High-temperature oxidation-resistant thermal-insulation composite ceramic coating

A high-temperature anti-oxidation and ceramic coating technology, applied in the field of ceramic coatings, can solve the problems of high thermal conductivity, achieve high porosity, small thermal stress, and not easy to crack and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

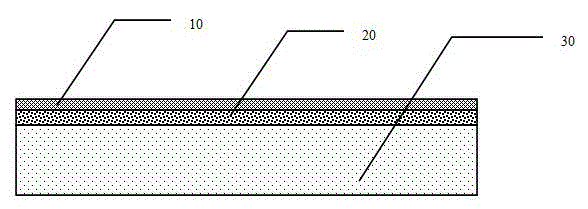

[0012] A high-temperature anti-oxidation heat-insulating composite ceramic coating, which is composed of a zirconium silicate coating, is characterized in that the ceramic coating is composed of two layers, the inner layer ceramic coating has a pore structure, and the outer layer coating is dense and free of holes, and The outer coating penetrates into the inner coating, the thickness of the inner coating is 200 μm, and the thickness of the outer coating is 100 μm. The holes are spherical structures, and the holes are connected with each other. The size of the pores is 1-10 μm, and the volume ratio of the pores to the inner coating is 50%. The penetration depth of the outer coating into the interior of the inner coating is 3 μm.

Embodiment 2

[0014] A high-temperature anti-oxidation heat-insulating composite ceramic coating is composed of an alumina coating and a mullite coating, the inner layer is an alumina ceramic coating, and the outer layer is a mullite coating. The inner ceramic coating has a porous structure, the outer coating is dense and has no pores, and the outer coating penetrates into the inner coating. The thickness of the inner coating is 100 μm, and the thickness of the outer coating is 50 μm. The hole structure is irregular, and the holes communicate with each other. The size of the pores is 1-10 μm, and the volume ratio of the pores to the inner coating is 40%. The penetration depth of the outer coating into the interior of the inner coating is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com