Patents

Literature

53results about How to "Fully miscible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

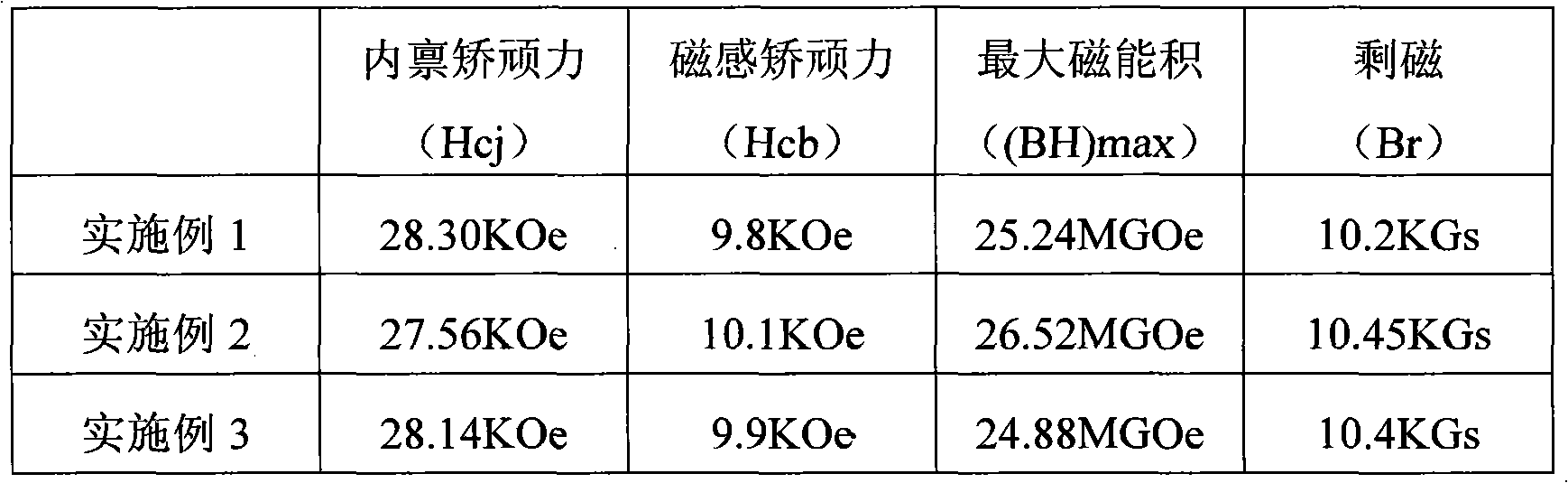

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

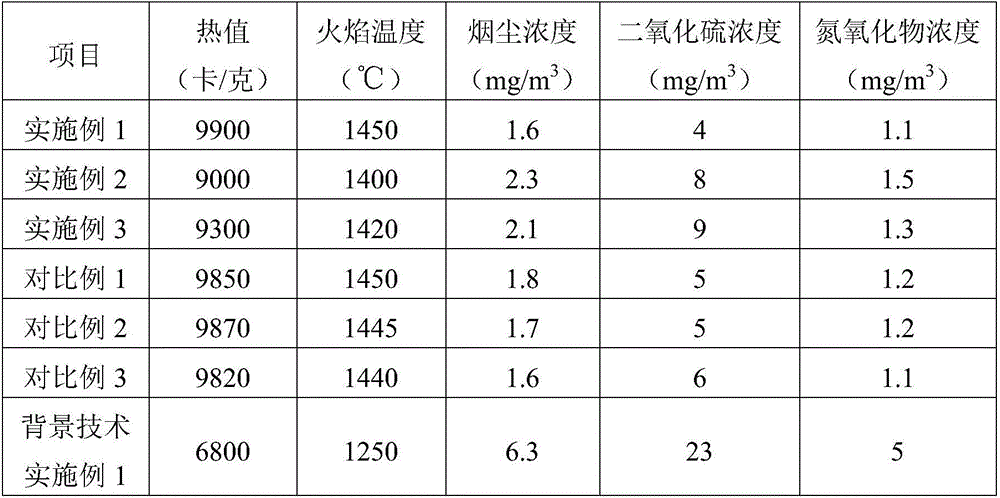

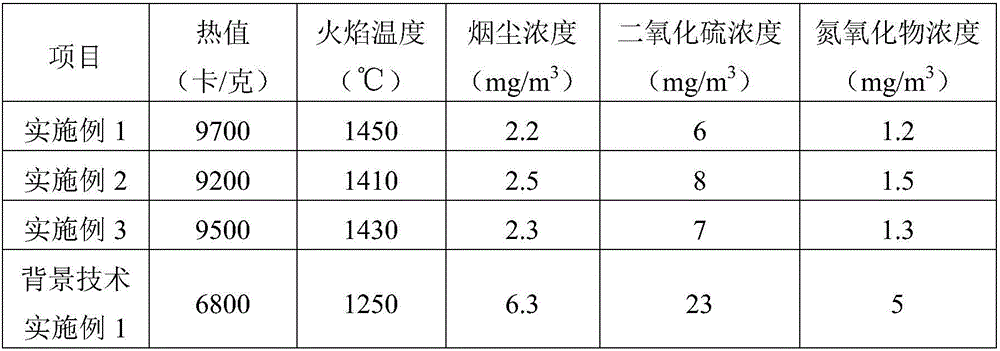

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

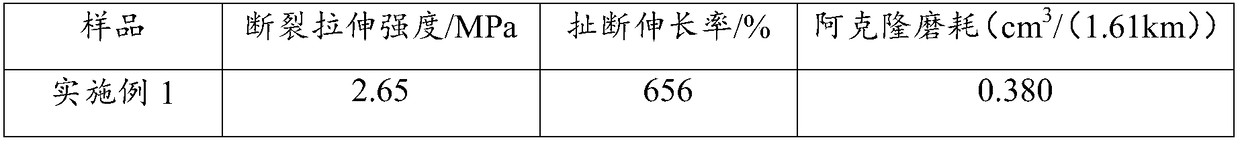

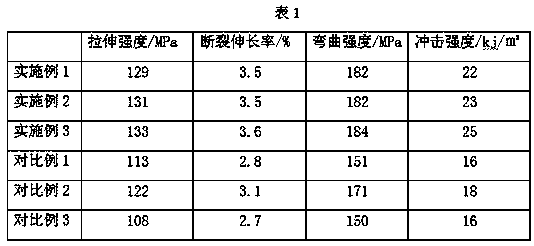

Environment-friendly rubber prefabricated track coiled material and preparation method thereof

The invention discloses an environment-friendly rubber prefabricated track coiled material and a preparation method thereof, and relates to the technical field of track coiled materials. The rubber prefabricated track coiled material is mainly prepared from the following raw materials in parts by weight: 30 to 60 parts of ethylene propylene rubber, 40 to 80 parts of reclaimed rubber, 20 to 50 parts of an LLDPE and HDPE blend, 1 to 30 parts of a nanometer rare earth oxide, 5 to 10 parts of a vulcanizing agent, 6 to 12 parts of paraffin oil, 10 to 15 parts of naphthenic oil, 1 to 5 parts of zincoxide and 50 to 200 parts of a filler, wherein the reclaimed rubber is a mixture of butyronitrile reclaimed rubber and butyl chloride reclaimed rubber, and the mass ratio of the butyronitrile reclaimed rubber to the butyl chloride reclaimed rubber is 2: (0.5 to 1). The environment-friendly rubber prefabricated track coiled material solves the problem that a rubber track coiled material is low inabrasive resistance, tensile strength and elasticity and not environmentally friendly at present, the obtained rubber prefabricated track coiled material is excellent in physical and mechanical performances and has excellent tensile strength and abrasive resistance, the product is free of noxious substance residue, and the recycled reclaimed rubber is cost-saving, safe and environmentally friendly.

Owner:湖南盛亚体育实业有限公司

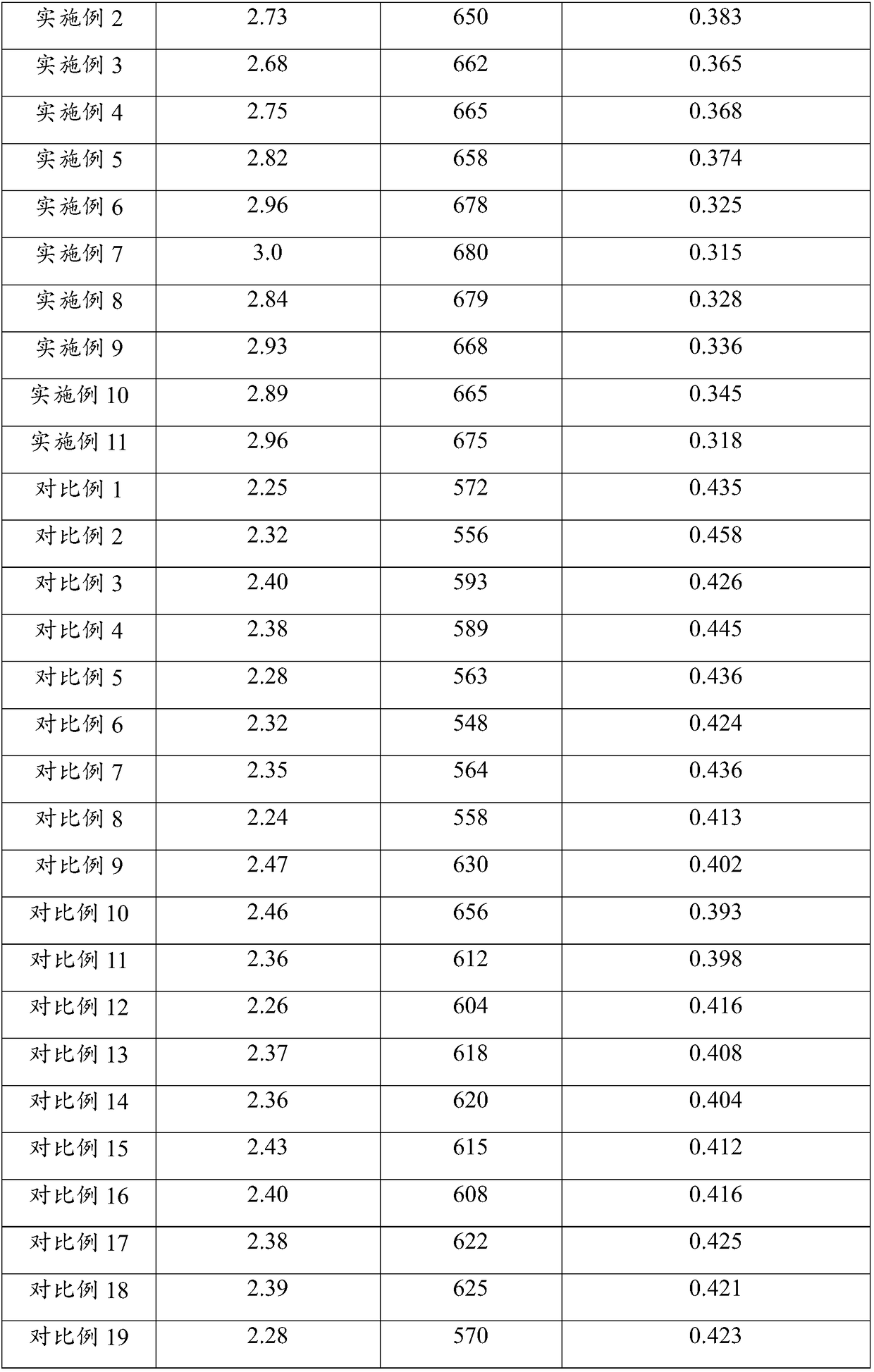

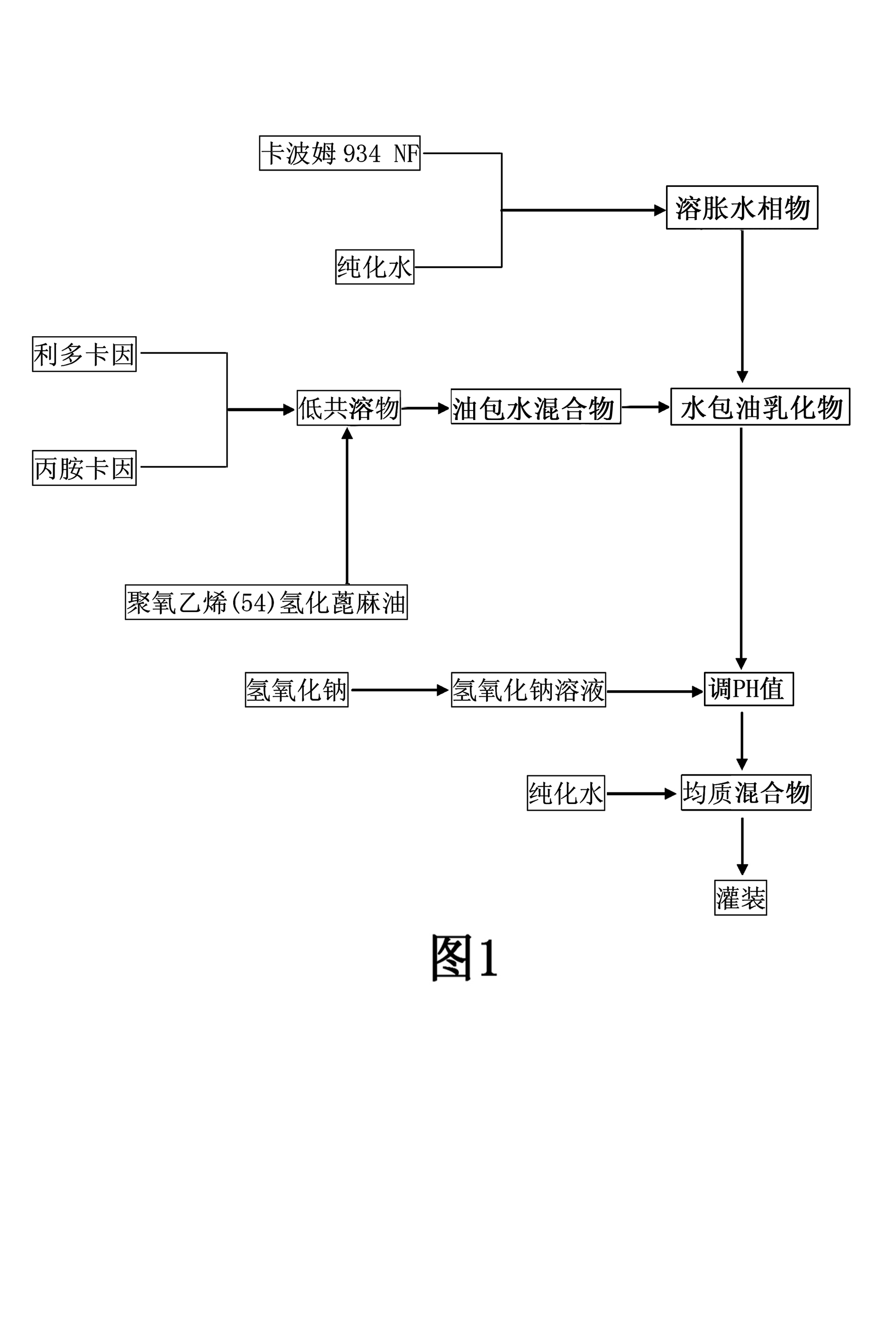

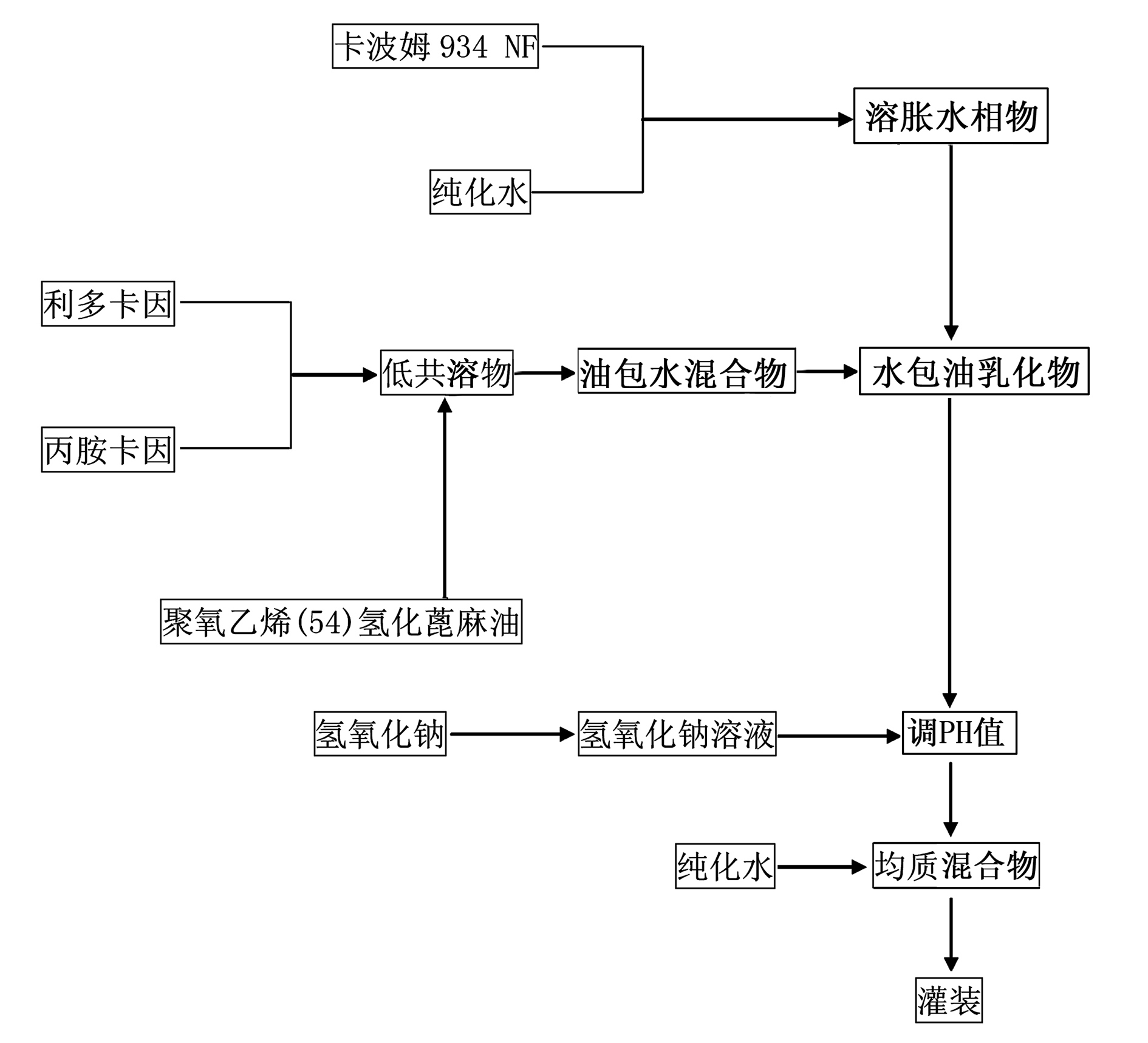

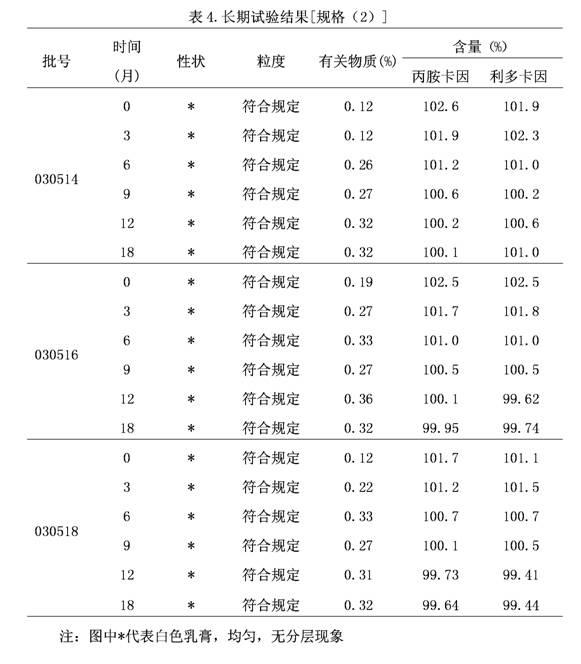

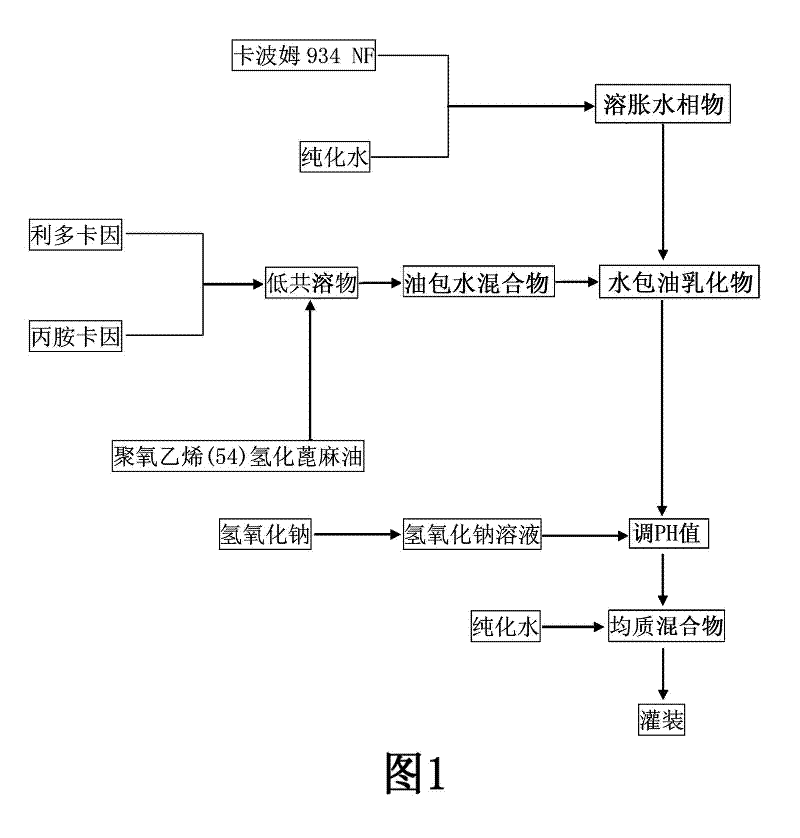

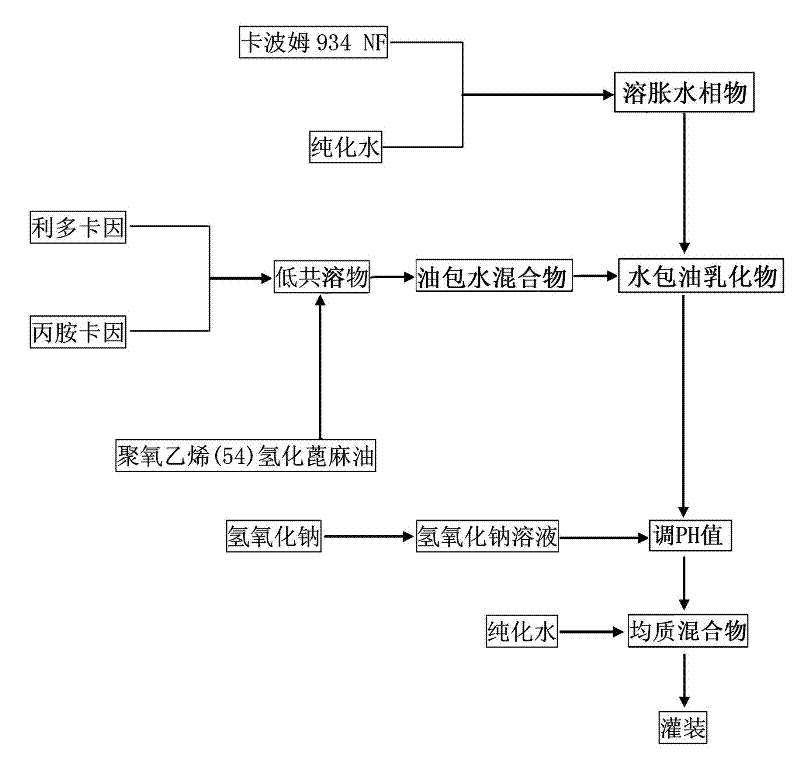

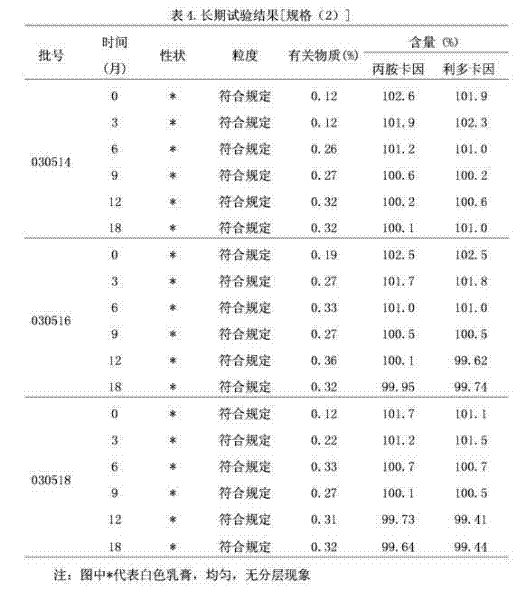

Compound lidocaine emulsifiable paste and preparation method thereof

ActiveCN101816642AAchieve anesthesiaNo corrosionAntibacterial agentsOrganic active ingredientsActive agentSurface-active agents

The invention discloses a compound lidocaine emulsifiable paste and a preparation method thereof. Each 10kg of the compound lidocaine emulsifiable paste comprises the following components according to the weight: 50-1000g of base lidocaine, 50-1000g of base prilocainum, 10-500g of polyoxyethylene hydrogenated castor oil, 10-300g of Carbomer, 40-200g of sodium hydroxide and the balance of pure water. The invention increases clinical use security through releasing lidocaine and prilocainum in base modes to the subcutaneous layer with the depth of 5mm without containing a penetrating agent or a surface active agent component, which is particularly suitable for children patients and patients for face beauty. Through improvement on production process steps, the invention enables the production operation to become easy and feasible, is easy to control the product quality and increases the product stability. The whole production cycle is only half day, and the production efficiency is improved by more than 3 times, thereby the raw materials are saved and the production cost is reduced.

Owner:北京中泰邦医药科技有限公司

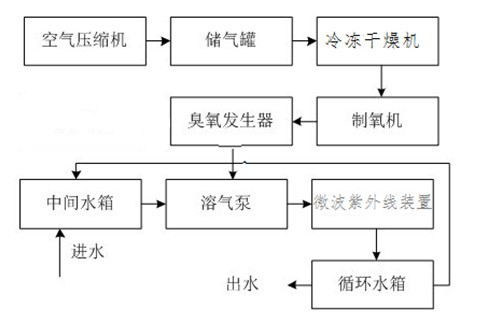

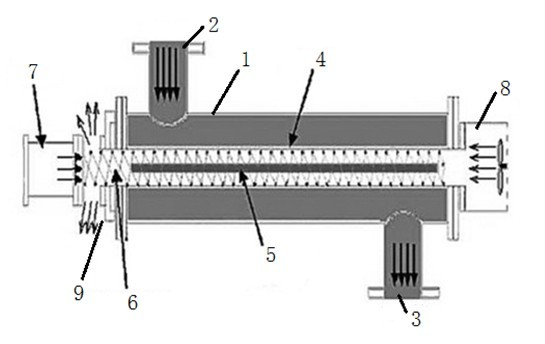

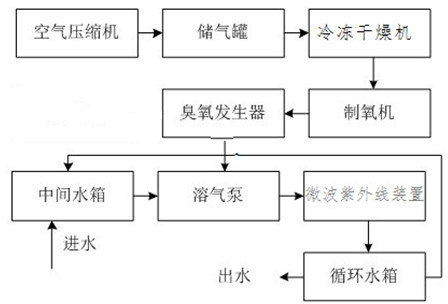

Advanced wastewater treatment system by aid of ozone and microwave ultraviolet light oxidation

InactiveCN102616882AOvercome strengthOvercome electrode failureWater/sewage treatment by irradiationMixing methodsFreeze-dryingUltraviolet lights

The invention relates to an advanced wastewater treatment system by aid of ozone and microwave ultraviolet light oxidation, and relates to an organic wastewater treatment device. The technical scheme includes that the advanced wastewater treatment system comprises an air compressor, a gas storage tank, a freezer dryer, an oxygenerator, an ozone generator and a dissolved gas pump which are successively connected, wherein two inlets and an outlet are arranged on the dissolved gas pump, the ozone generator is connected with one of the inlets of the dissolved gas pump, the other inlet of the dissolved gas pump is connected with an intermediate water tank, the outlet of the dissolved gas pump is connected with a microwave ultraviolet light device, the rear end of the microwave ultraviolet light device is connected with a circulation water tank, a partition board is arranged in the circulation water tank, water on the upper layer of the partition board is drained out, and water on the lower layer of the partition board returns to the intermediate water tank via a pipe. The advanced wastewater treatment system has higher oxidation efficiency, the service life of equipment is prolonged, the wastewater is sufficiently mixed with ozone, and the efficiency of the advanced wastewater treatment system under actions of microwave ultraviolet light is greatly increased as compared with a system independently using ozone or ultraviolet light technology.

Owner:四川省科学城中心科技有限公司

Heavy asphalt warm mixing agent and preparation method thereof

InactiveCN102838317AImprove viscosity-temperature characteristicsTechnical nature does not affectClimate change adaptationAsphaltPitch blende

The invention provides a heavy asphalt warm mixing agent, and particularly relates to a heavy asphalt warm mixing agent and a preparation method thereof. The heavy asphalt warm mixing agent consists of raw materials in parts by weight as follows: 8-10 parts of heavy aromatics, 50-60 parts of tall oil polycarboxylic acid, 15-20 parts of diethanolamine ester, and 10-15 parts of allyl alcohol polyoxy alkyl ether. According to the preparation method provided by the invention, the tall oil polycarboxylic acid is used as a main raw material to prepare the warm mixing agent, so that the conventional limitation on raw materials of the warm mixing agent and the synergistic effect of various raw materials can be expanded, and a very small amount of the prepared warm mixing agent can be sufficiently mixed and dissolved with heavy asphalt. On the premise of not changing key technical indexes of the heavy asphalt, and the viscoelastic property and the rheological property of the asphalt, the interface tension between the asphalt and aggregates is reduced, so that the bituminous mixture mixing and pressing temperature is reduced by 20-40 DEG C, and the effects of energy conversation and emission reduction can be realized.

Owner:SHANDONG JIANZHU UNIV

Blend edible oil of peony seed oil and rice germ oil and preparation method of blend edible oil

ActiveCN103815058ALow in linolenic acidNot easily oxidizedEdible oils/fatsOil and greaseHeating time

The invention provides a blend edible oil of peony seed oil and rice germ oil and a preparation method of the blend edible oil. The blend edible oil comprises 42-65% of peony seed oil, 33-52% of rice germ oil, 1-4% of tomato extractive and 1-2% of catechin; the preparation method of the blend edible oil comprises the following steps: the preparation of the peony seed oil; the mixing of main materials; the formation of an emulsification system, and finally, the formation of the finished product of clarified blend edible oil, wherein a subcritical extraction technology and a molecular distillation technology are adopted and combined to extract the peony seed oil, so that the operating temperature is low, the heating time is short, the grease oxidation and rancidification caused by high-temperature can be avoided, the separation degree and the yield coefficient of the product are relatively high, and the acid value of the peony seed oil can also be reduced by the molecular distillation; meanwhile, the blend edible oil is reasonable in matching, healthy, and balanced in nutrition, so that blend oil with high stability and low oil fume generation volume can be formed, and health of long-term cooks is maintained.

Owner:LUOYANG CHUNKUI AGRI DEV

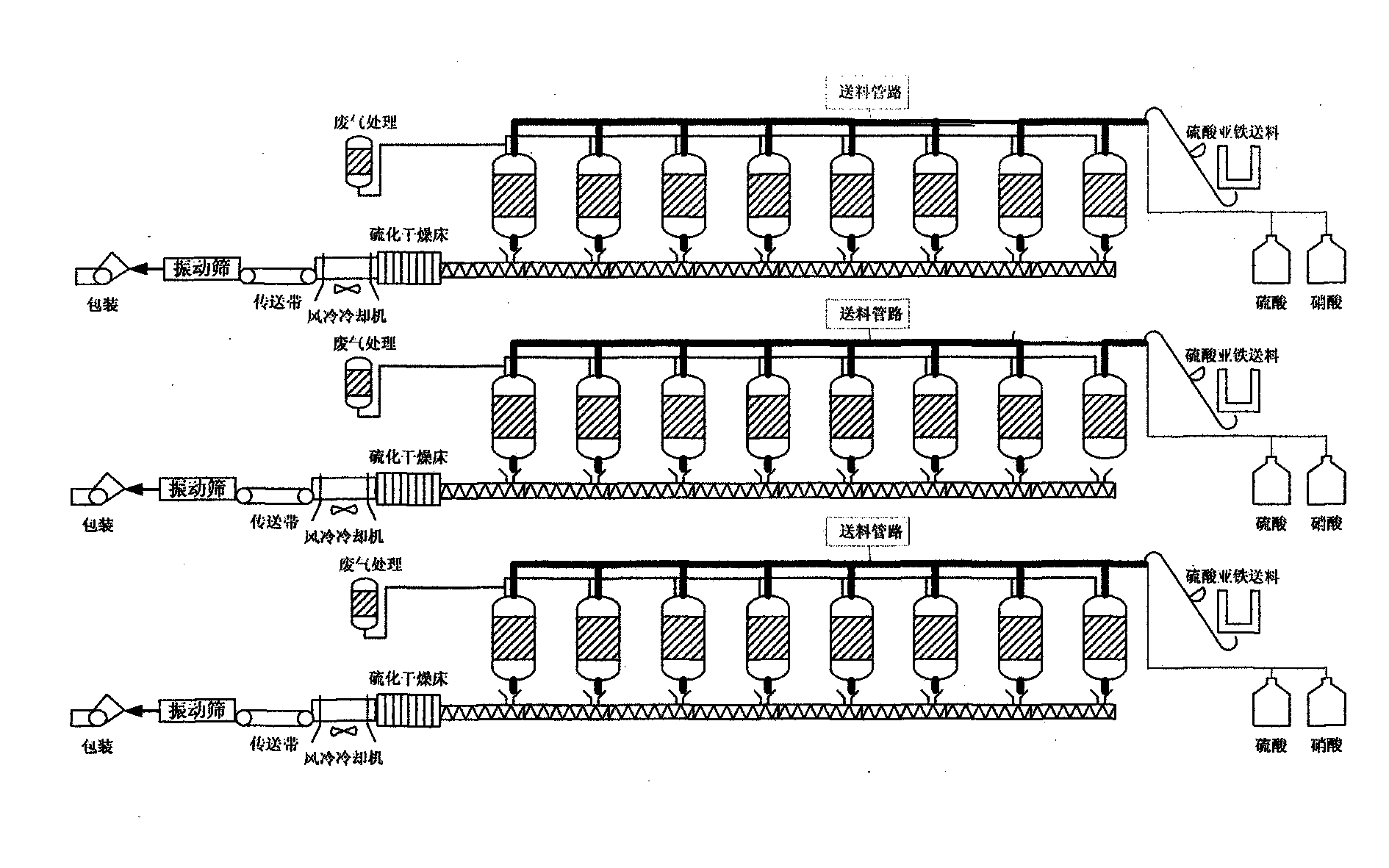

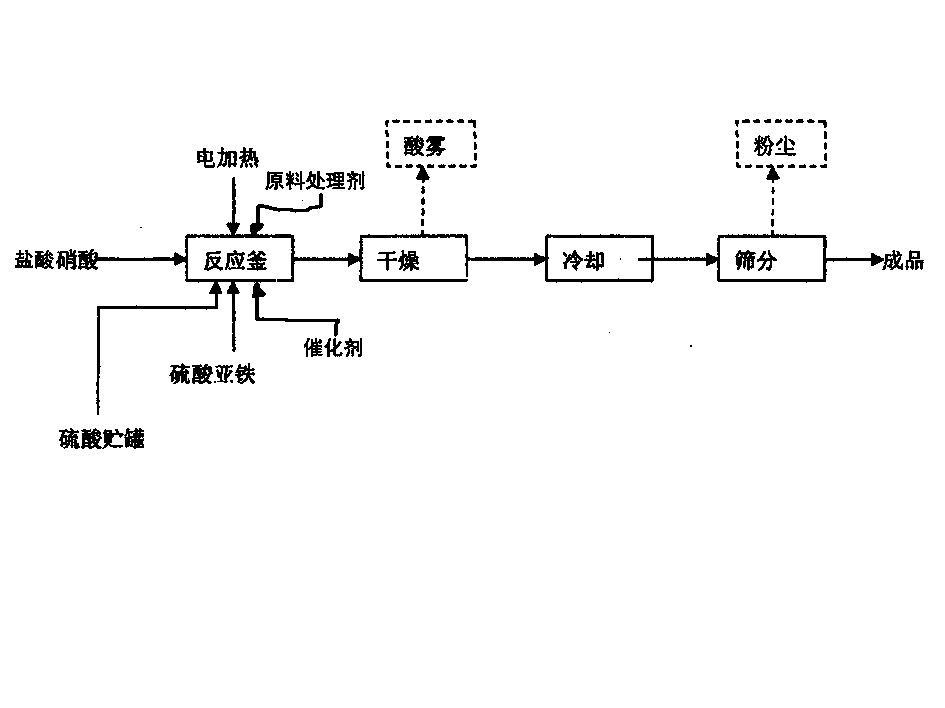

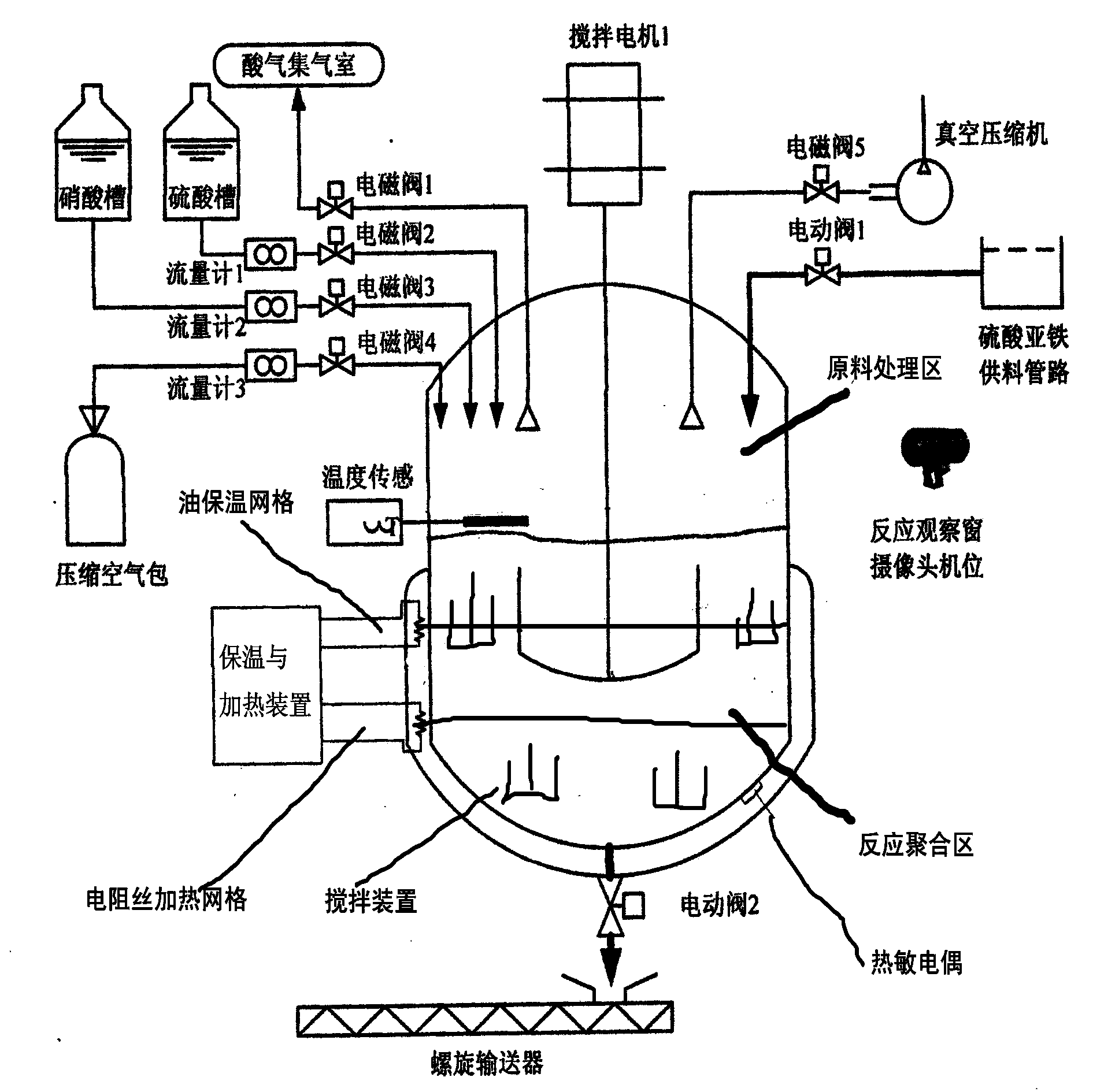

Production method for solid polyferric sulphate

InactiveCN103449535AFully aggregatedFully miscibleIron sulfatesWater/sewage treatment using germicide/oligodynamic-processIron sulfatePhysical chemistry

The invention belongs to the field of water treatment, and particularly discloses a production method for high-purity solid polyferric sulphate, wherein ferrous sulphate and concentrated sulphuric acid are used as raw materials, and ferrous sulphate is treated at first in a reaction kettle; the treatment method comprises the following steps of: uniformly mixing 7-11% of solid acid and 1-2% of rare earth in ferrous sulphate; pouring the ferrous sulphate in the heating area of the reaction kettle; and feeding the treated ferrous sulphate in the reaction area of the reaction kettle, and performing reaction polymerization. The solid polyferric sulphate (SPFS) produced by the production method disclosed by the invention is high in purity, high in iron content of greater than 23%, high in heating amount after being contacted with water, serious in reaction and capable of generating a dynamic energy. The product can be directly poured in water and used for performing a purification treatment on water, simple in use method, low in dosage, and remarkable in water treatment effect.

Owner:白占卿

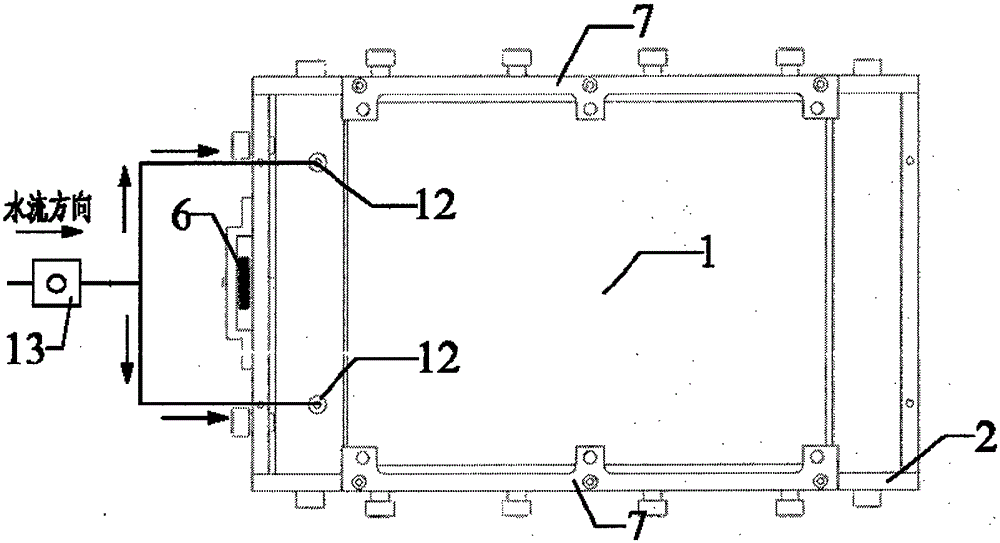

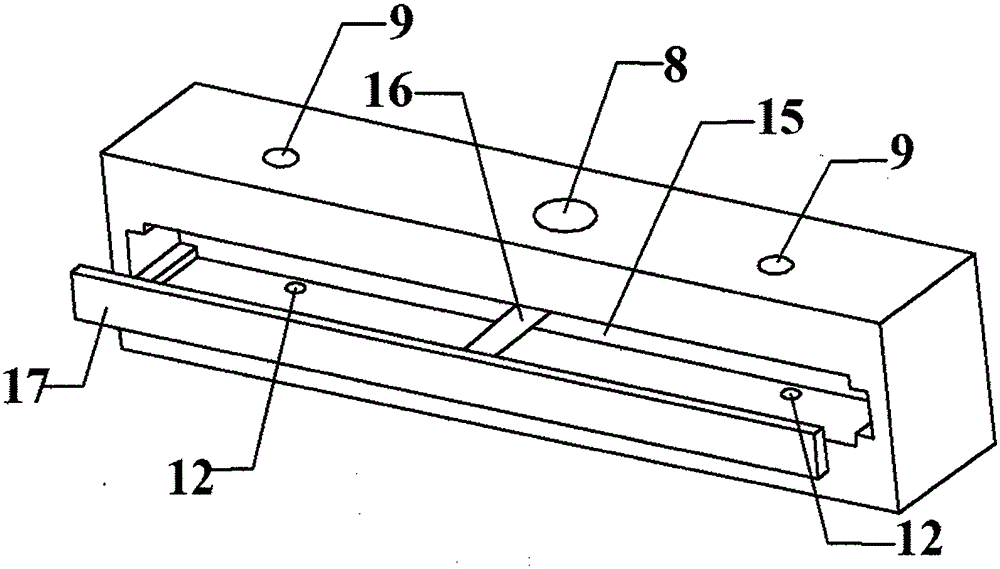

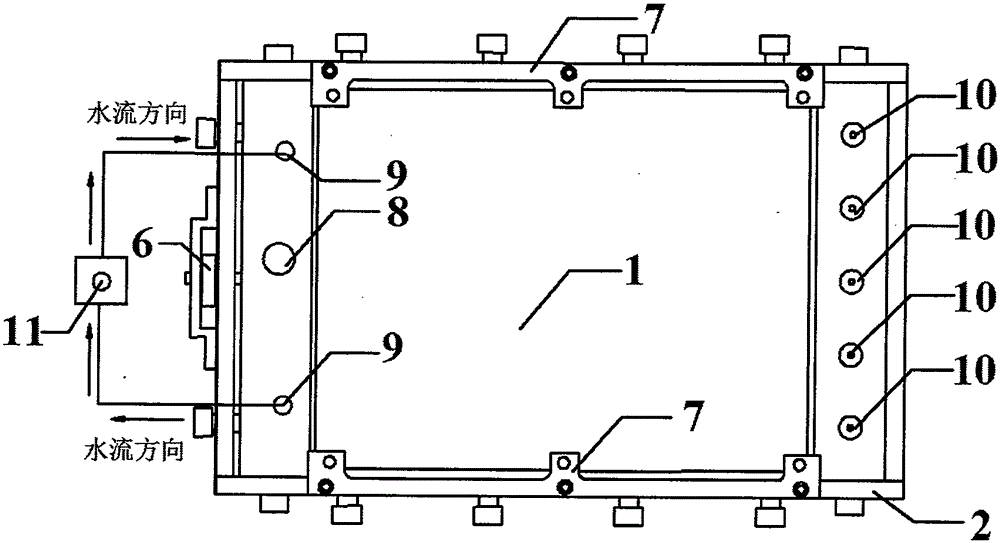

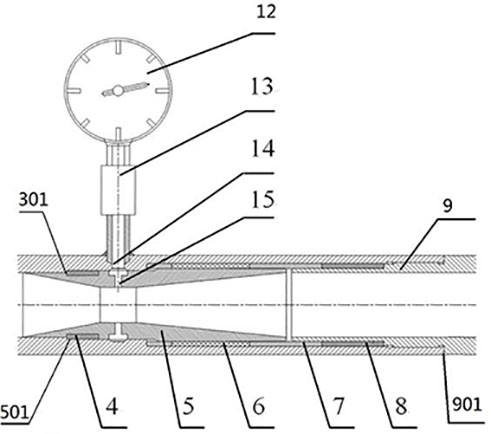

Multifunctional fissure medium underground water testing device

InactiveCN106546707AAchieve regulationFollow-upGeneral water supply conservationTesting waterWater flowBioremediation

The invention discloses a multifunctional fissure medium underground water testing device. The device utilizes a simulation transparent single fissure as a test object, can conveniently and rapidly simulate actual water flow and solute transport conditions in the fissure, can carry out ordinary fissure water flow and solute transport testing, fissure medium underground water pollution simulation testing and fissure medium underground water pollution bioremediation testing and can achieve adjustable fissure position and real time monitoring and data synchronous connection inside the fissure.

Owner:NANJING HYDRAULIC RES INST

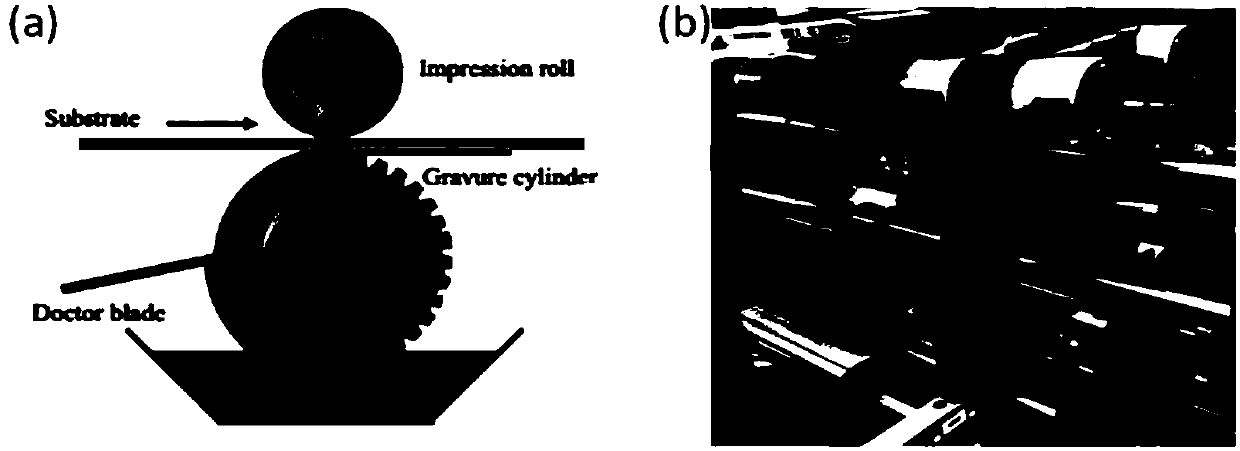

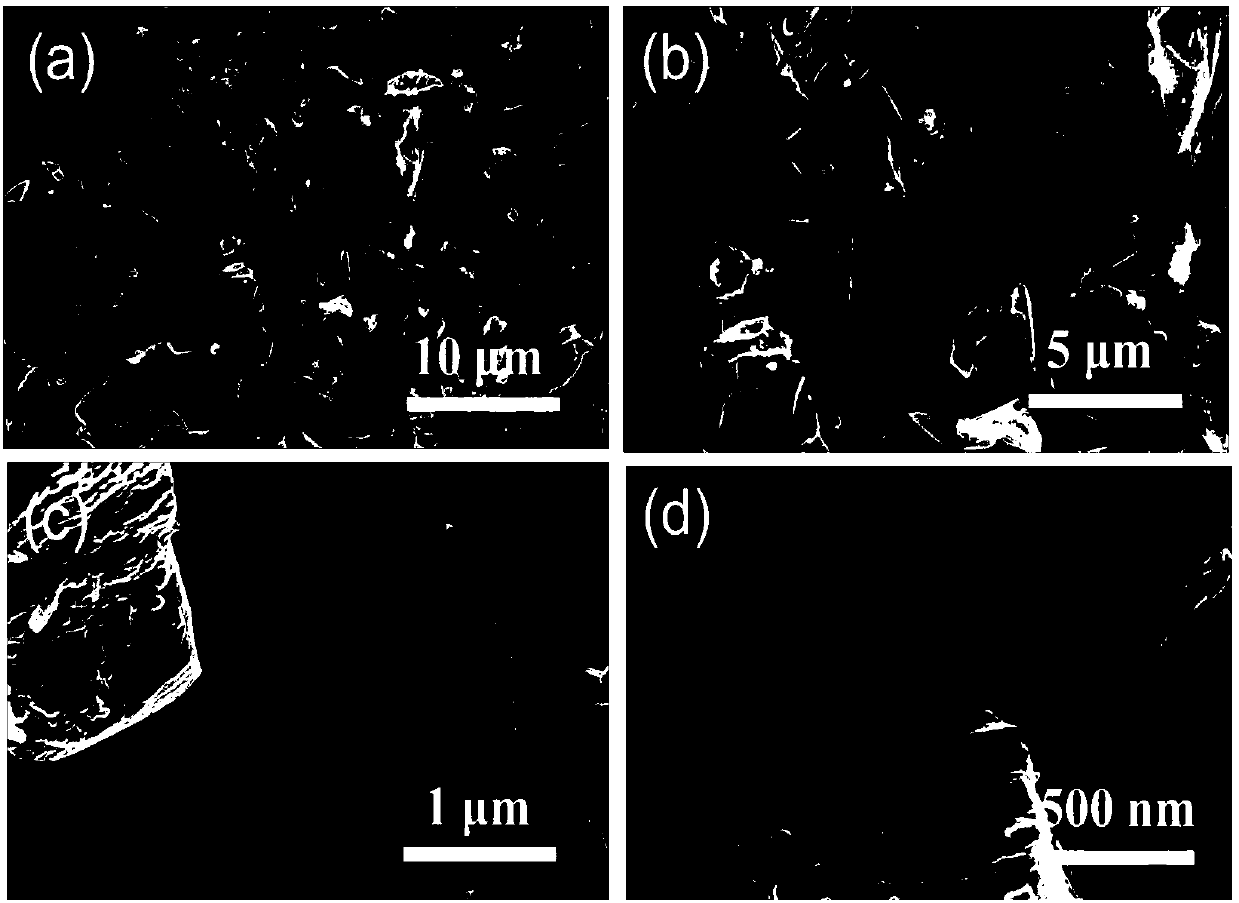

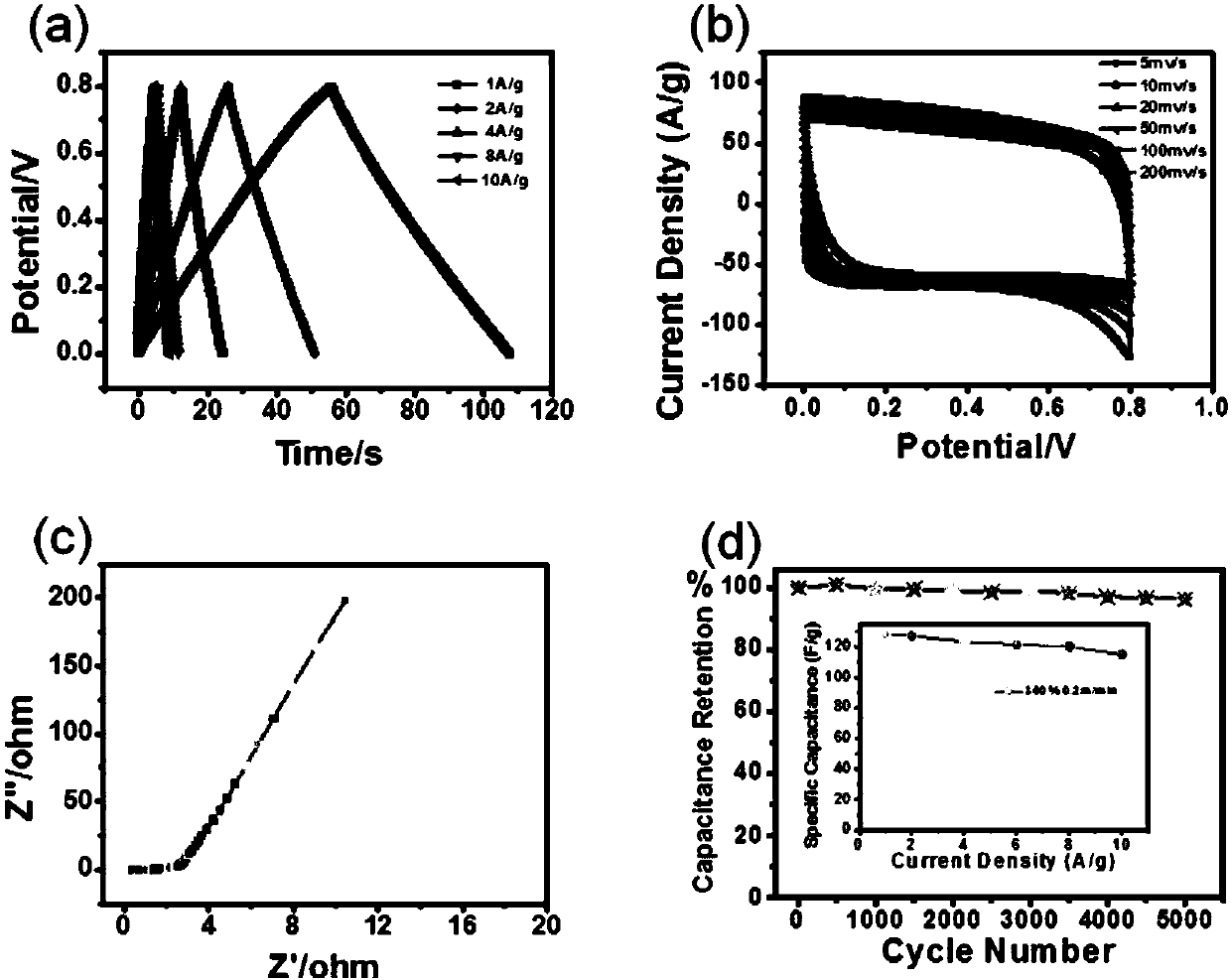

Method for preparing electrode of supercapacitor based on reel-to-reel printing technique

InactiveCN108039290AFully miscibleThe whole is dense and uniformHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorPole piece

The invention discloses a method for preparing an electrode of a supercapacitor based on a reel-to-reel printing technique. According to the method, by utilizing the reel-to-reel printing technique, asilver nano-wire is taken as a conductive agent and is mixed with a binder and active matters so as to form slurry, foamed nickel is used as a current collector for preparing an electrode pole piece,and the electrode pole piece is assembled with a diaphragm and electrolyte so as to form the supercapacitor. The method has the advantages of rapidness, high efficiency, excellent performance, good continuity and the like and has wide development prospects in industrial production and actual application, and the large-scale production can be realized.

Owner:湖南纳昇电子科技有限公司

Preparation technology of two-component resin adhesive with water resistance and wear resistance

ActiveCN105441013AImprove liquidityReduced shrinkage deformationNon-macromolecular adhesive additivesEpoxy resin adhesivesHigh pressureWear resistance

The invention discloses a preparation technology of a two-component resin adhesive with water resistance and wear resistance. The preparation technology comprises following steps: preparing a component A adhesive; preparing a component B adhesive; mixing the component A adhesive and the component B adhesive, and homogenizing a mixture by a high pressure homogenizer at the pressure of 19-22 MPa to prepare the two-component resin adhesive. The preparation technology has the advantages as follows: the production and construction environments are improved, and product curing time is optimized; the technical procedure is simple, the operation is convenient, the construction efficiency and the construction quality are guaranteed, and the prepared adhesive has both wear resistance and water resistance.

Owner:平顶山鑫晟新材料有限公司

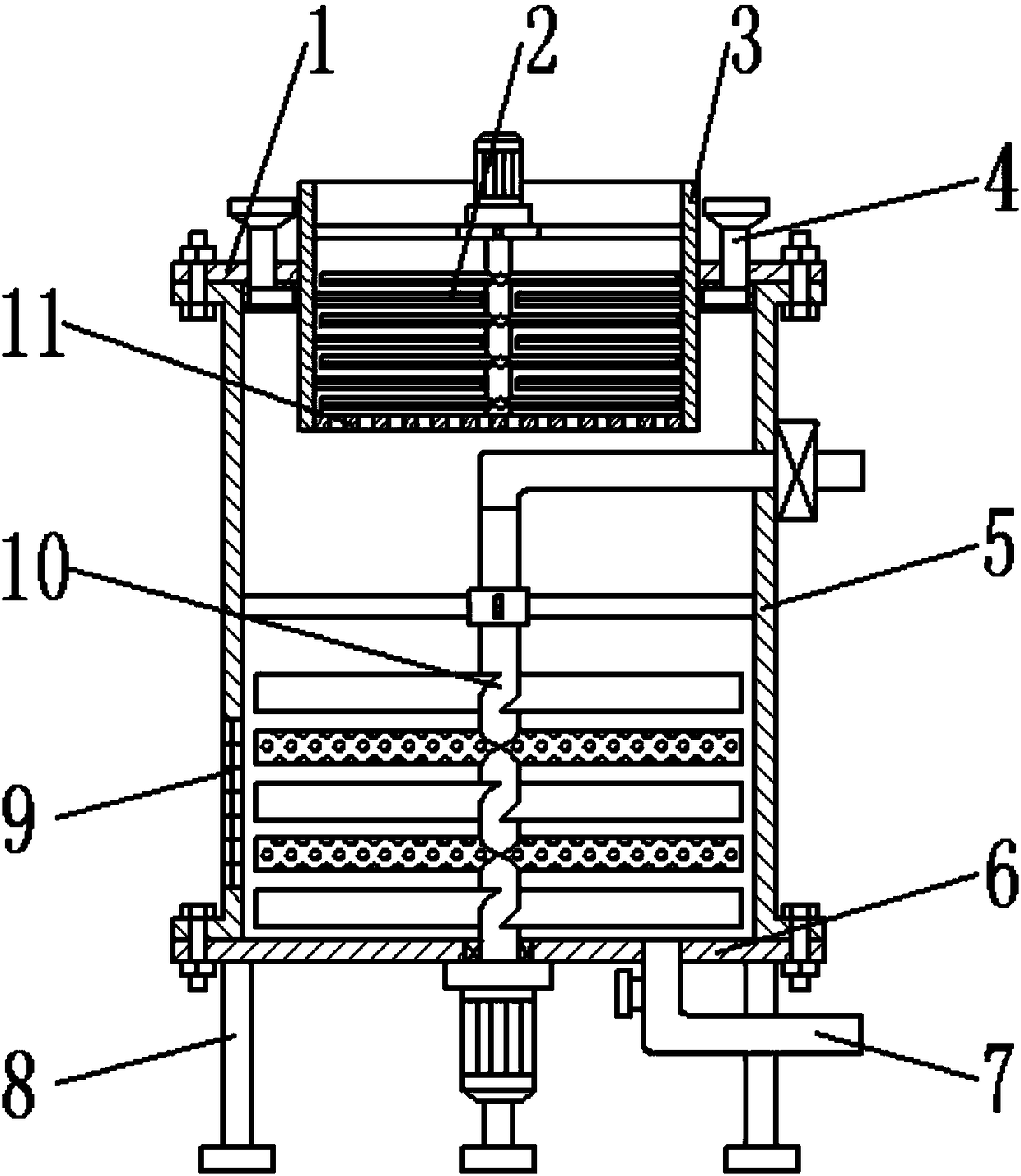

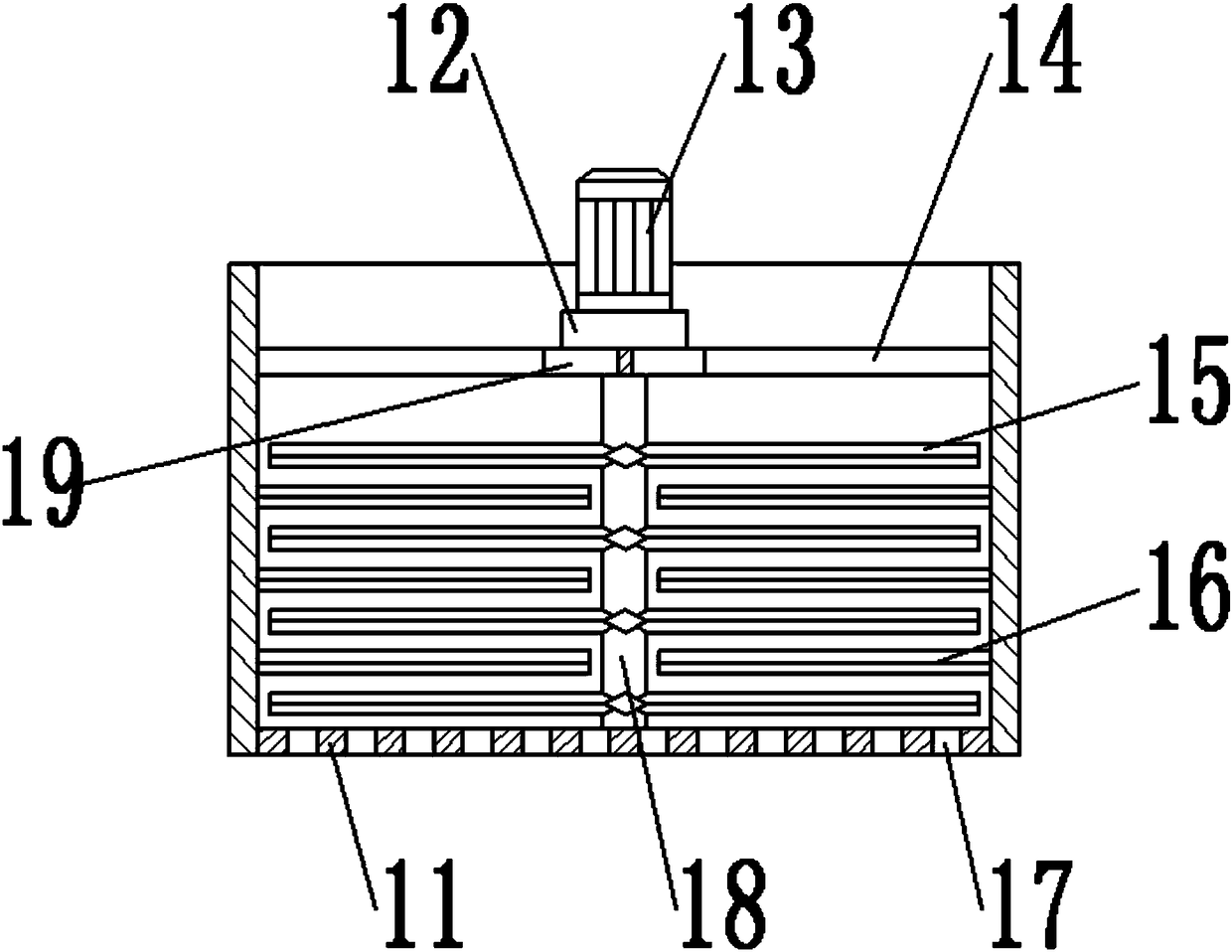

Solid-liquid material blast stirring mutually-soluble equipment used for chemical engineering

InactiveCN108097073AIncrease surface areaExpand the drop areaRotary stirring mixersTransportation and packagingSolventHollow cylinder

The invention provides solid-liquid material blast stirring mutually-soluble equipment used for chemical engineering. The equipment comprises a tank body; the tank body is designed as a hollow cylinder of which two ends communicate with each other, and the tank body is perpendicularly arranged; the opening position of the top of the tank body is provided with a top cover, and the opening positionof the bottom of the tank body is provided with a bottom cover; the middle of the top cover is welded and fixed with a crushing cylinder; the bottom of the crushing cylinder is welded and fixed with amaterial blocking plate; a solute crushing device is arranged in the crushing cylinder; a solvent adding device is arranged at the edge of the top cover; and the bottom of the tank body is provided with a wind-distributing stirring device. According to the equipment provided by the invention, a solid solute added into the crushing cylinder is sheared and crushed by the solute crushing device to enlarge the surface area of the solute; an added liquid solvent is uniformly distributed through the solvent adding device to enlarge the dropping area of the solvent and facilitate full contact with the solid solute; and mechanical stirring and wind power stirring are performed on a solute and solvent located at the bottom of the tank body through the wind-distributing stirring device to facilitate accelerating of the mutually-soluble speed of the solute and the solvent.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

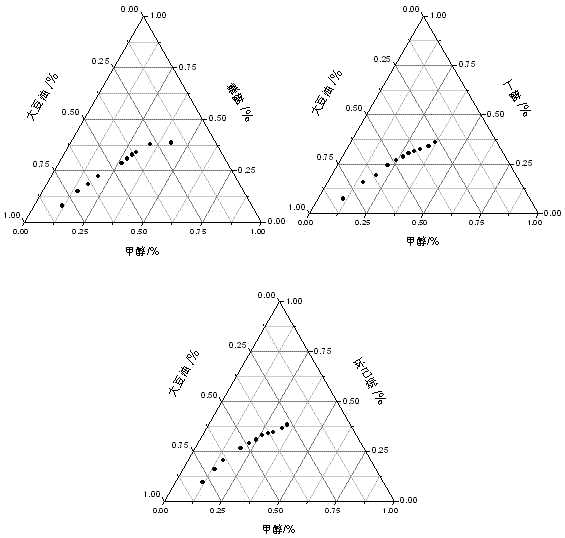

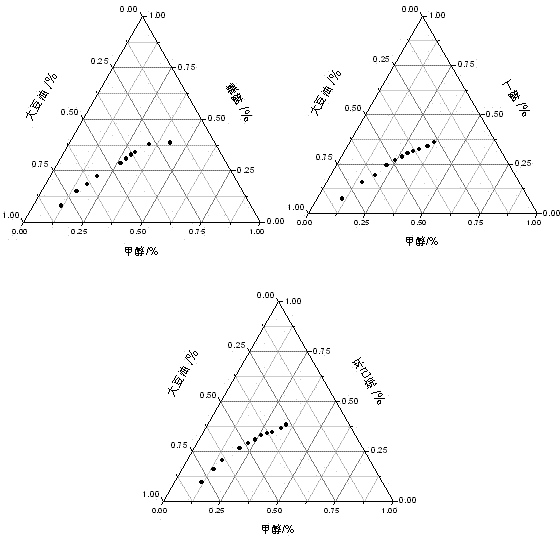

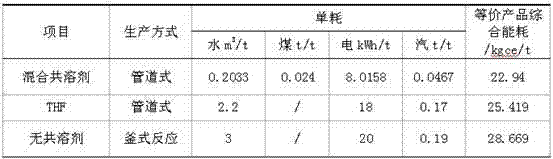

Method for preparing biodiesel by grease continuity ester exchange and mixing cosolvent used in method

The invention discloses a method for preparing biodiesel by grease continuity ester exchange and a mixing cosolvent used in the method. The mixing cosolvent comprises 50% to 90% butanone or acetone, and any one or both of 5% to 15% of furfuryl alcohol or 5% to 15% of C4 to C7 hydrocarbons by volume percent, wherein the sum of the volume percent of all the components is 100%. In the method for preparing the biodiesel by grease continuity ester exchange, the dosage of the mixing cosolvent is 5 to 30% of the volume of the lower alcohol. The cosolvent is mainly used for increasing the intersolubility of triglyceride and the low alcohol so that a homogeneous reaction system is formed, a reaction interface is increased, the reaction speed is accelerated and the continuity of the production process of the biodiesel is realized. The biodiesel has the advantages of moderate boiling point, easiness in recycling and moderate price.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

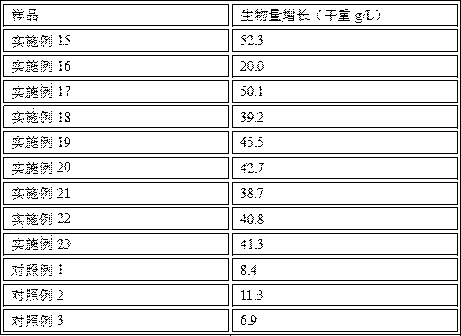

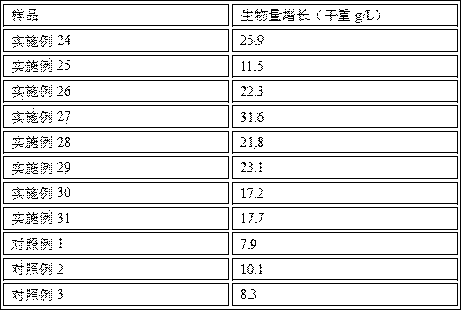

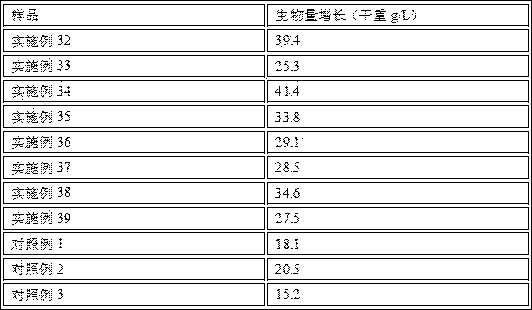

Tricholomataceae fungi culture medium and preparation method and application thereof

InactiveCN103724127AFully miscibleNot easy to affect the production effectHorticultureFertilizer mixturesTricholomataceaeBiomass

Owner:魏晓辰

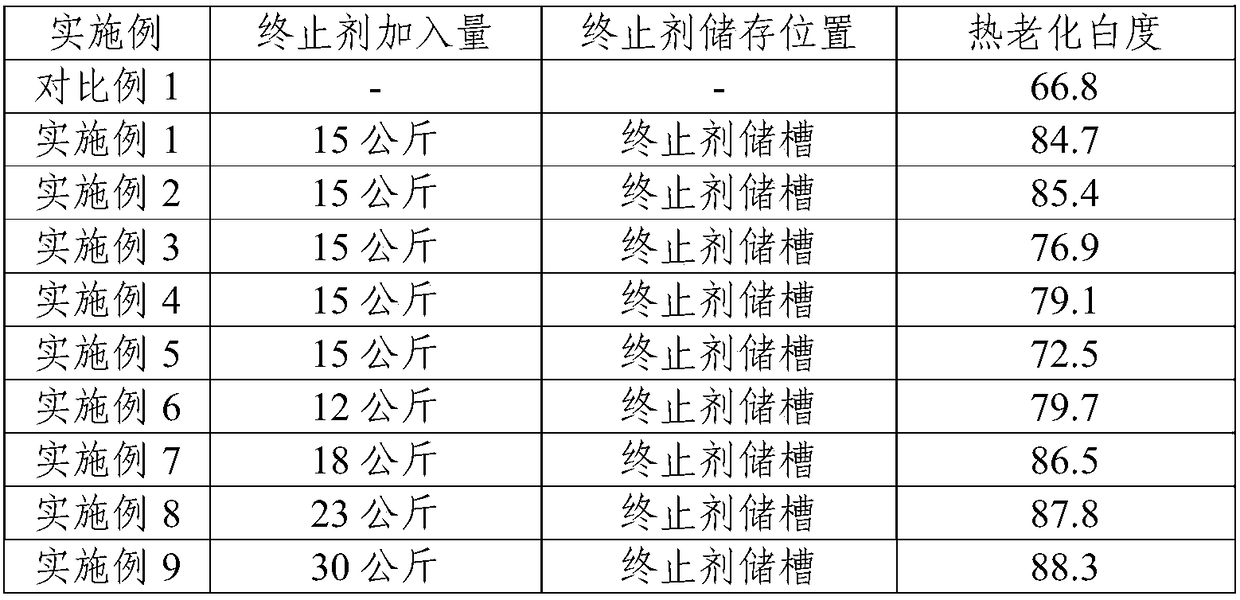

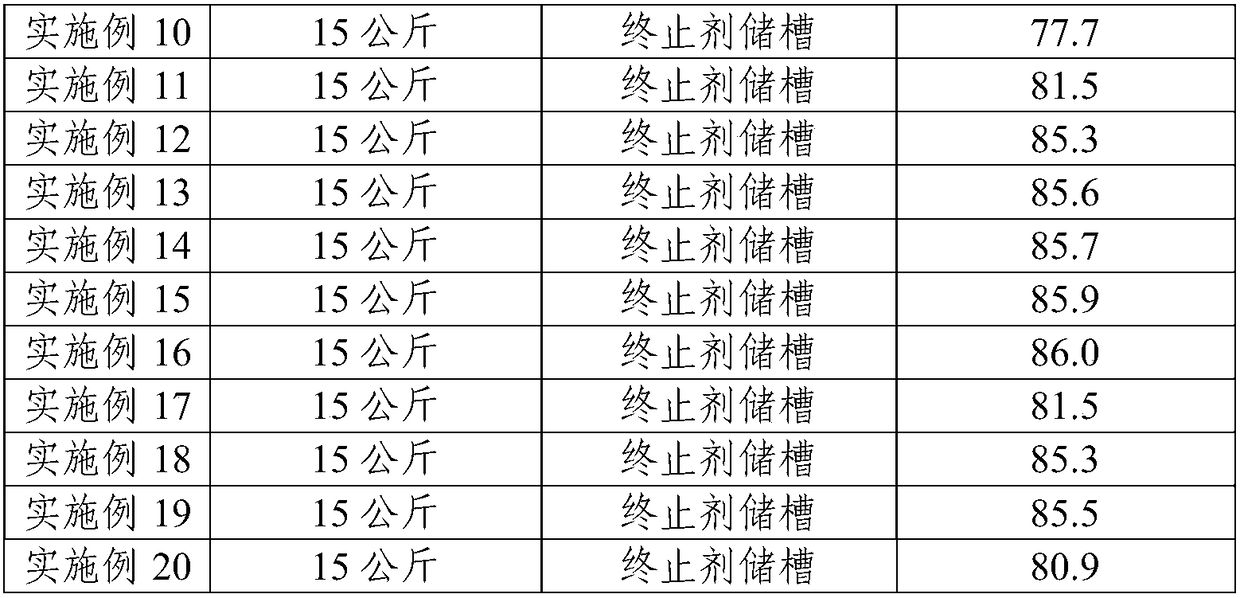

Polyvinyl chloride thermal suspension polymerization terminating agent and application thereof

The invention provides a polyvinyl chloride thermal suspension polymerization terminating agent and application thereof. The terminating agent is prepared from the following components by mass percent: 20 to 40 percent of alky substituted dithiocarbamate, 10 to 30 percent of perchlorate, and the balance of deionized water. According to the polyvinyl chloride thermal suspension polymerization terminating agent, under the synergistic acceleration effect of the alky substituted dithiocarbamate and the perchlorate, the free radicals and initiator in the polymerization reaction can be rapidly eliminated, the polymerization reaction can be rapidly terminated, the low-molecular-weight polyvinyl chloride molecules, the branch-chained polyvinyl chloride molecules, the terminal dual-bond polyvinyl chloride molecules and the polyvinyl chloride molecules with an allyl chloride structure can be greatly reduced, so that the thermal stability and thermal aging whiteness index of the finished productresin can be increased; and the terminating agent is simple in preparation method, cheap in raw material and capable of decreasing the production cost of polyvinyl chloride.

Owner:鄂尔多斯市瀚博科技有限公司

The preparation method of methylene dithiocyanate

ActiveCN103351319BWide range of production enterprisesIncrease profitOrganic chemistryRotary stirring mixersMethylene DichlorideMethylene dithiocyanate

The invention relates to a preparation method of methylene dithiocyanate. Ammonium thiocyanate, dichloromethane, methanol and water are put into a reaction kettle at a weight ratio of 2:2:1:0.1:5, and auxiliary When the temperature rises to 90°C and the air pressure is 0.4MPa, the synthesis time is more than 6 hours; then the above-mentioned composition is put into a crystallization kettle, cooled with water in the crystallization kettle, and Stir at the same time to accelerate cooling; then put the material in the crystallization tank into a filter for vacuum filtration; then use water twice the weight of the vacuum filtered product, add detergent to stir and wash; finally refine and crystallize the washed product to produce To obtain methylene dithiocyanate products. The ammonium thiocyanate synthesis method is used to improve the utilization rate of resources, reduce environmental pollution, and reduce production costs. The propulsion type agitator is used to fully dissolve the water and oil, and the reaction is thorough. The reaction is complete by using additives, and the product yield reaches 80%.

Owner:南雄市汇源化工科技有限公司

Alcohol-based fuel and preparation method thereof

InactiveCN107502391ANon-emulsifyingIncrease the calorific value of combustionLiquid carbonaceous fuelsFuel additivesHydrogenAlcohol

The invention relates to alcohol-based fuel and a preparation method thereof. The alcohol-based fuel comprises the following raw materials in part by weight: 150-300 parts of sodium, 100-200 parts of potassium, 500-800 parts of ester, 1000-1500 parts of oxygen water, 50-100 parts of iron, 1300-5500 parts of alcohol and 200-400 parts of water. The alcohol-based fuel and the preparation method thereof, provided by the invention, have the benefits that through reasonably adjusting the mixing ratio of hydrogen to oxygen to carbon in the alcohol-based fuel, the efficient and full combustion of the alcohol-based fuel is promoted, a combustion heat value and a flash point of the alcohol-based fuel are improved, the volatility of the alcohol-based fuel is reduced, and safety and environmental protection are achieved.

Owner:李峰

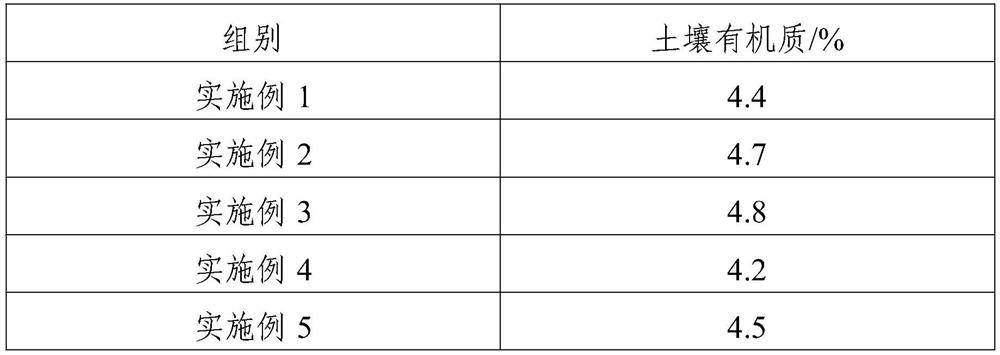

Liquid organic fertilizer prepared from kitchen waste, and production process thereof

PendingCN112028687APromote full maturityImprove fertilizer supply capacityCalcareous fertilisersBio-organic fraction processingAmmonium sulfateHumic acid

The invention discloses a liquid organic fertilizer prepared from kitchen waste, and a production process thereof, and belongs to the technical field of fertilizers. The liquid organic fertilizer comprises, by weight, 60-70 parts of kitchen waste, 15-20 parts of straw, 2-3 parts of zymophyte, 1-1.5 parts of nitrogen-fixing bacteria, 0.5-1 part of bacillus mucilaginosus, 0.2-0.5 part of purple bacteria, 3-5 parts of supplementary nutrients, 10-15 parts of potassium hydroxide solution, 4-8 parts of decomposed coal, 5-10 parts of urea, and 200-300 parts of deionized water. Nutrient substances aresupplemented, zymophyte continuously consumes the nutrient substances in the high-temperature fermentation process, after high-temperature fermentation is finished, the nutrient substances in fermentation liquor are sharply reduced, ammonium sulfate, magnesium sulfate, potassium phosphate and calcium carbonate are additionally added into the fermentation liquor to supplement elements needed by the zymophyte, the nutrient substances are kept sufficient, and the nutrient content of the zymophyte is increased. By adding the decomposed coal and a potassium hydroxide solution, the activation of the decomposed coal is facilitated, so that humic acid is converted into a soluble state, and the absorption of crops is facilitated.

Owner:周鹏

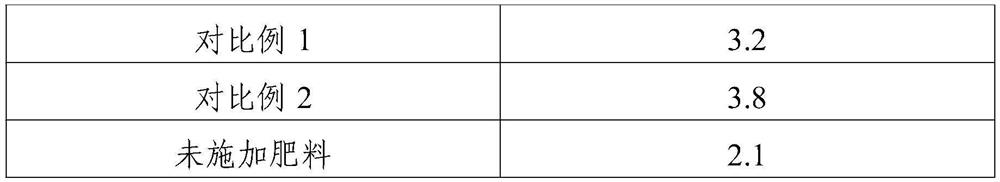

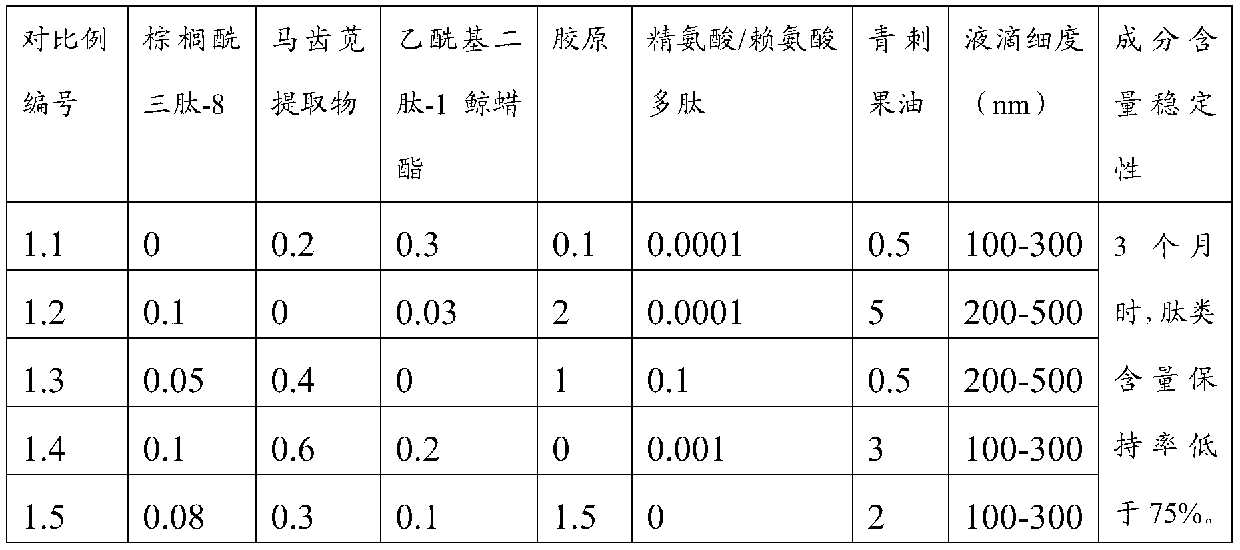

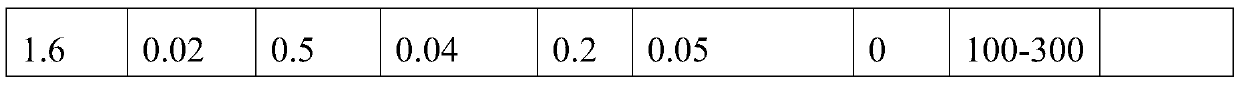

Allergy-relieving repair composition, preparation and freeze-dried mask, and preparation methods thereof

ActiveCN111544311AFully miscibleHigh stability of ingredient contentCosmetic preparationsToilet preparationsDipeptideArginine

The invention discloses an allergy-relieving repair composition. The allergy-relieving repair composition is composed of 0.01 to 0.1 part of palmitoyl tripeptide-8, 0.2 to 0.6 part of a purslane herbextract, 0.03 to 0.3 part of acetyl dipeptide-1 cetyl ester, 0.1 to 2 parts of collagen, 0.0001 to 0.1 part of arginine / lysine polypeptide, 0.5 to 5 parts of prinsepia utilis royle oil, and the balance being a solvent. The allergy-relieving repair composition can be effectively co-dissolved in a composite preparation, the droplet fineness reaches 100 nanometers or below, meanwhile, the allergy-relieving repair composition has good activity preservation performance, and the component content stability is high. The invention also discloses a preparation method of the allergy-relieving repair composition. The invention also discloses an allergy-relieving repair preparation and a preparation method thereof; the allergy-relieving repair preparation comprises the allergy-relieving repair composition, a water-phase material and / or an oil-phase material, has a good micro-ecological repair effect, and can protect the balance being facial flora. The invention further discloses an allergy-relieving repair freeze-dried mask, preservatives do not need to be added, and the influence of the mask on skin micro-ecology in the using process can be greatly reduced.

Owner:上海贝泰妮健康科技有限公司

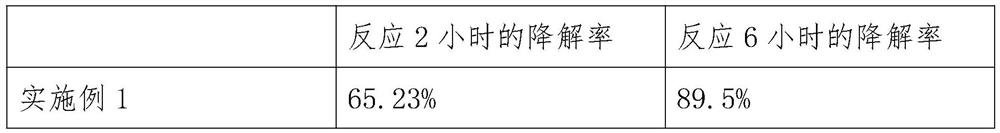

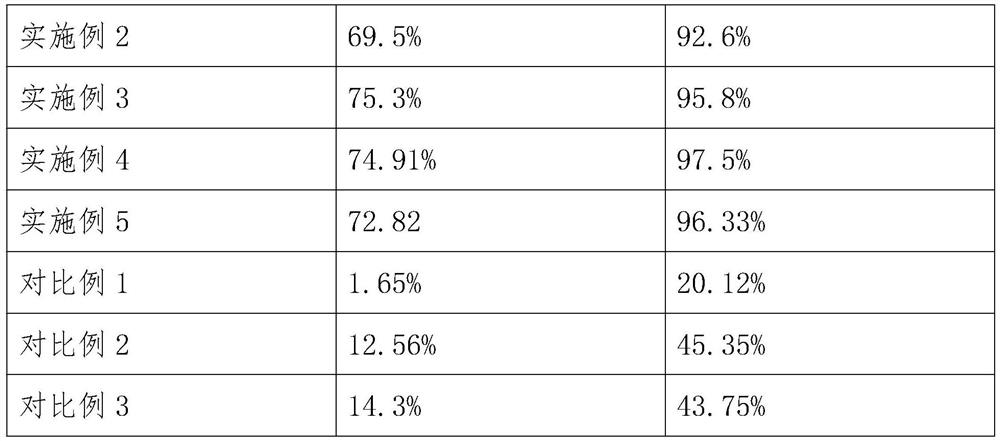

Preparation method of photocatalyst with super-strong degradation effect

ActiveCN111921516AFully miscibleHigh catalytic efficiencyWater/sewage treatment by irradiationWater treatment compoundsHydrogen fluoridePtru catalyst

The invention provides a preparation method of a photocatalyst with a super-strong degradation effect, and relates to the technical field of photocatalysts. The preparation method comprises the following steps: taking titanium dioxide, carrying out segmented calcination, grinding and filtering so that titanium dioxide powder is obtained, adding titanium dioxide powder and anhydrous toluene into asingle-neck flask, carrying out ultrasonic treatment for 5-15 minutes to fully disperse the titanium dioxide powder and anhydrous toluene, adding an aqueous solution containing hydrogen fluoride and sodium fluoride into the single-neck flask, reacting for 4-6 hours under magnetic stirring, filtering, drying in vacuum to obtain surface-fluorinated nano titanium dioxide particles, adding the nano titanium dioxide particles subjected to surface fluorination treatment and ferroferric oxide powder into a sodium hydroxide solution, uniformly stirring, transferring into a water bath kettle, carryingout water bath reaction, filtering after the water bath reaction to obtain a precipitate, dissolving the precipitate in deionized water, adjusting the pH value of the obtained solution, carrying out suction filtration, drying the obtained product in an oven at 80 DEG C to obtain a compound, and calcining the compound in sections to obtain the photocatalyst.

Owner:HARBIN NORMAL UNIVERSITY

Compound lidocaine emulsifiable paste and preparation method thereof

ActiveCN101816642BAchieve anesthesiaNo corrosionAntibacterial agentsOrganic active ingredientsActive agentSurface-active agents

The invention discloses a compound lidocaine emulsifiable paste and a preparation method thereof. Each 10kg of the compound lidocaine emulsifiable paste comprises the following components according to the weight: 50-1000g of base lidocaine, 50-1000g of base prilocainum, 10-500g of polyoxyethylene hydrogenated castor oil, 10-300g of Carbomer, 40-200g of sodium hydroxide and the balance of pure water. The invention increases clinical use security through releasing lidocaine and prilocainum in base modes to the subcutaneous layer with the depth of 5mm without containing a penetrating agent or a surface active agent component, which is particularly suitable for children patients and patients for face beauty. Through improvement on production process steps, the invention enables the productionoperation to become easy and feasible, is easy to control the product quality and increases the product stability. The whole production cycle is only half day, and the production efficiency is improved by more than 3 times, thereby the raw materials are saved and the production cost is reduced.

Owner:北京中泰邦医药科技有限公司

Blend oil containing peony seed oil and preparation method thereof

The invention relates to blend oil containing peony seed oil and the preparation method thereof. The blend oil comprises 20 to 38 percent of the peony oil, 25 to 30 percent of corn germ oil, 25 to 30 percent of peanut oil, 3 to 5 percent of tea-seed oil, 4.5 to 7 percent of wheat germ oil, 0.5 to 2 percent of catechinic acid and 4 to 6 percent of a luffa extract; the preparation method of the blend oil comprises the preparation of peony seed oil, the mixing of the main raw material, the formation of an emulsification system and final formation of a clean and dirty-free blend oil product, wherein the peony seed oil is treated through the combination of sub-critical fluid extraction and molecular distillation technologies, the operating temperature is low, the heating time is short, grease oxidation and rancidity caused by high temperature are avoided, the separating degree and the product yield are higher, and the acid value of the peony seed oil can be lowered through molecular distillation; the blend oil is reasonable and healthy in matching up, the nutrition is balance, the blend oil with high stability and less oil-fume output can be formed, and the health of a cook person can be maintained for a long time.

Owner:LUOYANG CHUNKUI AGRI DEV

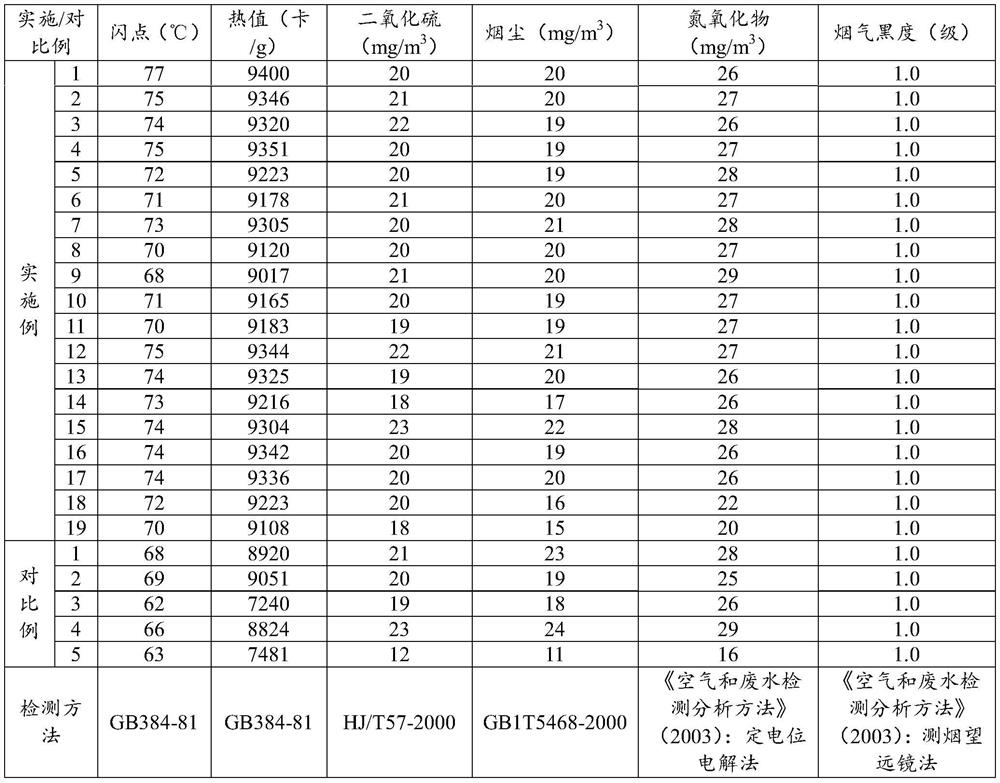

High-performance alcohol-based fuel and preparation method thereof

The invention relates to the field of fuels, and discloses a high-performance alcohol-based fuel, which is prepared from the following raw materials in parts by weight: 70-85 parts of an alcohol, 5-10parts of a surfactant and 10-20 parts of water. According to the invention, the hydroxypropyl methyl cellulose in the surfactant performs modifying compounding on the alcohol-based fuel, so that thealcohol solution is non-volatile and high in stability, the flash point and the combustion working condition of the fuel are improved, and the safety coefficient of storage and transportation environments is improved; and by using the low-carbon alcohol with high mass percentage content as the raw material, the secondary pollution after the fuel combustion is reduced.

Owner:SICHUAN LUTIANHUA

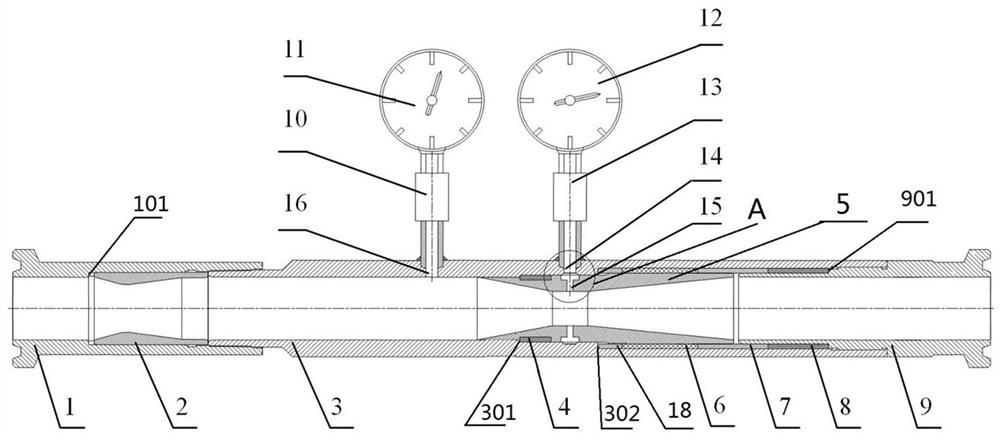

Steam flow measuring device and steam injection pipeline using same

ActiveCN112033483AImprove safety and reliabilityExtended service lifeSurveyFluid removalThermodynamicsEngineering

The invention relates to the technical field of steam flow measurement, in particular to a steam flow measuring device and a steam injection pipeline using the same. The steam flow measuring device comprises a flow choking piece and a venturi tube, wherein the venturi tube is located behind the flow choking piece, and a throat pressure tapping hole is formed in the throat of the venturi tube. Thedevice further comprises a tube main body; a front joint and a rear joint are respectively arranged at the front end and the rear end of the tube main body and are used for connecting the steam flow measuring device to a steam injection pipeline in series; the venturi tube is fixed in the tube main body; an inlet pressure tapping hole and a throat pressure leading hole are formed in the tube mainbody; the inlet pressure tapping hole is formed in the front side of the venturi tube so as to be communicated with an inlet of the venturi tube; the throat pressure leading hole is communicated withthe throat pressure tapping hole. The steam flow measuring device further comprises a front sealing structure and a rear sealing structure; the front sealing structure is arranged between the tube main body and the venturi tube; and the rear sealing structure is arranged between the tube main body and the venturi tube. According to the steam flow measuring device, the overall material and processing cost of the measuring device can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981BBurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

Composite alcohol-base fuel

InactiveCN106381177ALow costPromotes full combustionLiquid carbonaceous fuelsFuel additivesChemistryIron oxide

The invention discloses a composite alcohol-base fuel which is prepared from the following components in parts by weight: 60-70 parts of methanol, 2-4 parts of isobutanol, 1-3 parts of isoheptanol, 1-3 parts of acetone, 0.2-0.4 part of pentanone, 0.6-0.8 part of phenol, 0.3-0.5 part of benzene, 0.4-0.6 part of ethyl-tertiary butyl ether, 1-3 parts of tertiary pentyl methyl ether, 2-4 parts of strontium peroxide, 0.5-0.7 part of glycerol, 0.01-0.03 part of ethylene-vinyl acetate copolymer, 0.5-0.9 part of nano magnesium powder and 0.3-0.6 part of nano iron oxide. The composite alcohol-base fuel has the characteristics of favorable combustion performance, especially high heat value, low corrosivity, high stability and the like, and has development prospects.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN111909735AIncrease calorific value and flash pointHigh flash pointLiquid carbonaceous fuelsFuel additivesMethanol formationEnvironmental geology

The invention discloses an alcohol-based fuel combustion improver, which comprises the following components in parts by weight: 80-90 parts of a cosolvent, 20-30 parts of solvent oil, 1.5-5 parts of asmoke abatement combustion improver and 3.5-10 parts of a cosolvent; wherein the cosolvent is at least one of butanol, octanol, hydrogenated anthracene oil and light oil, and the solvent oil is at least one of pine nut oil, turpentine oil, turpentine and glycerol. The combustion improver can form an ideal mixed solution with methanol, so that the flash point and heat value of the whole fuel are improved, and the final combustion efficiency of the alcohol-based fuel is promoted to be remarkably improved. The alcohol-based fuel combustion improver is wide in raw material source, clean, environmentally friendly and capable of achieving industrial mass production. The invention further discloses an alcohol-based fuel prepared by mixing 20-40 parts of the alcohol-based fuel combustion improverand 60-80 parts of methanol, wherein the content of methanol is reduced, and all components in the alcohol-based fuel form an ideal mixed solution; in addition, the added combustion improver component enables the overall heat value and flash point to be improved, the fuel combustion efficiency is high, and safety pollution is little.

Owner:广东一诚环保科技有限公司

Novel alcohol-based fuel

InactiveCN106367137ALow costPromotes full combustionLiquid carbonaceous fuelsFuel additivesBrown iron oxideIsobutyl alcohol

The invention discloses a novel alcohol-based fuel. The novel alcohol-based fuel is prepared from the following components in parts by weight: 60-70 parts of methyl alcohol, 3-6 parts of ethyl alcohol, 2-4 parts of isobutyl alcohol, 1-4 parts of propylene glycol, 1-3 parts of isopropyl ether, 3-5 parts of di-tert-butyl peroxide, 0.4-0.8 part of glycerol, 0.02-0.04 part of polyoxyethylene-polyoxypropylene copolymer, 0.3-0.5 part of triethanolamine, 0.5-0.9 part of nano magnesium powder and 0.3-0.5 part of nano iron oxide. The novel alcohol-based fuel has the characteristic of high combustion performance, particularly high heat value, low corrosion and high stability and has a good development prospect.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Bee venom liniment for treating prostatitis and preparation method therefor

ActiveCN104906531AEasy to useHigh cure rateAnthropod material medical ingredientsUrinary disorderPropolisCure rate

The invention discloses a bee venom liniment for treating prostatitis. The bee venom liniment comprises the following materials, by weight, 40-60 parts of bee venom, 5-10 parts of propolis, 1-5 parts of pearls, 20-30 parts of plant extract and 15-30 parts of lanolin oil. The preparation method comprises the following steps: pearls are ground to 100-150 meshes, the pearl powder, the plant extract, bee venom, propolis and lanolin oil are mixed according to the above weight parts and stirred uniformly, and the finished product is obtained. The bee venom liniment has advantages of good stability, uniform coating and good spreadability. Human body trial experiment results prove that the bee venom liniment is safe, has no stimulation or optical allergenicity to skins and can treat prostatitis effectively. The bee venom liniment has advantages of rapid onset, obvious effects and safe usage, and raises the cure rate of prostatitis.

Owner:陕西美芙康生物科技有限公司

High-friction and low-loss nylon composite material for castor of trolley luggage and preparation method of nylon composite material

The invention discloses a high-friction and low-loss nylon composite material for a castor of a trolley luggage and a preparation method of the nylon composite material. The material is prepared fromcomponents in parts by mass as follows: 30-35 parts of PA (polyamide), 10-15 parts of PAR (polyarylester), 5-10 parts of hollow glass beads, 10-15 parts of activated carbon fibers, 5-10 parts of an interfacial solubilizer and 3-5 parts of nano-aluminum chloride. With addition of PAR, rigidity and toughness of the composite material are optimized effectively, so that the castor has higher toughnesswhile having certain rigidity, and integration of high friction coefficient and low loss is realized; by means of integrated reinforcing filler, more sufficient carbon fiber strength improvement andtoughness improvement of the hollow glass beads of the material can be realized; by combined use of EPDM-g-MAH and LLDPE-g-MAH, the solubilizing effect of the components is greatly improved, the solubilizing target range is wider, and rigid and tough performance of the material is effectively improved.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com