Aluminium-coated microprism product with large angle

A micro-prism, large-angle technology, used in layered products, metal layered products, instruments, etc., can solve the problems of small refraction angle, material shrinkage, poor refraction effect of reflective materials, etc., to increase the large incident angle and improve the angle. , the effect of increasing the reflection brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

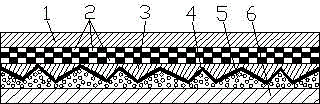

Embodiment 1

[0021] An aluminum-plated microprism product with a large angle, which consists of the following materials:

[0022] The first layer 1: The resin layer is made of acrylic resin, polyester resin, polycarbonate resin, vinyl chloride resin, polystyrene resin, polyolefin resin, fluorine resin, cyclic olefin resin, silicon At least one of ketone resin and polyurethane resin polymethyl methacrylate;

[0023] The second layer 2: use transparent ink to print different changing patterns,

[0024] The third layer 3: the microprism layer is a thermosetting resin coating;

[0025] The fourth layer 4: aluminum metal reflective layer;

[0026] The fifth layer 5: pressure-sensitive adhesive layer;

[0027] The sixth layer 6: release paper.

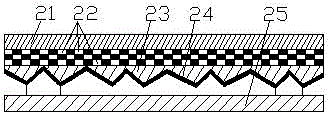

Embodiment 2

[0029] Such as figure 2 As shown, an aluminized microprism product with a large angle is made into a clothing-type flexible reflective tape, which includes the following materials:

[0030] The first layer 21: using ultra-transparent PVC resin, the PHR of the resin is 40-60, and the thickness is 100 μm-200 μm;

[0031] The second layer 22: using transparent ink to print different changing patterns;

[0032] The third layer 23: a microprism layer formed by thermosetting resin coating;

[0033] The fourth layer 24: is a reflective aluminum layer, which can increase the large-angle reflectivity;

[0034] The fifth layer 25: adopts ordinary white PVC resin, and its thickness is 100 μm-200 μm.

[0035] The first material composed of the first layer to the fourth layer is combined with the second material (that is, the fifth layer) by high-frequency hot pressing.

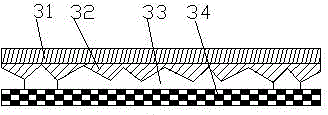

Embodiment 3

[0037] Such as image 3 As shown, an aluminized microprism product with a large angle is made into another clothing-type flexible reflective tape, which consists of the following materials:

[0038] The first layer 31: the material is made of ultra-transparent PVC resin with a PHR of 40-60 and a thickness of 100 μm-200 μm;

[0039] The second layer 32 is a microprism layer formed by a thermosetting resin coating;

[0040] The third layer 33 is made of ordinary white PVC resin, and printed with transparent ink to change different patterns, and its thickness is 100 μm-200 μm;

[0041] The first material composed of the first layer to the second layer is combined with the second material (that is, the third layer) by high-frequency heat pressing.

[0042] For materials printed on the 4th layer 34, the printed pattern cannot be seen on the front, but the printed pattern can be seen on the side, which is similar to a phantom effect. (Microprism dead angle) does not reflect, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com