Chip removal device of lathe

A chip removal device, lathe technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment and other directions, can solve the problem of time-consuming and laborious cleaning, inability to clean up, etc., to achieve easy to manufacture, simple structure, easy to replace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

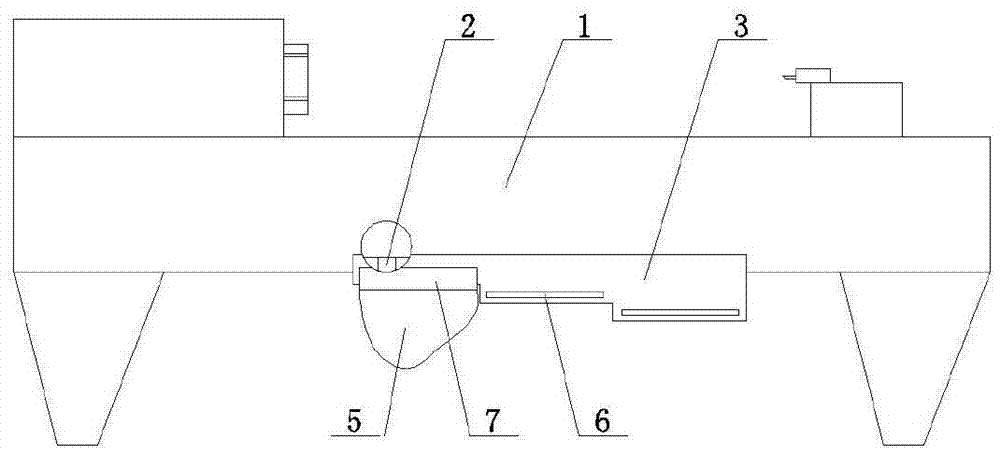

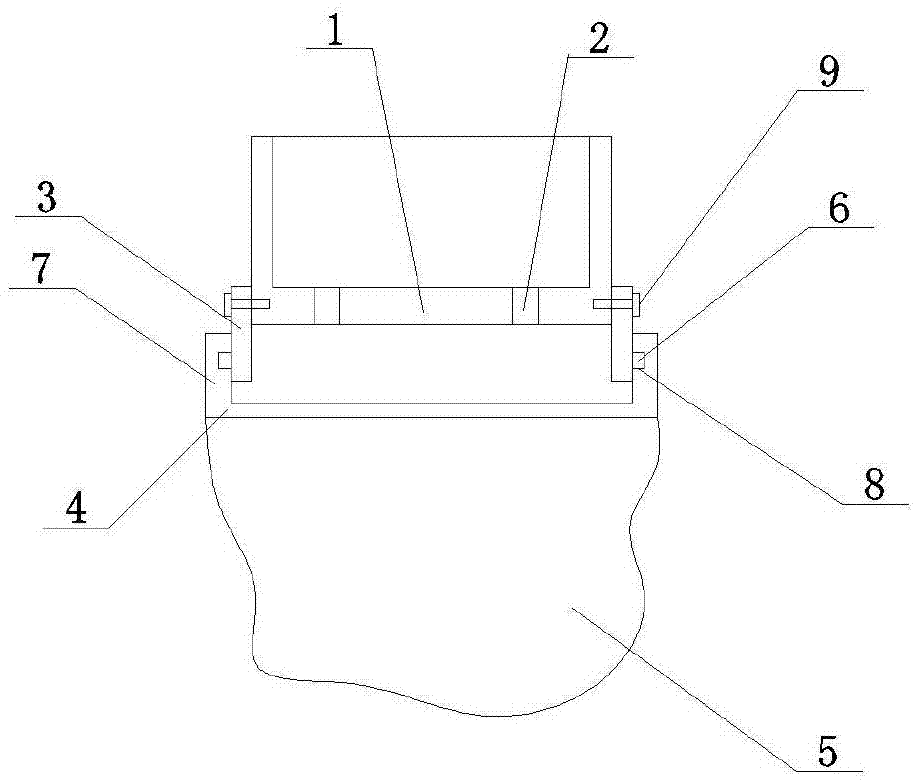

[0019] like figure 1 , 2 As shown, a chip removal device for a lathe, which includes: a lathe bed 1, at least two through holes 2 are provided on the bottom surface of the lathe bed 1, stepped plates 3 are respectively provided on both sides of the lathe bed 1, two steps A rectangular frame 4 is correspondingly provided below each step of the plate body 3, and a bag body 5 is provided on the lower side of the rectangular frame 4, and the through hole 2 corresponds to the bag body 5, and the further rectangular frame 4 and the stepped plate body 3 can be directly connected to each other. Disassemble the structure.

[0020] In a specific embodiment of the present invention, a plurality of slide bars 6 are provided along the longitudinal direction of the stepped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com