Epoxy joint mixture and preparation method thereof

A technology of epoxy caulking agent and caulking agent, which is applied in the field of architectural decoration and caulking agent, and can solve the problems of discoloration, easy falling off and cracking, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

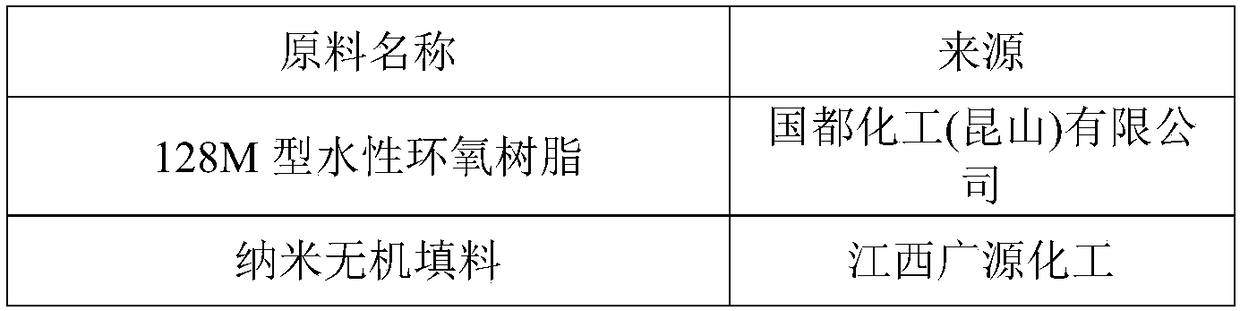

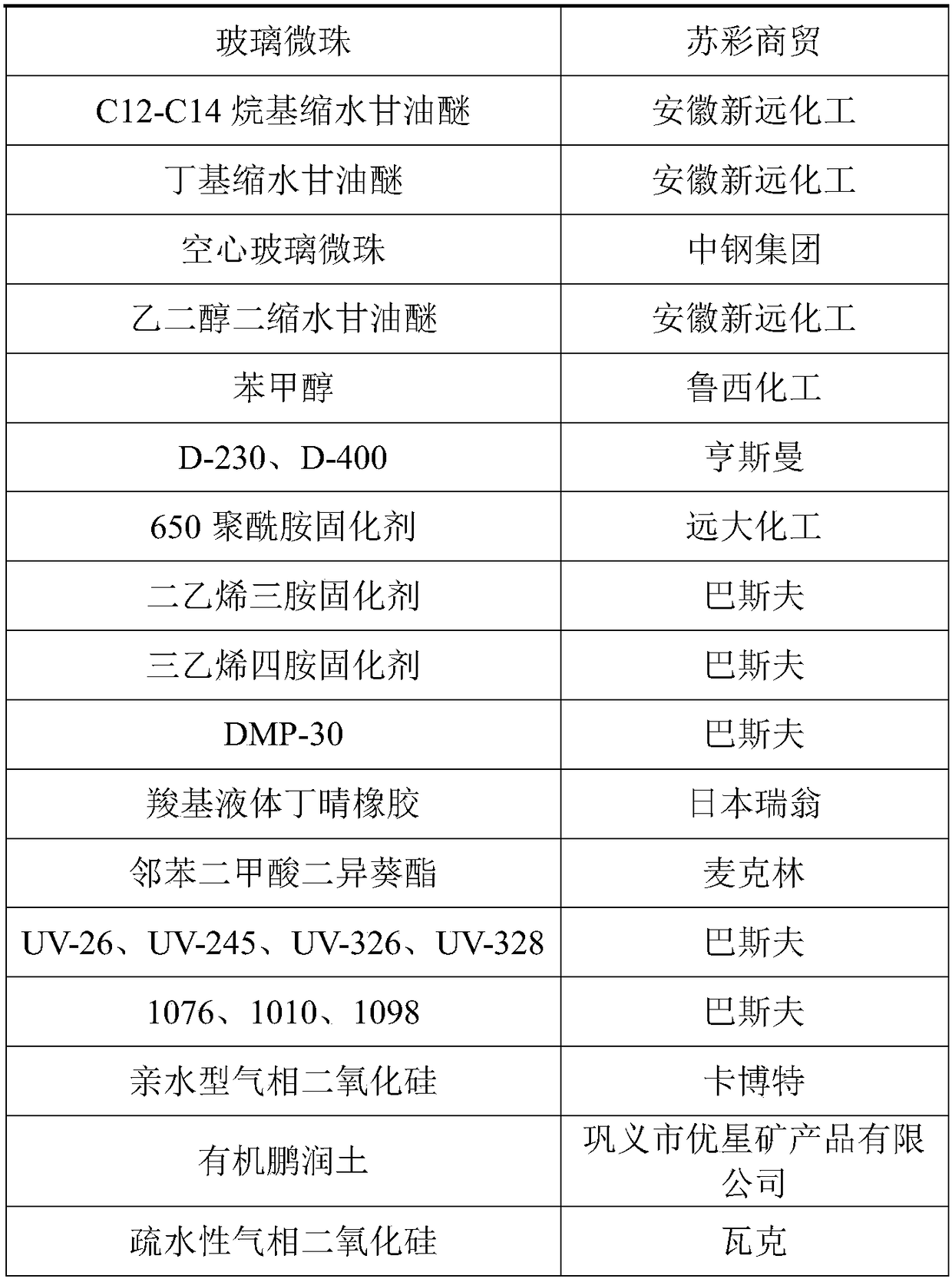

Method used

Image

Examples

preparation example 1

[0081] 2 parts by weight of polyhexamethylene biguanide hydrochloride with a viscosity average molecular weight of 800 (Shanghai Shande Industrial Co., Ltd., PHMB) was dissolved in 5.5 parts by weight of tetrahydrofuran at 40° C. to obtain a guanidine salt solution. 2.5 parts by weight of γ-glycidoxypropyltrimethoxysilane was dissolved in 3 parts by weight of tetrahydrofuran to obtain a silane solution. Add the two solutions into the reactor for mixing, then heat the mixture to 76°C, and stir for 3 hours; after the reaction, remove the solvent in the reaction mixture under reduced pressure to obtain liquid The silane coupling agent product, the viscosity (25 ℃, cps) is 1570.

Embodiment 1

[0083] A kind of epoxy caulking agent, this epoxy caulking agent comprises A component and B component, and wherein A component comprises: 128M type waterborne epoxy resin (Guodu Chemical Industry (Kunshan) Co., Ltd.) 35 parts by weight, nano sulfuric acid 10 parts by weight of barium, 8 parts by weight of nano silicon dioxide, 75 parts by weight of calcined glass microspheres, 6 parts by weight of ethylene glycol diglycidyl ether, 6 parts by weight of hollow glass microspheres; 2 parts by weight of carboxyl liquid nitrile rubber, UV -26 (BASF) 0.5 parts by weight, 1076 (BASF) 0.5 parts by weight, 2 parts by weight of a mixture of hydrophilic fumed silica and hydrophobic fumed silica; wherein: the glass microspheres are attached with inorganic pigments, glass microspheres The diameter of the beads is 200 mesh, and the specific gravity of the hollow glass microspheres is between 0.15-0.3.

[0084]Component B includes: D-400 (Hunsman) 60 parts by weight, 650 polyamide curing age...

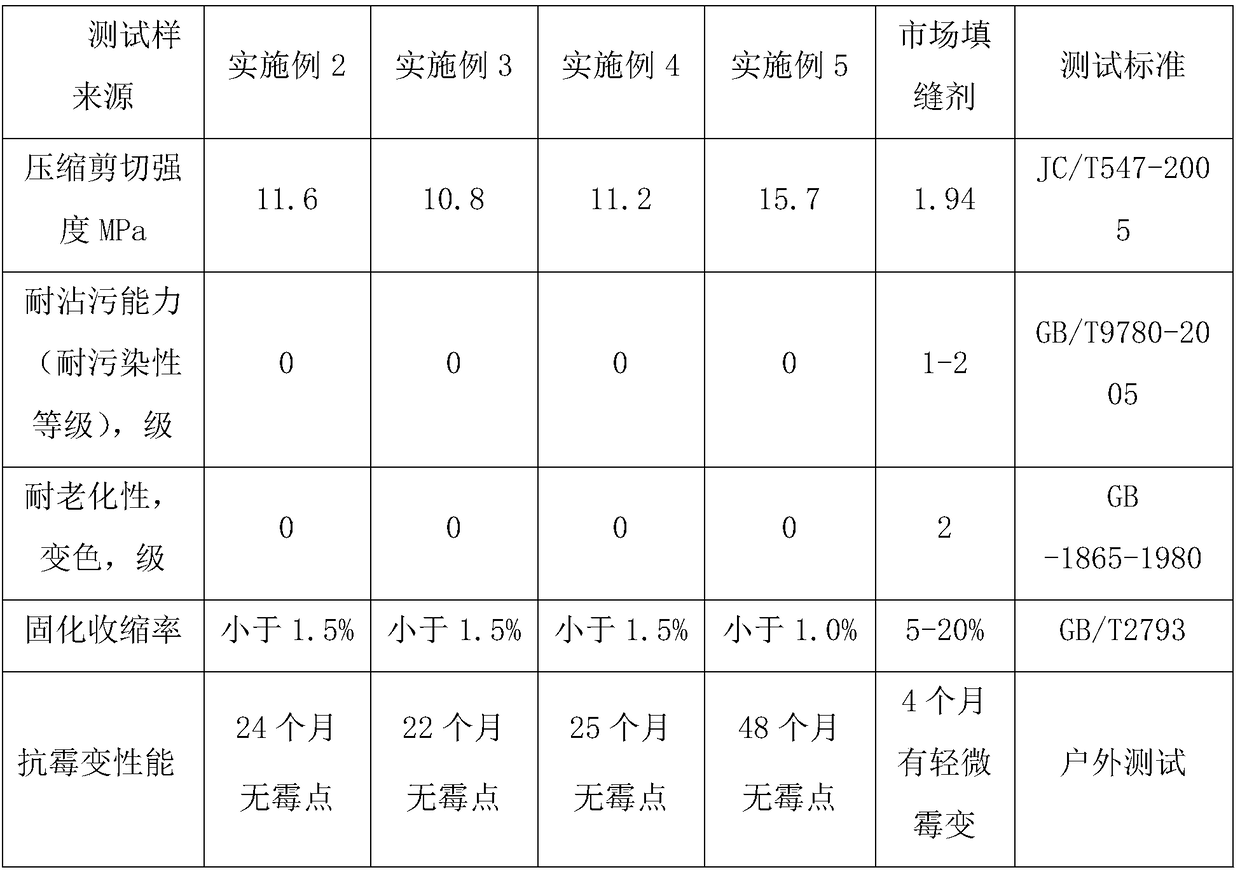

Embodiment 2

[0086] A preparation method of epoxy sealant, the method comprises the following steps:

[0087] (1) Preparation of component A: In the reaction kettle, add 40g 128M type water-based epoxy resin (Guodu Chemical Industry), 6g butyl glycidyl ether, 4g carboxyl liquid NBR, 1g UV-26, 1g 1076, and stir Uniformly, then add the mixture of 4g hydrophilic fumed silica and hydrophobic fumed silica, 24g nano-titanium dioxide, 120g calcined glass microspheres, stir again evenly, then add 6g hollow glass microspheres, continuously stir to obtain A Component;

[0088] (2) Preparation of component B: Mix 24g of bisphenol A epoxy resin (NPEL 127 from Nanya Company, viscosity (cps / 25°C) in the range of >6000 to <11000) and 20g of benzyl alcohol to obtain bisphenol A A mixture of type epoxy resin and benzyl alcohol; in the reactor, add 20g ethylene glycol diglycidyl ether and 80g D-230 (Hunsman), heat up to 55°C, react for a period of time, then add 40g 650 polyamide Curing agent, 40g diethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com