Patents

Literature

58results about How to "Reduce the safety of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

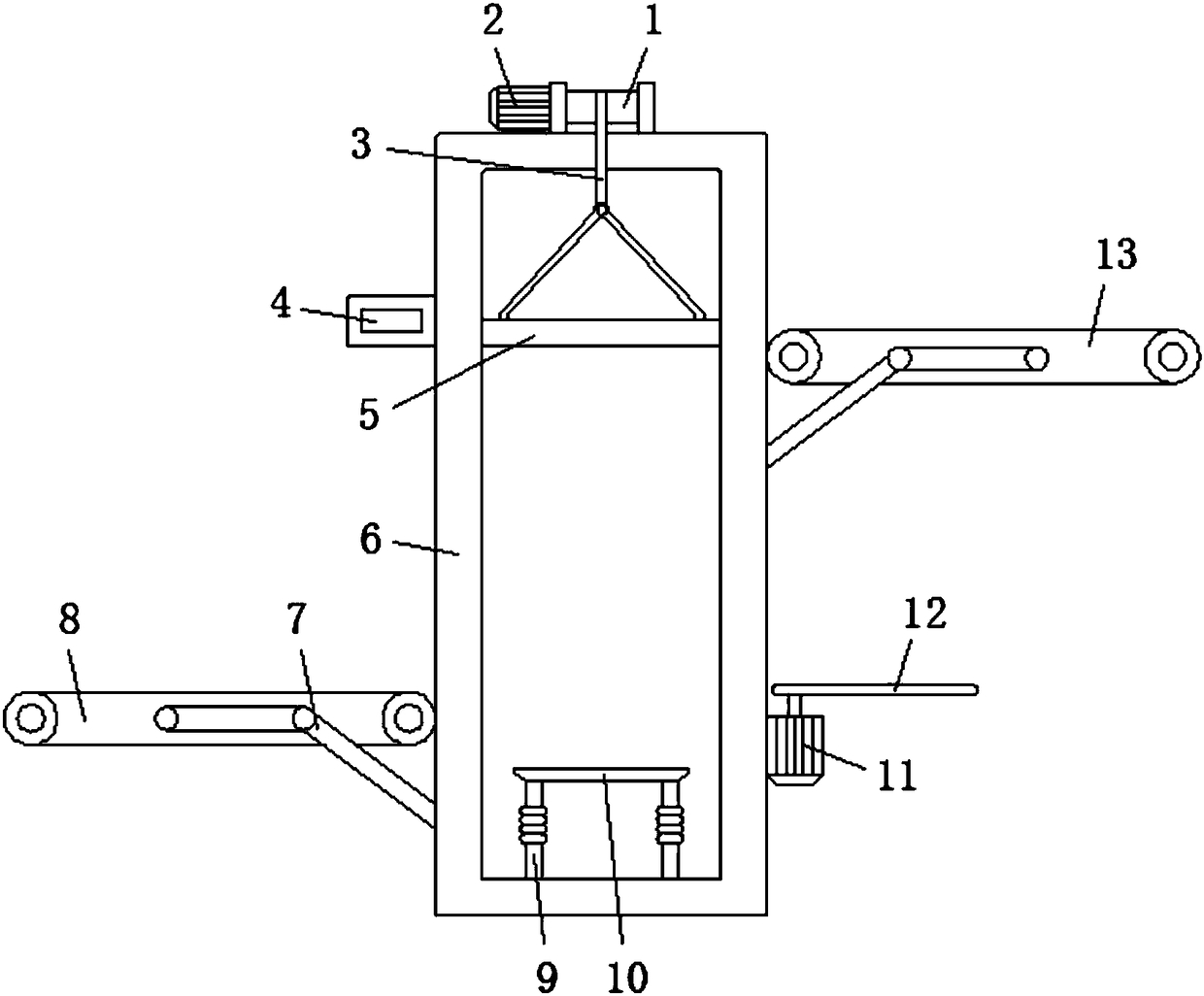

Lifting and carrying device for warehouse cargoes

InactiveCN108545392AImprove handling capacitySafe handling effectLifting framesStorage devicesEngineeringConveyor belt

The invention discloses a lifting and carrying device for warehouse cargoes. The lifting and carrying device for warehouse cargoes comprises a supporting rack, wherein a roll is fixed to the horizontal end of the top of the supporting rack through a bolt; one side of the roll is in transmission connection to a servo motor through an output shaft; the lower side of the roll is connected to a lifting plate on the inner surface wall of the supporting rack through a hinge by means of a steel rope; a driving air cylinder is fixed to the upper end of the outer surface wall on one side of the supporting rack through a bolt; the lower end of the outer surface wall on one side of the supporting rack is connected to a loading conveyor belt through a connecting rod; the upper end of the outer surfacewall on the other side of the supporting rack is connected to an unloading conveyor belt through a connecting rod; and a driving motor is fixed to the outer surface wall on the other side of the supporting rack through a bolt, and the upper side of the driving motor is in transmission connection to a hairbrush disc through an output shaft. The lifting and carrying device for warehouse cargoes disclosed by the invention is simple and reasonable in design of integral structure, flexible and convenient to operate and safe and stable to operate, achieves the quick and safe lifting and carrying effect of cargoes, and is of relatively high practicality.

Owner:ZHENGZHOU AOTUOKELAN MACHINERY EQUIP CO LTD

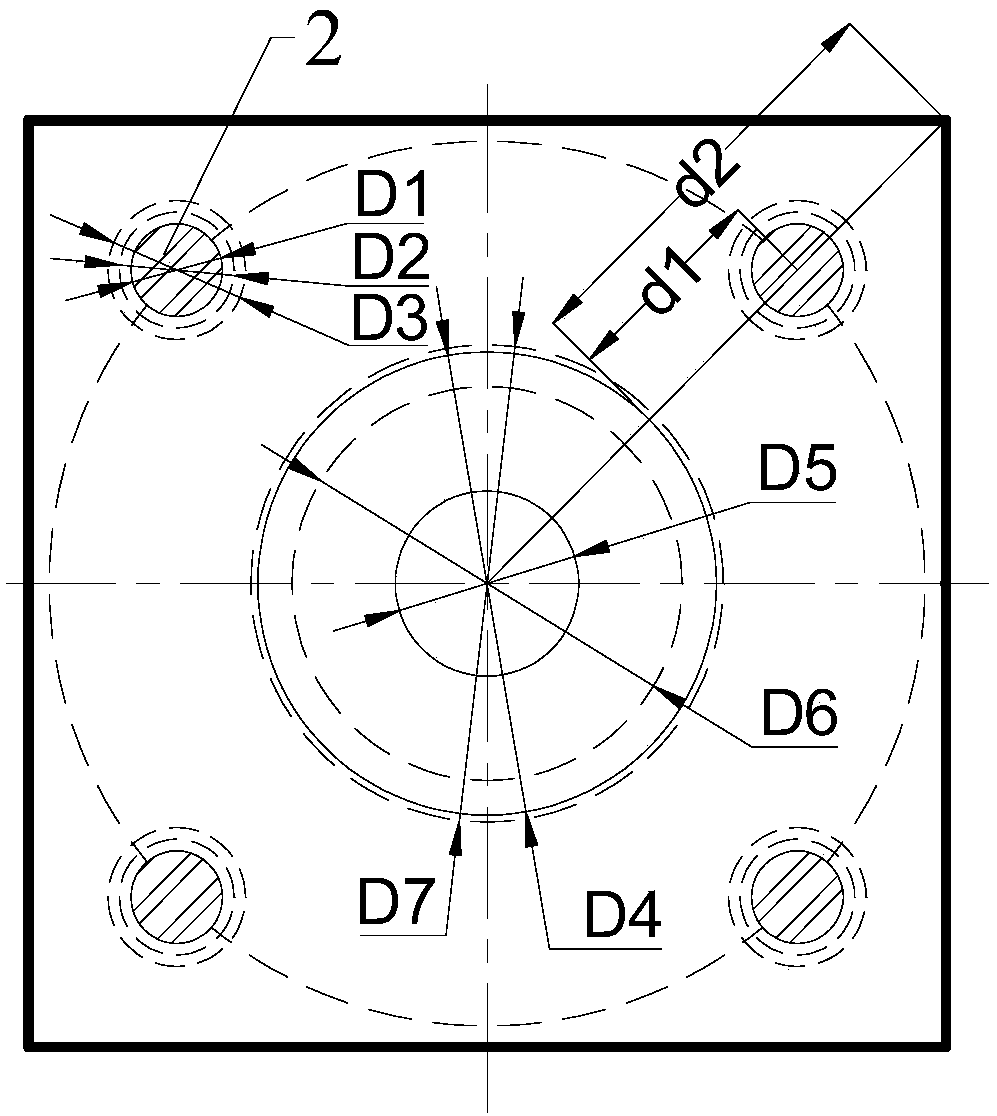

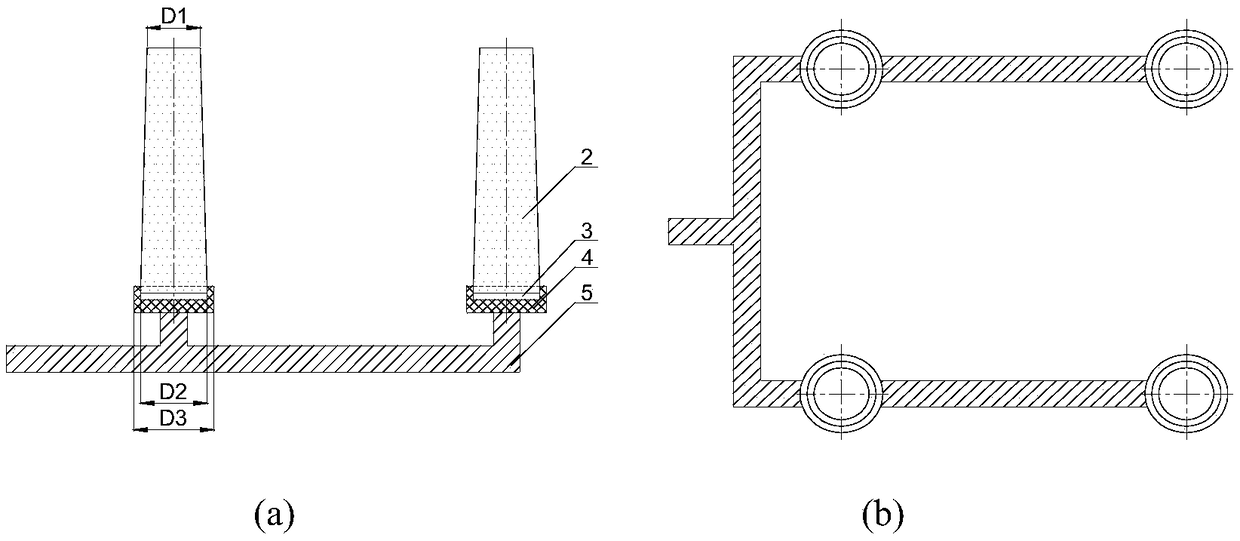

Steel ladle gas-breathable upper water gap seat brick and method for controlling steel ladle to unload slag by same

The invention discloses a steel ladle gas-breathable upper water gap seat brick and a method for controlling a steel ladle to unload slag by same. The steel ladle gas-breathable upper water gap seat brick comprises a steel ladle upper water gap seat brick body, a gas-breathable plug, a gas chamber box, a gas-breathable plug base, a gas-blowing pipeline, a runner hole and an upper water gap mounting hole. The control method comprises the following steps of: 1) putting the steel ladle upper water gap seat brick at a bottom tap hole of the steel ladle, and enabling the gas-blowing pipeline whichgets out from the steel ladle gas-breathable upper water gap seat brick to communicate with a gas path pipeline; 2) when a ratio of height of molten steel in the steel ladle to height of the steel ladle is 1 to (16-35), blowing inert gas into the molten steel through the gas-blowing pipeline, forming a circular concave region free of a slag layer on the surface of molten steel, and restraining steel ladle from unloading slag; and 3) when the steel ladle has slag unloading, closing a steel ladle water hole, and stopping blowing gas through the gas-blowing pipeline. According to the steel ladlegas-breathable upper water gap seat brick disclosed by the invention, argon gas is blown in at a last stage of casting, the circular convex region free of the slag layer is formed on the surface of molten steel, steel ladle slag unloading caused by conflux vortex and drainage sunken pits is effectively restrained, casting margin, which is reduced by 35% or more in comparison with existing castingmargin, of molten steel in the steel ladle is reduced.

Owner:NORTHEASTERN UNIV

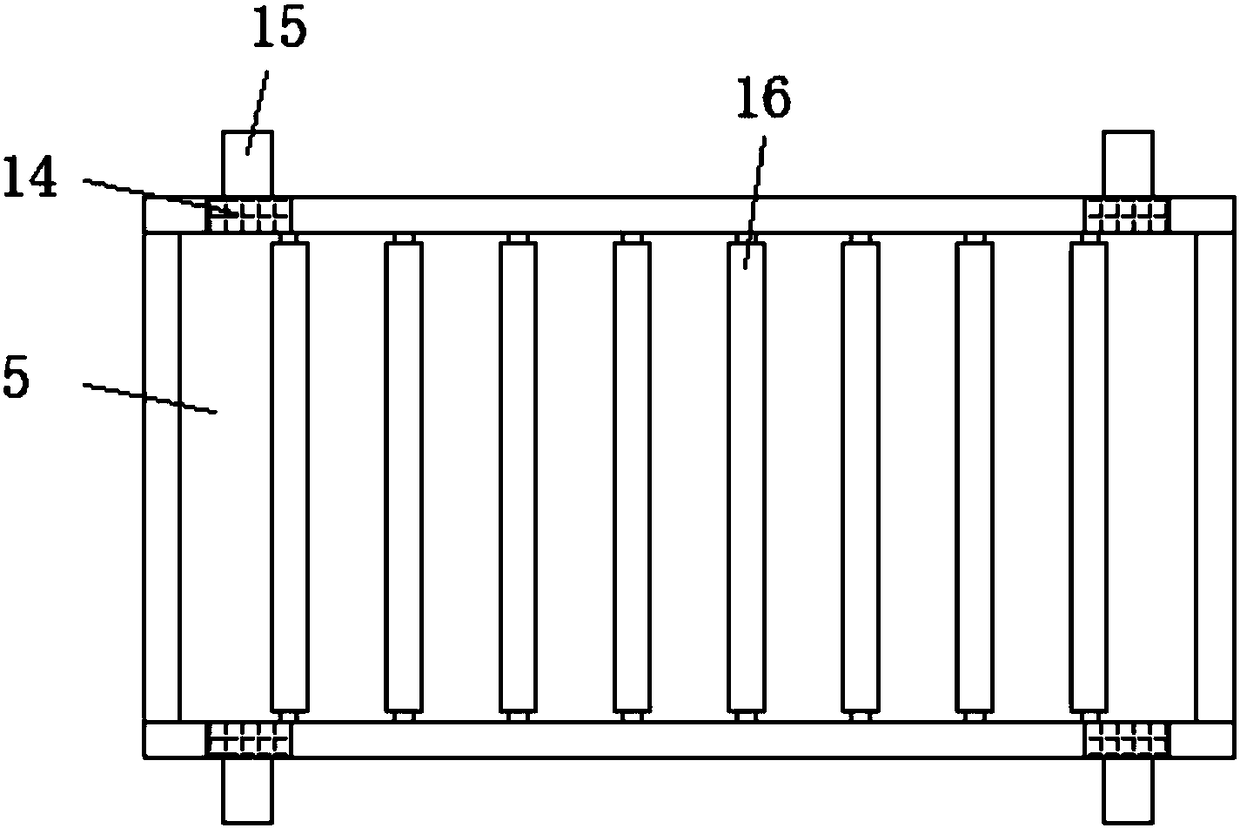

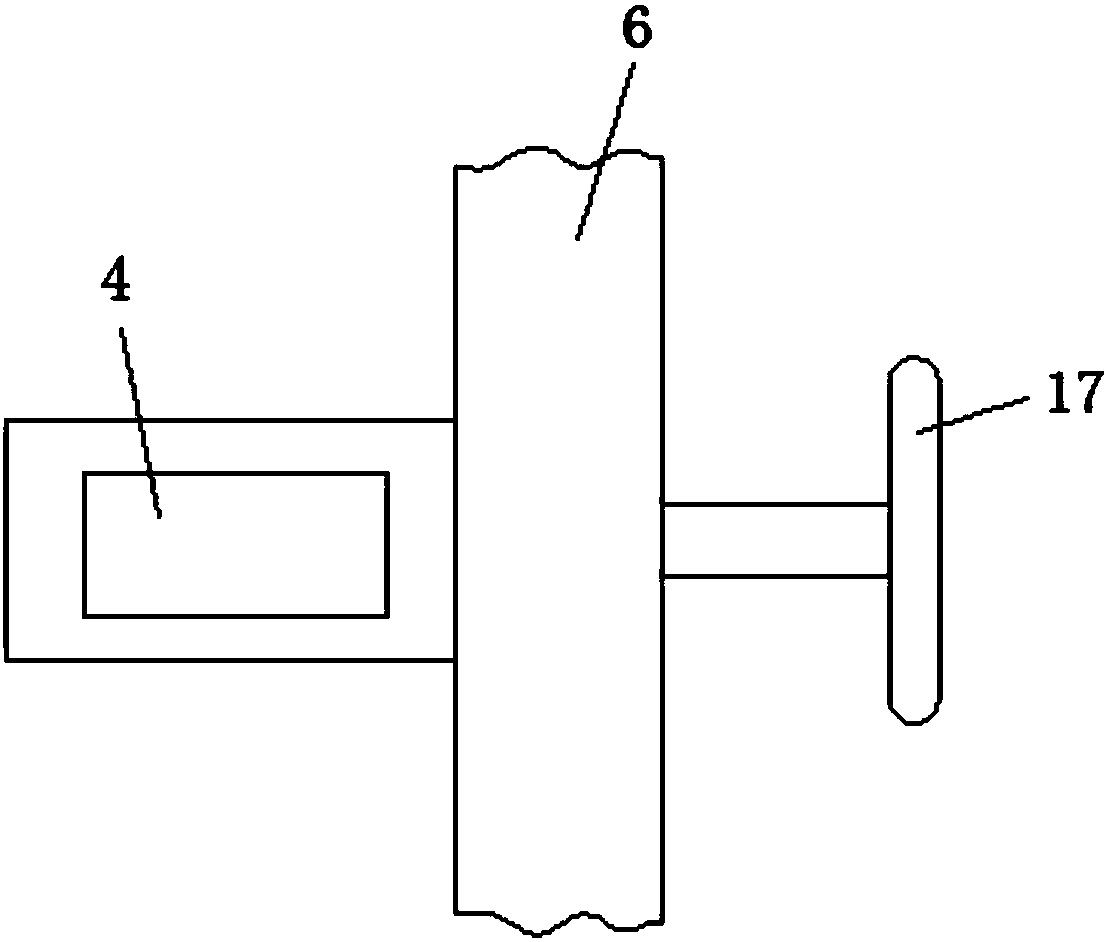

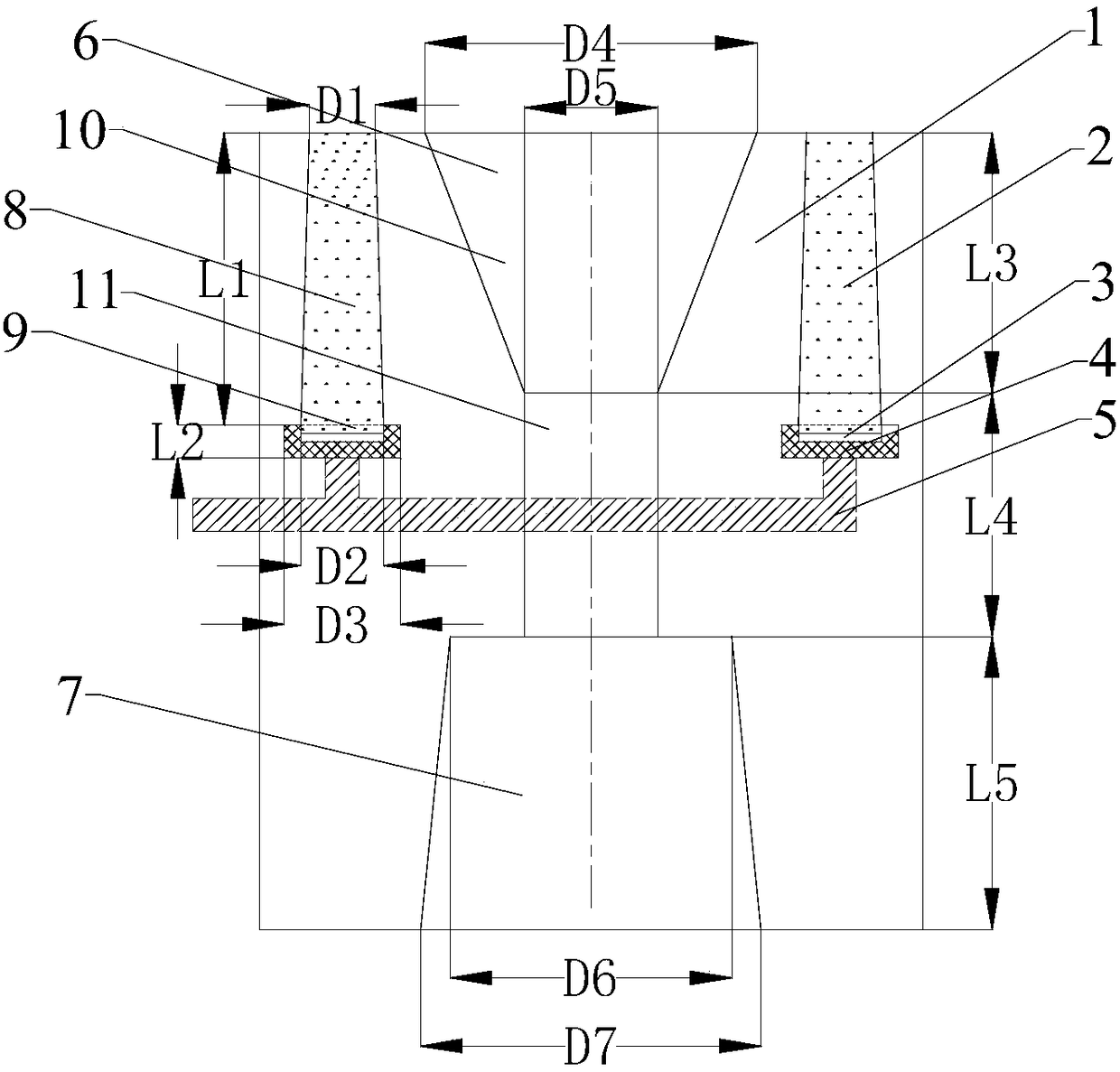

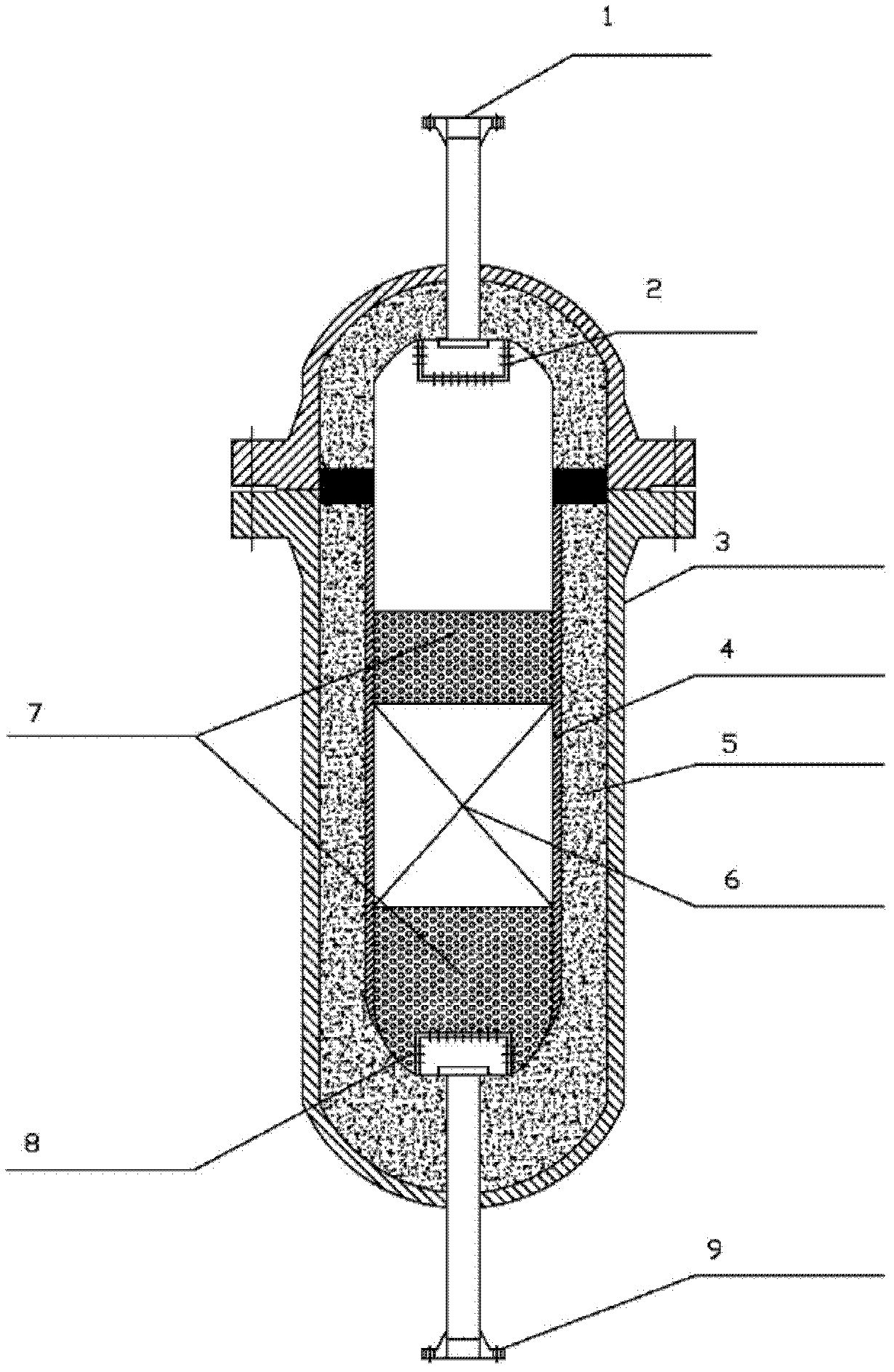

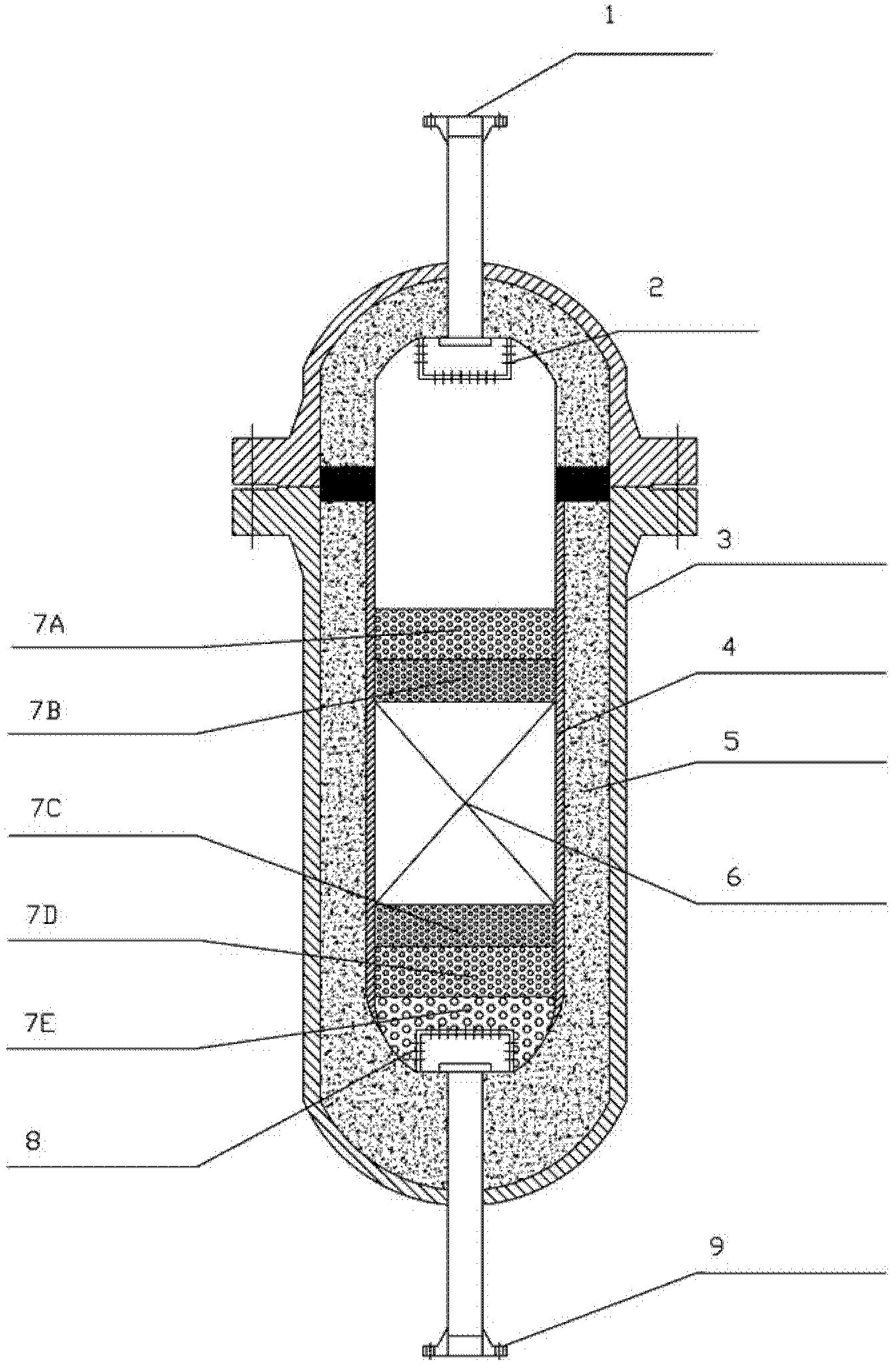

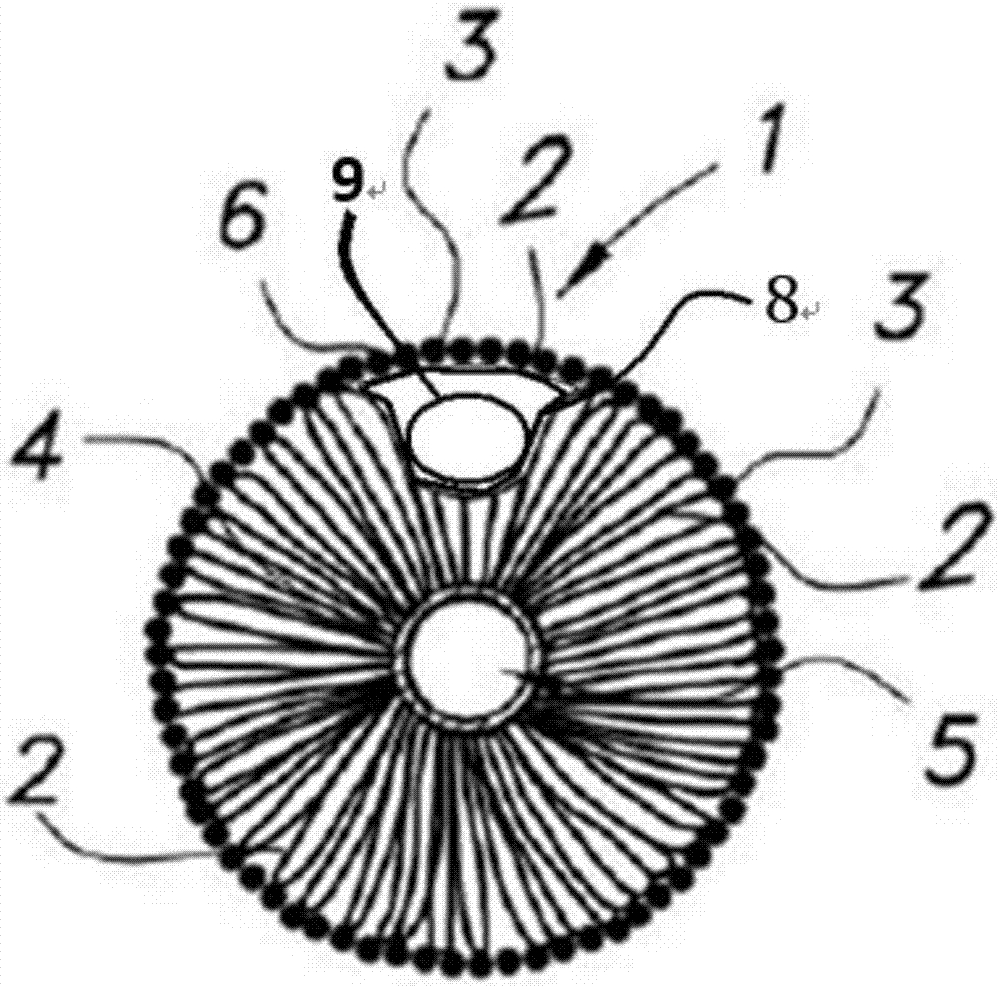

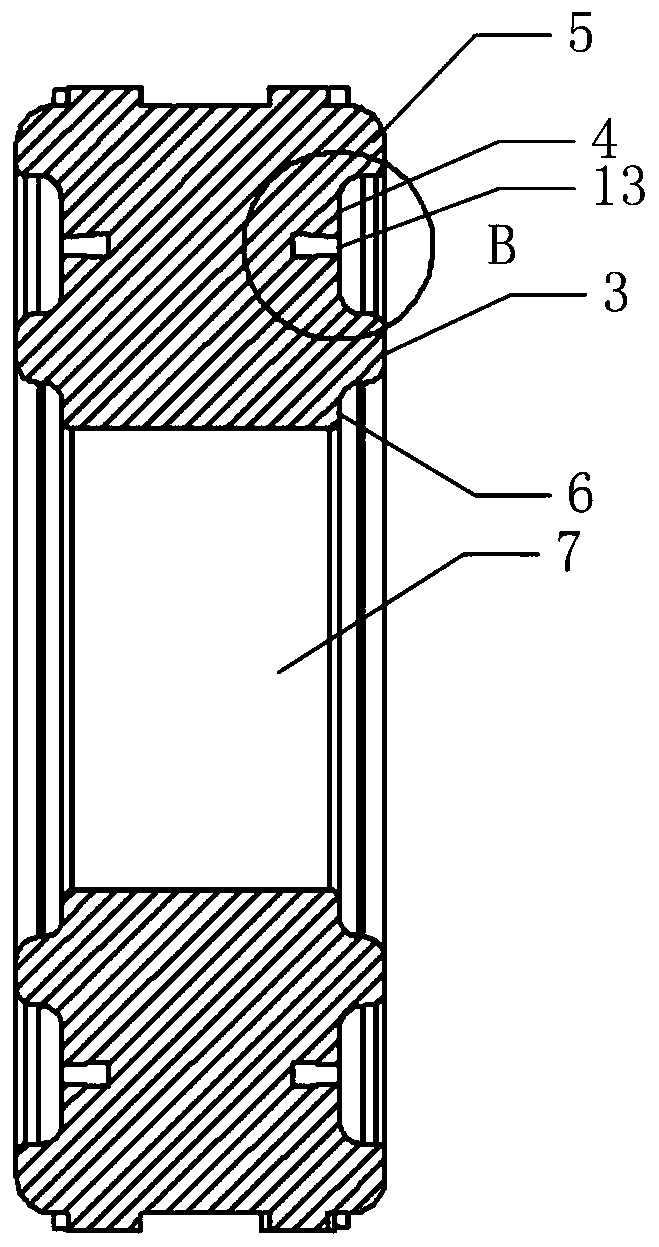

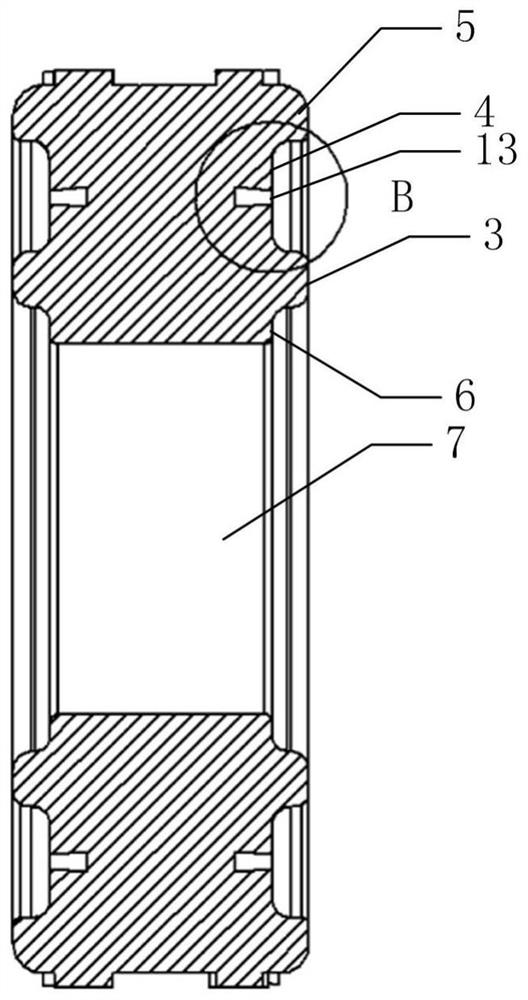

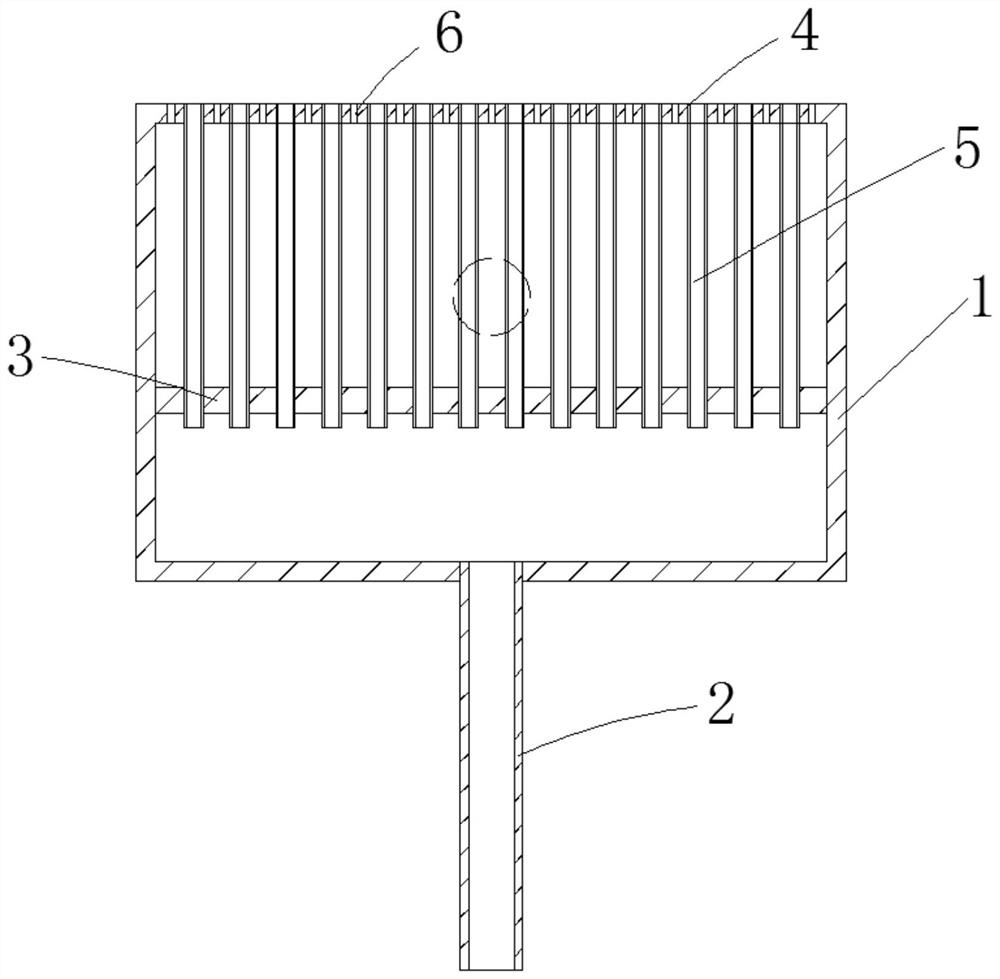

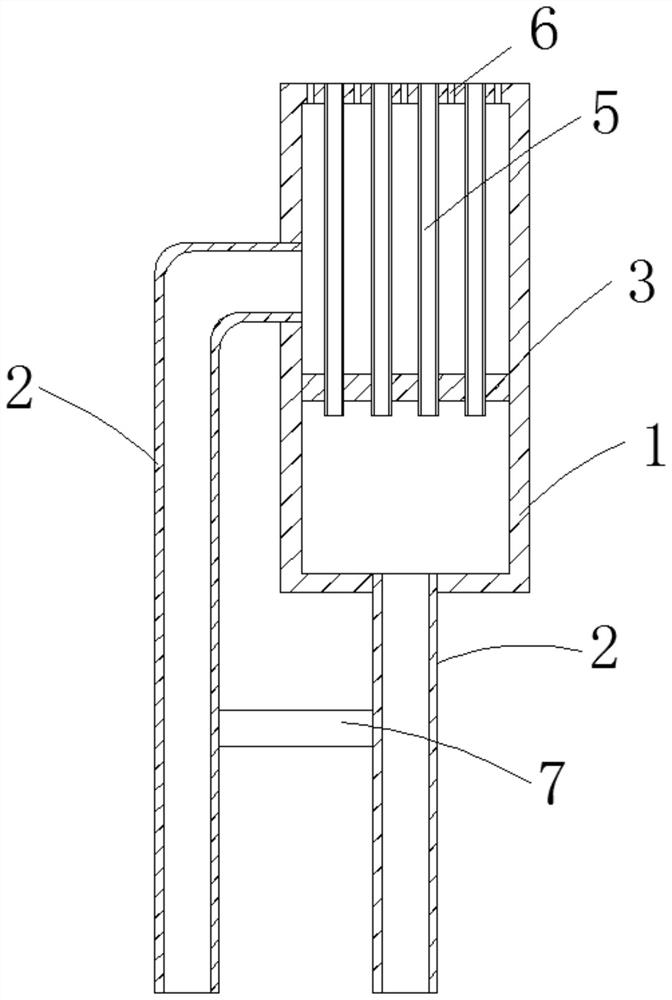

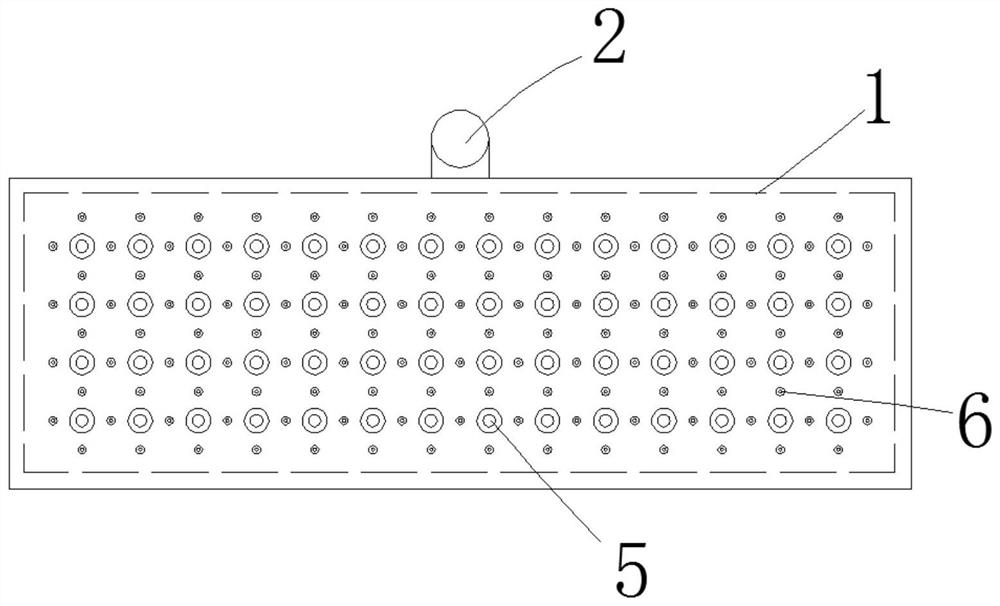

High temperature methanation reactor

InactiveCN103157408ANot easy to crack and fall offExtended service lifeHydrocarbon from carbon oxidesChemical/physical processesProcess engineeringThermal shock

The invention provides a high temperature methanation reactor, which comprises a reactor cylindrical body. The reactor cylindrical body includes a reactor external cylindrical body (3), a reactor internal cylindrical body (4) and a jacket layer (5) between the internal and external cylindrical bodies. The upper part of the reactor cylindrical body is provided with a reaction gas inlet (1) and a gas distributor (2), and the lower part is equipped with a gas collector (8) and a reaction gas outlet (9). The jacket layer (5) is filled with a high temperature refractory material. The reactor cylindrical body is loaded with a catalyst bed (6) inside. An inert filler (7) fills the space between the gas distributor (2) and the catalyst bed (6) and the space between the catalyst bed (6) and the gas collector (8). The reactor internal cylindrical body (4) of the reactor provided in the invention is a high temperature resistant stainless steel material, and is hard to crack and come off under a thermal shock, thus avoiding local clogging of the catalyst bed. The reactor is also provided with the gas distributor, the gas collector and the inert filler, so that a feed gas can pass the catalyst bed uniformly, and the product gas can leave the reactor uniformly.

Owner:DATANG INT CHEM TECH RESINST +1

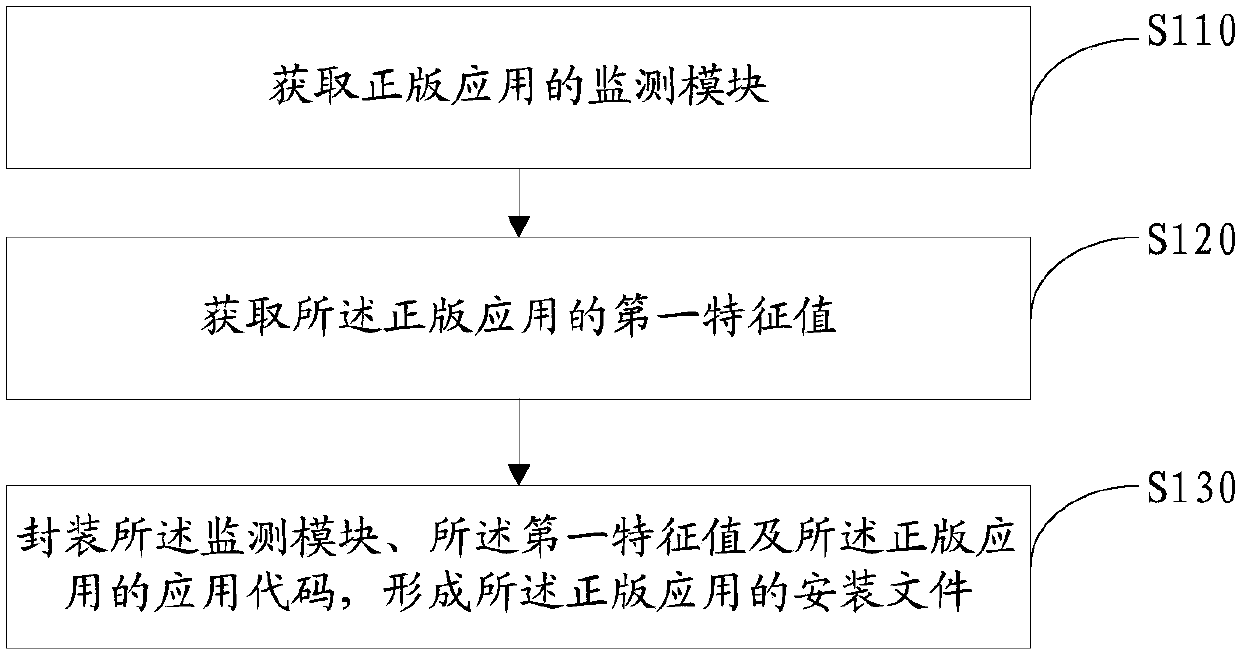

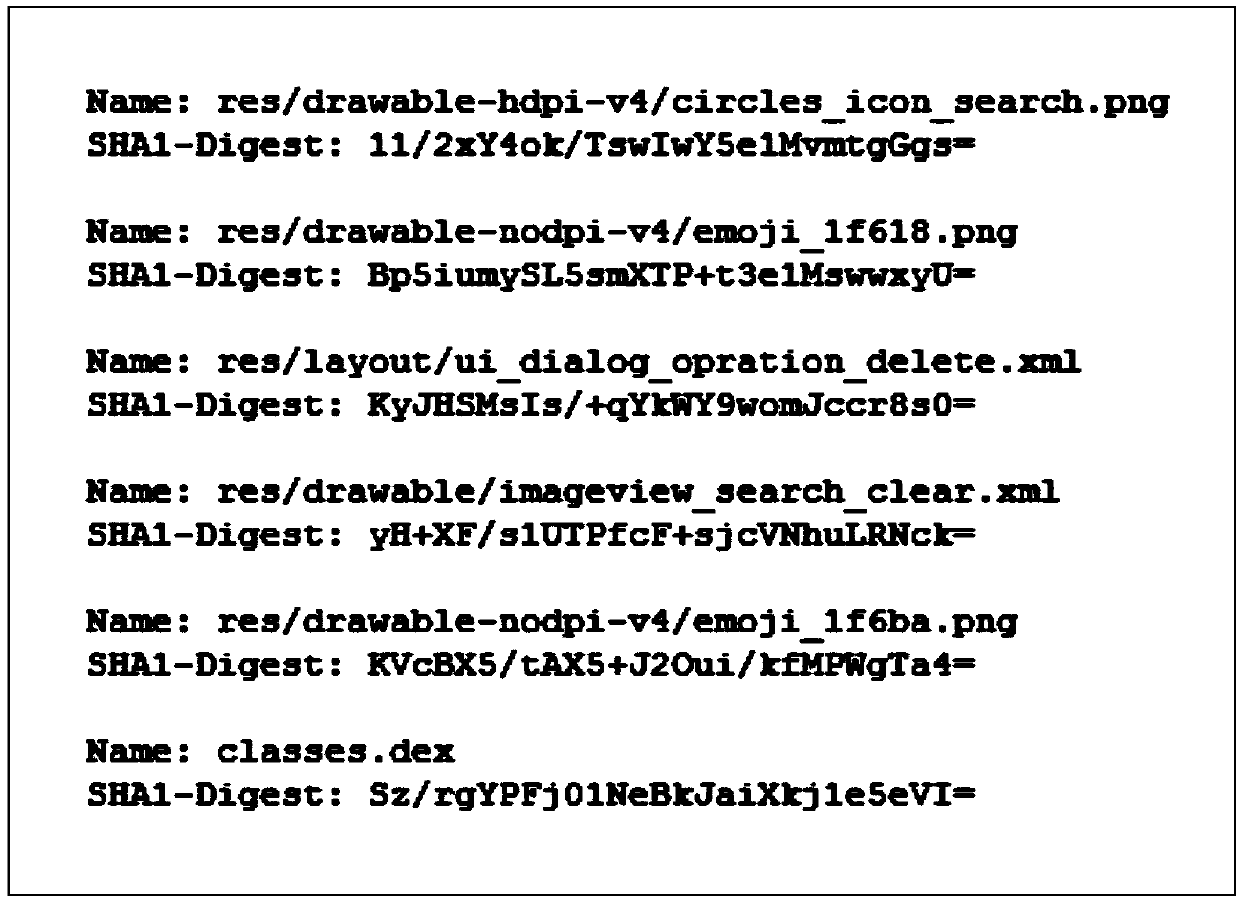

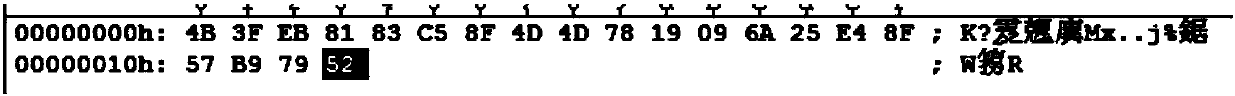

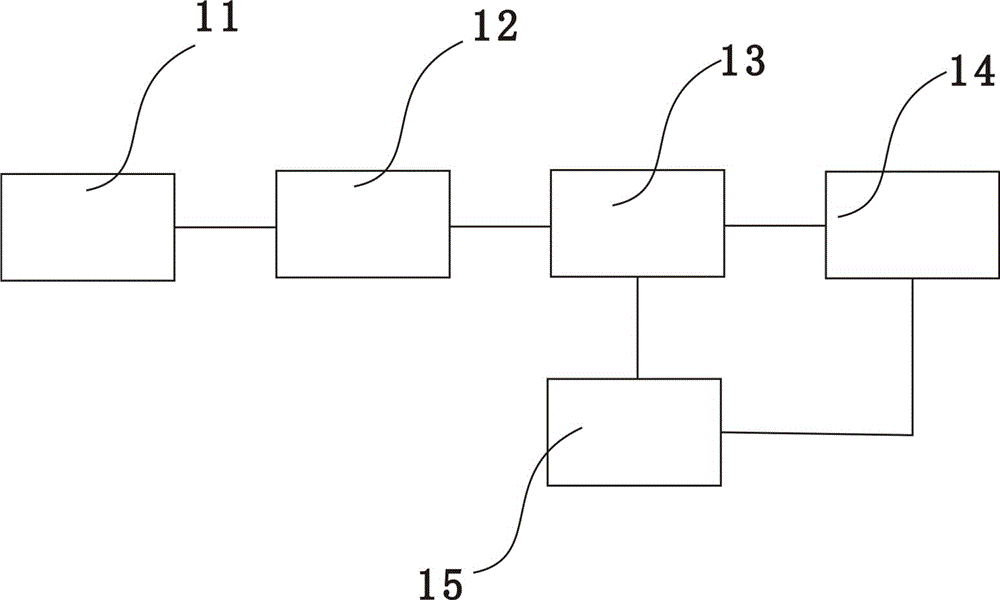

Application monitoring method, development platform, client and information system

InactiveCN107770144AImprove recognition efficiencyGuarantee the safety of useTransmissionProgram/content distribution protectionInformation systemSoftware engineering

The embodiment of the invention discloses an information processing method, a development platform, a client and an information system. The information processing method applied to the development platform includes the following steps: acquiring a monitoring module of a genuine application; acquiring a first characteristic value of the genuine application; and encapsulating the monitoring module,the first characteristic value and an application code of the genuine application to form an installation file of the genuine application, wherein the monitoring module is used for extracting a secondcharacteristic value of the current application in an application running process, comparing the second characteristic value with the first characteristic value, and further determining whether the current application is a pirated application. Thereby, by adding the monitoring module and the first characteristic value to the genuine application, the operation of automatically acquiring the secondcharacteristic value of the current application in a subsequent application running process can be facilitated; and through the comparison with the first characteristic value, whether the current application is the pirated application can be found in time, and the characteristic of simple operation can also be achieved.

Owner:CHINA MOBILE COMM LTD RES INST +1

Filler for self-repairing of insulating layer of cable and preparation method

InactiveCN108299682ASelf-healing success rate advantageExtended service lifeMicroballoon preparationMicrocapsule preparationUltravioletSolvent

The invention provides filler for self-repairing of an insulating layer of a cable and a preparation method. Urea formaldehyde resin is added after surface modification treatment through nano silica and uniformly dispersed, a composite is obtained, the composite is sprayed to an enveloping machine with a curing agent added, a capsule with the curing agent as a core and the urea formaldehyde resin / nano silica composite as a shell is formed, a solvent is added, crushing is performed after freezing, a prepolymer is sprayed and irradiated by ultraviolet, and a microcapsule with a double-layer structure is prepared and is the filler for self-repairing of the insulating layer of the cable. By means of the method, the microcapsule is formed by coating the curing agent with urea formaldehyde resinand nano silica composite, self-repairing of the insulating layer of the cable is realized, the success rate and the repairing efficiency of self-repairing are increased, the service life of the cable is prolonged, and the product safety is improved; the preparation process is simple, the production cost is low, the repairing effect is good, and the application prospects are good.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Processing method of ultrafine grinding wires

InactiveCN109176332ASave production spaceReduce preparation timeGrinding devicesPelletizingMelt spinning

The invention discloses a processing method of ultrafine grinding wires. The processing method comprises the following steps of preparation of a treatment solution; preparation of a master batch; andmelt spinning. In the processing method, without using absolute alcohol, the risk that the absolute alcohol is inflammable and explosive is solved; the ultrafine grinding wires do not need to be laidand aired, so that the production space is greatly saved; without tedious programs including manual pelletizing, sieving and drying, the production efficiency is improved; and with a simple and convenient technology, the loss of diamond micropowder is reduced, and the cost is effectively lowered. In addition, for the ultrafine grinding wires produced by the processing method, the content of the diamond micropowder is full in content and uniform in distribution, so that the rigidity and the abrasion resistance of brush wires are improved, and the service life of the brush wires is prolonged; inthe use process, the fine polishing effect of the surface of a workpiece can be better; the diameter can be from 0.08mm to 0.149mm, and the blank of a product in the domestic and foreign markets is filled.

Owner:赵明余

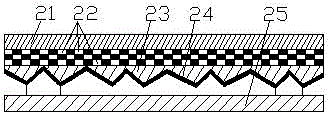

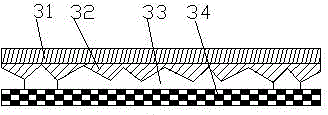

Aluminium-coated microprism product with large angle

InactiveCN104570179AReduce the safety of useIncrease the angleMetal layered productsOptical elementsPolymer sciencePolyolefin

The invention discloses an aluminium-coated microprism product with a large angle. The aluminium-coated microprism product comprises a first resin layer, a second printed layer, a third microprism layer, a fourth aluminium reflecting layer, a fifth pressure-sensitive adhesive layer and a sixth release paper layer, wherein the first resin layer can be acrylic resin, polyester resin, polycarbonate resin, vinyl chloride resin, polystyrene resin, polyolefin resin, fluorine resin, cyclic olefin resin, silicone resin, polyurethane resin and / or polymethyl methacrylate resin; the second printed layer adopts transparent ink and is printed with patterns; and the third microprism layer is a thermosetting resin coating. The microprism layer is coated with the aluminium reflecting layer through evaporation, the projected area can be up to 100%, the characteristics of reflective luminance and a large angle of incidence of the reflecting material can be improved, the angle of reflection can be increased effectively, and the use safety of road facilities and security uniform can be increased.

Owner:福建新力元反光材料有限公司

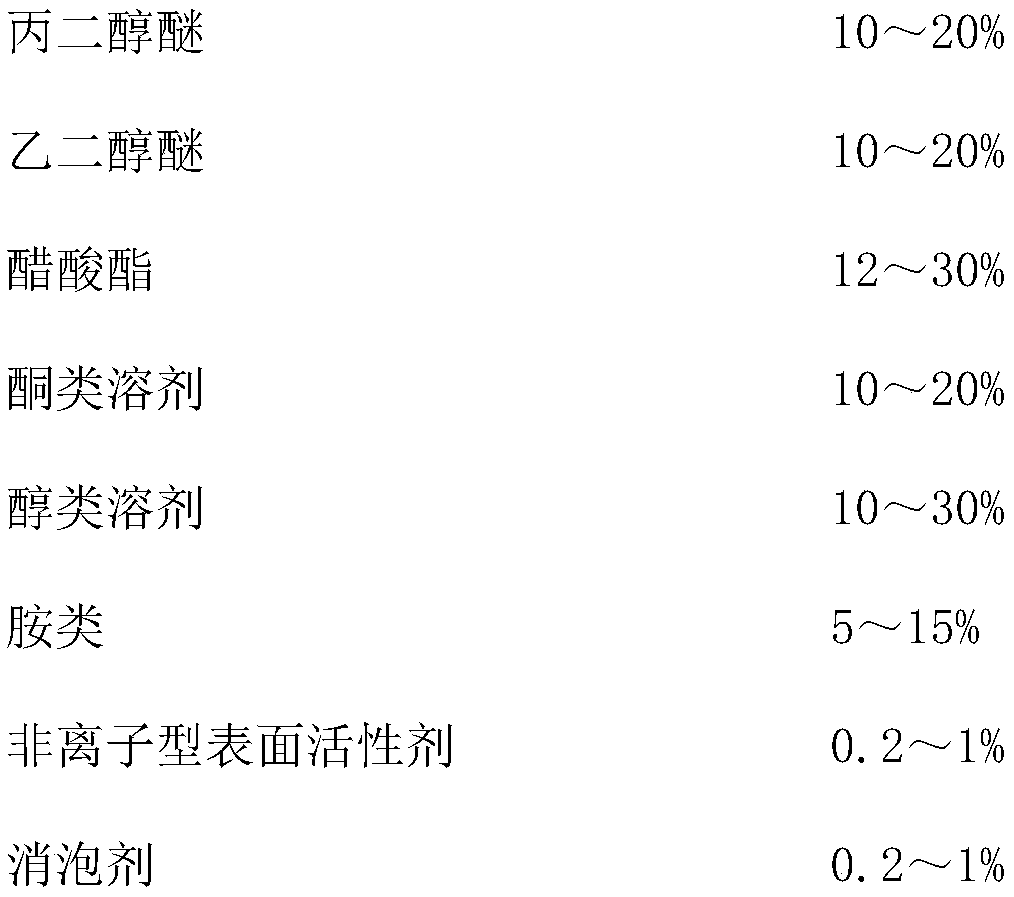

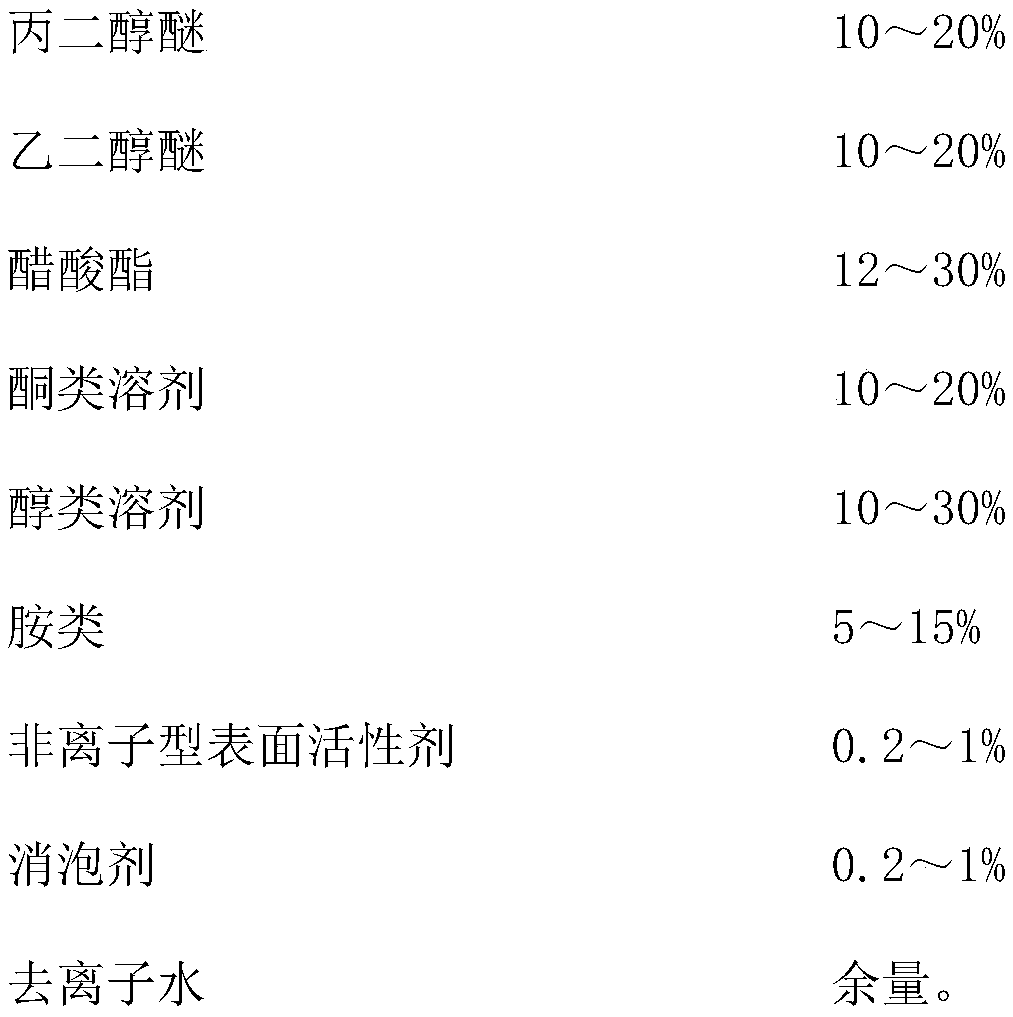

Environmentally-friendly red glue cleaning compound

InactiveCN108929797AReduce the safety of useIncrease relative volatilityNon-ionic surface-active compoundsOrganic detergent compounding agentsAlcoholKetone solvents

The invention discloses an environmentally-friendly red glue cleaning compound. The environmentally-friendly red glue cleaning compound comprises the following components by mass: 10 to 20% of propanediol ether, 10 to 20% of glycol ether, 12 to 20% of acetate, 10 to 20% of a ketone solvent, 10 to 30% of an alcohol solvent, 5 to 15% of amines, 0.2 to 1% of a nonionic surfactant and 0.2 to 1% of anantifoaming agent, with the balance being deionized water. The environmentally-friendly red glue cleaning compound provided by the invention can rapidly and effectively dissolve components of a curedred glue during cleaning of a red glue, enables subsequent scrubbing and flushing to be more clean under the synergistic effects of components in the environmentally-friendly red glue cleaning compound, and has the characteristics of environmental friendliness, low toxicity, low volatility, good oil removal ability and good cleaning effect.

Owner:惠州市兴都化工科技有限公司 +1

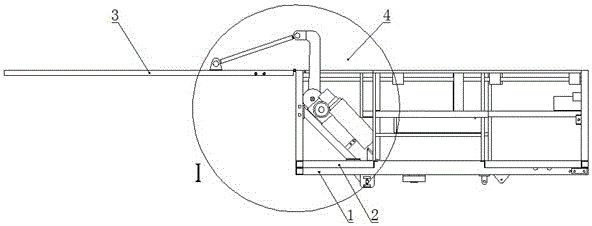

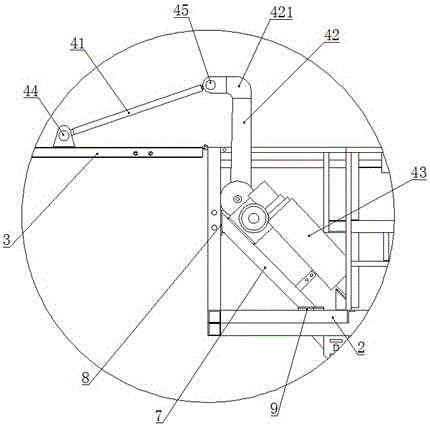

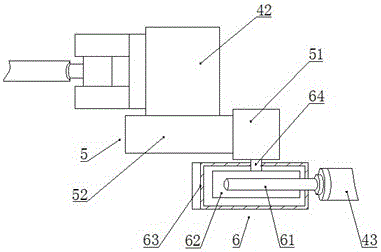

Motor home carriage roof cover overturning device

PendingCN106740407AReasonable designTurning labor intensity is lowVehicle with living accommodationItem transportation vehiclesVehicle frameMotor home

The invention discloses a motor home carriage roof cover overturning device to solve the problems that manual carriage cover pushing is high in labor intensity and poor in use safety. The motor home carriage roof cover overturning device comprises a motor home frame, a carriage, a carriage roof cover and an overturning unit. The carriage is fixed to the motor home frame. One end of the carriage roof cover is hinged to the top of the carriage. The overturning unit comprises a pull rod, an overturning arm and a drive motor. One end of the pull rod is hinged to the carriage roof cover. The other end of the pull rod is hinged to one end of the overturning arm. The other end of the overturning arm is connected to the output end of a transmission mechanism in a non-rotation mode. The input end of the transmission mechanism is connected with an output shaft of the drive motor through a retarding mechanism. The drive motor drives the overturning arm to swing through the retarding mechanism and the transmission mechanism, and the carriage roof cover overturns around a hinged point through the pull rod. The motor home carriage rood cover overturning device is reasonable in design, convenient to operate, low in overturning labor intensity and good in use safety.

Owner:荣成康派斯新能源车辆股份有限公司

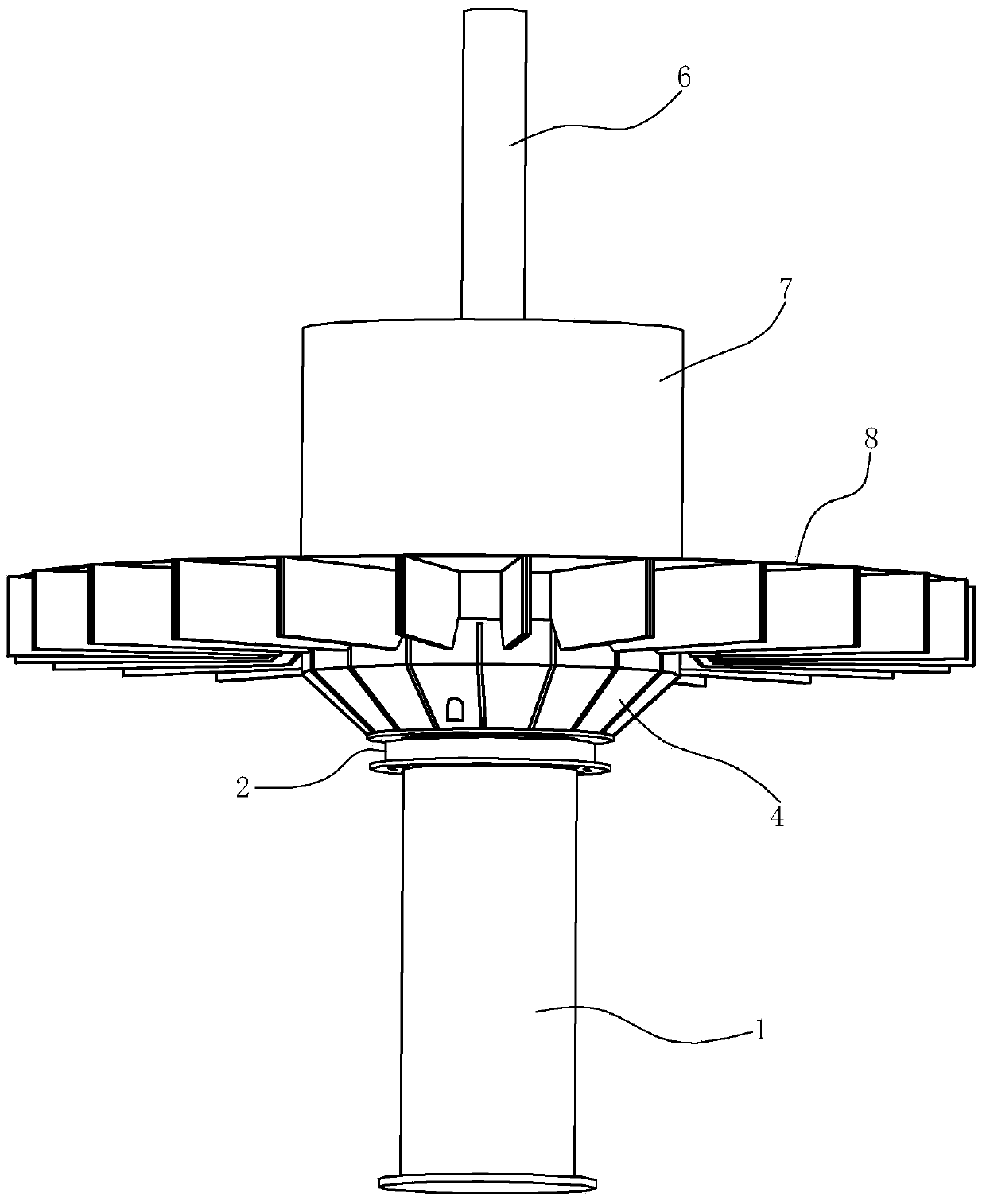

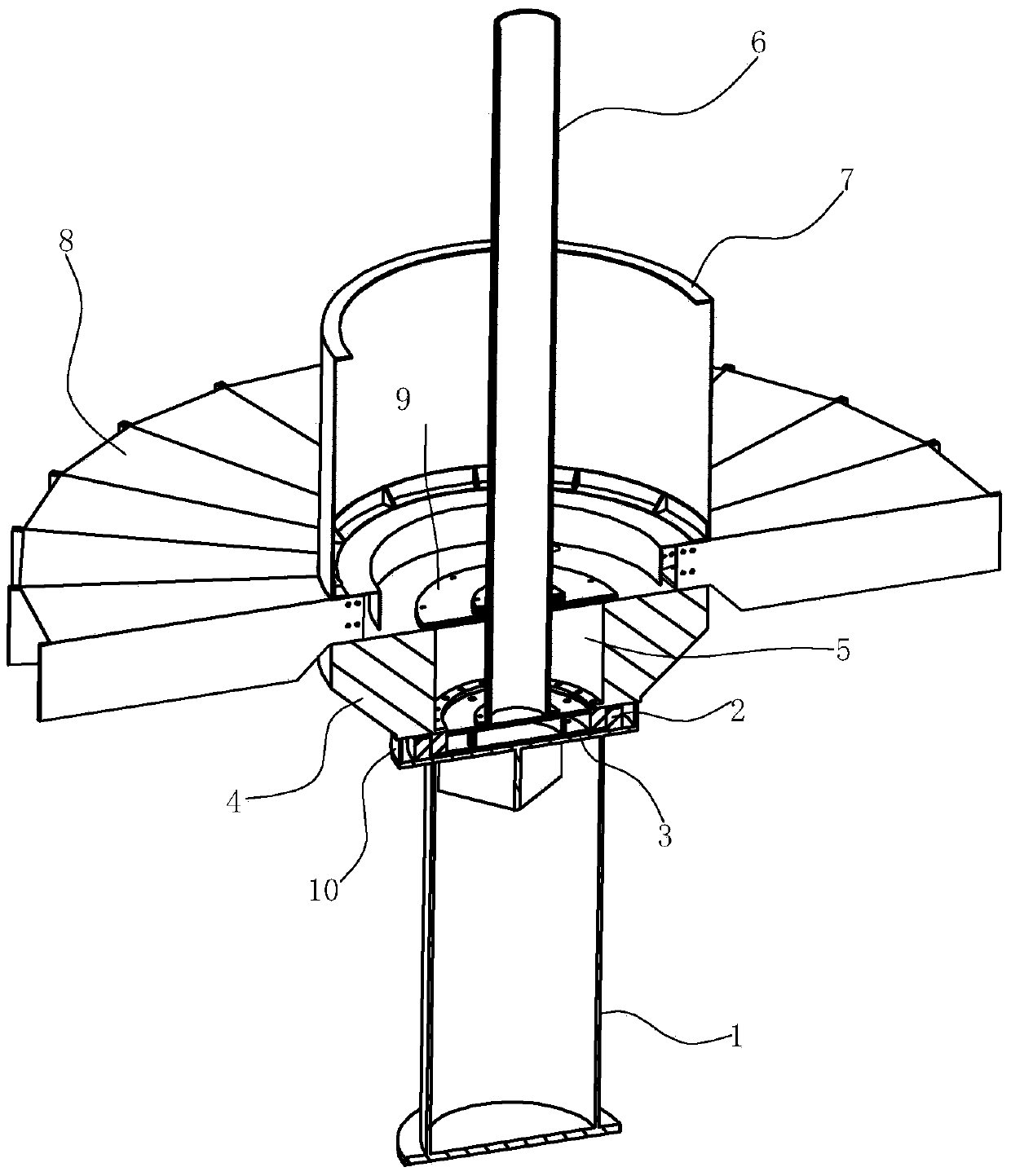

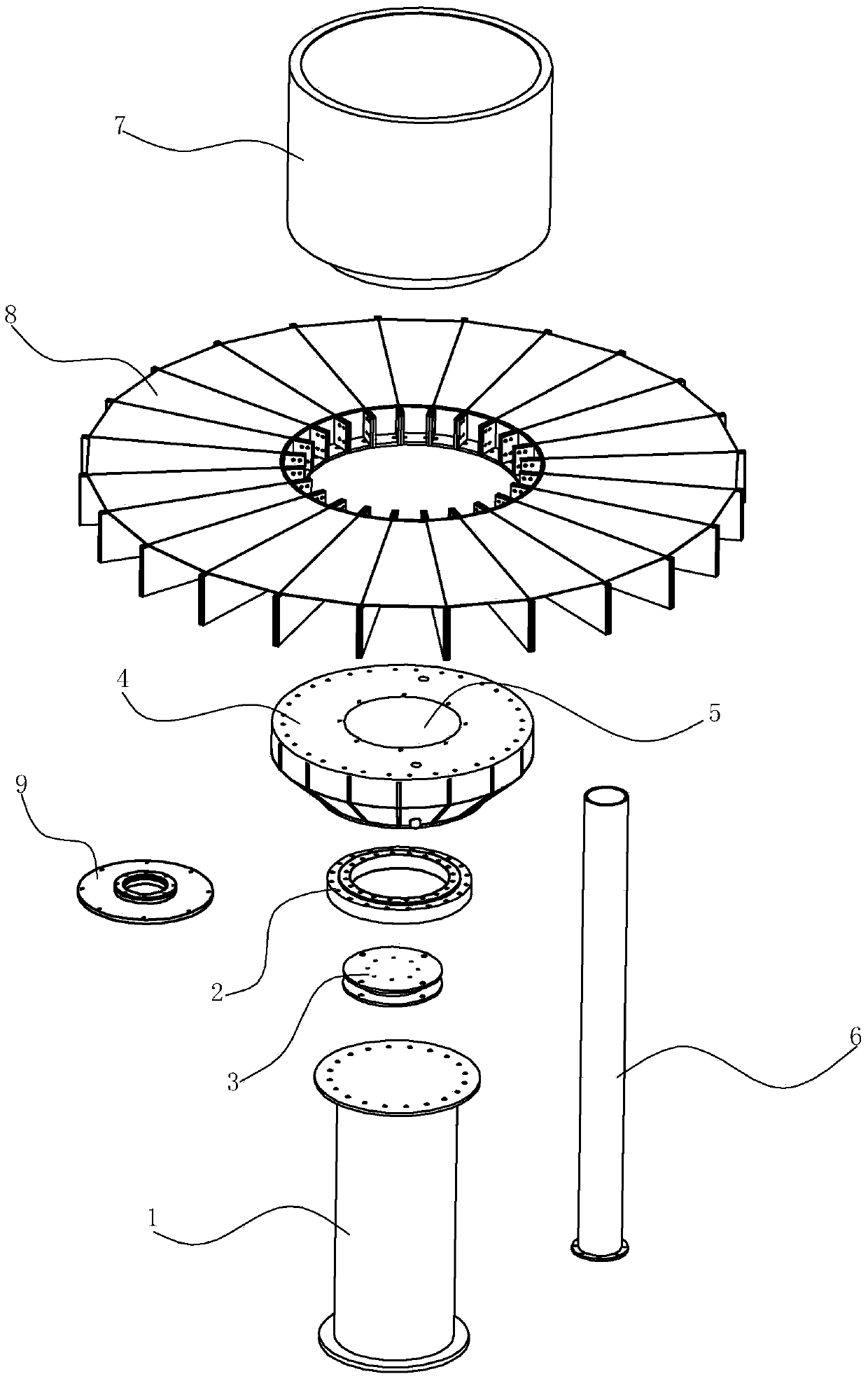

Rotary structure of starter-making machine

ActiveCN103740536ALow installation accuracy requirementsEasy to replaceAlcoholic beverage preparationVinegar preparationEngineeringHygiene

The invention relates to a rotary structure of a starter-making machine. The rotary structure comprises a supporting column and a turntable. The rotary structure is characterized in that the supporting column comprises a lower vertical column and an upper vertical column which are detachably integrally connected; a bearing is detachably connected to the upper end surface of the lower vertical column; the turntable is detachably connected to an inner ring of the bearing; a connecting component as high as the bearing is arranged in an inner hole in the bearing; the upper vertical column is detachably connected to the connecting component; a through central hole is formed in the turntable; a baffle ring is also arranged between the central hole and the upper vertical column. The rotary structure of the starter-making machine is of an open design and convenient to clean, thus the hygiene in preparation can be effectively ensured, and the starter pollution due to infectious microbe generating in a closed rotary mechanism can be avoided; in addition, the requirement on installation precision of each component can be greatly reduced, and the coaxial precision after assembling is well above that in the prior art, so that the safety of the rotary mechanism in use can be effectively ensured, and the service life of the bearing is greatly prolonged; the bearing is convenient to replace and maintain; the rotary structure is high in commonality, high in bearing capacity, and compact in structure, and also reduces the floor area.

Owner:NINGBO CHANGRONG BREWING EQUIP

Vascular stent system and application method thereof

PendingCN107440822AAvoid damageGuaranteed safety and reliabilityStentsBalloon dilatation catheterVascular disease

The invention provides a vascular stent system and an application method thereof. The vascular stent system comprises a radial expansion balloon, a balloon expansion dilating catheter and a radial expansion stent; the position between the radial expansion balloon and the radial expansion stent is enclosed with a guide wire reserved channel, a guide wire reserved channel protection tube and a protection tube filler are arranged in the guide wire reserved channel, the inner wall of the guide wire reserved channel is attached to the guide wire reserved channel protection tube, and the guide wire reserved channel protection tube is filled with the protection tube filler. The application method of the vascular stent system includes: taking out the protection tube filler from the guide wire reserved channel protection tube; piercing additional guide wires out of the guide wire reserved channel protection tube and a center wire out of the balloon expansion dilating catheter; taking out the guide wire reserved channel protection tube; moving the radial expansion balloon and the radial expansion stent to corresponding vascular disease sites along the center guide wire and the additional guide wires for treatment of vascular diseases. The vascular stent system and the application method thereof have the advantages of high long service life and high security and can be applied to narrow blood vessels and the like.

Owner:唐利龙

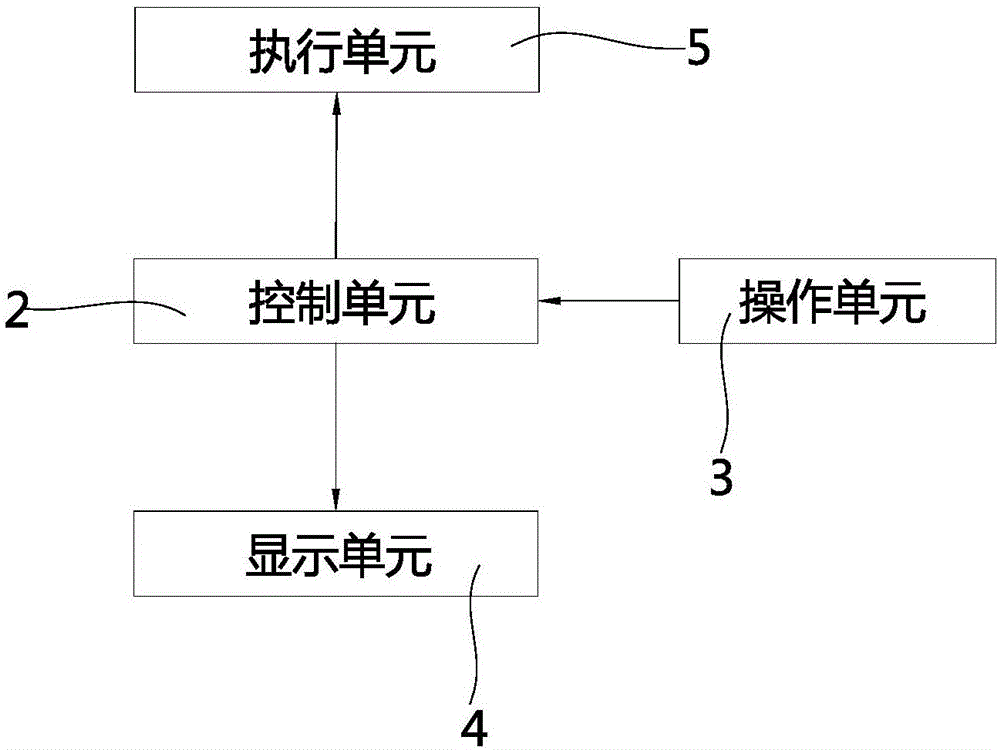

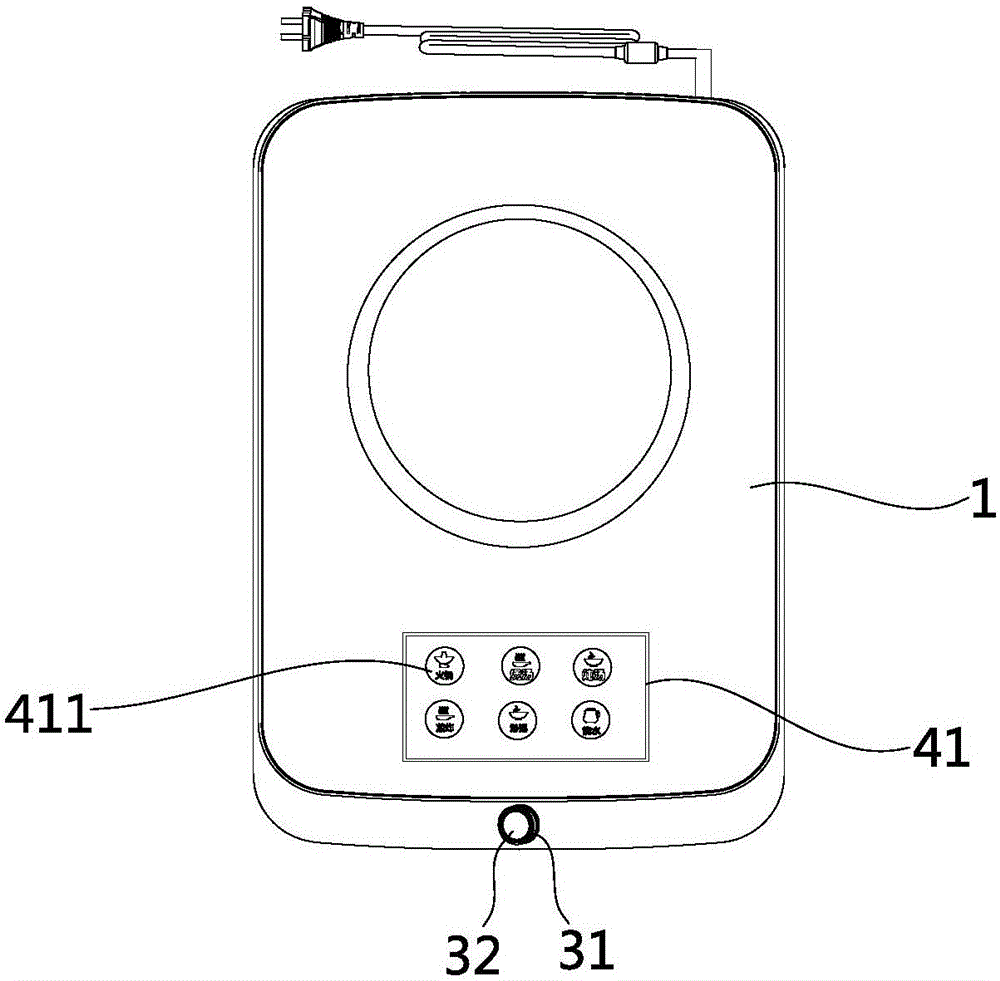

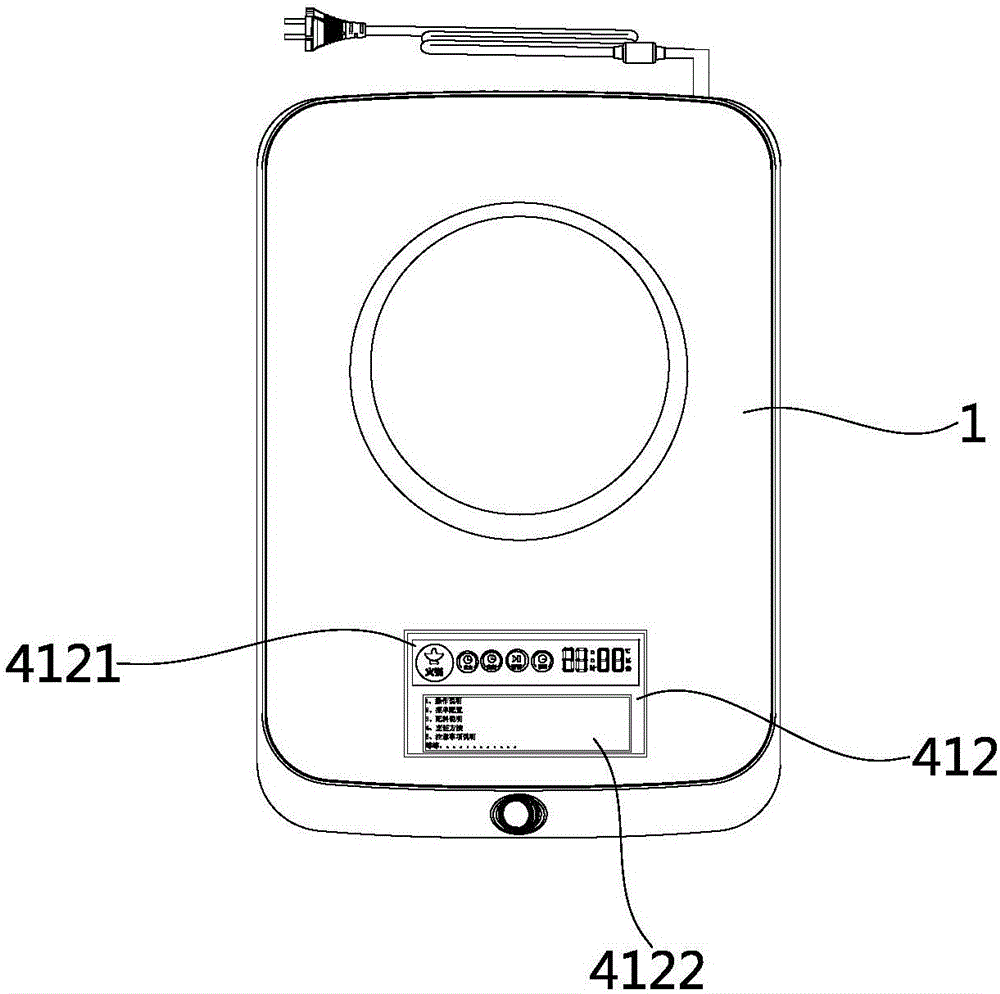

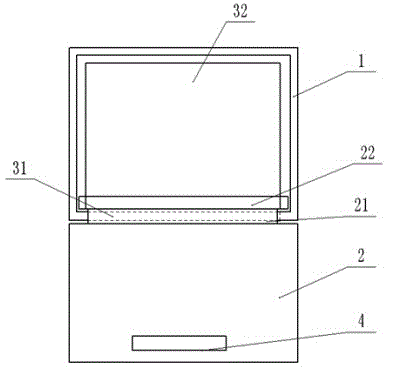

Kitchen appliance

InactiveCN106444440AImprove user experienceEasy to viewProgramme control in sequence/logic controllersInput/output processes for data processingComputer scienceControl unit

The present invention discloses a kitchen appliance, belonging to the household appliance technology field, The technical problem is solved that the user experience of the kitchen appliances is bad in the prior art. The kitchen appliance comprises a body and a display unit, an operation unit and a control unit which are arranged in the body; the display unit is configured to display the display state 1 of the work information and form a first information display area and a second information display area in the display state 1, and the work information displayed by first information display area is associated with the work information displayed by the second information display area; the operation unit is configured to select the display state of the display unit; and the control unit is configured to electrically connect with the display unit and the operation unit and control the display unit to display the display state 1.

Owner:JOYOUNG CO LTD

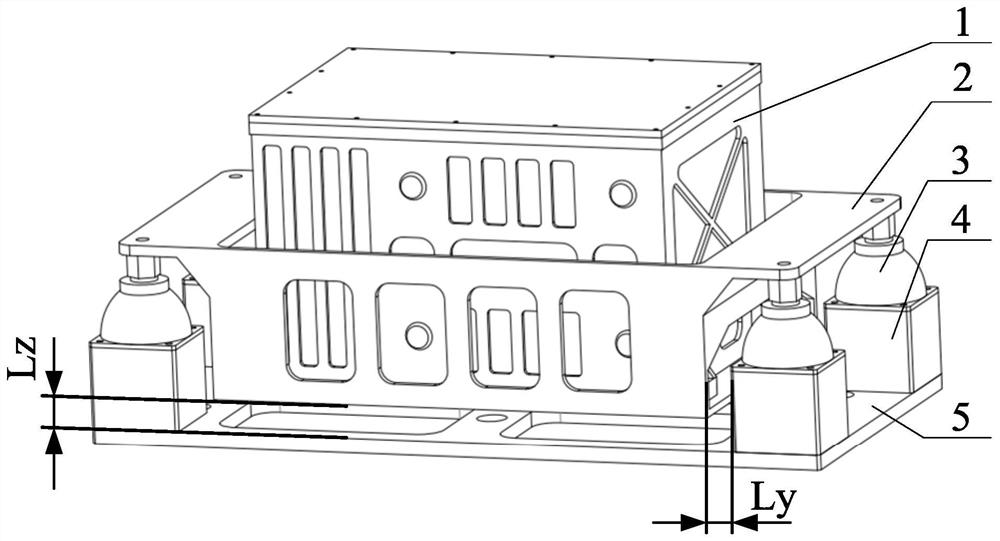

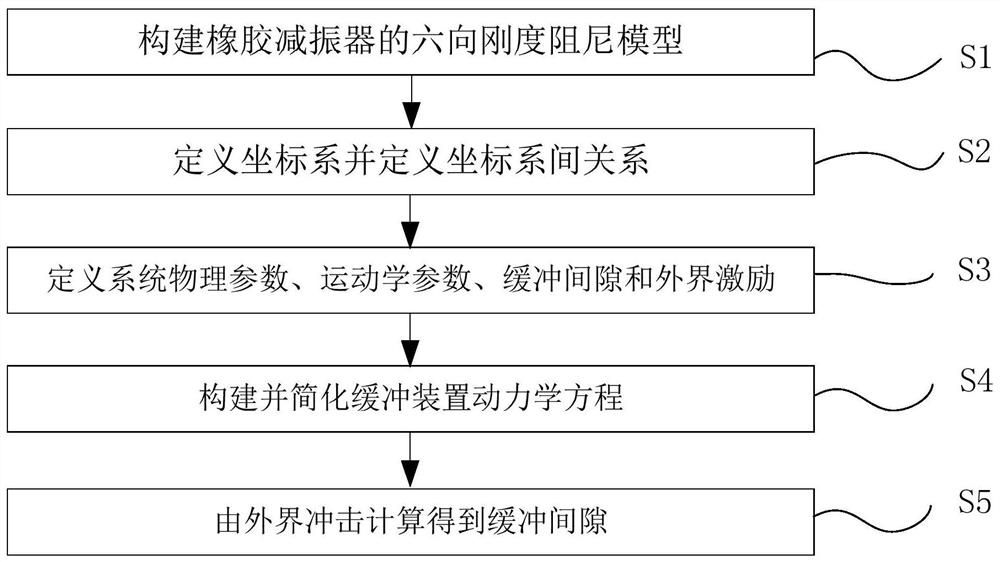

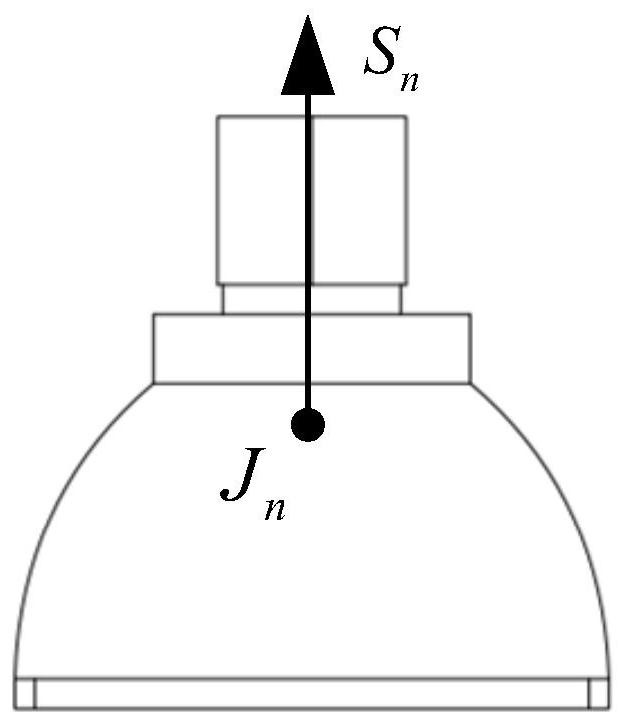

Method for determining buffer gap of large impact attenuation buffering device of inertial navigation system

ActiveCN112762136AReduce the safety of useGuarantee the safety of useSpringsSustainable transportationClassical mechanicsEngineering

The invention discloses a method for determining a buffer gap of a large impact attenuation buffering device of an inertial navigation system. The method comprises the following steps of S1, carrying out six-direction rigidity damping model construction and physical parameter definition on each rubber shock absorber; S2, constructing an inertial coordinate system, an inertial navigation coordinate system and a shock absorber coordinate system, and defining relationships among the coordinate systems; S3, defining system physical parameters, kinematics parameters, the buffer gap and external excitation; S4, constructing a six-degree-of-freedom kinetic equation of the buffering device; and S5, calculating according to external impact and obtaining y-direction and z-direction buffer gap design quantities Ly and Lz based on the design margin. The method for determining the buffer gap of the large impact attenuation buffering device of the inertial navigation system is simple and convenient to calculate, easy to operate and high in result accuracy and reliability, the use safety of the large impact attenuation buffer device of the inertial navigation system can be effectively guaranteed, and the service life is prolonged.

Owner:厦门华源嘉航科技有限公司

Decolorizing agent for reducing brown stain index of yellow pear juice

InactiveCN107252028AImprove appearance qualityImprove the safety of useFood sciencePear juiceMolecular sieve

The invention discloses a decolorizing agent for reducing the brown stain index of yellow pear juice, and relates to the technical field of processing of yellow pear juice. A modified molecular sieve is used as a carrier, poloxamer / crospovidone is used as an adsorbent, a microwave impregnation method is used, and the decolorizing agent is prepared. The decolorizing agent disclosed by the invention is prepared through using the modified molecular sieve after modification strengthening treatment as the carrier; the decolorizing agent is specially used for reducing the brown stain index of the pear juice; and in the respect of the occurred brown stain of the yellow pear juice, after the decolorizing agent is used, the color value of the yellow pear juice is effectively increased, so that the appearance quality of the yellow pear juice is improved.

Owner:安徽好多多饮品有限公司

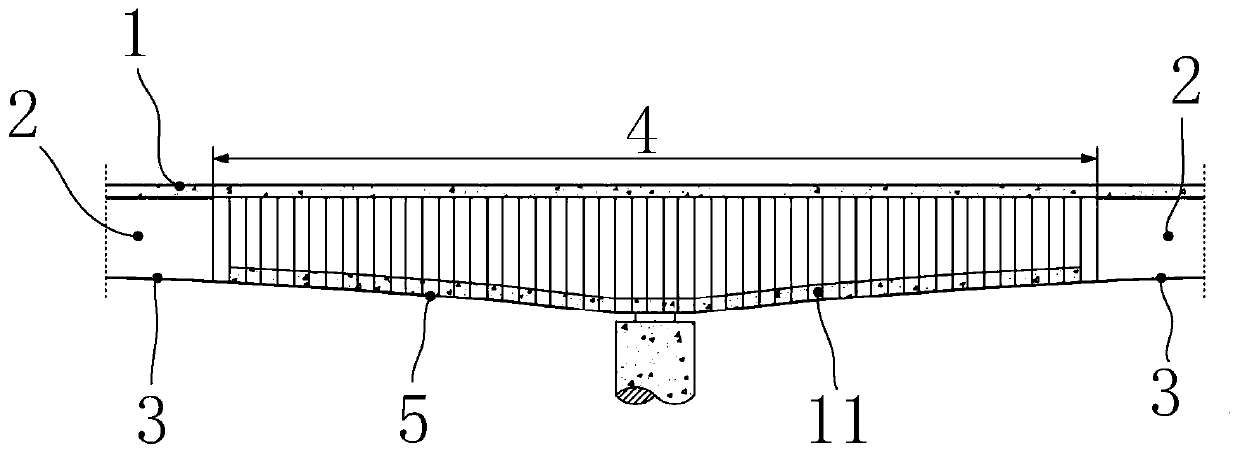

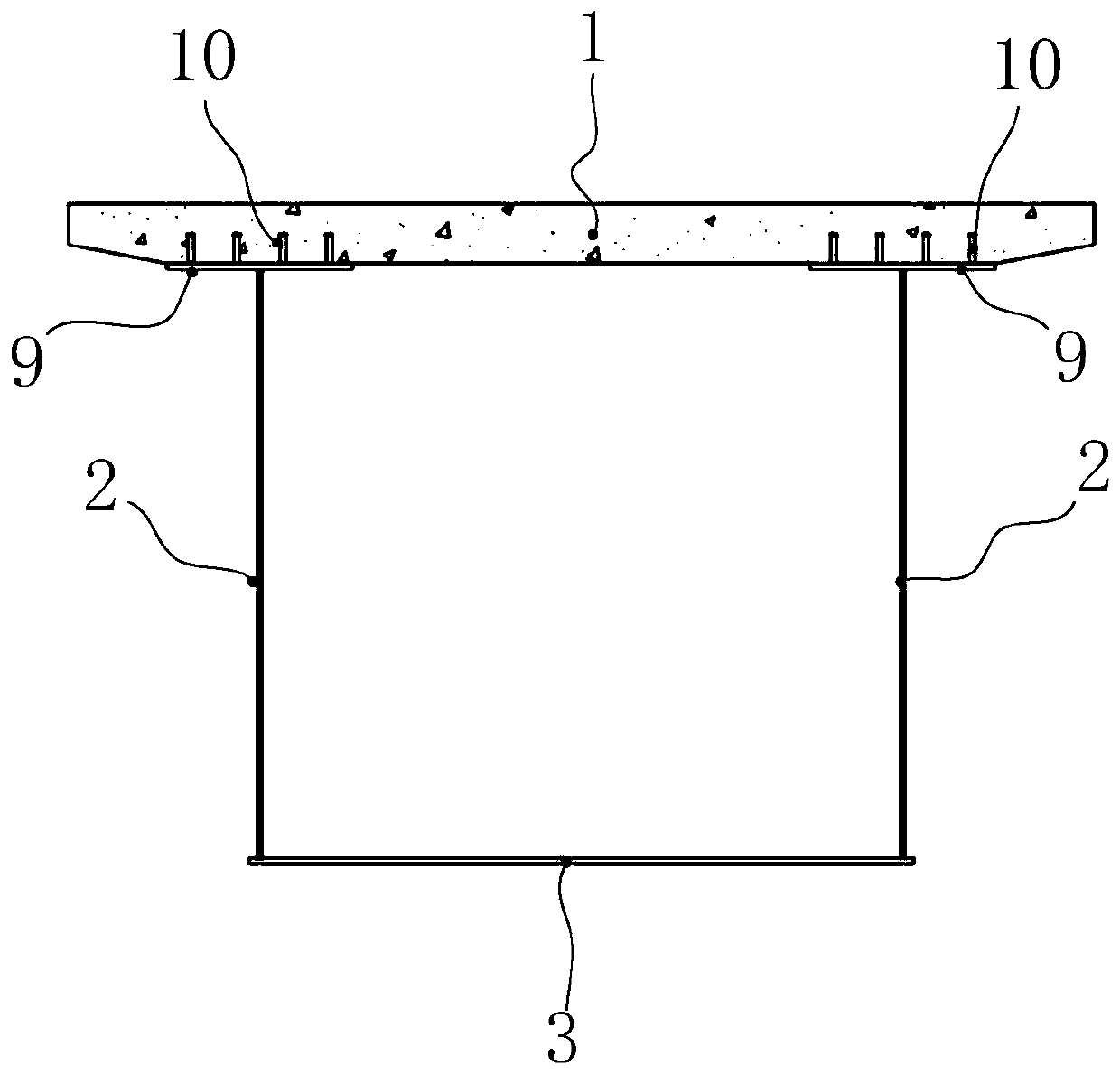

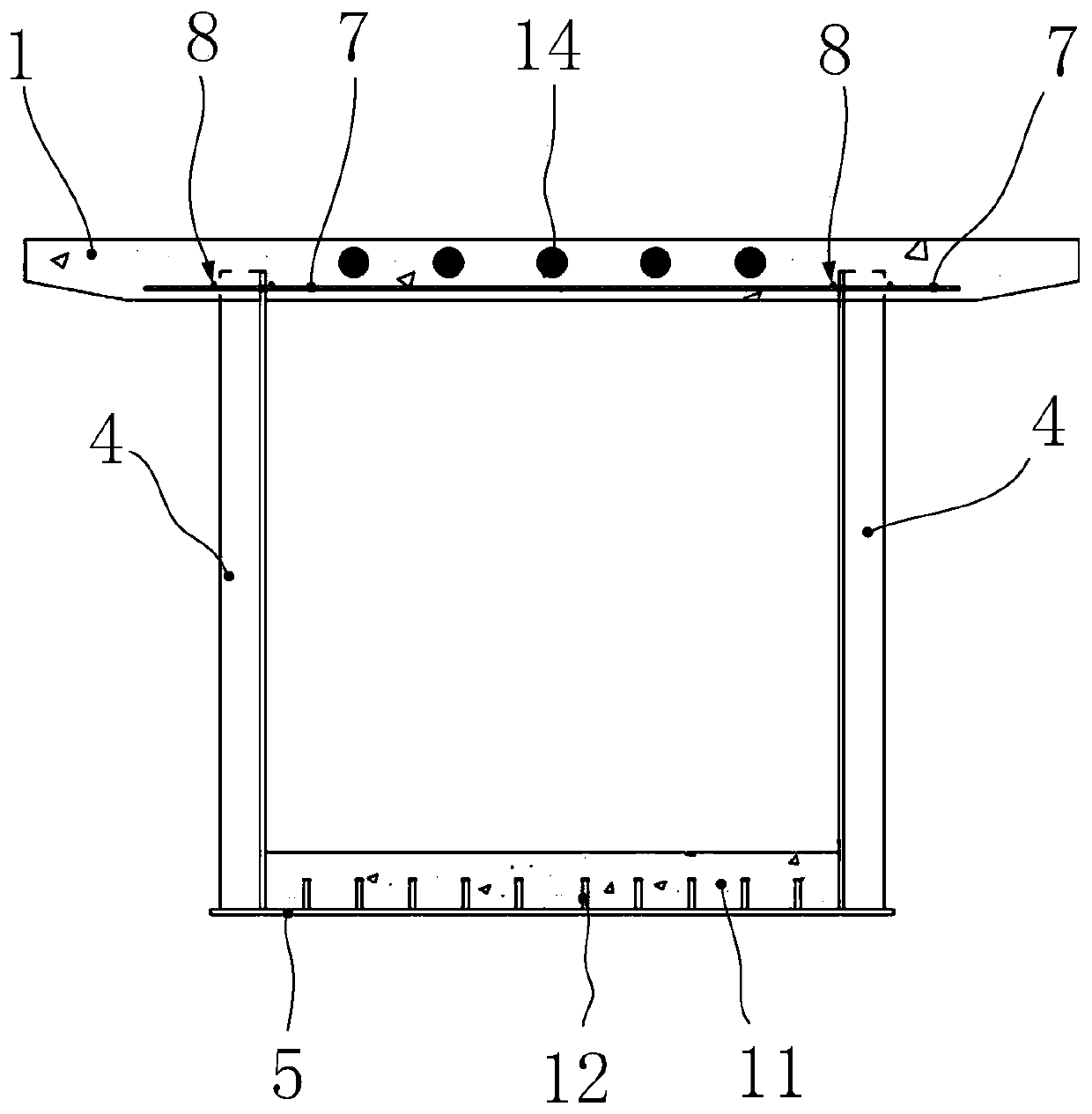

Steel-concrete composite structure continuous box girder and manufacturing method thereof

ActiveCN111021227AEffective wrinkle effectAvoid time costBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a steel-concrete composite structure continuous box girder and a manufacturing method thereof, and belongs to the technical field of bridge structures. The continuous box girder still adopts a flat steel web in a sagging moment area, but adopts a corrugated steel web to replace a conventional flat steel web in a middle fulcrum hogging moment area, adopts an embedded PBL shear connector to connect the corrugated steel web and a concrete top plate, and is filled with an elastic material between the outer sides of a wave crest section and a wave trough section of the corrugated steel web and a concrete contact surface to form a reserved deformation buffer area. Once prestress is applied to the hogging moment area, compressive deformation is prone to occurring under pressure due to the fact that the longitudinal rigidity of the corrugated steel web is small, and meanwhile, the elastic material allows the corrugated steel web to transversely expand and deform. By means of the combined action of the two factors, the pre-pressing stress can be effectively applied to the concrete top plate, and the prestress applying efficiency is effectively improved. The compositestructure effectively relieves the possibility of concrete cracking in the hogging moment area, and the safety and durability of the bridge are improved.

Owner:SOUTHEAST UNIV

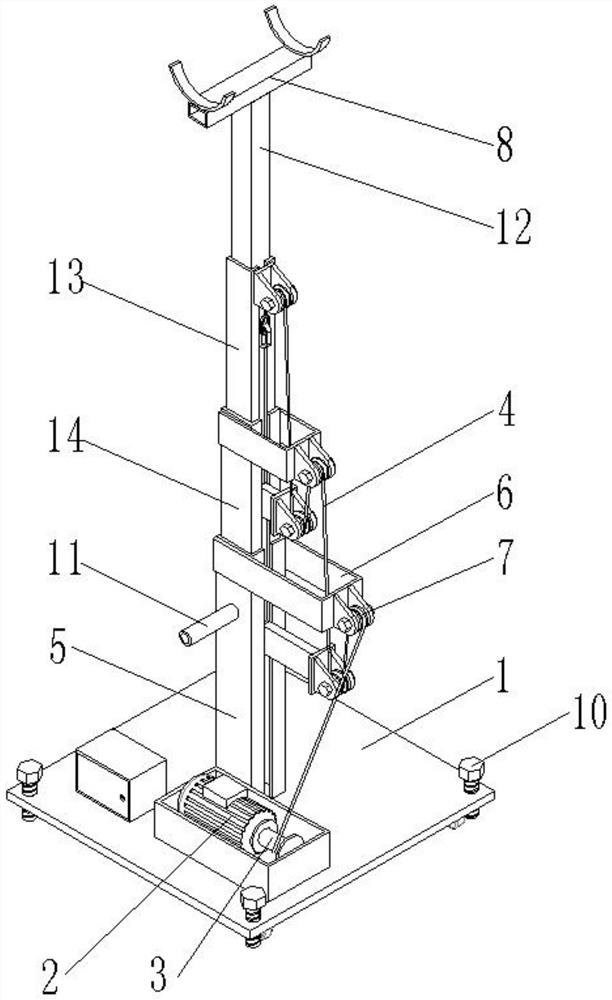

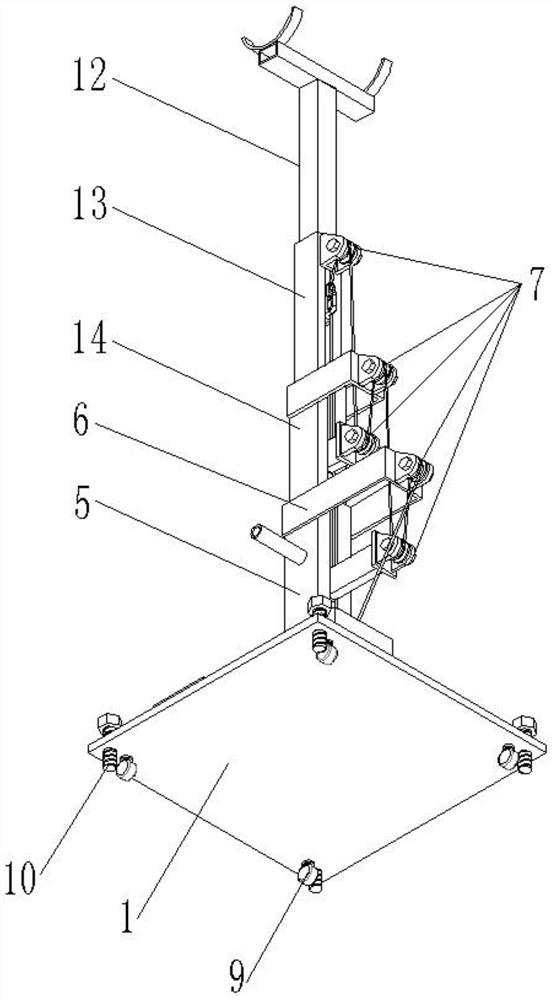

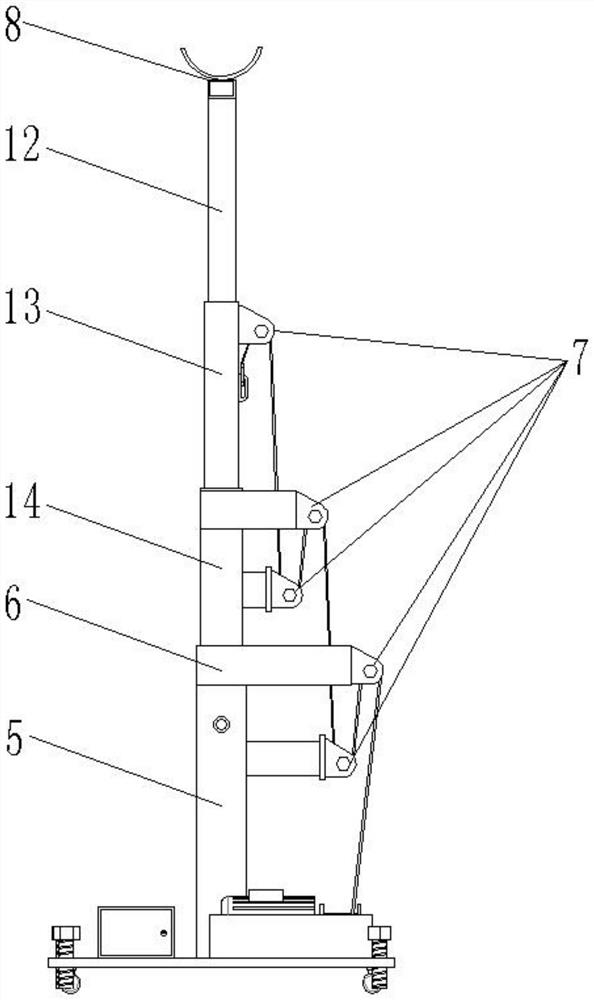

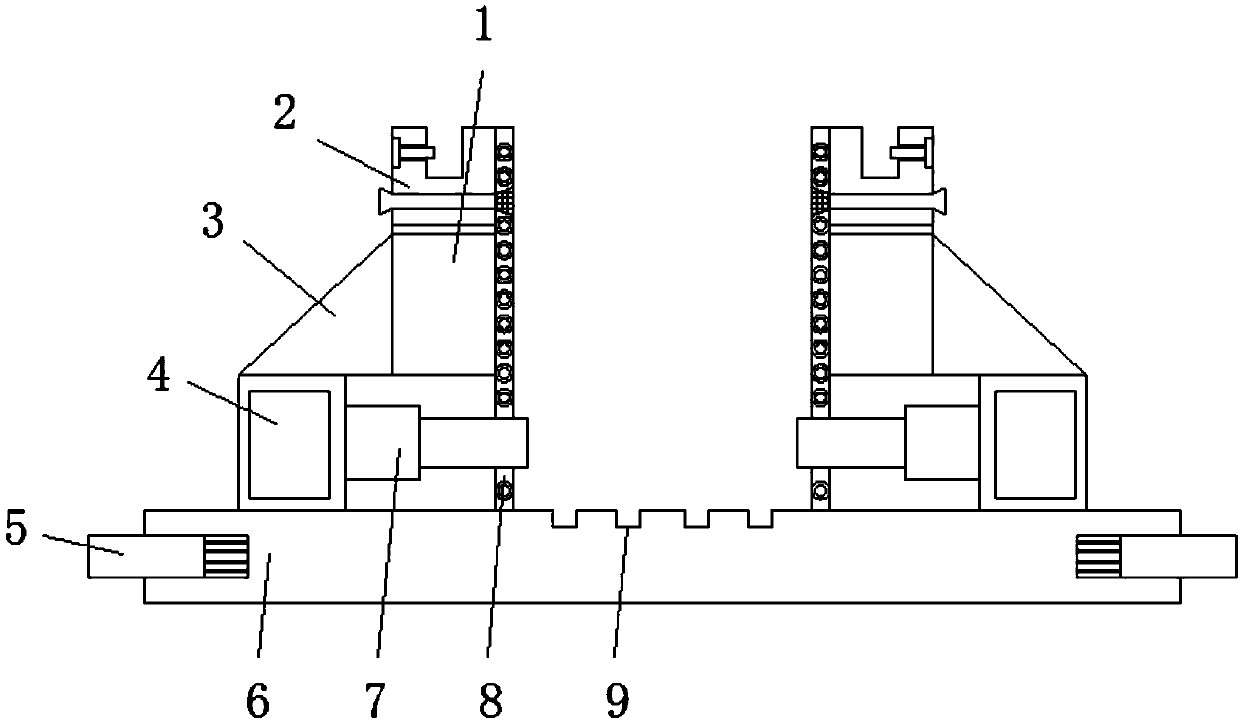

Lifting type lifting device

PendingCN112607655AReduce volumeEasy to useSafety devices for lifting equipmentsLifting framesClassical mechanicsElectric machinery

The invention discloses a lifting type lifting device which comprises a bottom frame, a telescopic pipe assembly and a motor are vertically arranged on the bottom frame, the motor is connected with a winding drum, and a steel wire rope is wound on the winding drum; the telescopic pipe assembly comprises an outer pipe and at least one inner pipe, an outer pipe opening is formed in the pipe wall of the outer pipe, the length direction of the outer pipe opening is in the height direction of the outer pipe, the upper end of the outer pipe opening extends to the upper end of the outer pipe, an outer pipe mounting frame is arranged at the upper end of the outer pipe, and pulleys are arranged on the outer pipe mounting frame; and a lifting assembly is inserted into the upper end of the inner pipe on the innermost side, and the lifting assembly is used for placing a lifted object. The lifting type lifting device has the advantages of being small in size, convenient to carry and convenient to use, and also has the advantages of reducing labor intensity and being safe to use when used for auxiliary installation of objects such as a roller shutter door needing to be installed at a high position.

Owner:常雷

Emulsion explosive for exploitation

PendingCN112920000AModerate viscosityHigh viscosityNon-explosive fillers/gelling/thickening agentsEnvironmental chemistryPolluted environment

The invention discloses an emulsion explosive for exploitation, and the emulsion explosive comprises the following components in percentage by weight: 50 to 65 percent of ammonium nitrate, 3 to 10 percent of sodium nitrate, 2 to 10 percent of oil phase, 5 to 10 percent of water, 0.2 to 4 percent of a sensitizer, 3 to 10 percent of a viscosity reducer and 3 to 10 percent of a thickening agent. According to the invention, aiming at the problems of serious explosive return phenomenon, environmental pollution caused by explosive powder and the like, various components in the material and properties thereof are reasonably blended and optimized according to specific requirements of the explosive, so that a corresponding new emulsion explosive for exploitation is created, which is an objective need of a development period at present and even in the future.

Owner:湖北东神楚天化工有限公司

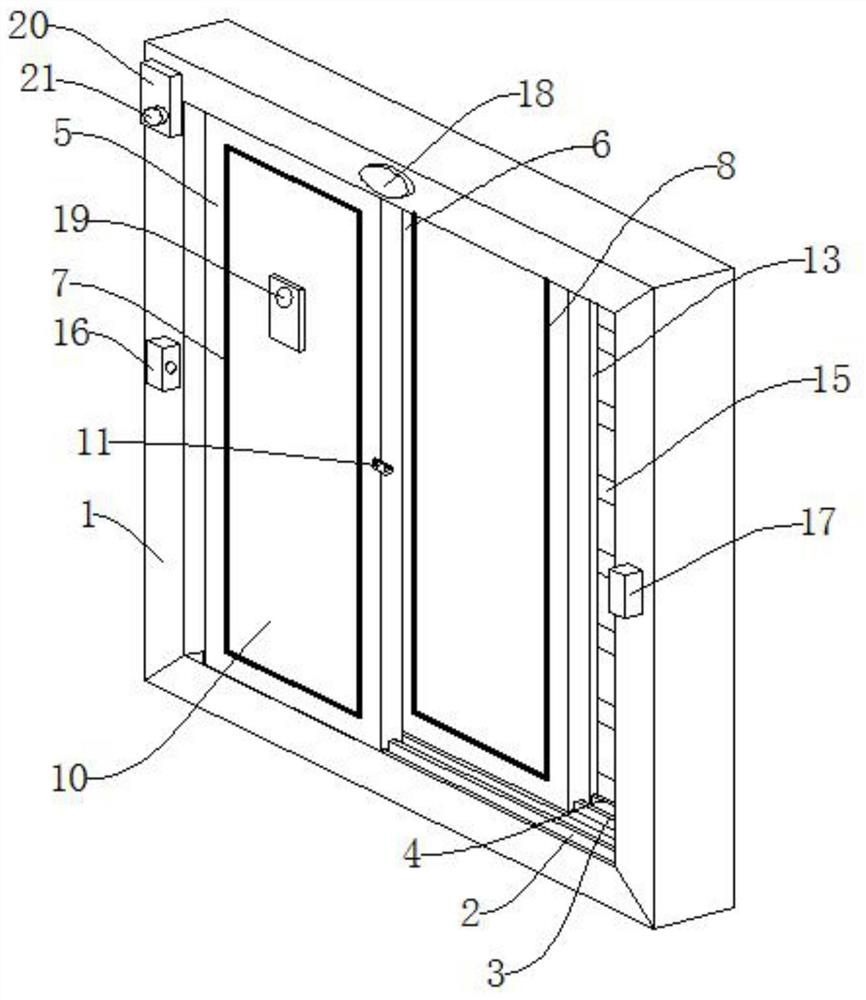

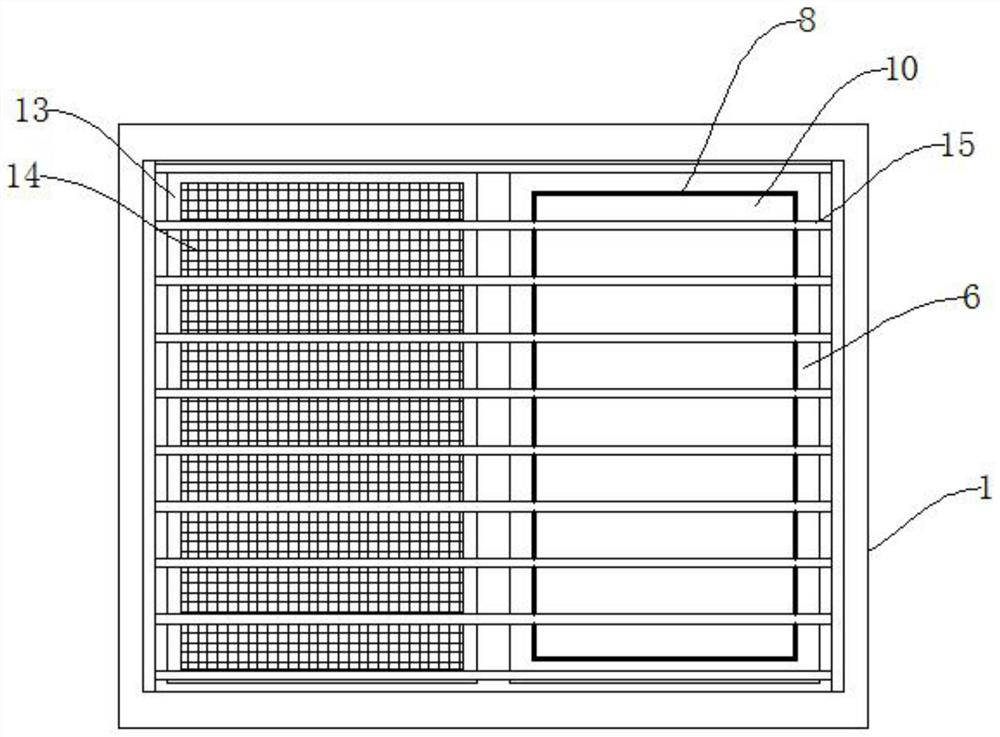

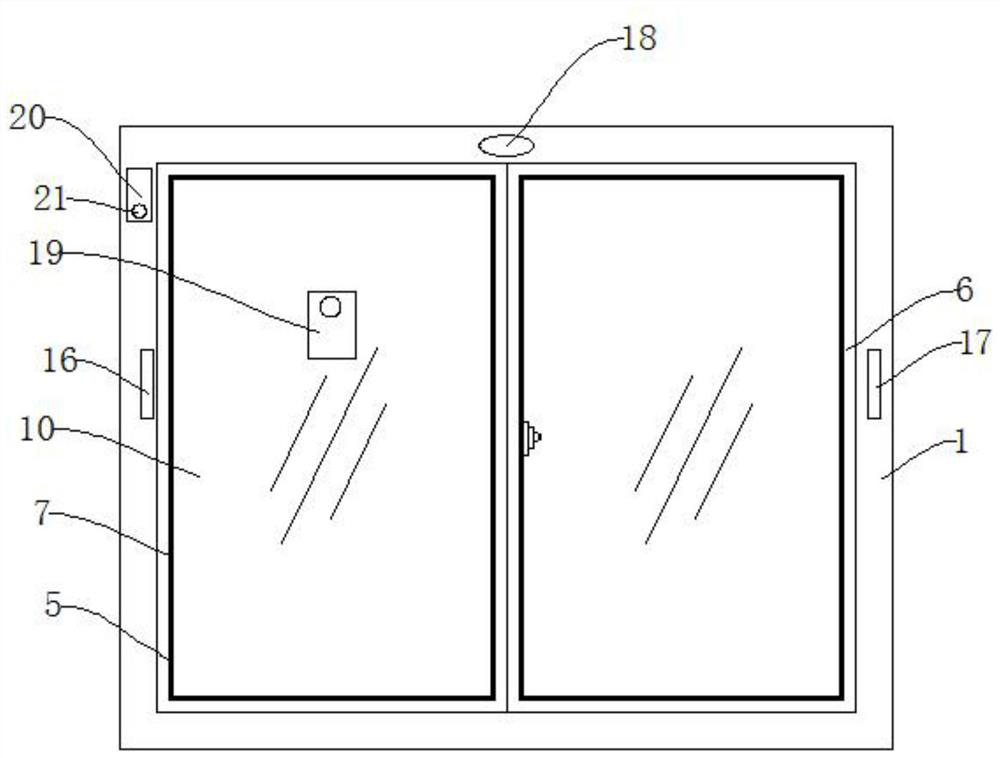

Intelligent alarm device for sliding door and window and use method thereof

InactiveCN111852266AReduce the safety of useImprove the safety of useBurglar alarm by openingBurglary protectionSlide windowGSM

The invention discloses an intelligent alarm device for a sliding door and window and a use method thereof. The intelligent alarm device comprises a frame, a touch alarm and a voice recognition module. A first slide way is disposed on the inner side of the frame. A second slide way is disposed on one side of the first slide way. A third slide way is disposed on one side of the second slide way. Afirst inner frame is disposed on the upper side of the first slide way. A first sealing strip is disposed on the inner side of the first inner frame. The intelligent alarm device has the beneficial effects that the structure is novel, and operation is convenient; by arranging a circuit board, an intelligent module, a WIFI module and a GSM network alarm module, an alarm can be given intelligently for a sliding window, it is avoided that a manual control speed is low, resulting in low use safety of the sliding window, and the use efficiency of the sliding door and window alarm device is improved; and secondly, by arranging a first infrared detector, a second infrared detector and an alarm lamp, sensing and monitoring can be performed for the sliding window, it is avoided that safety controlover the sliding window is not comprehensive, resulting in use inconvenience, and the requirements for alarm and safety use of the sliding door and window are met.

Owner:CHONGQING RUIMING ENERGY SAVING DOOR & WINDOW CO LTD

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981BBurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

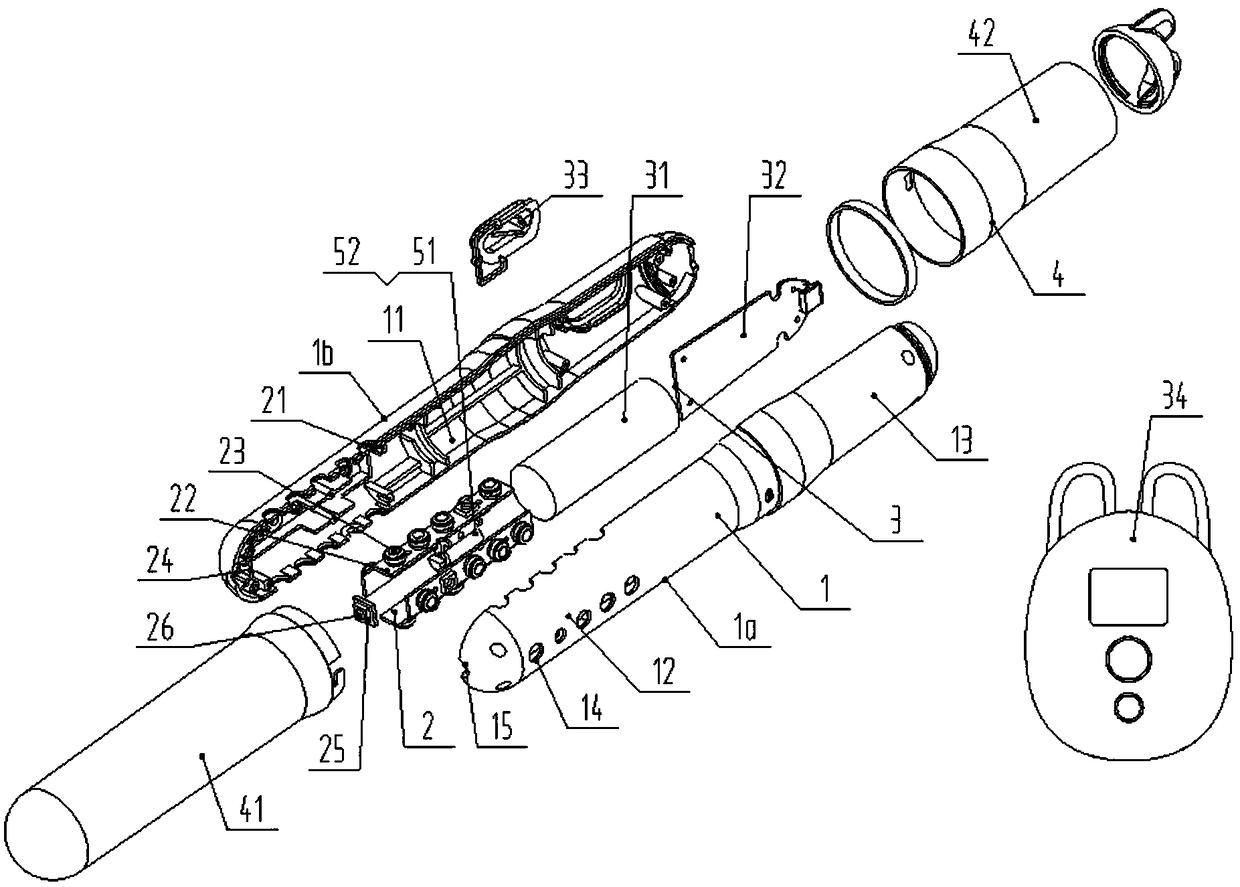

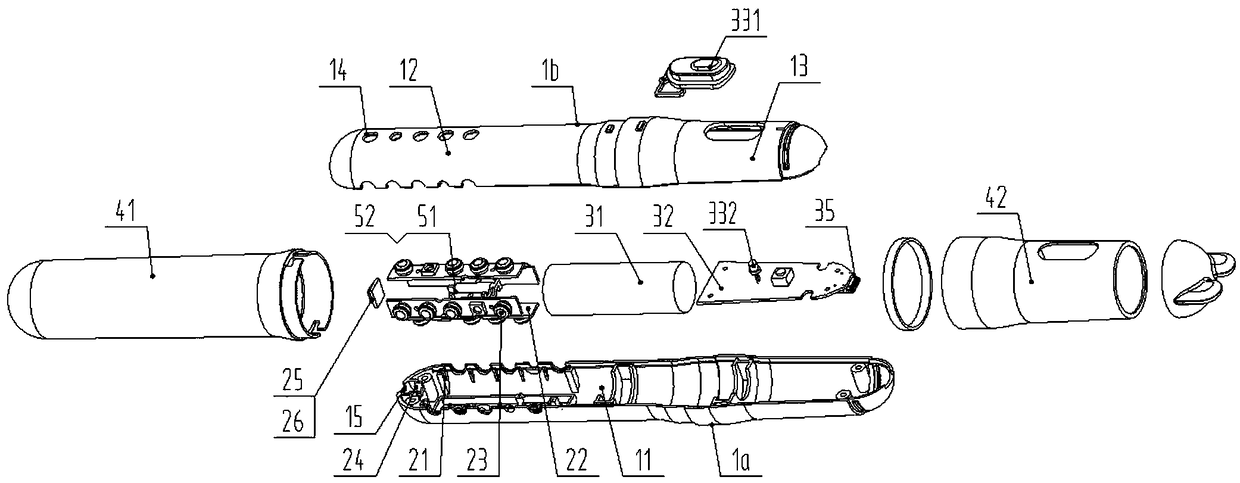

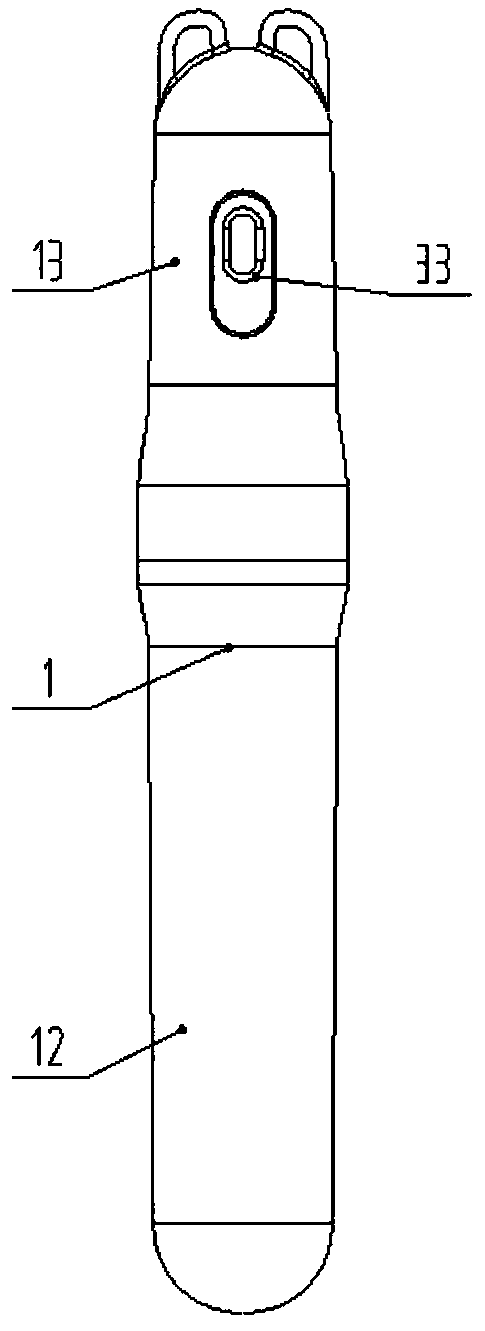

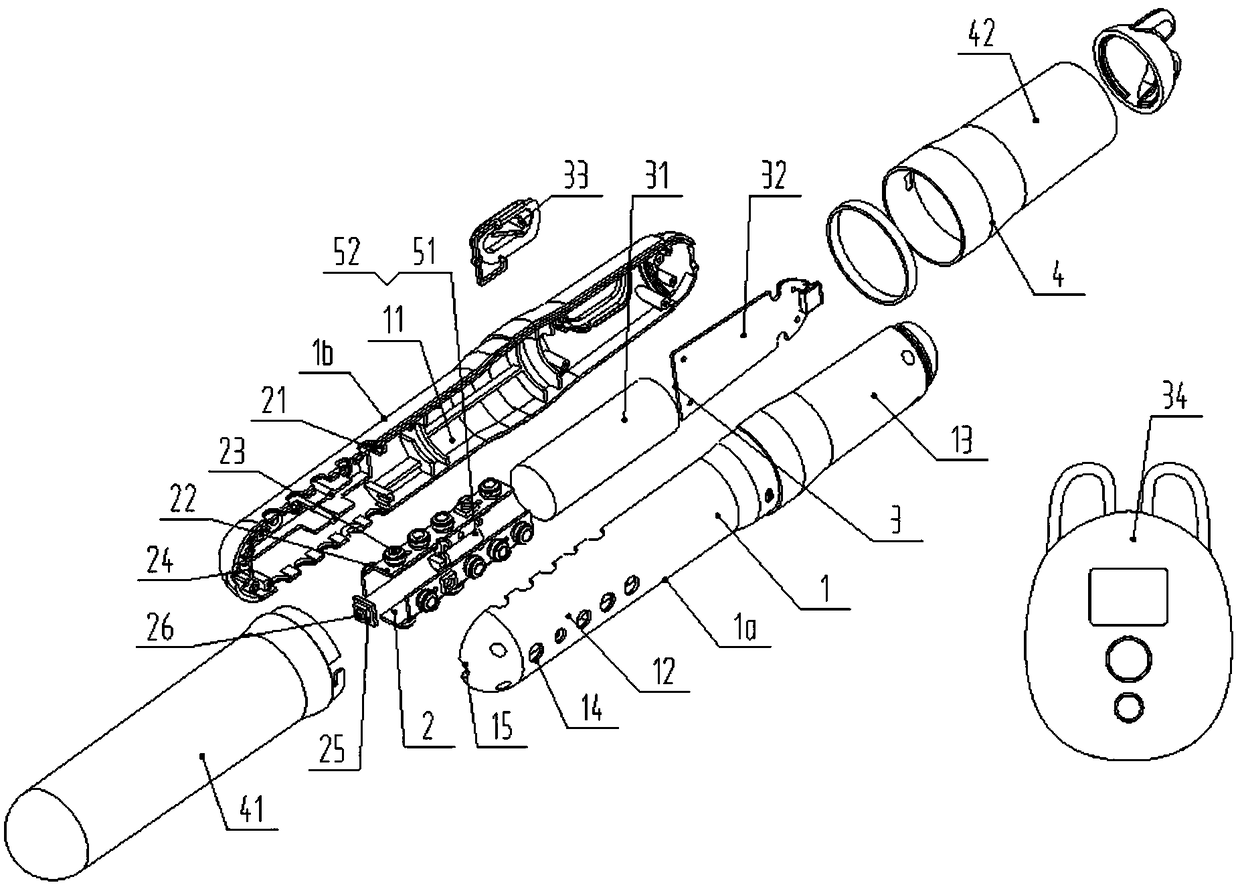

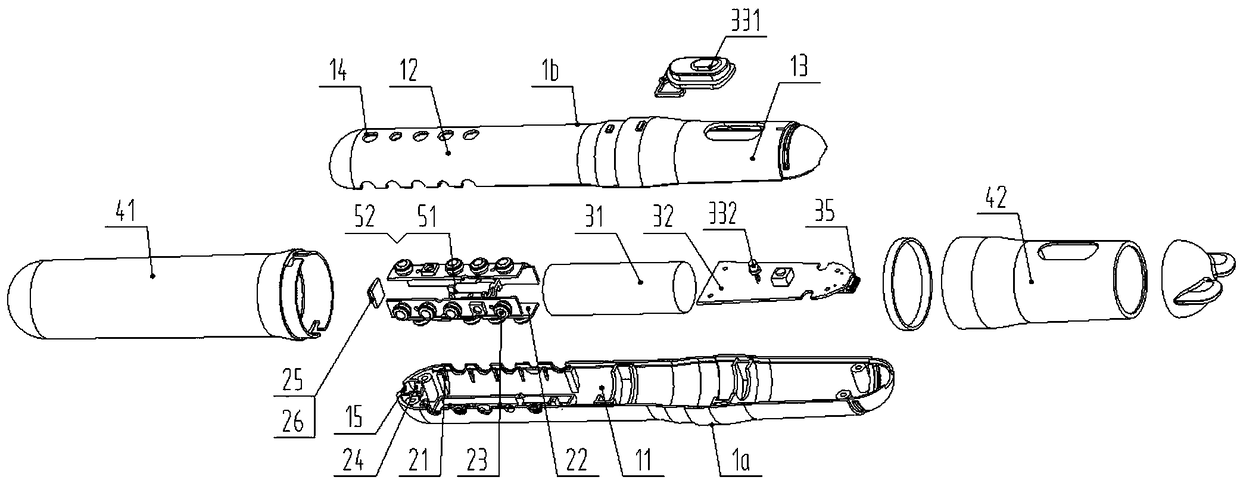

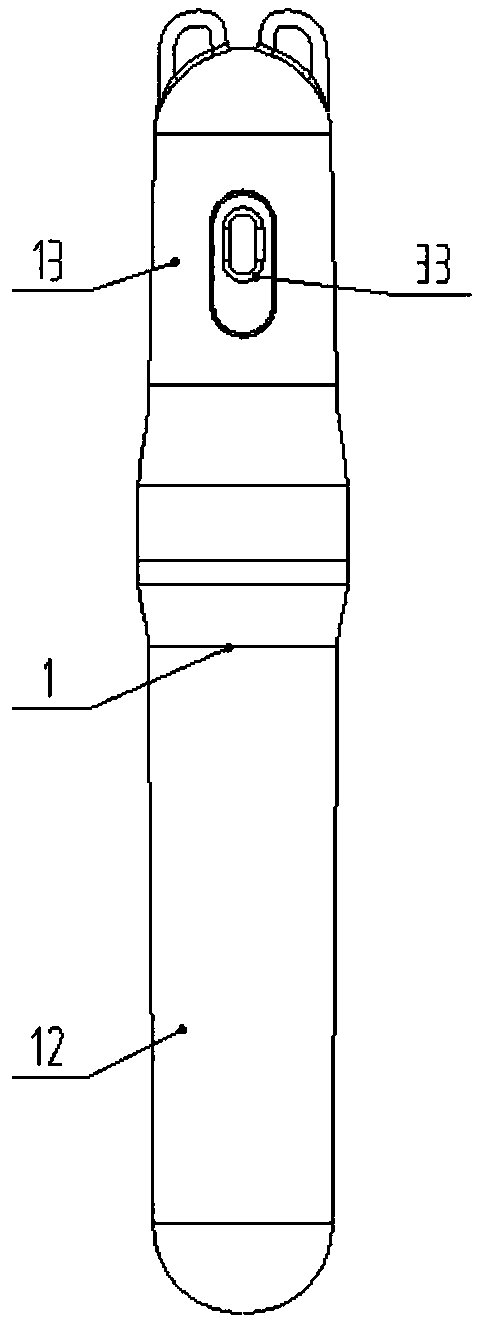

Female private care device

The invention discloses a female private care device. According to the female private care device, the energy light sterilization working principle of a light source assembly is adopted. The female private care device comprises a columnar body, a light source assembly, a driving assembly and a protective cover assembly; a hollow inner cavity is defined in the columnar body; and the columnar body is divided into a care section and a handle section along the axial direction of the columnar body. The female private care device is used, a switch button is pressed, a display light is turned on, and, then the care section is sent into the vagina of a user through the handle section; the turning on of a first lamp tube, a second lamp tube and a vibration motor is realized by remote control through a remote control device; energy light generated by the first lamp tube and the second lamp tube can effectively perform sufficient sterilization or cleaning on the vagina; the user can sense the working of the female private care device through the vibration motor; and the front end of the care section is semi-elliptical or hemispherical, so that the injection of the care section into the vaginaof the user can be benefitted. The female private care device of the invention has the advantages of simple structure, portable convenience, safe use, low cost and high practicability, and is suitable for being popularized and applied in the corresponding field.

Owner:北京立雅科技有限公司

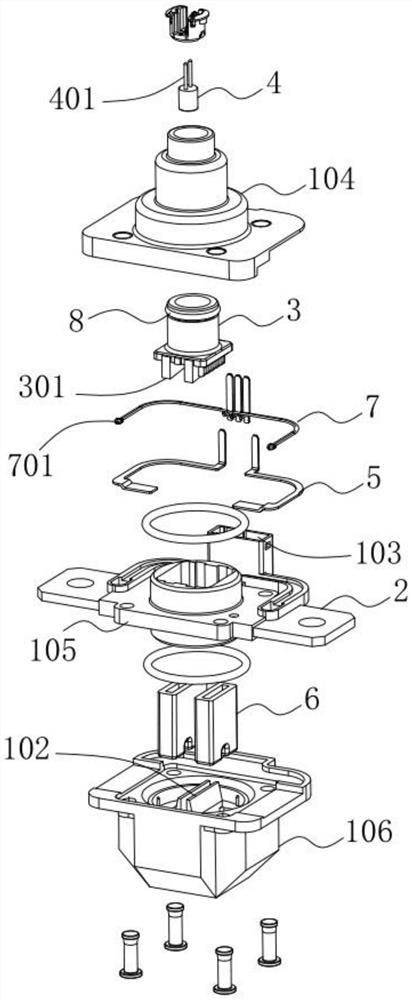

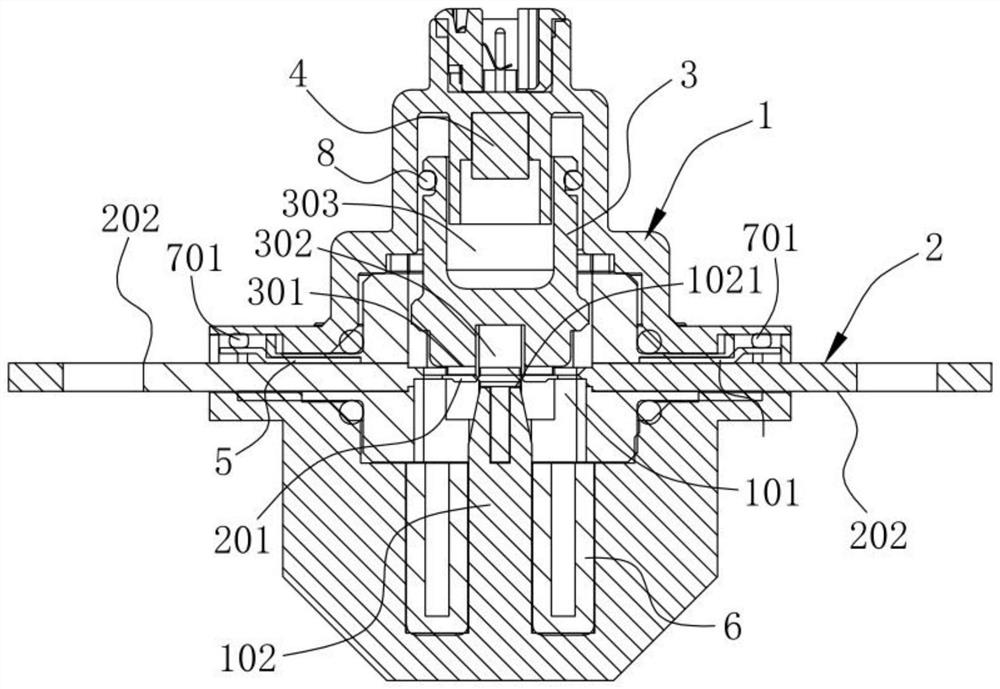

Multifunctional power-off acquisition protection device

PendingCN114334566AProtect the safety of useReduce usageSwitching device condition indicationProtective switch terminals/connectionsElectrical resistance and conductanceElectrical connection

The invention discloses a multifunctional power-off acquisition protection device, which comprises a shell, a working copper bar conductor, a cut-off piston, an ignition trigger and a pair of first signal acquisition terminals, and is characterized in that the shell is internally provided with a cut-off working chamber; the working copper bar electric conductor is inserted into the shell in a penetrating manner, at least one cutting reed is arranged in the cutting working cavity, and the cutting reed is an alloy resistor part made of an alloy material; the cut-off piston is arranged in the cut-off working chamber in a manner of moving up and down and is positioned right above the cut-off reed; the ignition trigger is arranged on the shell and used for driving the cut-off piston to move so as to cut off the cut-off reed when the ignition trigger is triggered to be started. The pair of first signal acquisition terminals is electrically connected to the two ends of the working copper bar conductor respectively. The multifunctional power-off acquisition protection device can realize the functions of current monitoring, overload protection, loop breaking and temperature monitoring.

Owner:昆山国力源通新能源科技有限公司

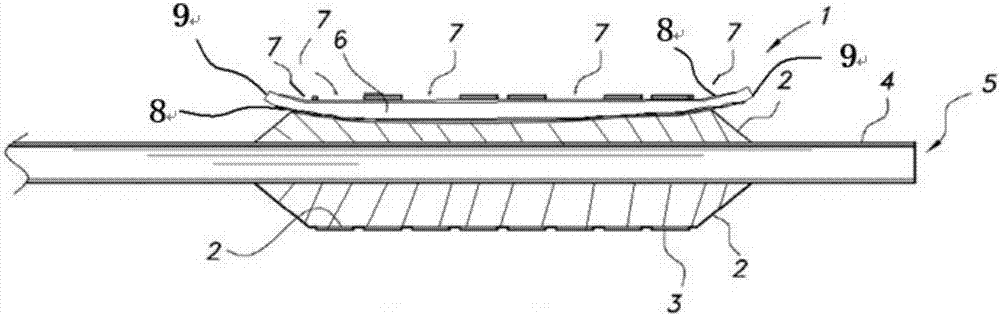

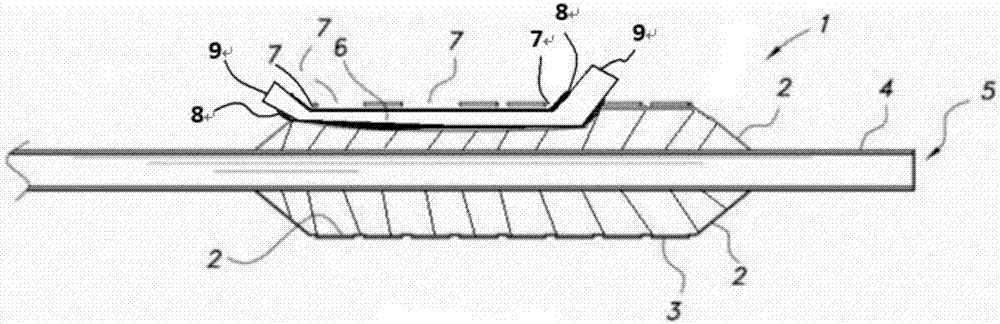

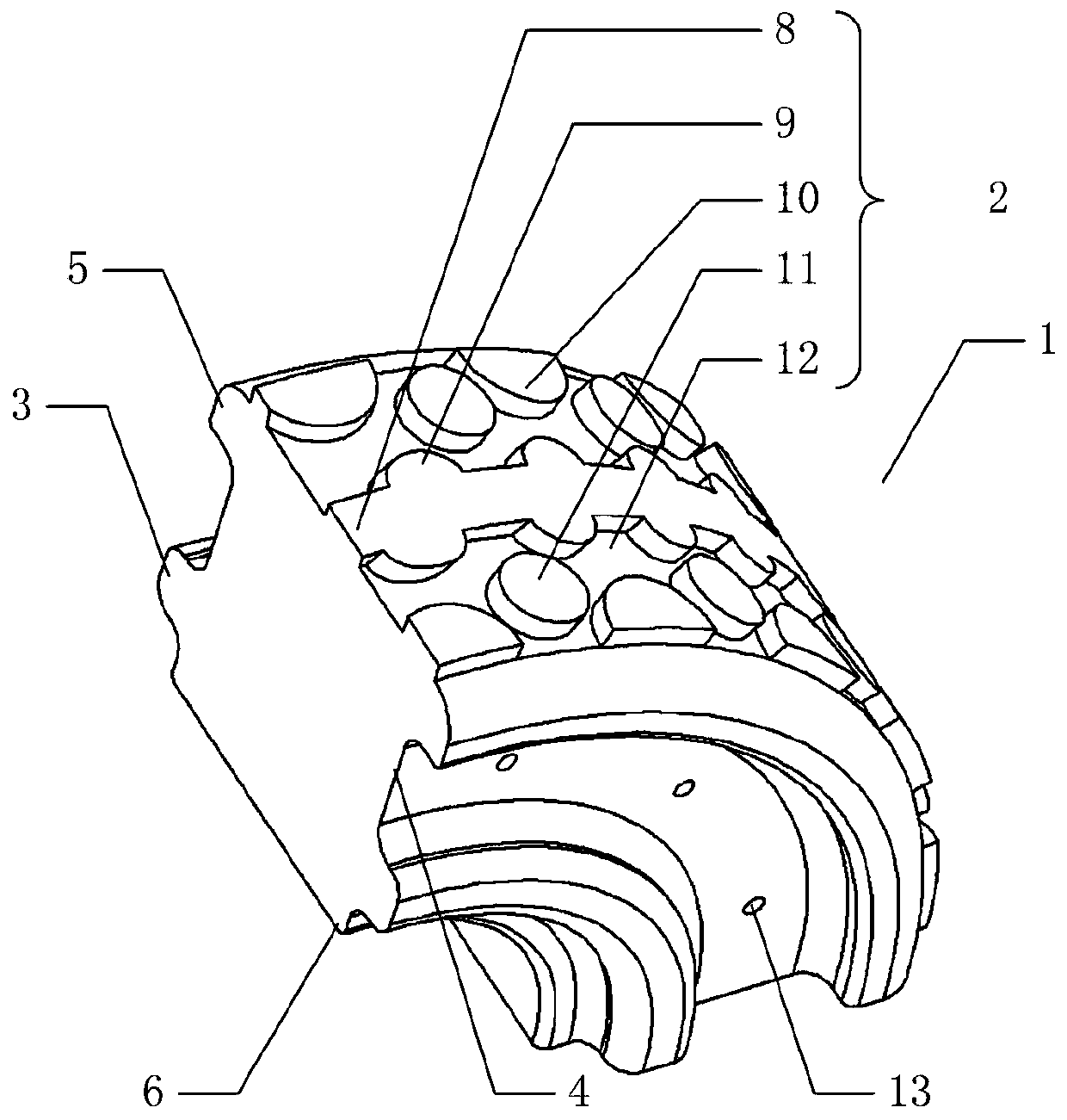

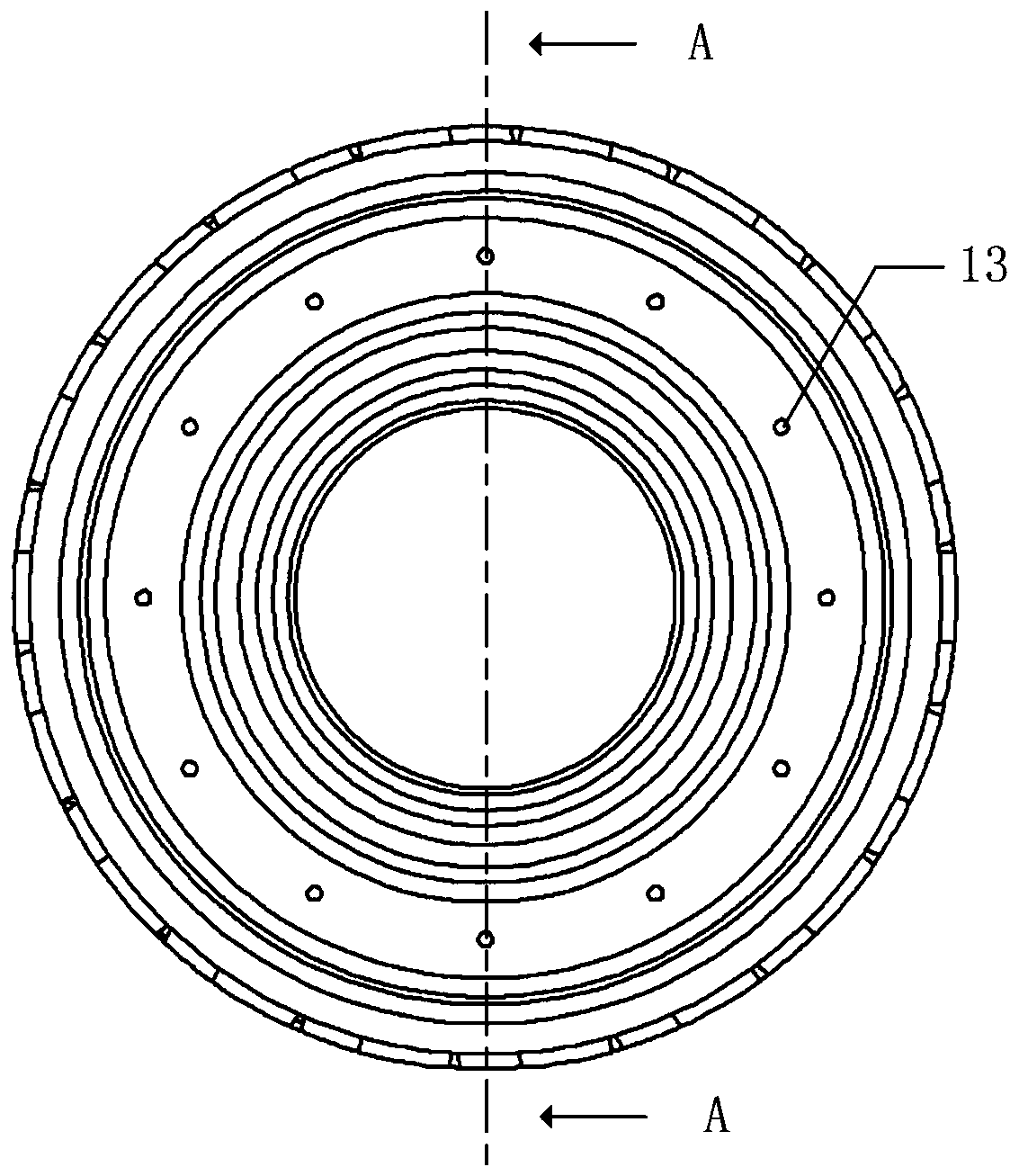

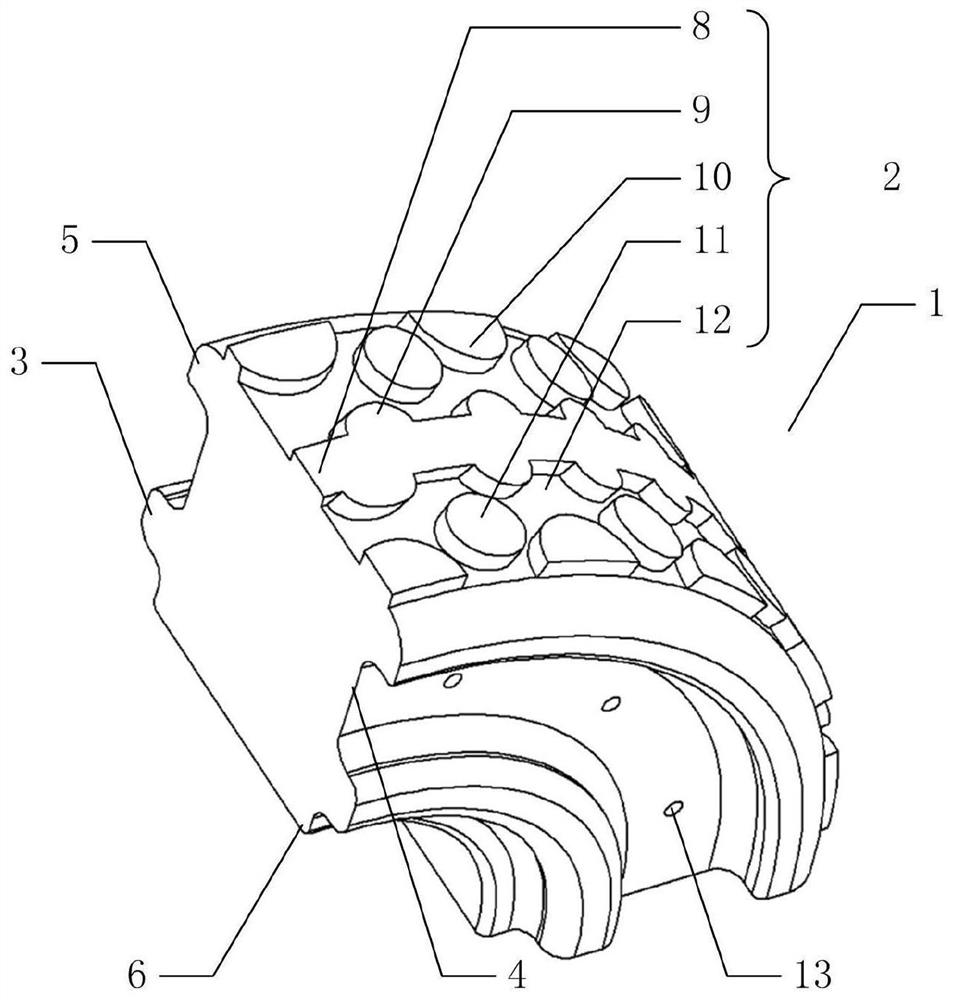

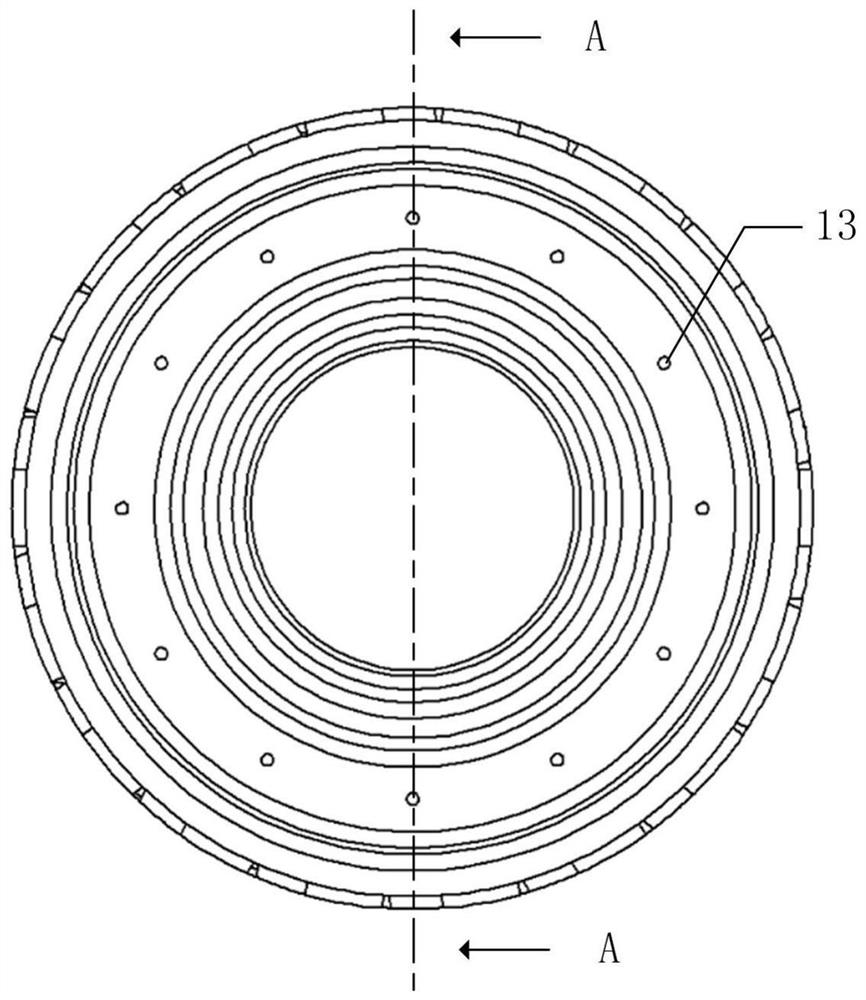

Damping and noise-reducing solid tire and preparation method thereof

ActiveCN110936768AGood barrier and absorbencyReduce vibrationNon-inflatable tyresTyresAutomotive engineeringEngineering

The invention discloses a damping and noise-reducing solid tire and a preparation method thereof, and relates to the technical field of damping and noise-reducing solid tires. Center pattern blocks (8), side pattern blocks (10) and filling pattern blocks (11) are regularly distributed on a tread (2) of the tire body (1), side holes (13) are circumferentially distributed in the second tire side area (4) with the center line of the tire body (1) as the axis, the side holes (13) are inclined taper holes, and open hole circles exposed on the tire side are small circles of the side holes (13). Compared with the prior art, the solid tire has the beneficial effects that the method of adding the hollow inorganic particles into the polyurethane material of the solid tire and improving the structureof the solid tire is adopted, the tread is provided with the pattern blocks, the tire side wall is provided with the side holes, the vibration of the solid tire can be effectively reduced, and the noise is reduced by 2-8 dB.

Owner:YONGYI RUBBER CO LTD

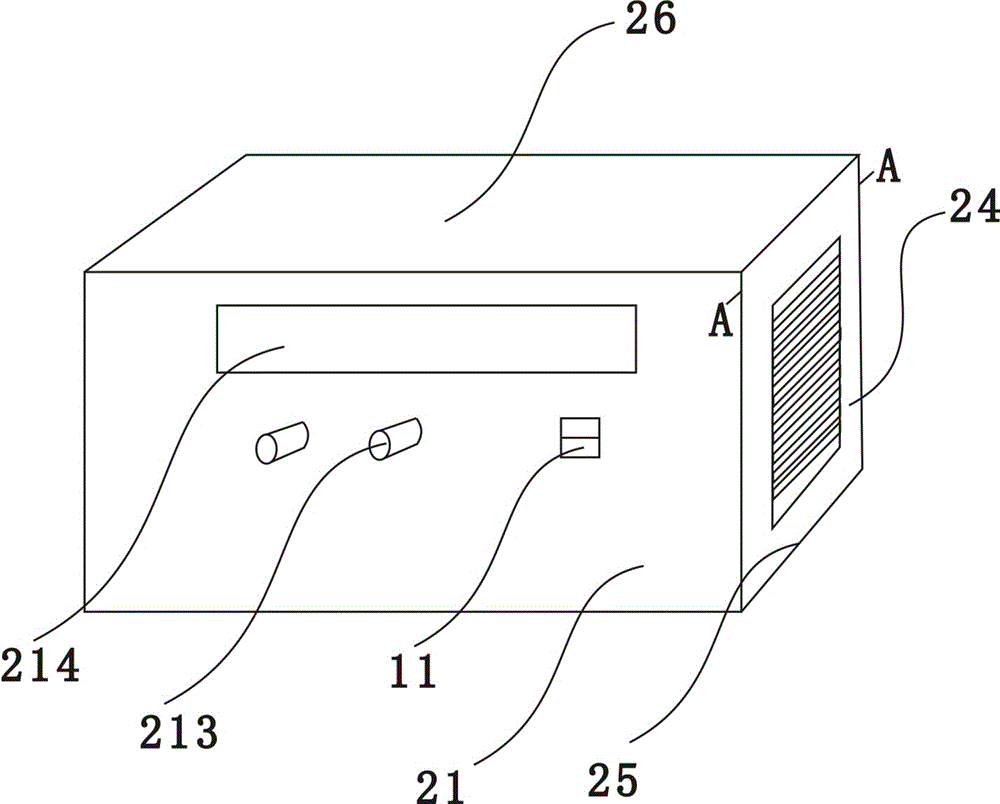

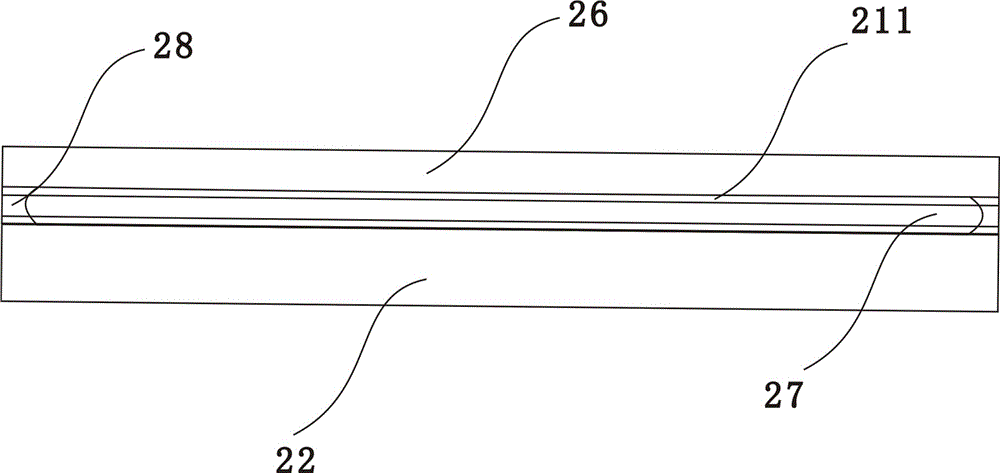

Variable-frequency power source

PendingCN106787784ATimely maintenanceReduced usage stabilityModifications for power electronicsAc-ac conversionFailure rateFrequency changer

The invention discloses a variable-frequency power source, which comprises a housing and frequency changer circuit installed in the inner of the housing, wherein the housing comprises a head board, a backboard, a left board, a right board, a baseplate and a cover plate, wherein on the top of the head board and the back board are both arranged with smooth edges, the cover board is installed with chute, on the inside of the left board and the right board are both arranged with a radiator, at least two through-holes is arranged on the back board, and a radiator fan is installed in the inner of the through-holes. The housing is set to detachable structure for convenient and timely maintenance when the inner of variable-frequency power source breaks down. In the meantime, heat radiation structure is set, which can reduce the stability and safety of power supply due to low heat dissipation. Adopting the variable-frequency power source, the failure rate of variable frequency power supply can be reduced by at least 50%, thereby the performance of the appliance is greatly improved, and the stability is increased.

Owner:四川恒隆电源有限公司

Portable female intimate part nursing device

PendingCN109364382AEasy to feedPlay a role in perceptionLight therapyRemote controlBiomedical engineering

The invention discloses a portable female intimate part nursing device. An energy light sterilization working principle of a light source assembly is employed. The portable female intimate part nursing device comprises a cylindrical body, a light source assembly, a driving assembly and a shield assembly. The cylindrical body has a hollow inner cavity and is divided into a nursing section and a handle section along the axial direction. When the device is in use, a switch key is pressed down and a display light is turned on; the handle section is held and the nursing section is sent into a vagina; a remote control device carries out remote controlling to turn on a first lamp tube, a second lamp tube, and a vibration motor; and the energy light emitted by the first lamp tube and the second lamp tube can carry out full sterilization or cleaning on the vagina effectively. The vibration motor can sense the body when the device works; and the nursing section can be sent into the vagina basedon the semi-elliptical or hemisphere front end of the nursing section. The portable female intimate part nursing device has characteristics of simple structure, high portability, safe use, low cost and strong practicability and is suitable for popularization and application in the field.

Owner:北京立雅科技有限公司

A kind of shock-absorbing and noise-reducing solid tire and preparation method thereof

ActiveCN110936768BSmooth dischargeReduce vibrationNon-inflatable tyresTyresEngineeringInorganic particles

Owner:YONGYI RUBBER CO LTD

Safe ring main unit

InactiveCN104577762ASmooth switchingExtended service lifeSubstation/switching arrangement casingsPulley

The invention discloses a safe ring main unit which comprises a cabinet body and a cabinet door, wherein a hollow cavity is formed in the top of the cabinet body and is open on the front side surface and closed on the other surfaces, and a chute is formed in the bottom surface of an inner cavity of the hollow cavity; the top end of the cabinet door is connected with a pulley through a shaft, the pulley is glidingly connected with the chute in the bottom surface of the inner cavity, and an opening in the front side surface of the hollow cavity adopts a rectangular through hole; a protective cover is arranged at the top end of the front side surface of the hollow cavity; a handle is arranged on the outer side of the lower part of the cabinet door, and a bulge is arranged on the inner side and is movably clamped with a clamping hole in the cabinet body; a mounting plate is arranged in the cabinet body, and radiating holes are uniformly distributed in the upper end and the lower end of the mounting plate. The cabinet door adopts a folding pull type door, the cabinet door can be concealed in the hollow cavity in the upper part of the cabinet body after opened, space outside the cabinet body is saved, maintenance and operation of a worker are facilitated, the safe ring main unit is safe and convenient to use, and the cost is saved.

Owner:STATE GRID CORP OF CHINA +2

Metal high-temperature fire head

PendingCN113666613AReduced form factorHigh temperature control accuracyGlass furnace apparatusTemperature controlEngineering

The invention provides a metal high-temperature fire head, and relates to the technical field of temperature control equipment. The metal high-temperature fire head comprises a fire head shell, gas inlet pipes, a partition plate, a fire distribution plate, gas distribution pipes and a fire outlet, the gas inlet pipe is communicated to the bottom of the fire head shell, the fire distribution plate is fixedly connected to the opening position of the top of the fire head shell, the fire outlet is formed in the fire distribution plate, the partition plate is installed in an inner cavity of the fire head shell, and the gas distribution pipe is arranged between the partition plate and the fire distribution plate. A stainless steel material is selected as a high-temperature fire head material, so that the defects of manufacturing shapes, easiness in breaking and the like are overcome; the two groups of air inlet pipes and the multiple groups of branch air pipes are arranged to form a double-layer steam inlet and multi-pipe branch structure, so that the defect of high-temperature tempering is effectively overcome, and the use safety is ensured; meanwhile, the appearance specification of the high-temperature fire head is reduced, the requirement for manufacturing a small high-temperature fire head is met, the temperature control precision during quartz crystal form transformation can be improved, and the quartz crystal form transformation effect is further improved.

Owner:江苏圣君纳米科技有限公司

Hydraulic locking mechanism for oil storage tank of oil tank truck

InactiveCN107776467AImprove installation stabilityImprove sturdinessTank vehiclesItem transportation vehiclesTelescopic cylinderOperation safety

The invention discloses a hydraulic locking mechanism for an oil storage tank of an oil tanker, which comprises a clamping plate, a clamping plate is arranged on the top of the clamping plate, a clamping groove is opened on the top of the clamping plate, and the clamping plate A positioning pin is arranged on one side of the groove, an oil guide pipe is arranged inside the clamping plate, an oil distribution pipe is arranged inside the oil guide pipe, an oil spray nozzle is arranged inside the oil guide pipe, and a return chamber is arranged on the top of the oil guide pipe. The inner and outer walls of the clamping plate are provided with a hollow plate, and the inside of the hollow plate is provided with balls, and the inner bottom of the clamping plate is provided with a telescopic cylinder, and the telescopic cylinder is connected with a hydraulic locking rod through a hydraulic telescopic rod. The bottom of the holding plate is welded with a bottom plate, the inner surface of the bottom plate is provided with positioning grooves, the two sides of the bottom plate are provided with anti-collision bars, and the outer side of the clamping plate is provided with reinforcing blocks. In the present invention, the overall structural design of the locking mechanism is simple and reasonable, the operation is safe and flexible, no loosening occurs after locking, and it has strong practicability.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

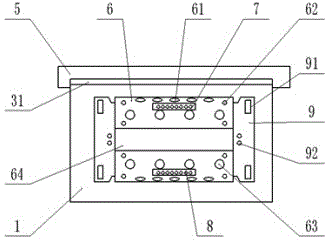

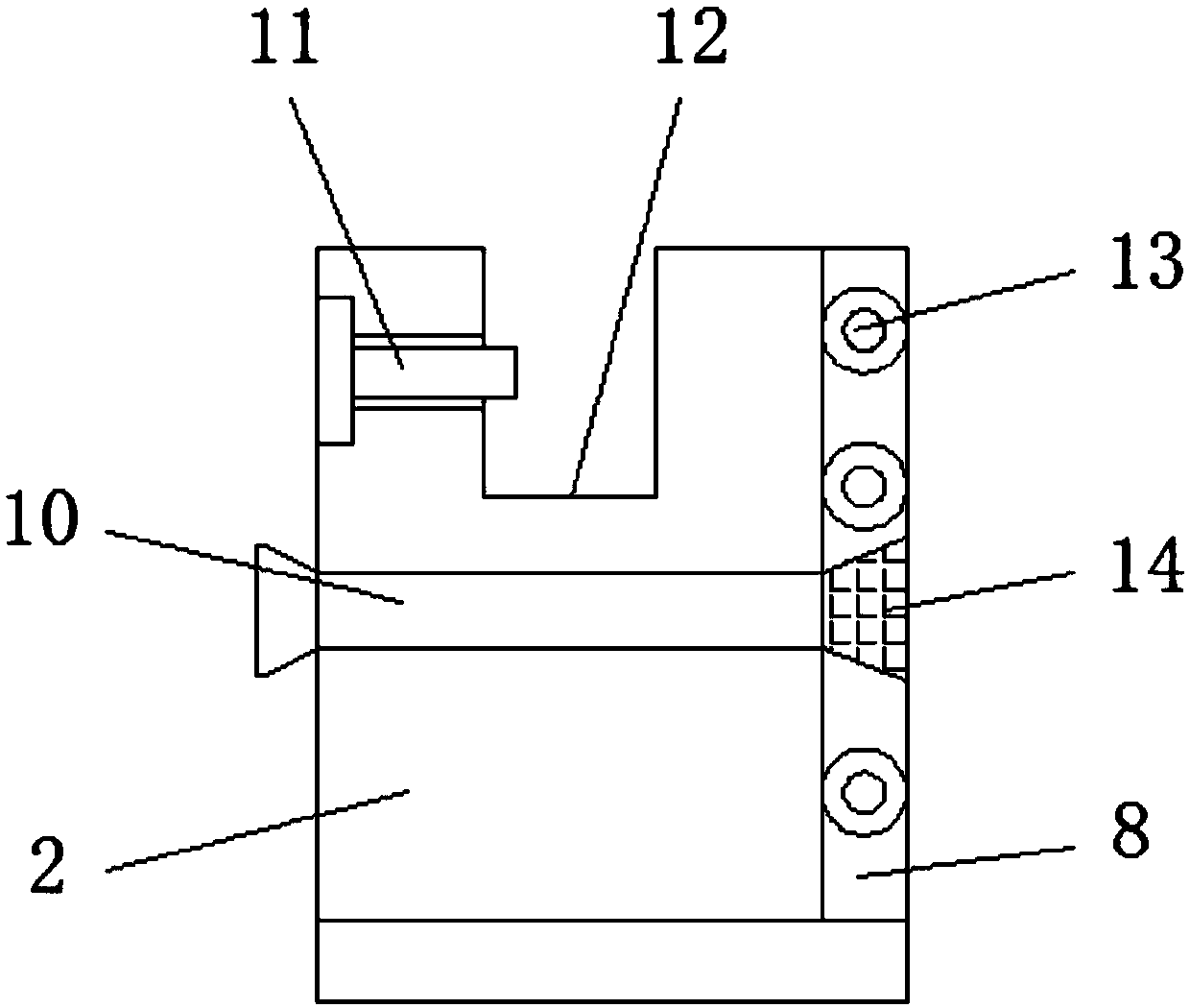

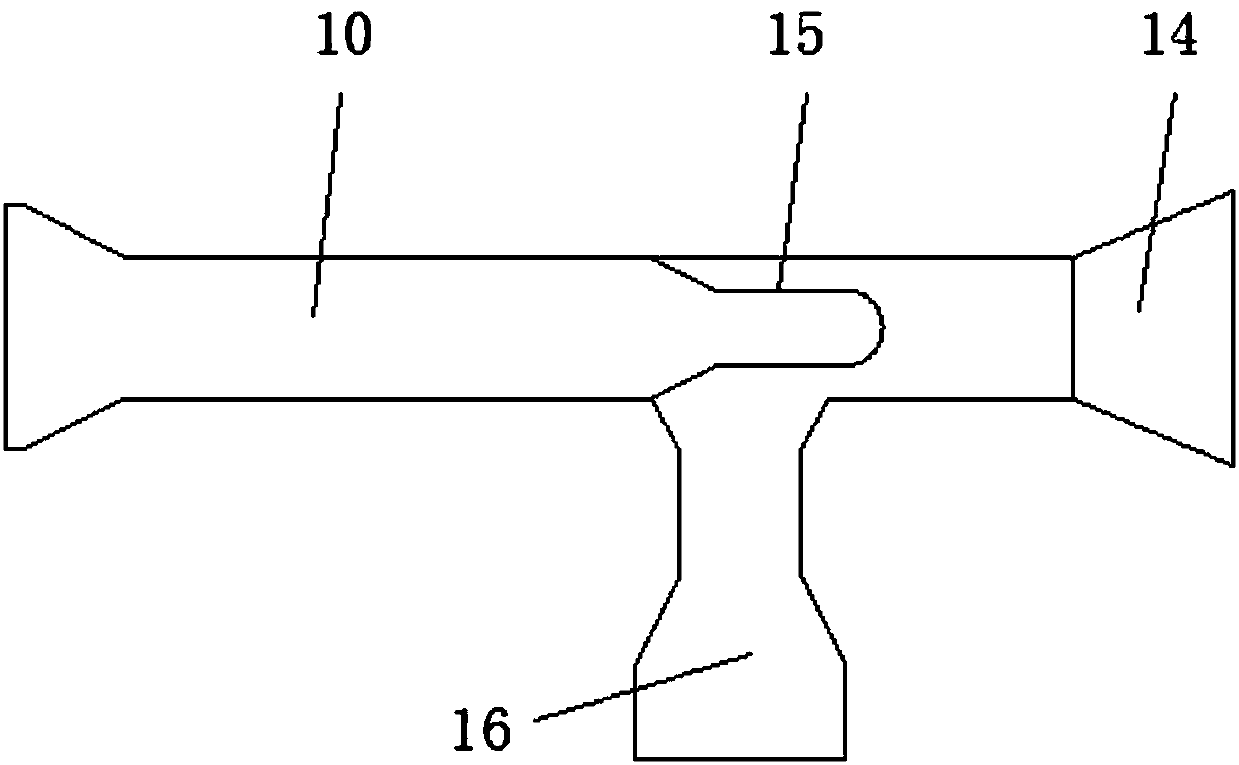

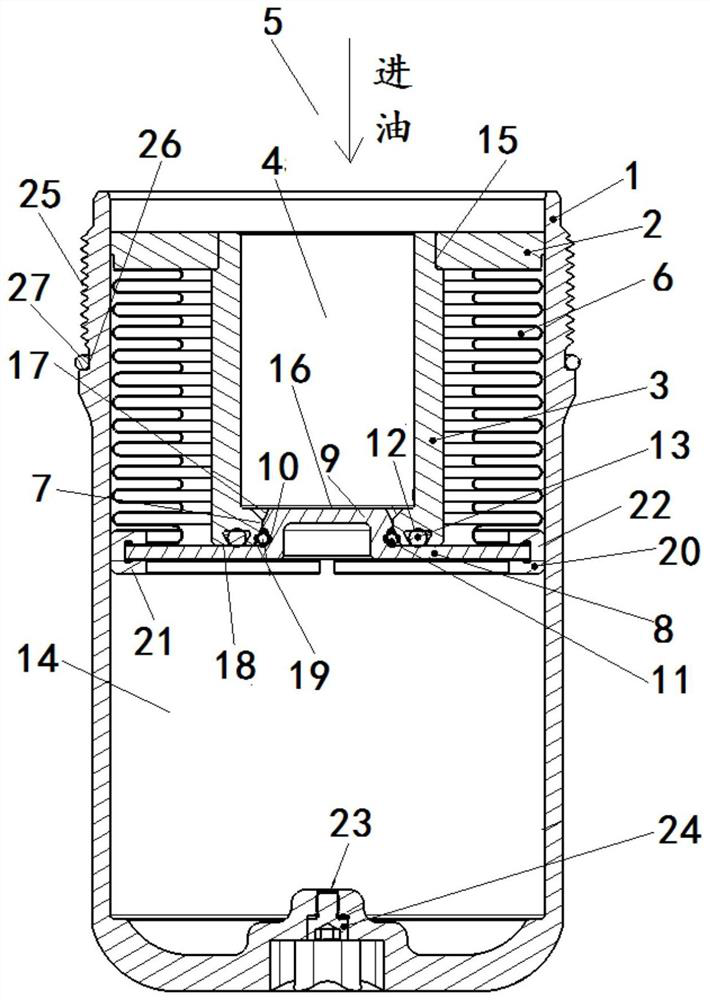

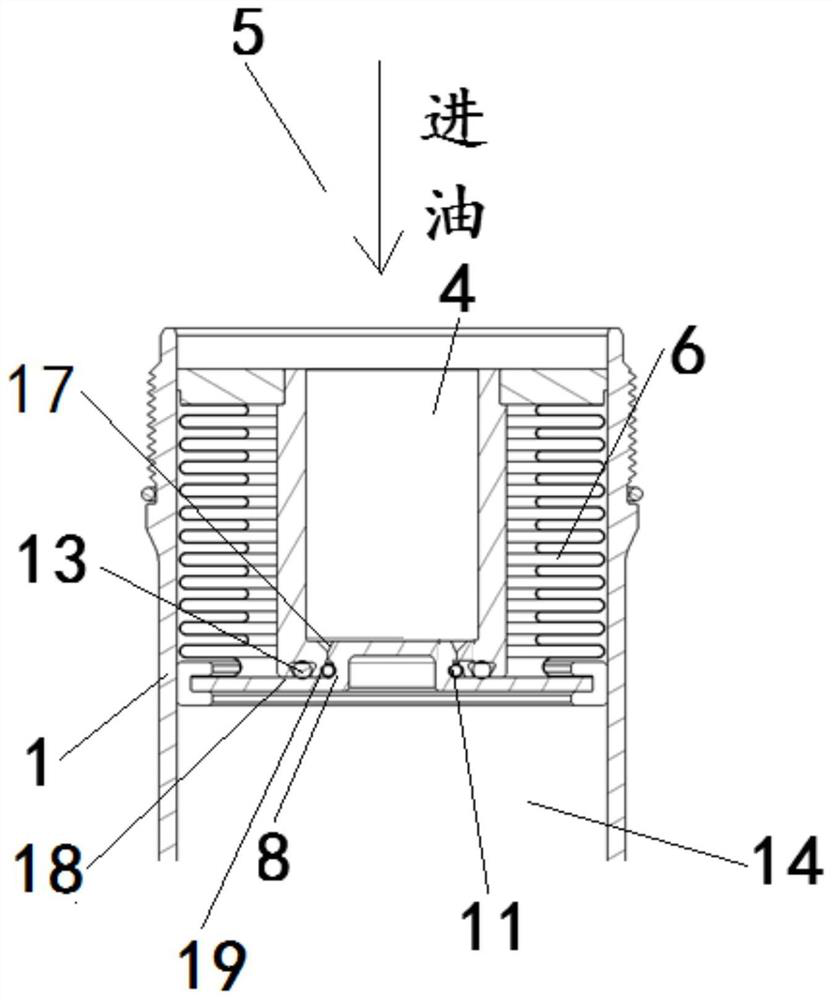

Corrugated pipe type energy accumulator

ActiveCN112324723AMeet the needs of useIncrease resistanceActuator accumulatorsEngineeringAutomotive transmission

The invention provides a corrugated pipe type energy accumulator applied to the technical field of automobile gearboxes. The corrugated pipe type energy accumulator is characterized in that the upperend of a sleeve (3) of the corrugated pipe type energy accumulator is connected with a cover plate (2), an oil cavity (4) is formed inside the sleeve (3), a through hole (7) is formed in the bottom ofthe sleeve (3), a piston (8) is arranged below the sleeve (3), a protrusion (9) on the upper surface of the piston (8) is arranged to be a structure capable of extending into a through hole (7) of the sleeve (3), a sealing ring I (11) is arranged at the outer ring of the protrusion (9) in a sleeving mode, a sealing ring II (13) is clamped to the end face of the end, close to the piston (8), of the sleeve (3), the upper end of a corrugated pipe (6) is connected with the cover plate (2), the lower end of the corrugated pipe (6) is connected with the piston (8), and an air cavity (14) is formedinside a tank body (1) below the piston (8). According to the corrugated pipe type energy accumulator, the upward moving speed of the piston is reduced, the situation that the piston and the sleeve deform or are damaged due to rapid collision of the piston and the sleeve is avoided, and the use safety performance is improved.

Owner:JAPHL POWERTRAIN SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com