Steam flow measuring device and steam injection pipeline using same

A technology of steam flow and measuring device, which is applied in the direction of measuring device, liquid/fluid solid measurement, measurement, etc., can solve the problem of high cost of flow measuring device, and achieve the effect of improving safety and reliability, high mechanical performance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

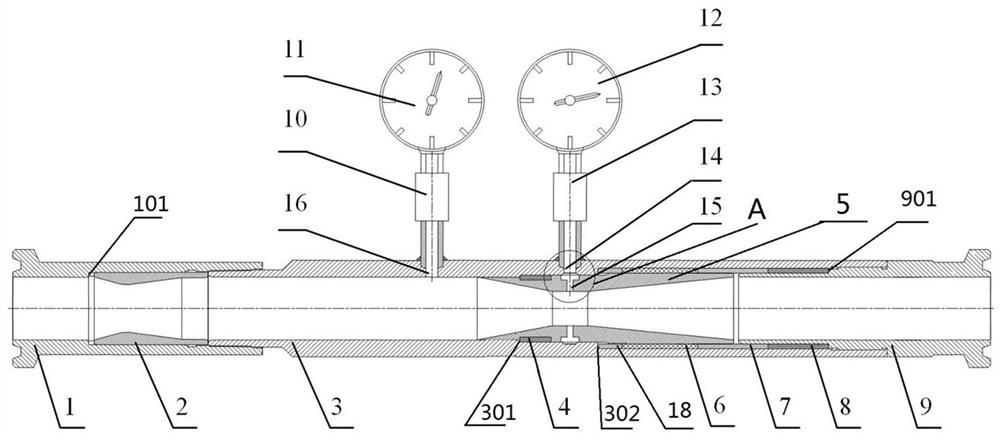

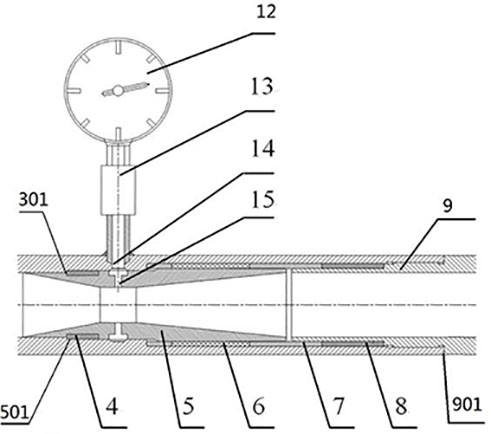

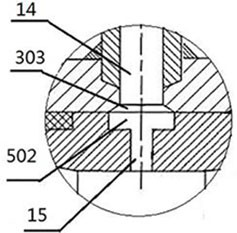

[0100] Such as figure 1 with figure 2 As shown, the steam flow measuring device includes a pipe main body 3 and two hoop heads, and the two hoop heads are screwed to both axial ends of the pipe main body 3 . The above two clamp heads are used as joints of the pipe main body for connection with the steam injection pipeline. The front side of the pipe main body 3 is provided with a flow blocking member 2 , and a Venturi tube 5 is fixed inside the pipe main body 3 , and the flow blocking member 2 is arranged on the front side of the Venturi pipe 5 . The choke piece 2 is a tubular structure, the inner diameter of the choke piece 2 shrinks from front to back and then gradually expands, and is used to mix the steam flowing through the choke piece 2 in a throttling manner. The steam flow measuring device also includes a pressure measuring device, and the pressure measuring device obtains the steam pressure difference between the inlet of the venturi tube 5 and the throat through m...

specific Embodiment 2

[0116] The steam pressure difference in the above-mentioned embodiment 1 is obtained by subtracting the pressure measured by the front pressure gauge arranged at the inlet of the Venturi tube and the pressure measured by the rear pressure gauge arranged at the throat of the Venturi tube; as Figure 4 As shown, in this embodiment, a differential pressure transmitter 17 is connected between the inlet pressure hole 16 and the throat pressure introduction hole 14, and the steam pressure at the inlet of the Venturi tube and the throat is directly obtained through the differential pressure transmitter 17 difference.

specific Embodiment 3

[0118] The baffle in the above-mentioned embodiment 1 is composed of a baffle; the baffle in this embodiment is composed of a porous plate, that is, the porous plate replaces the baffle in the above-mentioned embodiment 1, and the steam flowing into the main body of the pipe flows When passing through the porous plate, the two phases of the vapor and night of the steam are fully mixed through the throttling effect of the porous plate and the collision between the fluid and the hole wall of the porous plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com