High temperature methanation reactor

A methanation reactor and reactor technology, applied in chemical instruments and methods, organic chemistry, hydrocarbon production from carbon oxides, etc., can solve the problems of cracking, falling off, and inapplicability of heat-resistant linings, and avoid potential safety hazards. , long service life, reducing the effect of over-temperature inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

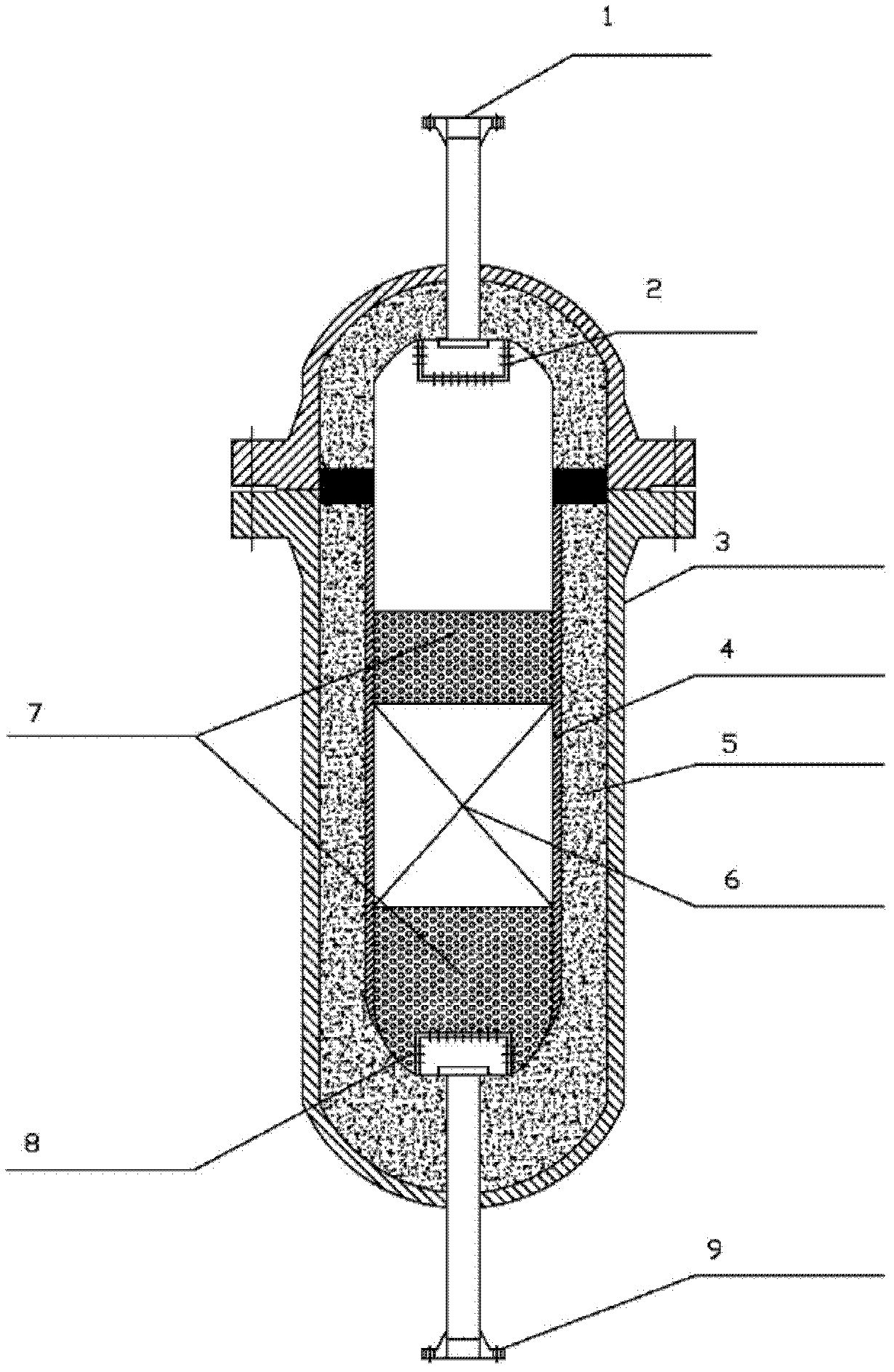

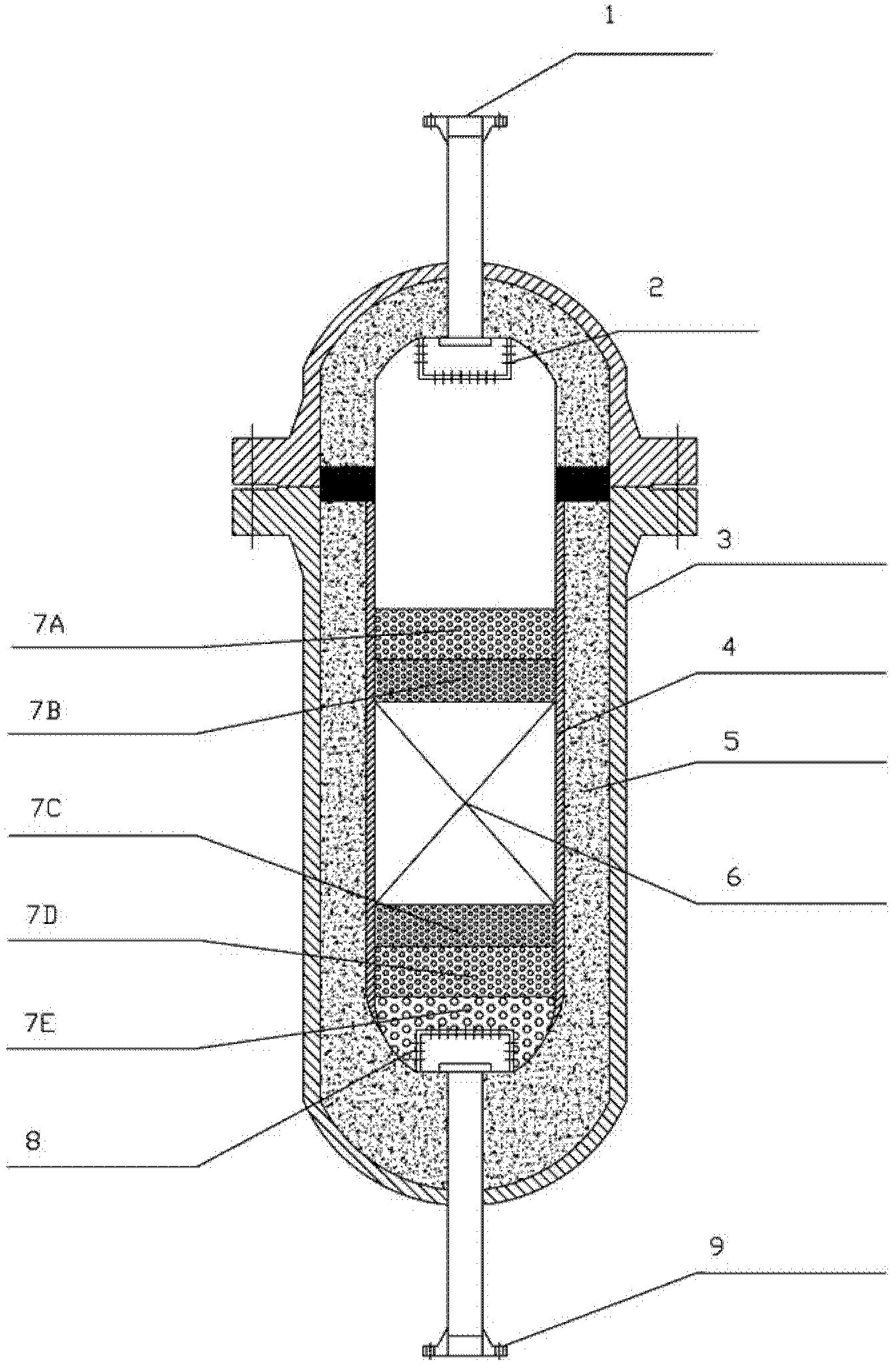

[0031] This embodiment adopts as figure 2 The high temperature methanation reactor shown performs the methanation reaction.

[0032] 1. The specific composition of the high temperature methanation reactor is as follows:

[0033] The material of the reactor outer cylinder (3) is 15MnVNR, and the thickness is 10 millimeters;

[0034] The material of cylinder (4) in the reactor is 0Cr19Ni13Mo3, and thickness is 5 millimeters;

[0035] The thickness of the jacket layer (5) is 280 mm, and the filled high-temperature refractory material is aluminum silicate;

[0036] The configuration of the gas distributor (2) is a divergent type with inclined upward nozzles;

[0037] The thickness of catalyst bed (6) is 500 millimeters;

[0038] The first inert packing (7A) between the gas distributor (2) and the catalyst bed (6) is alumina balls with a thickness of 30 mm and a particle size of 8 mm; the second inert packing (7B) is alumina balls , with a thickness of 20 mm and a particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com