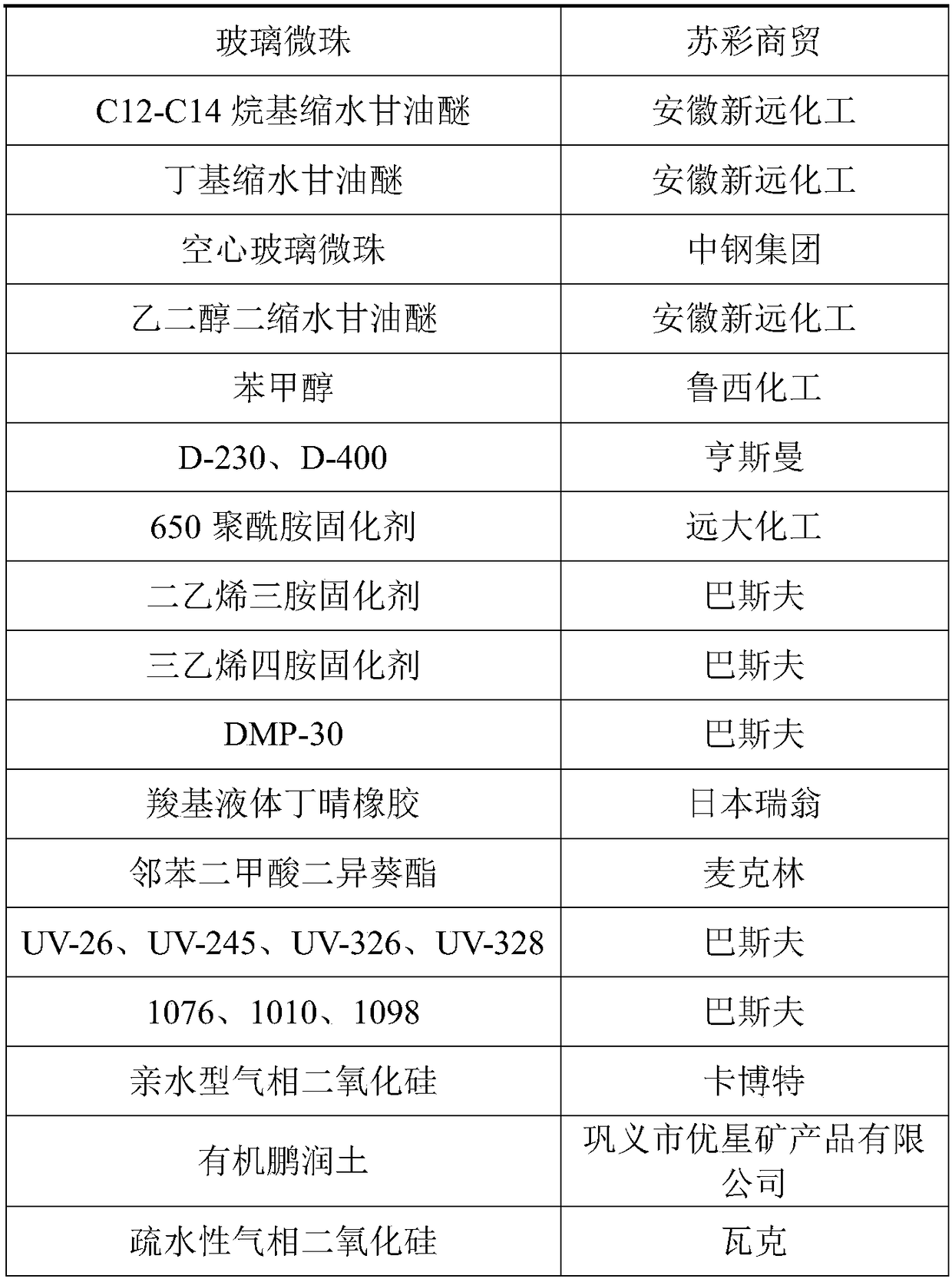

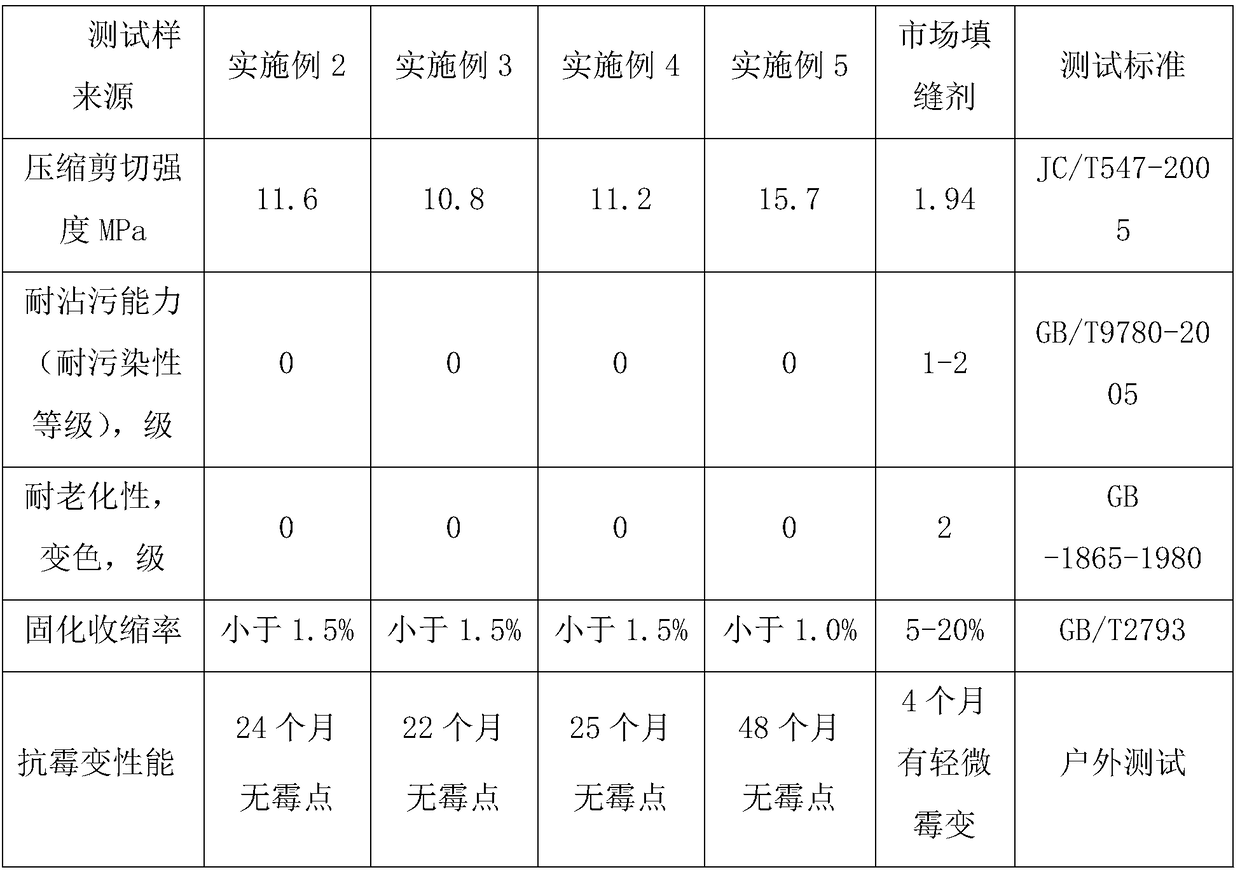

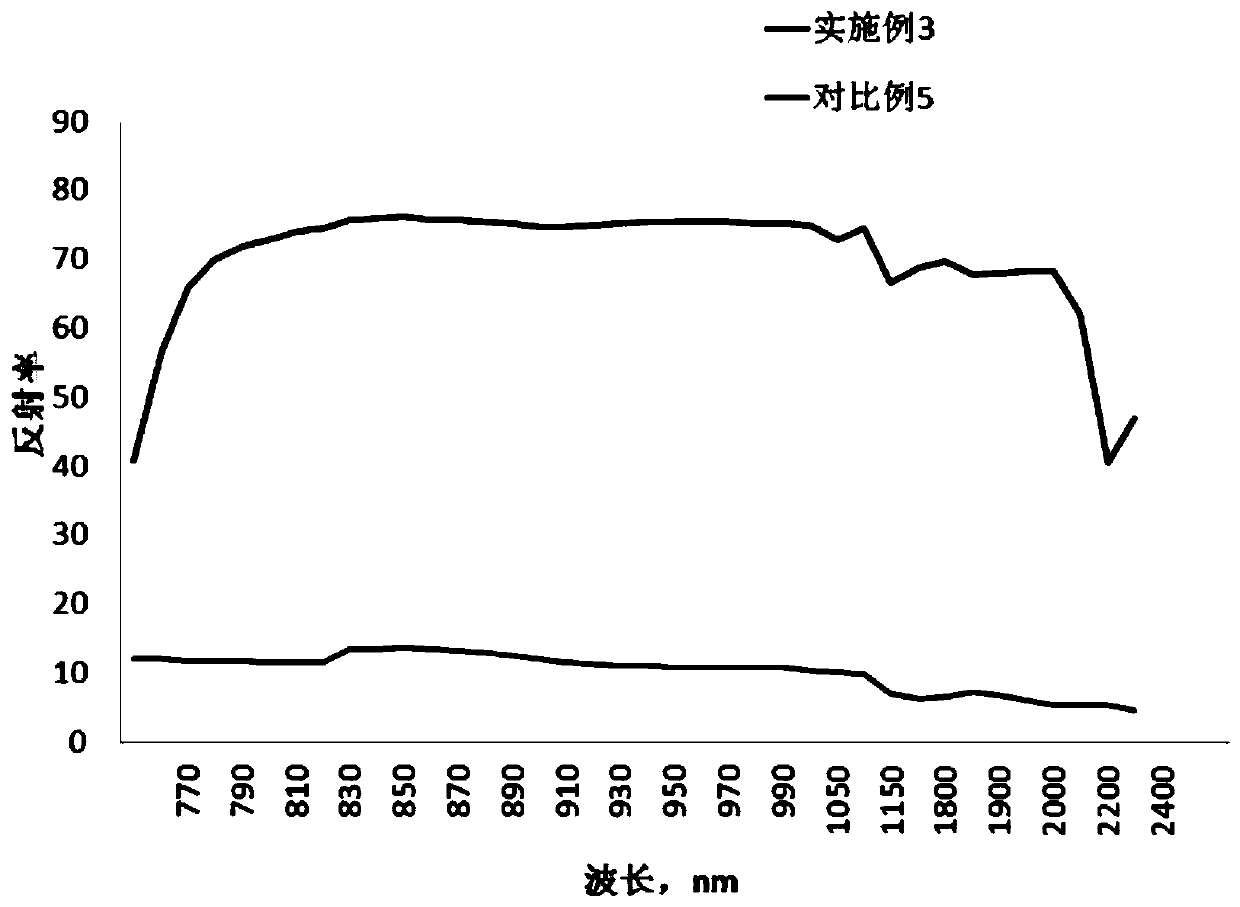

Epoxy joint mixture and preparation method thereof

ActiveCN109385242ANot easy to crack and fall offImprove adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyThermal expansion

The invention provides an epoxy joint mixture and a preparation method thereof. The problems that an existing joint filling material is poor in caking property, not water-resistant and dirt-resistantand easy to fall and crack, changes colors and the like are solved by selecting an epoxy joint mixture product prepared from raw materials such as an epoxy resin high molecular polymer, nano inorganicfiller and a modified amine curing agent by integrating an epoxy macromolecular material crosslinked three-dimensional netty structure and factors such as excellent aging resistance of the nano inorganic material, linear expansion coefficient close to a stone panel and the like. The prepared epoxy joint mixture is a joint mixture product which has integrated functions of filling joints, bonding,beautifying the joints and the like. The product has the characteristics of being good in water resistance and dirt resistance, high in bonding strength, various in color, low in cure shrinkage rate,small in influence by cold shrinkage and thermal expansion and good in antiageing performance.

Owner:HUNAN KOSEN NEW MATERIAL

Glass fiber blanket with high heat conductivity

The invention discloses a glass fiber blanket with high heat conductivity. The glass fiber blanket with high heat conductivity is characterized in that the glass fiber blanket is of a layer structure; a substrate is the glass fiber blanket, and an outer layer is a graphene layer; the thickness of the glass fiber blanket substrate is 5-10 mm; the graphene layer is made of monolayer graphene, multilayer graphene or a mixture of the monolayer graphene and the multilayer graphene; the thickness of the graphene layer is 0.1-10nm; the graphene layer contains silicon atoms, and the content of the silicon atoms and carbon atoms is 1%-3%. According to the glass fiber blanket with high heat conductivity, glass fiber serves as the substrate, so that the glass fiber blanket is low in cost; the graphene layer with high heat conductivity is arranged on the surface of the fiber, so that the mechanical strength of the whole glass fiber blanket is improved, and the heat conductivity of the whole glass fiber blanket is improved; the glass fiber can replace carbon fiber in a certain case; the glass fiber blanket with high heat conductivity has practicability and can be applied in various fields.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

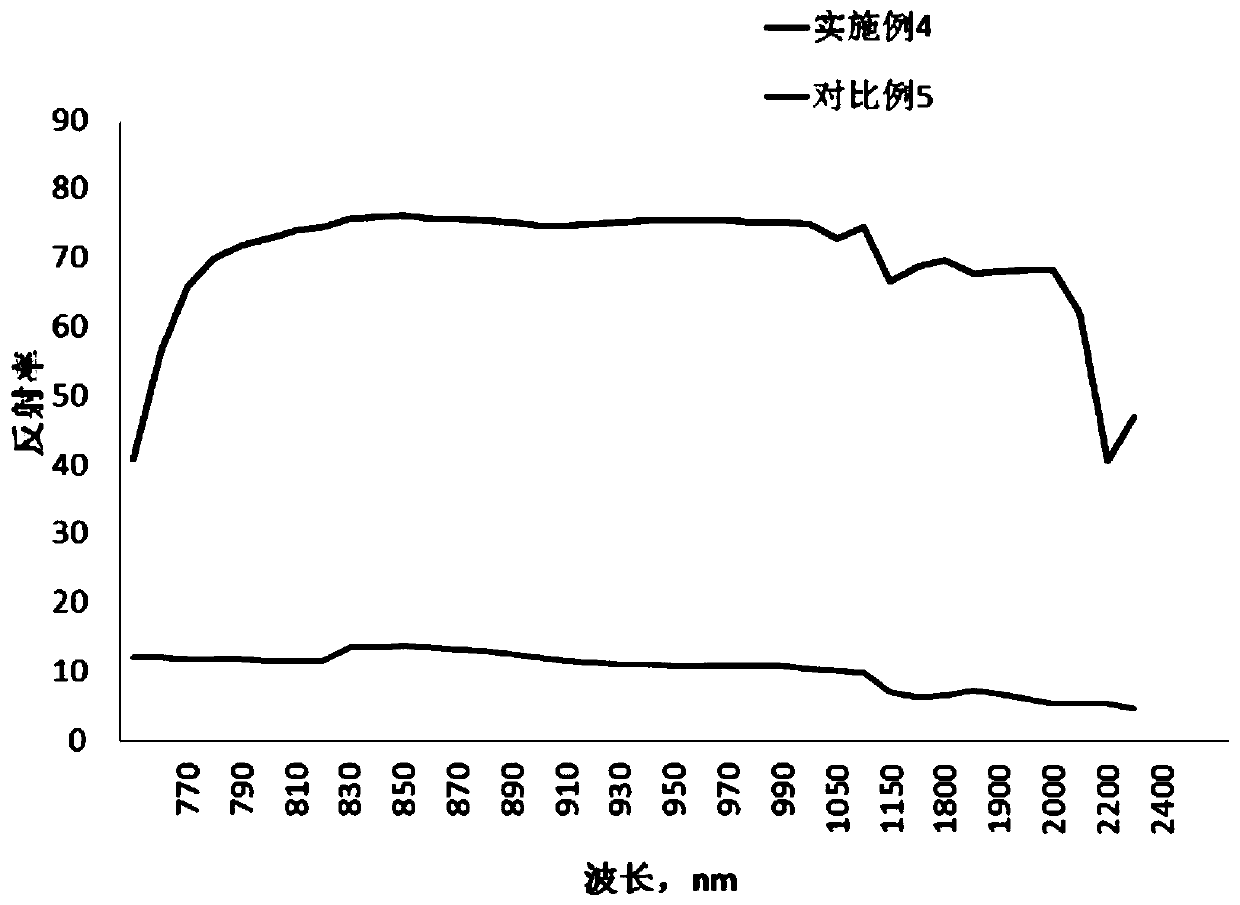

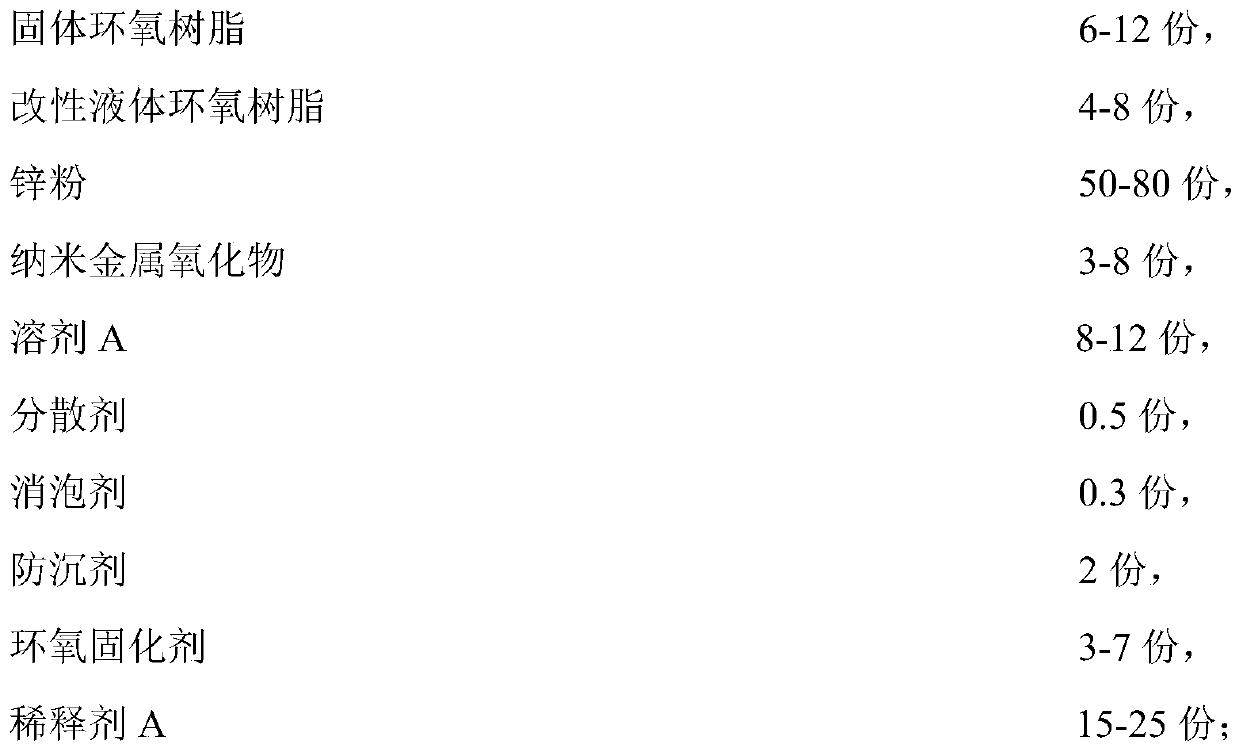

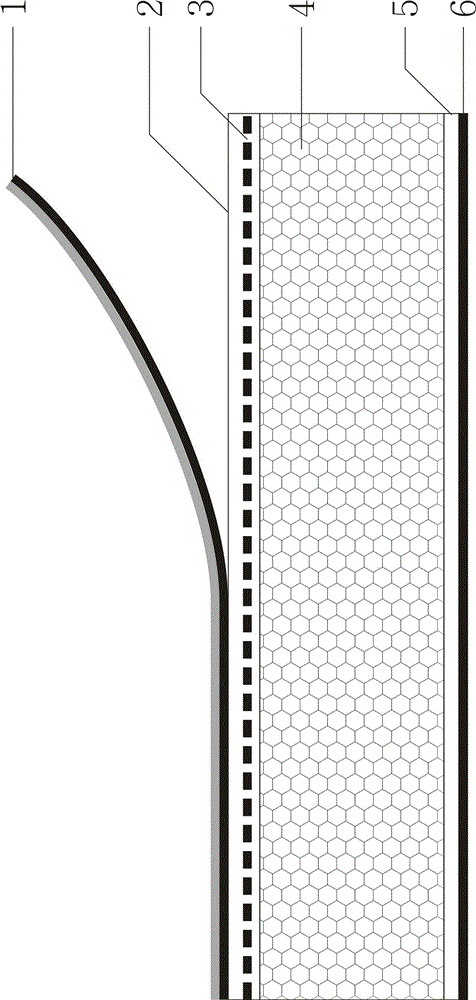

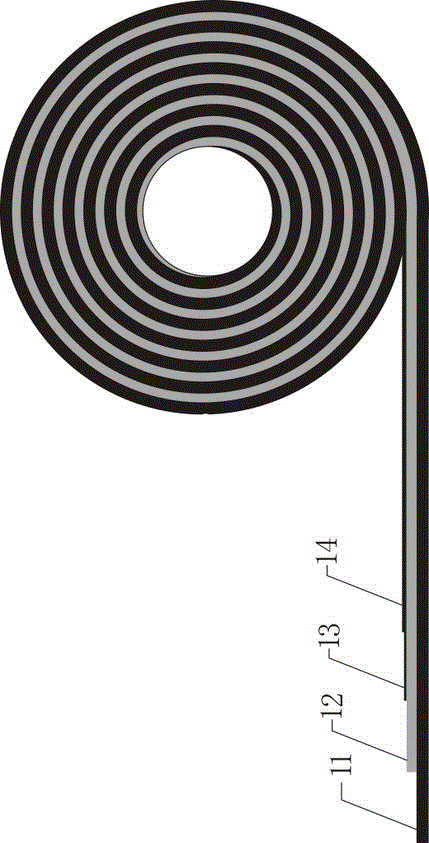

Self-repairing high-durability anticorrosive composite coating and preparation method thereof

ActiveCN110358406AImprove adhesionImprove salt spray resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention relates to a self-repairing high-durability anticorrosion composite coating, which sequentially comprises a nano modified epoxy zinc-rich primer layer, an elastic self-repairing epoxy micaceous iron oxide intermediate layer and an aliphatic polyurethane topcoat layer from bottom to top, wherein the primer layer is prepared from solid epoxy resin, modified liquid epoxy resin, zinc powder, nano metal oxide, solvent, dispersant, defoaming agent, anti-settling agent, epoxy curing agent and diluent A; The intermediate paint layer is prepared from solid epoxy resin, toughened epoxy resin, mica iron oxide, self-repairing microcapsules, solvents, dispersants, defoamers, anti-settling agents, modified polyamine curing agents and diluent A; The topcoat layer is prepared from modified hydroxyl acrylic resin, heat reflection pigment, solvent B, anti-aging additive, dispersant, defoaming agent, anti-settling agent, wetting dispersant, aliphatic isocyanate curing agent and diluent B ..The composite coating has excellent adhesive force, salt fog resistance, flexibility and heat reflection efficiency.

Owner:江阴市大阪涂料有限公司

Thermal insulation material for walls

The invention relates to a construction material, in particular to a thermal insulation material for walls. The thermal insulation material for the walls is prepared with the following raw materials according to parts by mass: 20 to 30 parts by mass of expanded perlite, 15 to 20 parts by mass of wollastonite, 0.5 to 2 parts by mass of asbestos, 5 to 10 parts by mass of floating beads, 5 to 10 parts by mass of cellulose, 10 to 20 parts by mass of gelatinized starch and 10 to 20 parts by mass of Portland cement. The thermal insulation material for the walls has the advantages of being good in thermal insulation performance, stable in structure, not prone to crack or fall, environmental friendly, convenient to construct and low in construction cost, and is an ideal thermal insulation material for buildings.

Owner:李建民

Integrated heat preservation decorative plate and production process thereof

InactiveCN104018636AReduce weightStrong weather resistanceCovering/liningsHeat proofingGlass fiberCompound a

The invention discloses a production process of an integrated heat preservation decorative plate. The production process comprises the steps of processing a glass fiber based decorative surface layer, compounding the glass fiber based decorative surface layer and a heat preservation core material, and compounding a glass fiber cement based cloth and the heat preservation core material. The integrated heat preservation decorative plate is light in weight, strong in weather resistance, high in strength, beautiful in appearance and low in cost; the production disclosed by the invention comprises the steps of processing the glass fiber based decorative surface layer, compounding the glass fiber based decorative surface layer and the heat preservation core material, and compounding the glass fiber cement based cloth and the heat preservation core material, is simple and reasonable in process step and convenient in operation and implementation, and can be used for greatly saving the investment of human resources, greatly reducing the production cost of products, improving the production efficiency, and reducing the potential safety hazards.

Owner:LANGFANG HOUDE TECH CO LTD

SiC-MgO-SiAlON ordinary steel heat treatment antioxidant coating and application method thereof

The invention relates to the technical field of coatings, and discloses a SiC-MgO-SiAlON ordinary steel heat treatment antioxidant coating and an application method thereof. A SiC-MgO-SiAlON material is adopted as filler of the coating, and the high temperature resistance and chemical stability of the coating are improved; and a phthalocyanine resin prepolymer is adopted for preparing a composite binder, the stability and stickiness of the binder at the high temperature are improved, a coating is not prone to cracking and falling off, and the high-temperature oxidization resisting capacity of the coating is enhanced. The surface of a steel blank with the room temperature being 500 DEG C can be coated or brushed with the coating, after heat machining is completed, the coating can naturally fall off in the cooling process, and the dephosphorization difficulty is reduced. The coating is prepared from, by weight, 30-50 parts of SiC-MgO-SiAlON powder, 3-5 parts of Cr2O3, 20-30 parts of the composite binder, 0.5-1.5 parts of potassium fluoborate and 0.5-1.5 parts of boron carbide.

Owner:长兴天晟能源科技有限公司

Sealant for automobiles

InactiveCN103805095AImprove stabilityGood adhesivenessNon-macromolecular adhesive additivesOther chemical processesZincSealant

The invention discloses a sealant for automobiles. The sealant comprises the following raw materials in parts by mass: 50-70 parts of butadiene rubber, 3-5 parts of calcium carbonate, 1-3 parts of polyisobutene, 1-2 parts of carbon black, 20-30 parts of dioctyl phthalate, 2-3 parts of calcium carbonate, 2-3 parts of lubricating agent, 2-4 parts of zinc oxide and 3-5 parts of sodium silicate. The sealant has the characteristics of high stability, firmness, durability, high adhesion and prevention of cracking and peeling, and is suitable for bonding various automobile sealing components.

Owner:HAIAN GUOLI CHEM

Paint spraying method for plastic shell

InactiveCN107999361AImprove stabilityImprove visual aestheticsVacuum evaporation coatingPretreated surfacesLacquerOptical coating

The invention discloses a paint spraying method for a plastic shell. The paint spraying method for the plastic shell comprises the following steps that cleaning treatment, electrostatic removing treatment and preheating treatment are sequentially conducted on the plastic shell; a layer of treatment agent is sprayed on the plastic shell subjected to preheating treatment; a layer of colored paint issprayed on the surface of the treatment agent; a layer of UV paint is sprayed on the surface of the colored paint; the surface of the UV paint is coated with a titanium, silicon and dioxide coating layer with the thickness being 0.6 [mu]m through an optical coating machine; a layer of UV intermediate paint is sprayed on the surface of the coating layer; and a layer of UV surface paint is sprayedon the UV intermediate paint. By using the provided paint spraying method for the plastic shell, the plastic shell can present the ceramic luster and texture and is not prone to being cracked and disengaged.

Owner:陈来运

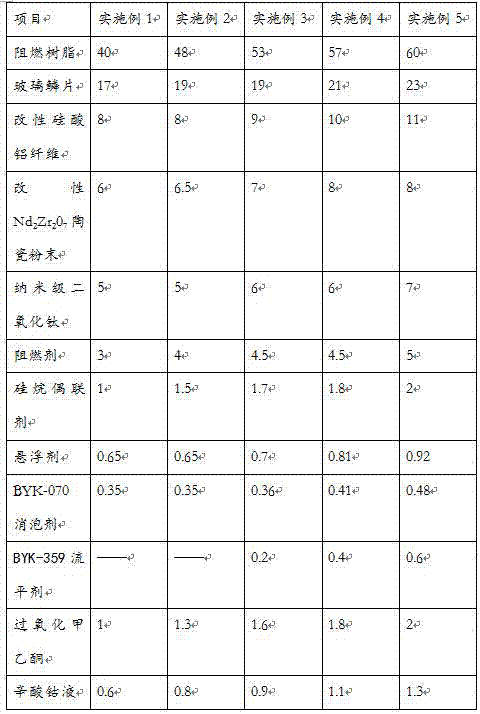

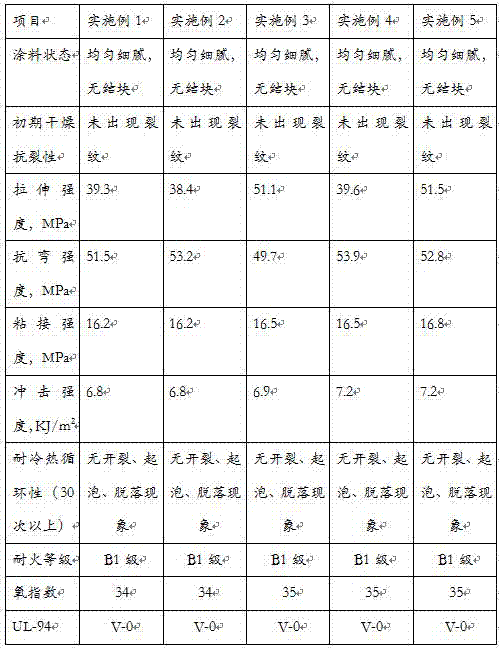

Flame-retardant glass flake daub for desulfurization corrosion prevention of thermal power plant and preparation method thereof

ActiveCN107057514AImprove toughnessImprove impact resistanceFireproof paintsAnti-corrosive paintsFiberAluminum silicate

The invention discloses flame-retardant glass flake daub for desulfurization corrosion prevention of a thermal power plant. The flame-retardant glass flake daub comprises, by weight, 40-60 parts of flame-retardant resin, 17-23 parts of glass flake, 1-2 parts f additive, 8-11 parts of modified aluminum silicate fiber, 6-8 parts of modified Nd2Zr207 ceramic powder, 5-7 parts of nanoscale titanium dioxide, 3-5 parts of flame retardant, 1-2 parts of coupling agent, 1-2 parts of solidifying agent and 0.6-1.3 parts of promoter, wherein the additive comprises a suspending agent and a defoamer according to a weight ratio of 2:1. By adding components like the modified aluminum silicate fiber and the modified Nd2Zr207 ceramic powder into glass flake daub, the defect that existing glass flake daub is low in binding strength and toughness, poor in impact resistance and short in service life is overcome; by combining flame-retardant characteristics of the glass flake daub itself and the flame retardant, the glass flake daub has excellent flame-retardant effect as a whole, flame-retardant grade reaches B1, oxygen index reaches 35, UL-94 is on grade V-0, and the flame-retardant glass flake daub is especially suitable for desulfurization corrosion preventive engineering of the thermal power plant.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

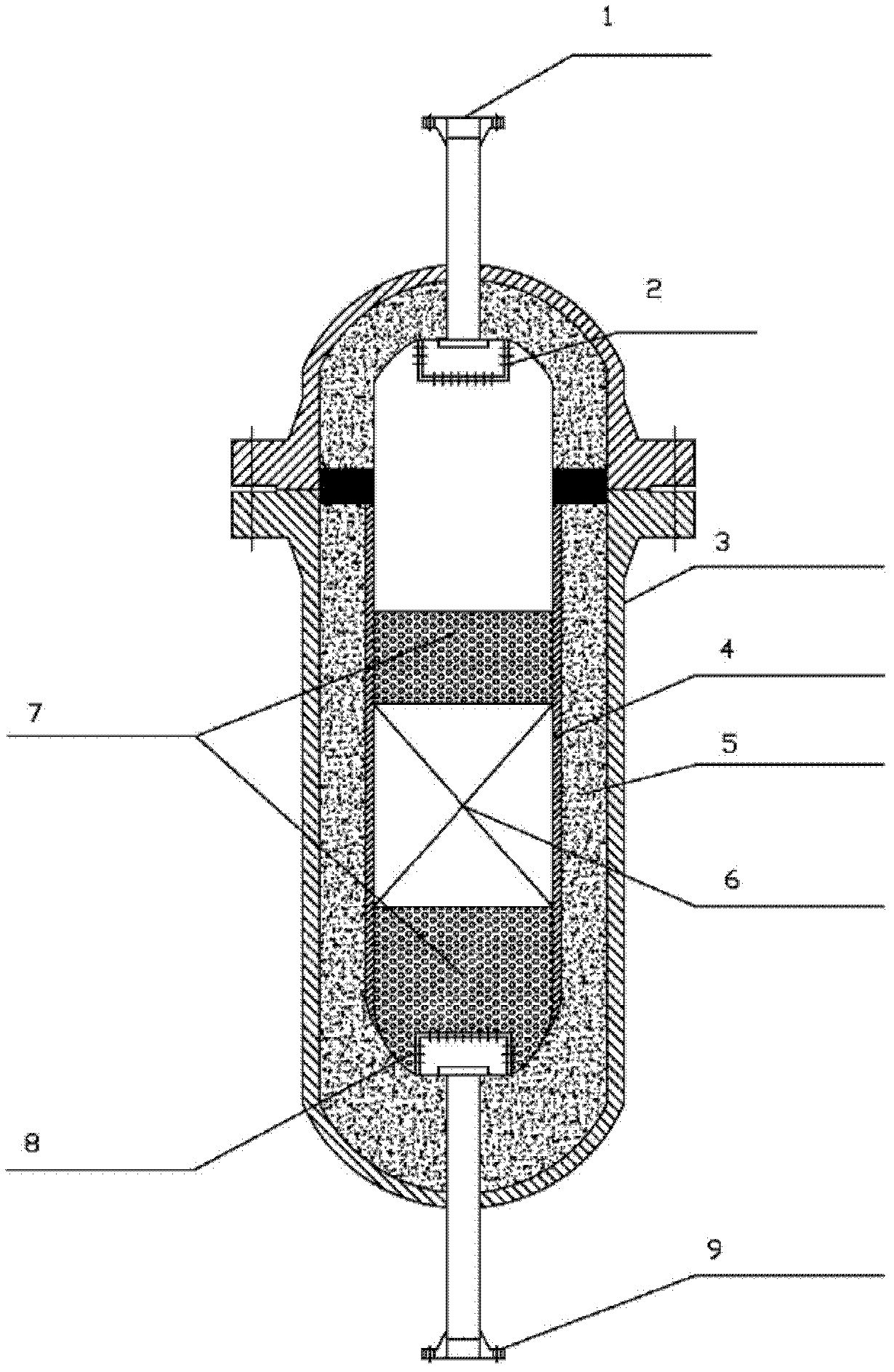

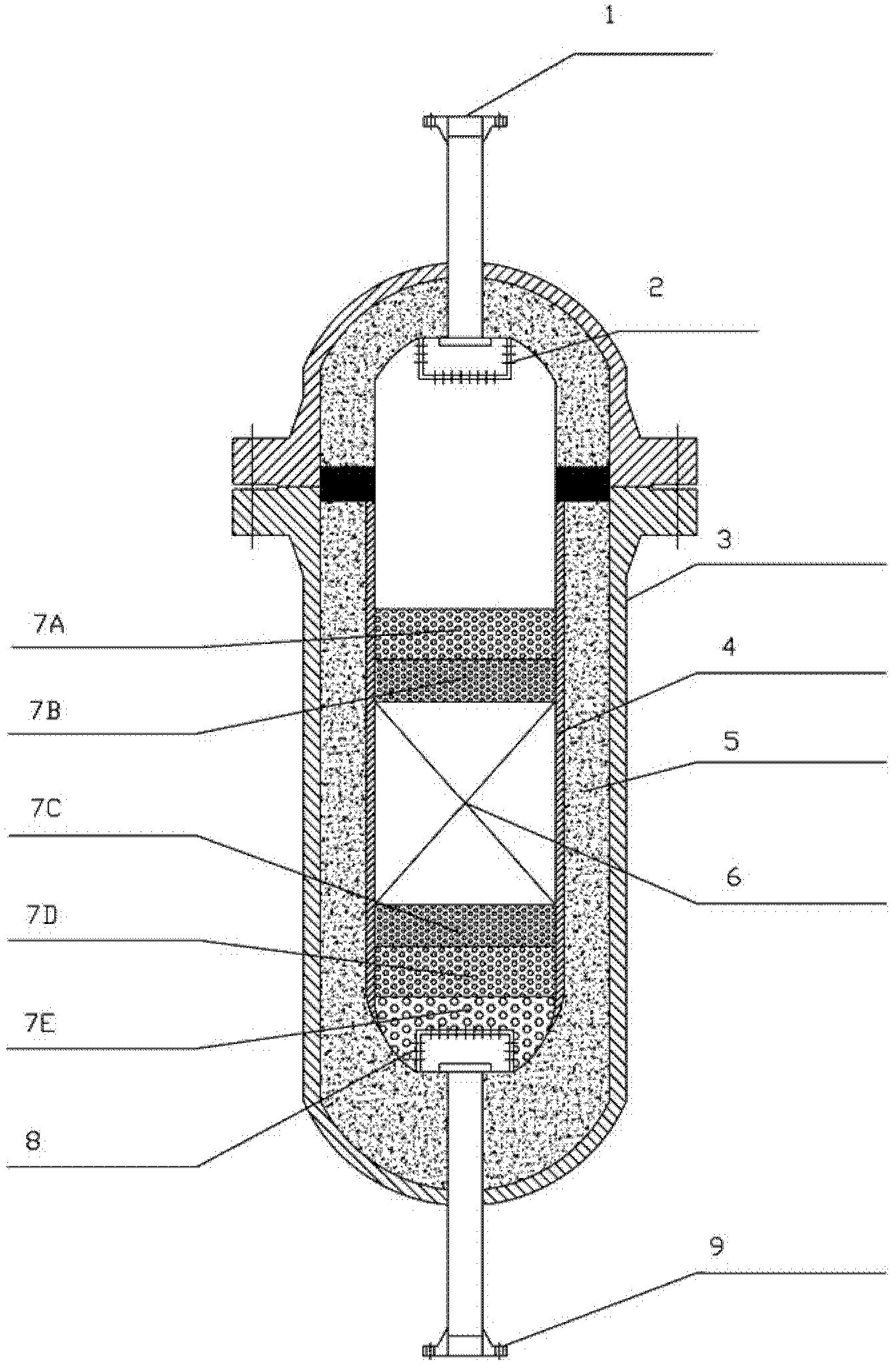

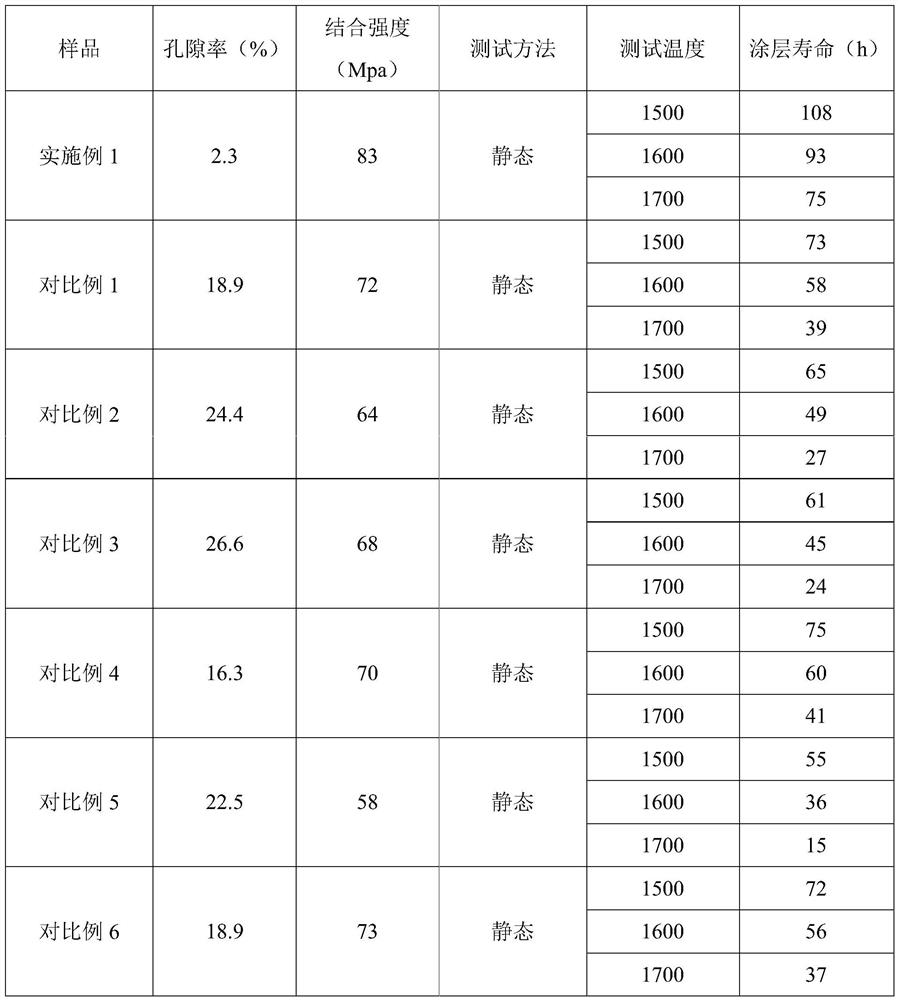

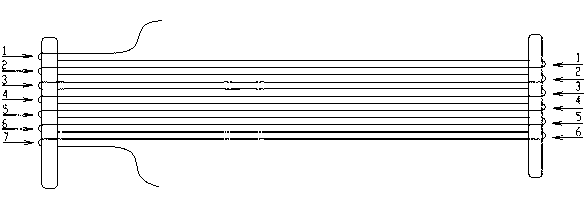

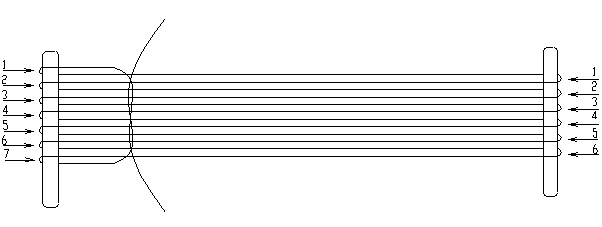

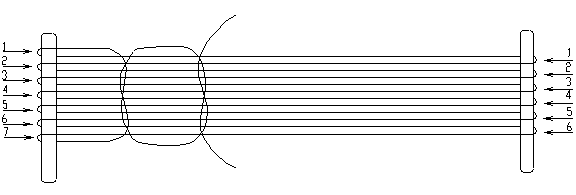

High temperature methanation reactor

InactiveCN103157408ANot easy to crack and fall offExtended service lifeHydrocarbon from carbon oxidesChemical/physical processesProcess engineeringThermal shock

The invention provides a high temperature methanation reactor, which comprises a reactor cylindrical body. The reactor cylindrical body includes a reactor external cylindrical body (3), a reactor internal cylindrical body (4) and a jacket layer (5) between the internal and external cylindrical bodies. The upper part of the reactor cylindrical body is provided with a reaction gas inlet (1) and a gas distributor (2), and the lower part is equipped with a gas collector (8) and a reaction gas outlet (9). The jacket layer (5) is filled with a high temperature refractory material. The reactor cylindrical body is loaded with a catalyst bed (6) inside. An inert filler (7) fills the space between the gas distributor (2) and the catalyst bed (6) and the space between the catalyst bed (6) and the gas collector (8). The reactor internal cylindrical body (4) of the reactor provided in the invention is a high temperature resistant stainless steel material, and is hard to crack and come off under a thermal shock, thus avoiding local clogging of the catalyst bed. The reactor is also provided with the gas distributor, the gas collector and the inert filler, so that a feed gas can pass the catalyst bed uniformly, and the product gas can leave the reactor uniformly.

Owner:DATANG INT CHEM TECH RESINST +1

High-temperature oxidation-resistant thermal-insulation composite ceramic coating

The invention discloses a high-temperature oxidation-resistant thermal-insulation composite ceramic coating which is composed of one or two of silicon carbide coating, silicon nitride coating, mullite coating, alumina coating, zirconium silicate coating and Sailong coating. The invention is characterized in that the ceramic coating is composed of an inner layer and an outer layer, wherein the inner layer has a porous structure, and the outer layer is compact and free of pores and permeates into the inside of the inner layer; and the pores are communicated mutually, the size of the pores is 1-20 mu m, and the pores account for 30-60 vol% of the inner layer. The depth of the outer layer permeating into the inside of the inner layer is 1-5 mu m. The coating has the advantages of excellent high temperature resistance, excellent oxidation resistance, excellent heat insulation property and the like. The inner layer has high porosity and loose structure, and thus, has low thermal stress at high temperature and low tendency to cracking and shedding. The outer layer permeates into the interior of the inner layer to form the mechanical bonding action, so that the inner layer and outer layer are combined closely.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

External wall coating

ActiveCN104402319AStrong dynamic crack resistanceStrong acid and alkali resistanceCrack resistancePolyvinyl alcohol

The invention discloses an external wall coating which is prepared from the following raw materials in parts by weight: 8-15 parts of mica powder, 20-40 parts of marbles, 3-10 parts of polyvinyl alcohol, 3-8 parts of acrylic resin, 0.2-0.4 part of lignocellulose, 1-5 parts of fibrous silicon ash powder, 10-30 parts of weight-calcium carbonate, 7-15 parts of asbestos fibers, 0.1-0.8 part of titanium dioxide, 1-3 parts of an anti-freezing agent and 50-100 parts of water. All the raw materials adopted by the external wall coating are natural minerals, so that the external wall coating is high in bonding strength and high in dynamic cracking resistance; the external wall coating has the characteristics of low expansion rate, high elastic viscosity, resistance to irradiation of ultraviolet rays, difficulty in cracking and falling, high acid and alkali resistance and long service life.

Owner:山东正大防水材料股份有限公司

Waterborne wood mothproof and fireproof coating

ActiveCN106883698ADoes not affect growthDelay or even hinder combustionFireproof paintsAntifouling/underwater paintsCalcium hydroxideFire retardant

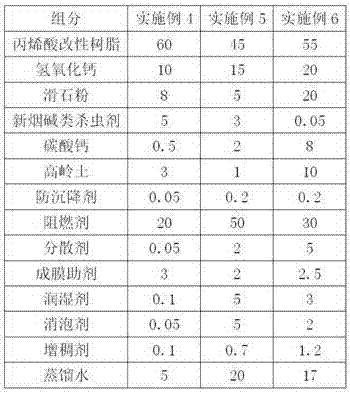

The invention relates to the technical field of waterborne coatings, in particular to a coating for nursery stock, and specifically discloses a waterborne wood mothproof and fireproof coating. The waterborne wood mothproof and fireproof coating is prepared from the following raw materials in parts by weight: 45 to 60 parts of acrylic modified resin, 0.5 to 20 parts of calcium hydroxide, 1 to 20 parts of talcum powder, 0.5 to 8 parts of calcium carbonate, 3 to 10 parts of kaolin, 0.05 to 5 parts of a neonicotine insecticide, 0.05 to 0.3 part of an anti-sedimentation agent, 10 to 50 parts of a fire retardant, 0.05 to 5 parts of a dispersing agent, 2 to 3 parts of a coalescing agent, 0.1 to 0.5 part of a wetting agent, 0.05 to 5 parts of a defoaming agent, 0.1 to 1.2 parts of a thickening agent and 5 to 20 parts of water.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

SiAlON-Al2O3-based high-temperature-resistant anti-oxidant coating for stainless steel

The invention discloses a SiAlON-Al2O3-based high-temperature-resistant anti-oxidant coating for stainless steel. The SiAlON-Al2O3-based high-temperature-resistant anti-oxidant coating for the stainless steel consists of the following raw materials in parts by weight: 30 to 50 parts of SiAlON-Al2O3 powder, 1 to 3 parts of nano-zirconium oxide powder, 20 to 30 parts of a composite adhesive, 0.5 to 1.5 parts of potassium fluoborate and 0.5 to 1.5 parts of boron carbide. According to the SiAlON-Al2O3-based high-temperature-resistant anti-oxidant coating for the stainless steel, the SiAlON-Al2O3 material is taken as filler, so that the high temperature resistance and the chemical stability of the coating are improved; the composite adhesive is prepared by adopting phthalocyanine resin prepolymer, so that the stability and the viscidity of the adhesive at a high temperature are improved, and a coating does not crack or fall off easily. The coating provided by the invention can be sprayed or brushed onto the surface of a steel blank at room temperature to 500 DEG C; after heat machining is completed, the coating can fall off naturally during a cooling process.

Owner:长兴天晟能源科技有限公司

Nontoxic cut-free flower mushroom stick composite water conservation film

InactiveCN101322461AModerate air permeabilityImprove water retentionOther chemical processesHorticultureParaffin waxFood grade

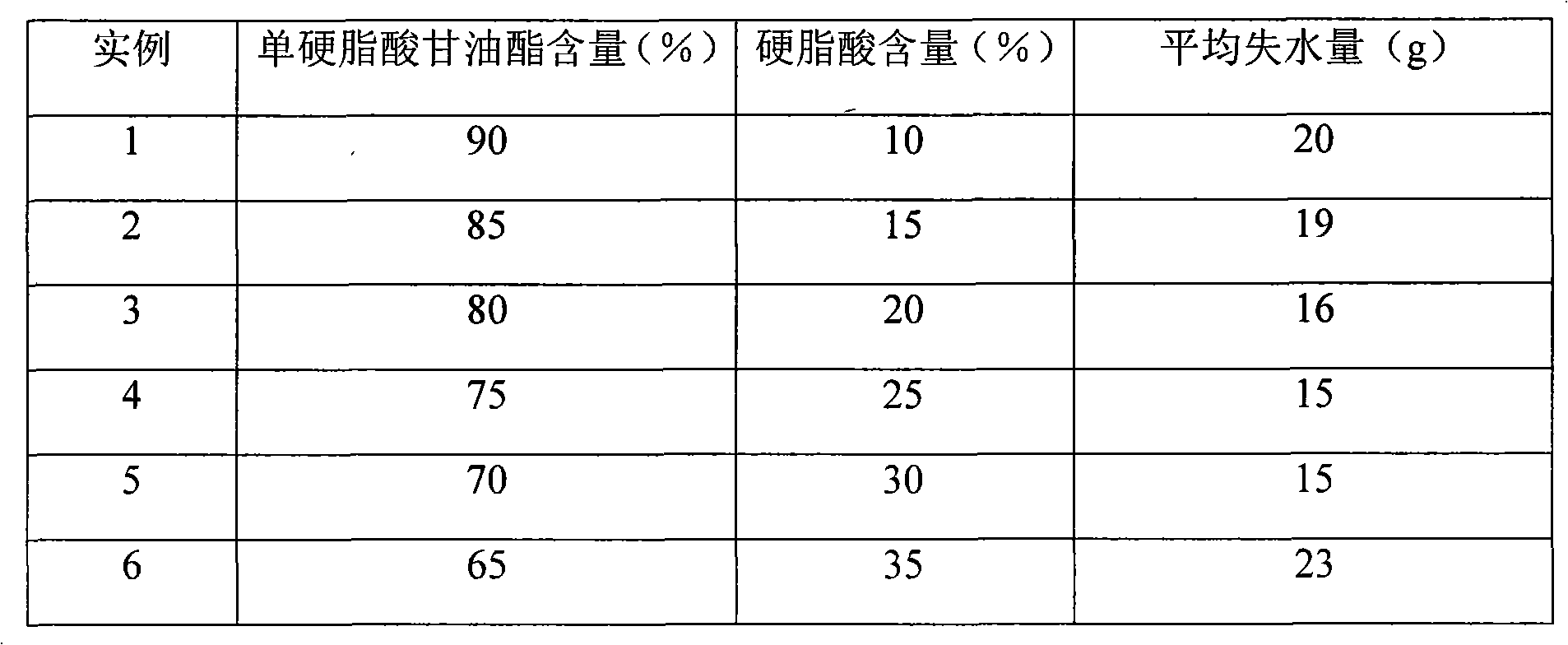

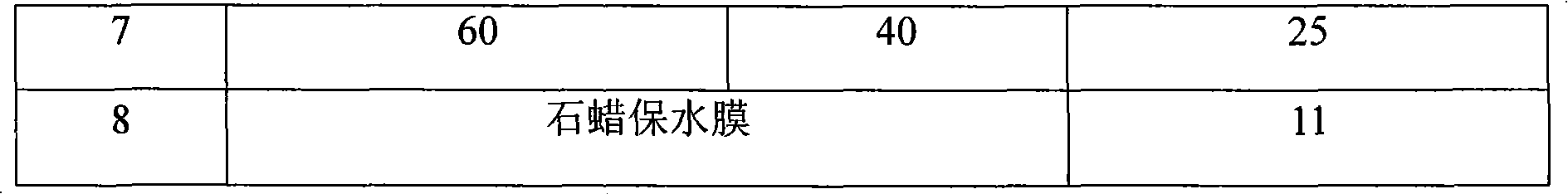

The invention provides a nontoxic incision-free mushroom stick water holding film, which is a film formed after congealing the following compounds: the weight percentage of food grade powdered glycerin monostearate is 60-90%, and the weight percentage of stearic acid is 10-40%. The water holding film not only can ensure the edible safety of produced mushroom but also has quick and even film production and moderate hardness, thereby having fine water holding capacity and moderate ventilation property; the production cost is 20-40% than olefin.

Owner:ZHEJIANG FORESTRY ACAD

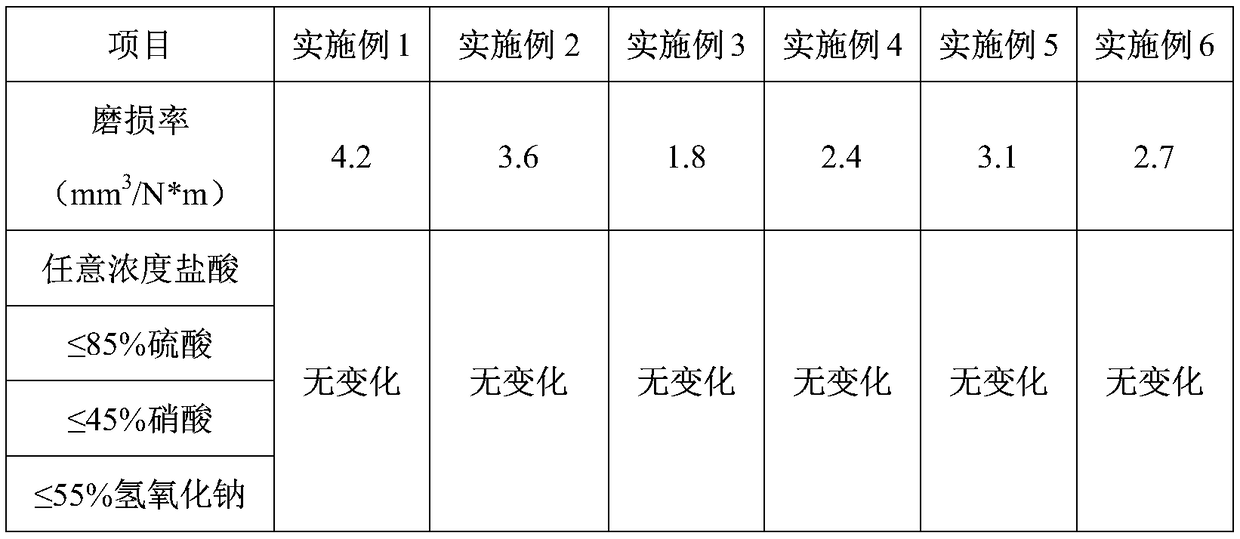

Anti-wear and anti-corrosion surface coating material and preparation method thereof

InactiveCN108841286AImprove wear and corrosion resistanceNot easy to crack and fall offFireproof paintsAnti-corrosive paintsCorrosion resistantToluene

The invention discloses an anti-wear and anti-corrosion surface coating material which is prepared from the following components in parts by weight: 22 to 35 parts of epoxy resin, 6 to 12 parts of acrylic resin, 5 to 10 parts of tetraethoxysilane, 6 to 11 parts of N-ethyl p-toluene sulfonamide, 3 to 6 parts of nano magnesia, 5 to 11 parts of monobutyl maleate, 10 to 25 parts of isophorone diisocyanate, 2 to 5 parts of a curing agent and 1 to 4 parts of calcium aluminate cement. The anti-wear and anti-corrosion surface coating material disclosed by the invention is prepared under the synergistic effect generated by mixing the epoxy resin, the acrylic resin, the tetraethoxysilane, the N-ethyl p-toluene sulfonamide, the nano magnesia, the monobutyl maleate, the isophorone diisocyanate, the curing agent and the calcium aluminate cement. The material produces bubbles hardly and is difficult to crack and fall off; furthermore, the wear resistance and the corrosion resistance can be effectively improved; the material can be widely applied to all fields of the modern industry and is used for protecting a workpiece from being corroded by high temperature, acid and alkali.

Owner:SANJIANG UNIVERSITY

Furnace roller thermal insulation protection process

InactiveCN1299847CReduce labor intensityReduce loadGratesRolling equipment maintainenceFiberThermal insulation

The invention relates to a furnace roller heat insulation protective technique, especially to a bearing cam roller heat insulation protective technique for roller-hearth soaking furnace or heating furnace. The technique includes following steps: cast the special roller high temperature adhesive on the appointed heat insulation sections on the bearing cam roller and then place the special made ceramic fiber blocks on above sections while cast the high temperature adhesive on the bonding sections; pressing on the blocks while keeping them clean; cast special high temperature infrared complex cement for rollers on the surface of the block and dry the block in shade; finally place heat resistant steel clasper on the blocks coated with the cement and tightly fix them together to make into use. The invention is of simple techniques, low cost, low labor intensity, fine working environment, heat resistance, enhanced heat shock resistance difficult to corrupt, light weight alleviating the load on the roller under high temperature, low heat conducting coefficient, low heat leaking, effective energy saving and long service life.

Owner:高峰 +2

SiAlON-SiC common steel heat treatment anti-oxidant coating and using method thereof

InactiveCN106700898ALower sintering temperatureShorten sintering holding timeFireproof paintsAdhesiveBoron carbide

The invention discloses a SiAlON-SiC common steel heat treatment anti-oxidant coating and a using method thereof. The SiAlON-SiC common steel heat treatment anti-oxidant coating consist of the following raw materials in parts by weight: 30 to 50 parts of SiAlON-SiC powder, 3 to 5 parts of Cr2O3, 20 to 30 parts of a composite adhesive, 0.5 to 1.5 parts of potassium fluoborate, and 0.5 to 1.5 parts of boron carbide. According to the SiAlON-SiC common steel heat treatment anti-oxidant coating, the SiAlON-SiC material is taken as filler, so that the high temperature resistance and the chemical stability of the coating are improved; the composite adhesive is prepared by adopting phthalocyanine resin prepolymer, so that the stability and the viscidity of the adhesive at a high temperature are improved, and a coating does not crack or fall off easily. The coating provided by the invention can be sprayed or brushed onto the surface of a steel blank at room temperature to 500 DEG C; after heat machining is completed, the coating can fall off naturally during a cooling process.

Owner:长兴天晟能源科技有限公司

Slag-doped high-intensity ceramic floor tile

InactiveCN104944917AGood for spraying glazesNot easy to crack and fall offCeramic materials productionClaywaresPerliteOxide

The invention discloses a slag-doped high-intensity ceramic floor tile, which comprises the following raw materials by weight part: 4-6 parts of meerschaum, 6-10 parts of perlite, 30-50 parts of converter slag, 20-25 parts of powdered steatile, 5-10 parts of kaolin, 15-25 parts of waste glass micro powder, 1-2 parts of hydroxyethyl methyl cellulose, 2-4 parts of water glass powder, 2-4 parts of zinc oxide, 5-8 parts of brown sugar, 0.1-0.3 parts of polyvinylpyrrolidone and a proper amount of distilled water. The floor tile has the advantages of high hardness, high mechanical strength, good heat stability and ageing resistance, little pollution, and wide application scope.

Owner:方堃

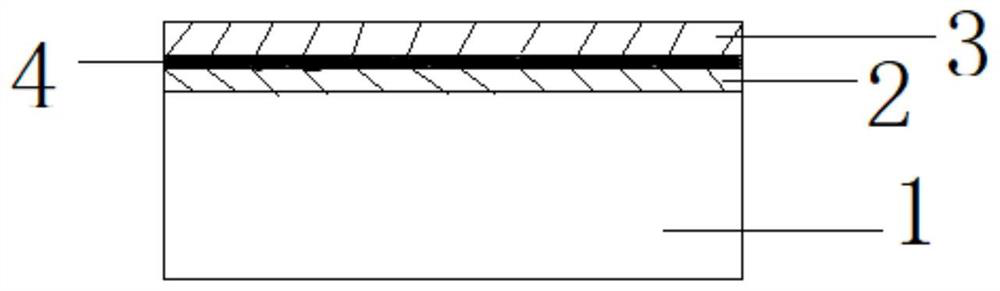

Coating for tungsten-copper alloy material and preparation method thereof

ActiveCN112662978AHigh bonding strengthImprove bindingMolten spray coatingPolyvinyl alcoholOxidation resistant

The invention discloses a coating for a tungsten-copper alloy material. The coating comprises a transition layer and an anti-oxidation layer formed on the surface of the alloy material in sequence, wherein the transition layer comprises the following raw materials in parts by weight: 15-20 parts of nano tin oxide, 10-15 parts of strontium fluoride, 0.1-0.5 part of tetrabutyl titanate and 1-5 parts of polyvinyl alcohol, and the anti-oxidation layer comprises the following raw materials in parts by weight: 10-20 parts of nano cerium oxide and 30-50 parts of silicon-barium-iron alloy powder. Two components of nano tin oxide and strontium fluoride are added into the transition layer so that the bonding strength of the transition layer is improved, and the porosity is reduced. The silicon-barium-iron alloy powder in the anti-oxidation layer reacts with oxygen in a high-temperature environment so that the alloy material is prevented from being oxidized at a high temperature, and the compactness of the anti-oxidation layer is improved through the nano cerium oxide. The invention further provides a preparation method of the coating for the tungsten-copper alloy material, the transition layer is prepared in a sintering mode, the anti-oxidation layer is sprayed to the surface of the transition layer through hypersonic flame, and it is guaranteed that the coating is uniformly distributed on the surface of the alloy material and does not easily crack or fall off.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Planting type food mixed adhesive for wood

ActiveCN109401670ANot easy to crack and fall offGuaranteed to be greenNon-macromolecular adhesive additivesStarch adhesivesCross-linkAdhesive

The invention discloses a planting type food mixed adhesive for wood. The planting type food mixed adhesive for the wood is prepared from the following raw materials in percentage by weight: 10%-30% of lotus root starch, 15%-35% of rice flour, 10%-25% of high gluten wheat flour, 10%-25% of germinant wheat powder, 3%-8% of soybean flour, 10%-20% of hydrated lime powder and 0.1%-1% of a cross-linking agent. The adhesive and a preparation method are unique, non-toxic and high in cohesiveness.

Owner:湖北志尚木业有限公司

Flat woven steel rope sling

ActiveCN103233379AStrong integrityNot easy to crack and fall offTextile cablesSteel ropeArchitectural engineering

The invention relates to a flat woven steel rope sling which is characterized by being formed by weaving a steel rope; the steel rope is wound between a fixed rod I and a fixed rod II that are arranged left and right; the steel rope wound on the fixed rod I forms two free ends of the steel rope; the two free ends of the steel rope are repeatedly crossed and knotted till the two free ends are woven on the left side of the fixed rod II; one free end of the steel rope bypasses the fixed rod II to be pulled back in the opposite direction; the two free ends of the steel rope are crossed and knotted oppositely again; residual rope heads at the two free ends of the steel rope are cut off, and the two free ends are wound with a rubber belt; the steel rope wound on the fixed rod I and the fixed rod II form garlands; the middle parts of the garlands are respectively clamped, and are rotated in clockwise direction, and two sides of the garland on one side are twisted leftwards and rightwards and are tightened by a tie wire. The flat woven steel rope tackle has the advantages that the sling is not easy to loose, the garlands are not easy to crack and fall, and the use effect and the service life are ensured.

Owner:JIANGYIN SUNCITY CABLES

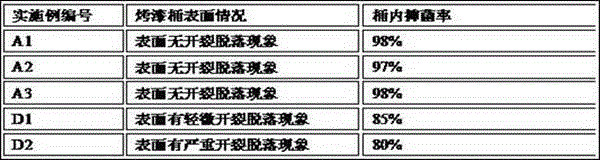

Anti-microbial stoving varnish cylinder and making method thereof

InactiveCN105885493ANot easy to breedNot easy to crack and fall offAntifouling/underwater paintsPaints with biocidesAcetic acidSurface layer

The invention discloses a method for making an anti-microbial stoving varnish cylinder. The method comprises the steps of obtaining a green cylinder body M through sheet iron cutting and welding; conducting acid pickling on the green cylinder body M by means of pickling solution, and drying the green cylinder body M for use; mixing and stirring nanometer iron trioxide, styrene, methyl acrylate, ethyl acetate and glycerinum to prepare anti-microbial anti-corrosion paint N, coating the surface of the green cylinder body M with the prepared anti-microbial anti-corrosion paint N evenly, and placing the green cylinder body M into a baking chamber to be baked to obtain the anti-microbial stoving varnish cylinder. The problems of a stoving varnish cylinder made with the traditional process that a stoving varnish surface layer falls off easily, and bacterium breeding occurs easily in the stoving varnish cylinder to affect the quality of materials in the cylinder are solved.

Owner:SUQIAN SANSHI PACKING CONTAINER

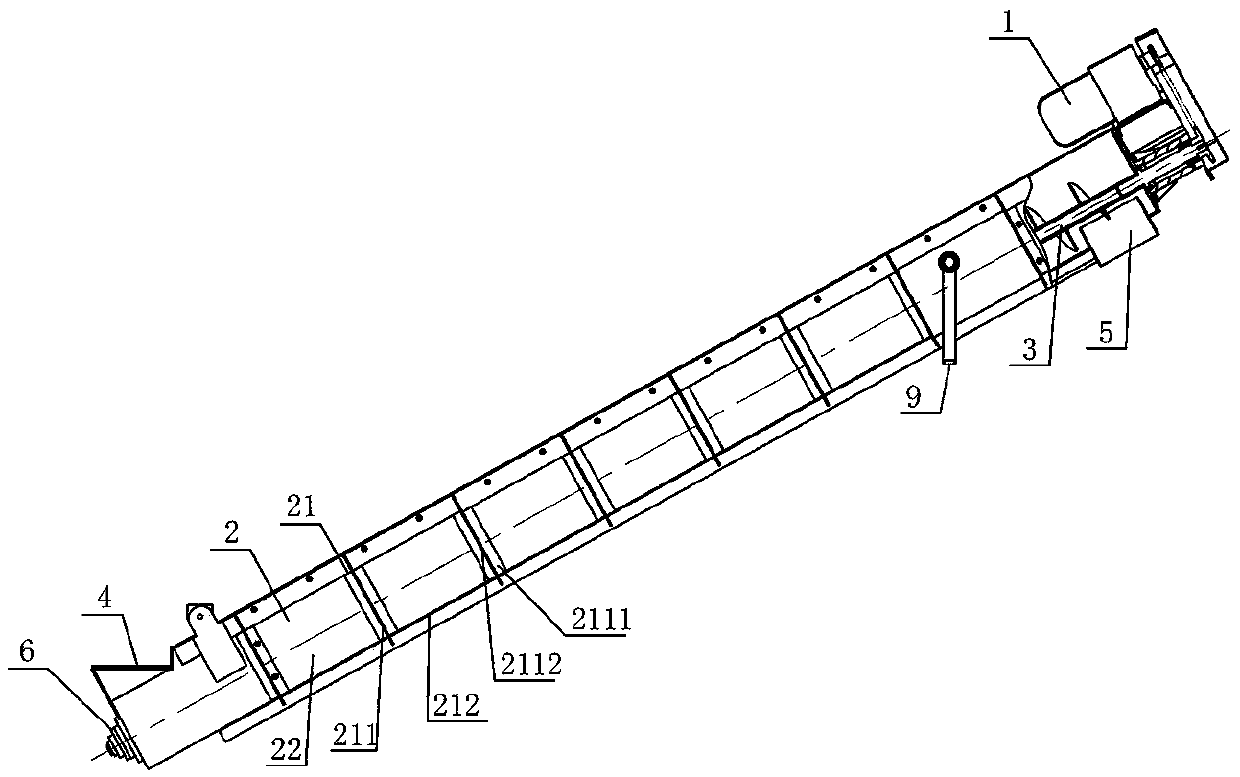

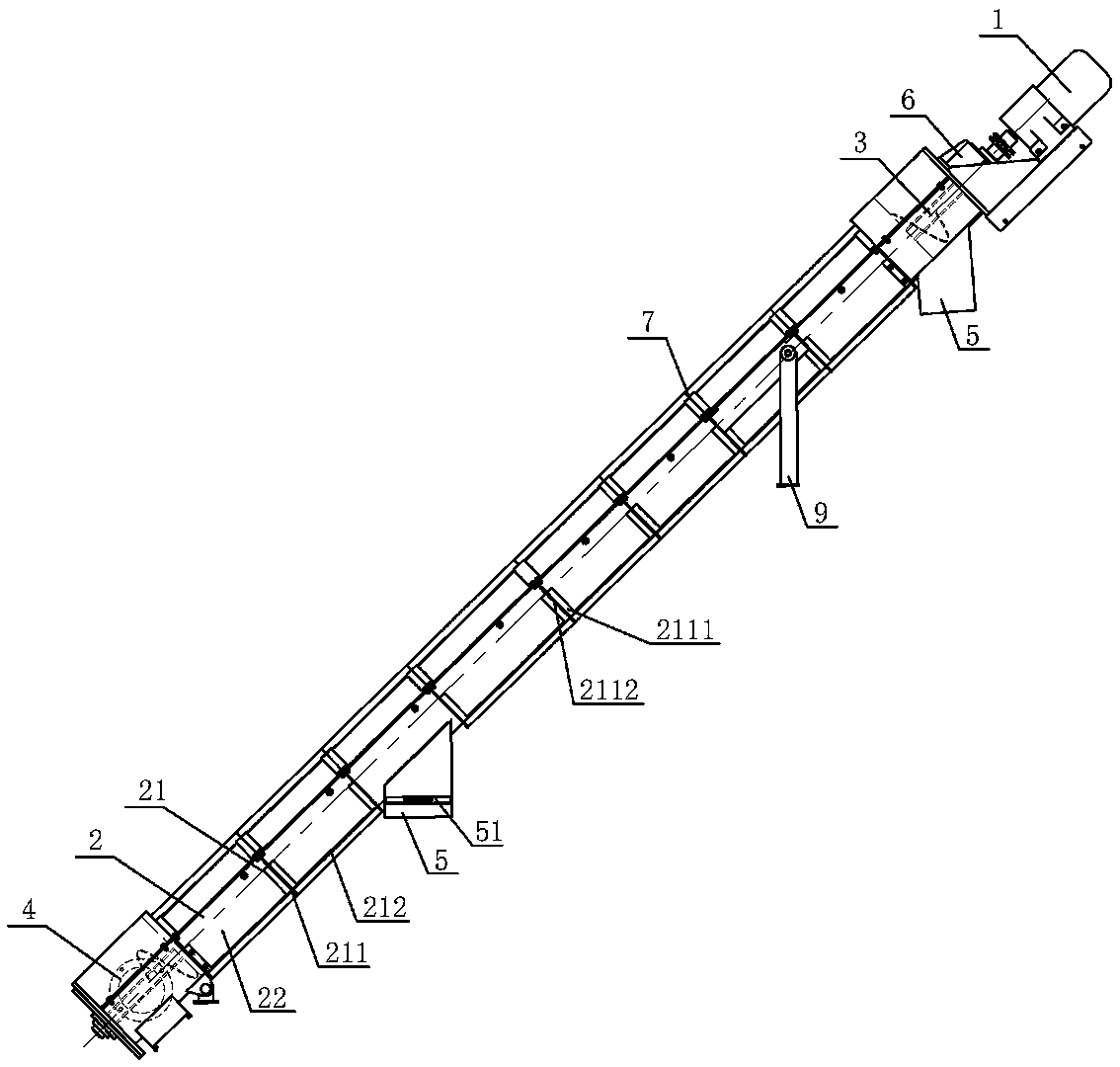

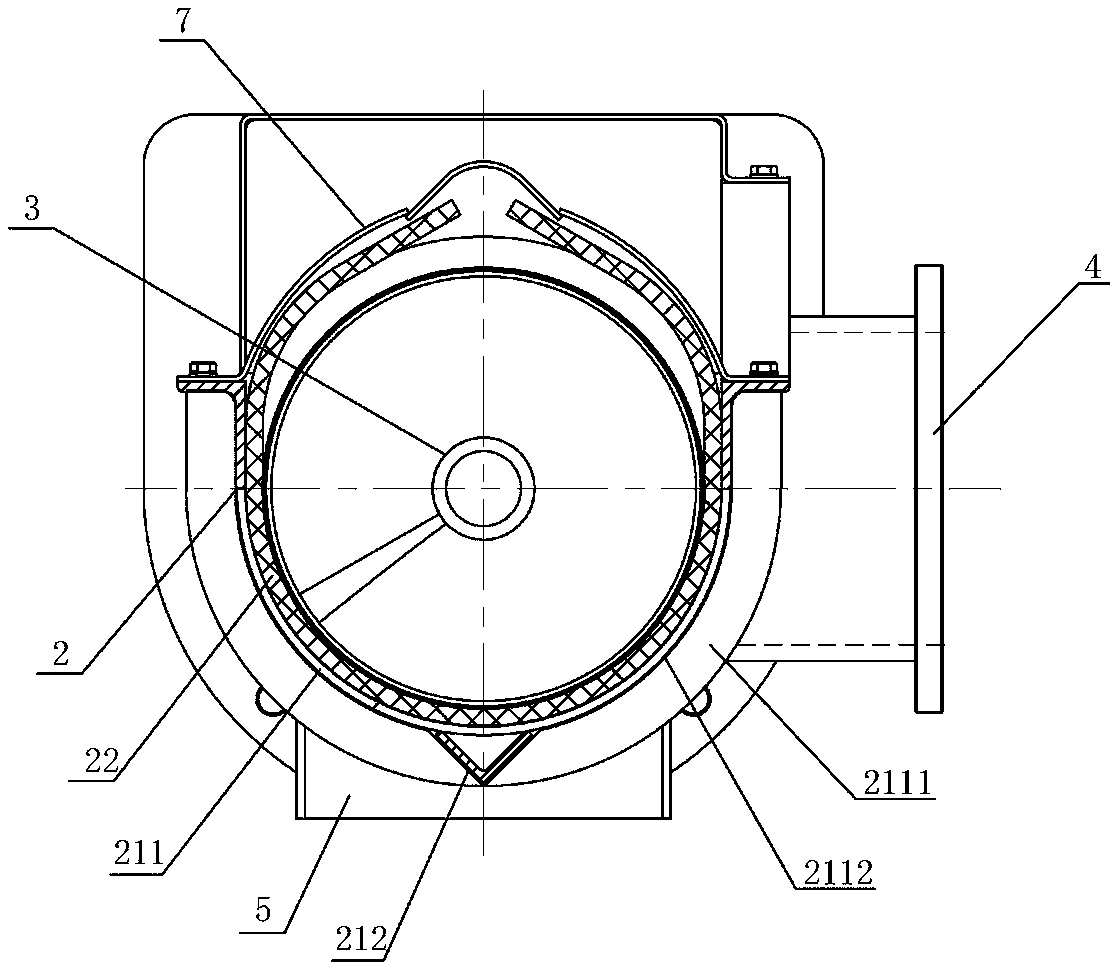

Anti-agglomerating screw conveyer

PendingCN110356787AClean up saves time and effortEasy maintenancePackagingWorking lifeSoft materials

The invention provides an anti-agglomerating screw conveyer. The anti-agglomerating screw conveyer comprises a speed reducing motor, a conveying cylinder, a screw conveying shaft, a feeding port, a discharging port and a screw bearing pedestal. On the basis of an existing screw conveyer, a semi-circular or circular-arc-shaped or U-shaped hollow skeleton is adopted to be connected and combined witha soft material plate, a semi-circular or oval or U-shaped soft conveying cylinder capable of achieving elastic bending is formed, the defects that the equipment load is large, halting is prone to occurring, equipment wear is fast, and the working life is short due to the fact that for an existing screw conveyer, agglomerating is prone to occurring, or cleaning is difficult after agglomerating occurs are overcome, the structure is skillful, the equipment manufacturing and maintaining cost is low, running is stable, no noise is generated, the working condition is stable, and the working efficiency is high.

Owner:GUANGXI LIYUANBAO SCI & TECH

Alkali efforescence resistant decorative plaster

InactiveCN107129229AExcellent anti-pan alkalinityGood wall hangingPolyvinyl alcoholCompressive strength

The invention discloses alkali efforescence resistant decorative plaster which is prepared from the following components in parts by weight: 50-60 parts of mixed sand, 5-7 parts of cement, 10-15 parts of coal gangue, 9-13 parts of basalt fibers, 3-4 parts of polyvinyl alcohol powder, 0.2-0.4 part of dipotassium sebacate, 0.1-0.3 part of N, N'-ethylenebisoleamide, 0.2-0.5 part of a water repellent and 0.04-0.06 part of an air entraining agent. The alkali efforescence resistant decorative plaster prepared according to the invention is excellent in alkali efforescence resistance, excellent in wall built-up property, excellent in processability and high in adhesive property with the wall, and is difficult to drop and fall and high in flexural and compressive strength in the using process. Moreover, the cheap coal gangue serves as one part of the raw materials, so that the production cost is reduced, and the problem that the environment is polluted by lots of coal gangue is solved.

Owner:安徽梦谷纤维材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com