Anti-agglomerating screw conveyer

A screw conveyor and screw conveyor shaft technology, which is applied in the field of anti-caking screw conveyors, can solve problems such as difficult cleaning and easy caking, and achieve high production efficiency, avoid fatigue damage, and stable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

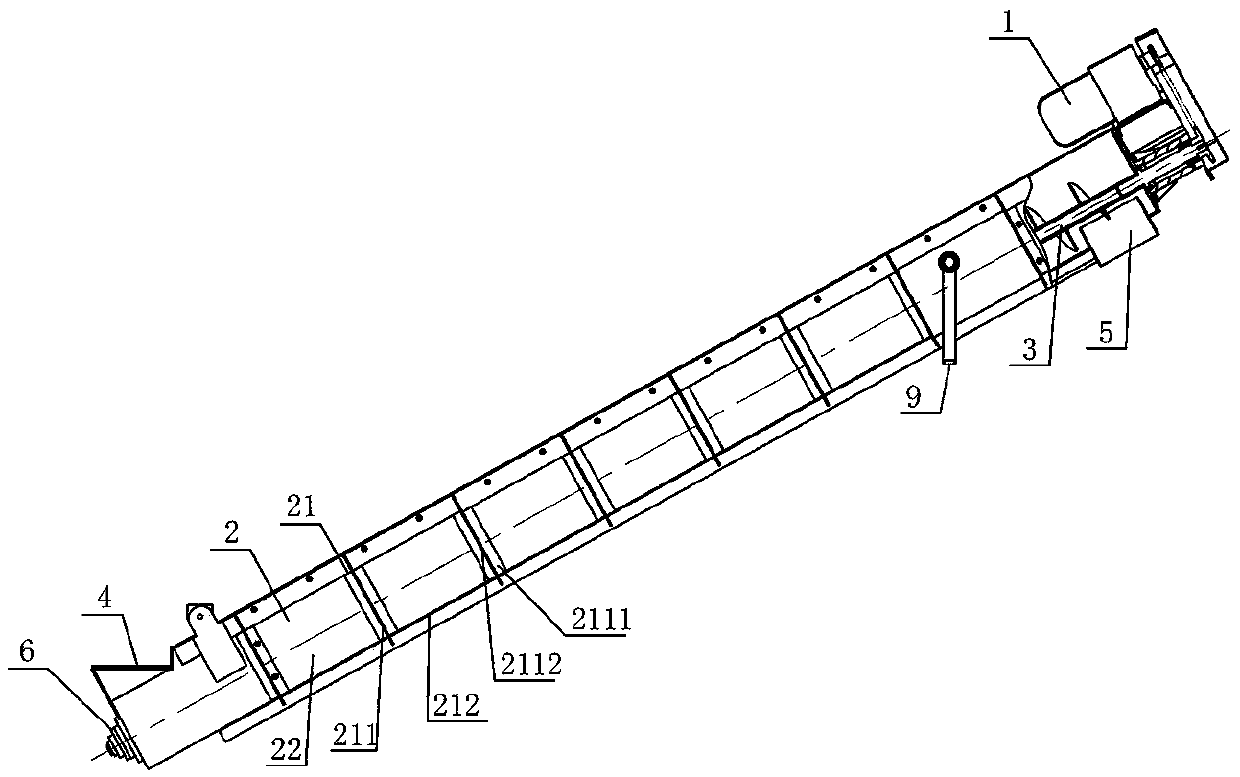

[0035] like figure 1 As shown, the anti-caking screw conveyor of the first embodiment of the present invention is mainly composed of a gear motor 1, a conveying cylinder 2, a screw conveying shaft 3, a feeding port 4, a discharging port 5, a screw bearing seat 6 and a mounting bracket 9. , wherein the reduction motor 1 is connected and installed at one end of the conveying cylinder 2, the screw conveying shaft 3 is connected and installed in the conveying cylinder 2 through the screw bearing seats 6 installed at both ends of the conveying cylinder 2, and the screw One end of the conveying shaft 3 is connected with the deceleration motor 1 for transmission, the feeding port 4 of the screw conveyor is arranged above the conveying cylinder 2, and the discharging port 5 is arranged on the conveying cylinder. 2 below.

[0036] The conveying cylinder 2 is formed by connecting and combining a U-shaped hollow frame 21 and a soft material plate 22; the soft material plate 22 is instal...

Embodiment 2

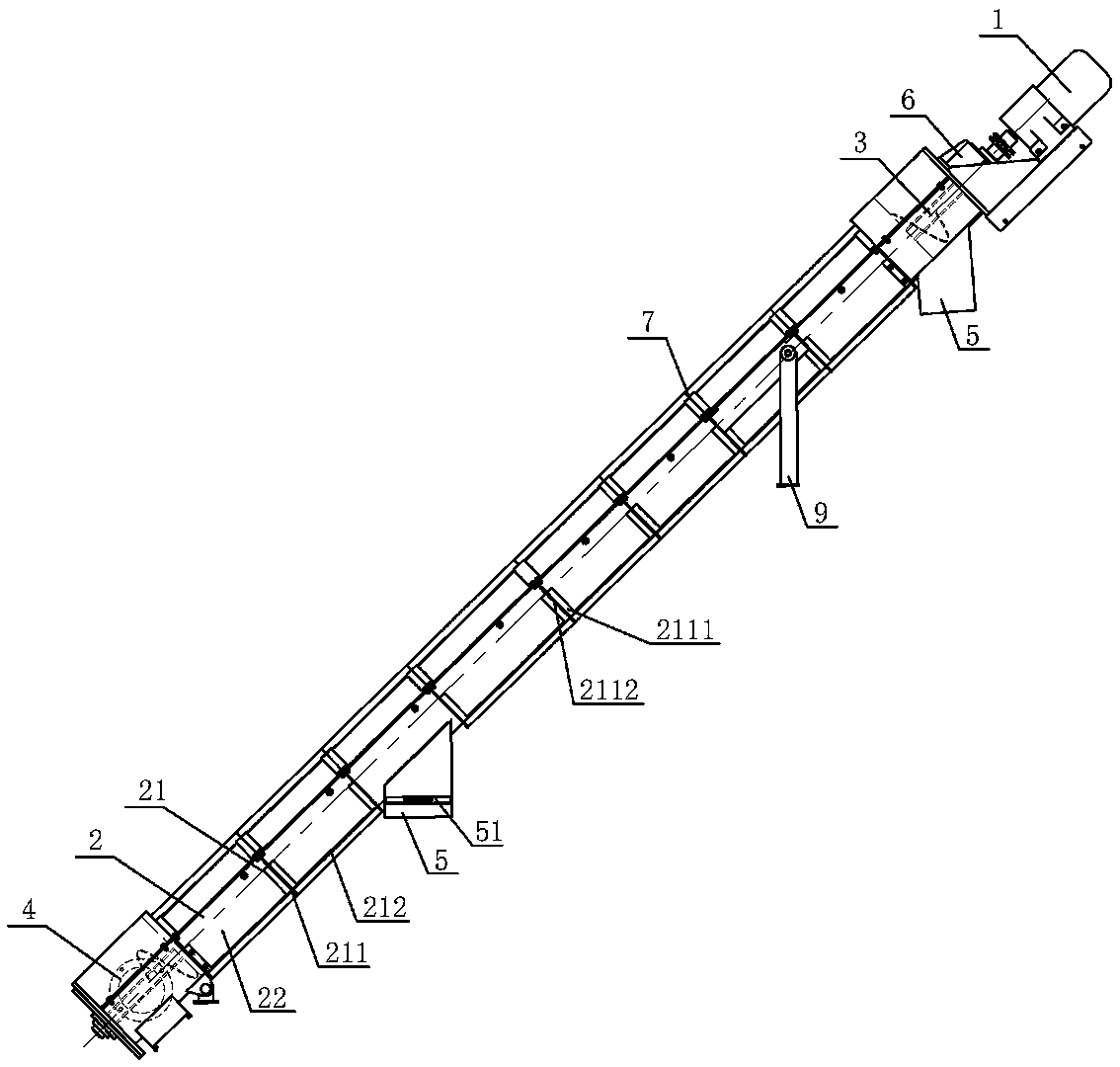

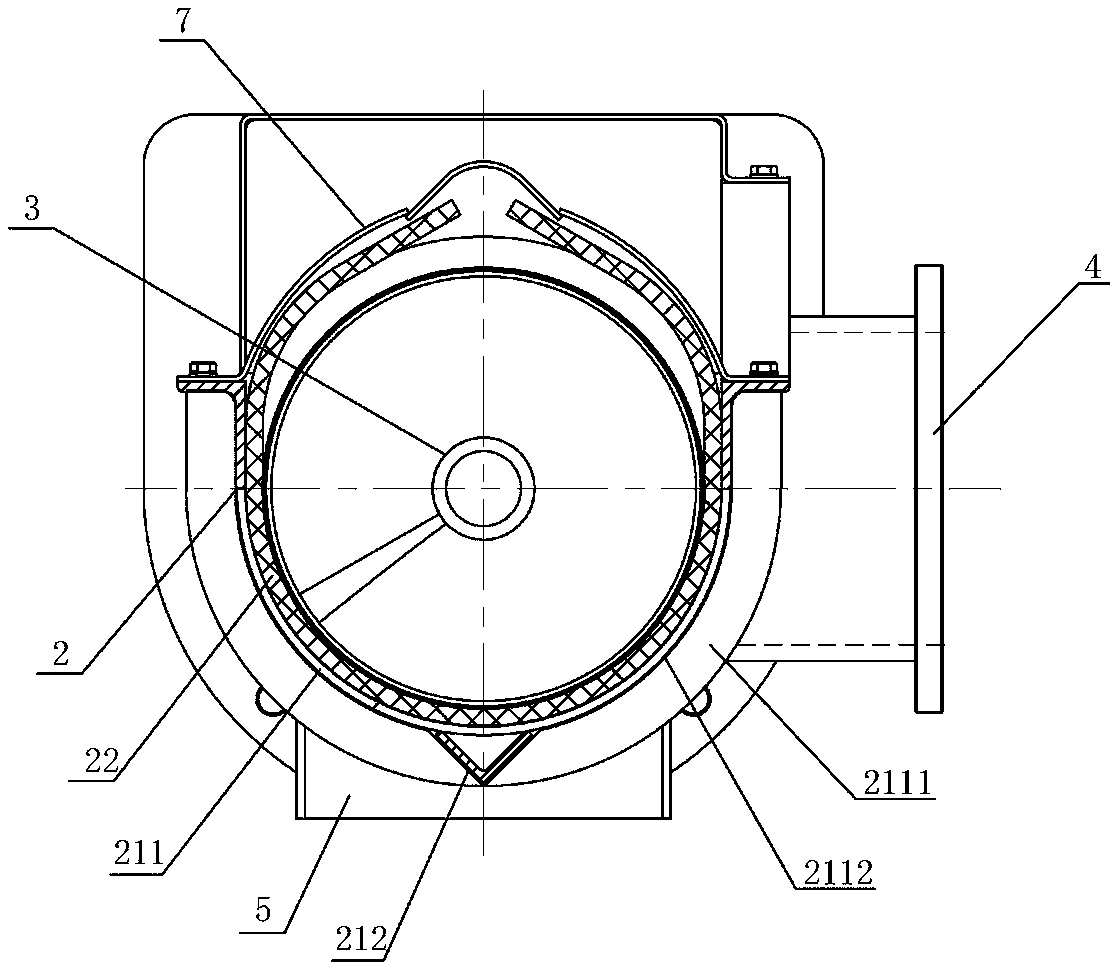

[0040] like figure 2 , image 3 As shown, the anti-caking screw conveyor of the second embodiment of the present invention is similar to that of the first embodiment, and the difference is only that:

[0041] The conveying cylinder 2 is formed by connecting a semi-circular hollow frame 21 and a soft material plate 22; the soft material plate 22 is connected and installed on the inner side of the semi-circular hollow frame 21 by means of countersunk screws. The cylinder body upper buckle 7 is provided; the cylinder body upper buckle 7 is arc-shaped, and is installed on the radial frame 212 of the hollow frame 21 above the conveying cylinder body 2 by screw connection, for withholding the soft material plate 22 is an oval-shaped soft conveying cylinder formed by bending inward; in order to facilitate disassembly and assembly, the upper buckle 7 of the cylinder is divided into a plurality of combined installations; the semicircular hollow frame 21 is composed of several axially a...

Embodiment 3

[0044] like Figure 4 , Figure 5 As shown, the anti-caking screw conveyor of the third embodiment of the present invention is similar to that of the first embodiment, and the difference is only that:

[0045] In order to make the screw conveyor realize the material distribution function of one-point feeding and multi-point discharging, one feeding port 4 is provided above the middle of the conveying cylinder 2, and four discharging ports 5 are provided. Two sides of the feeding port 4 are provided on each side, and the discharging port door 51 is installed under the discharging port 5 near both sides of the feeding port 4, and at the same time, the discharge port door 51 is installed for the mixed materials from the The feeding port 4 enters and discharges to the discharging ports 5 on both sides at the same time. The screw conveying shaft 3 is a combined shaft extending from the middle to both ends, and the directions of the screw blades on both sides are opposite.

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com