Polyvinyl chloride thermal suspension polymerization terminating agent and application thereof

A suspension polymerization and polyvinyl chloride technology, which is applied in the field of polyvinyl chloride thermal suspension polymerization terminator, can solve the problems of high cost and low thermal stability of the terminator, achieve cheap raw materials, improve thermal stability and thermal aging whiteness The effect of simple indicators and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

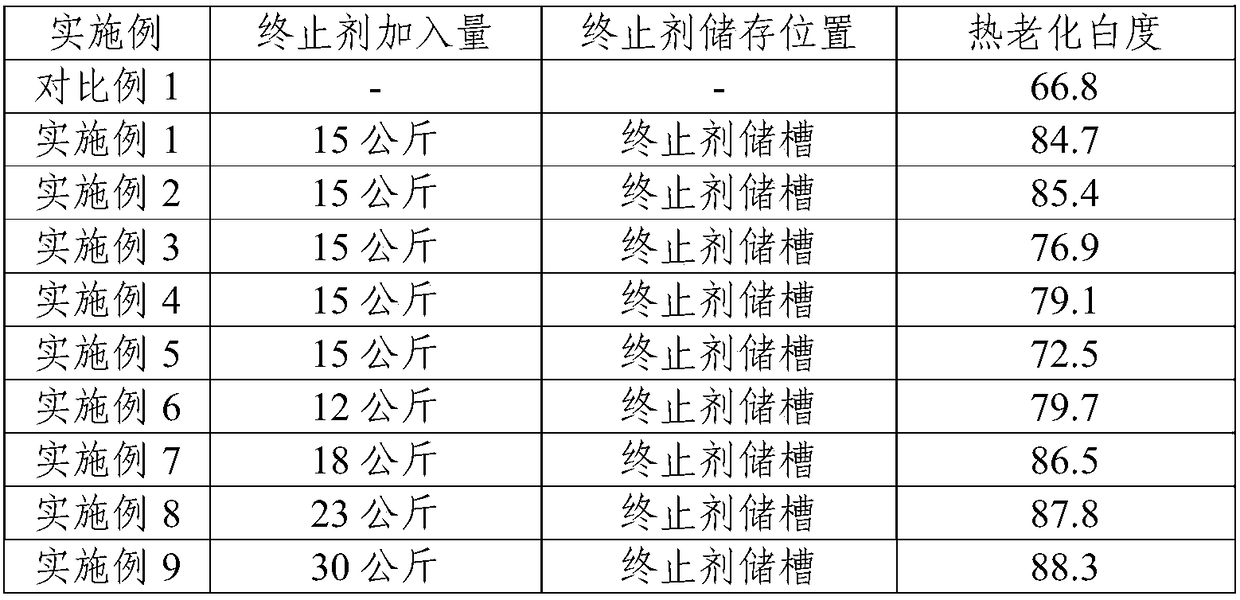

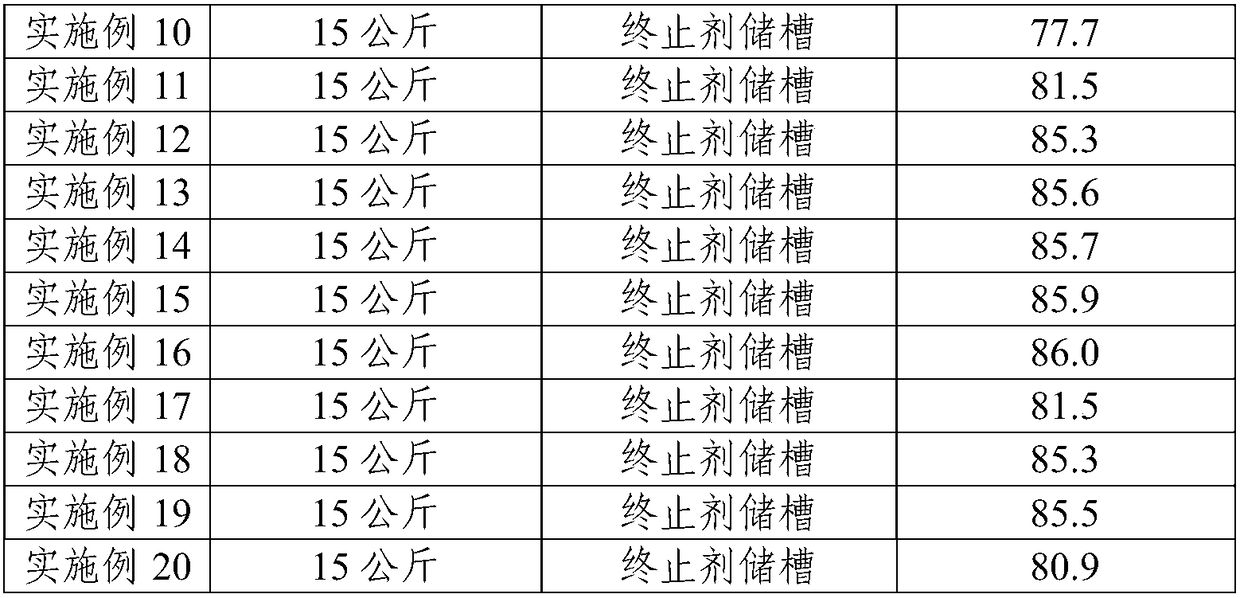

Examples

Embodiment 1

[0027] A polyvinyl chloride thermal suspension polymerization terminator of this embodiment is composed of the following components in terms of mass percentage: 30% sodium dimethyldithiocarbamate, 20% sodium perchlorate, and 50% deionized water.

[0028]The preparation method of the terminator is: add a certain amount of deionized water, add the sodium perchlorate of the formula amount, stir until it is completely dissolved, then add the sodium dimethyl dithiocarbamate of the formula amount, stir until it is completely dissolved, and make up the formula Measure the water, stir it for 15 minutes, pump it out and pack it in a 200L blue plastic bucket, and store it in a cool and ventilated place.

[0029] The specific process of applying the terminator of this embodiment to the polyvinyl chloride suspension polymerization reaction, taking the production of SG5 type resin as an example: at 105m 3 Atomize and add 12 kg of anti-sticking agent to the polymerization kettle to coat the...

Embodiment 2

[0031] A polyvinyl chloride thermal suspension polymerization terminator of this embodiment is composed of the following components in terms of mass percentage: 30% sodium dimethyldithiocarbamate, 20% sodium perchlorate, 2% sodium isooctanoate, D - Sodium Erythorbate 3%, Deionized Water 45%.

[0032] The preparation method of the terminator is: add a certain amount of deionized water, add the sodium perchlorate of the formula, stir until it is completely dissolved, then add the sodium dimethyl dithiocarbamate of the formula, stir until it is completely dissolved, add the formula A certain amount of organic heat stabilizer (sodium isooctanoate 2%, D-sodium isoascorbate 3%), stirred until fully dissolved, supplemented with the amount of formula water, stirred for 15min, pumped out and packaged in a 200L blue plastic bucket, stored in A cool and ventilated place.

[0033] The specific process applied to the termination of the polyvinyl chloride suspension polymerization reaction...

Embodiment 3

[0035] A polyvinyl chloride thermal suspension polymerization terminator of this embodiment is composed of the following components in terms of mass percentage: 20% sodium dimethyldithiocarbamate, 20% sodium perchlorate, and 60% deionized water.

[0036] The preparation method of the terminator and the specific process of applying it to the suspension polymerization of polyvinyl chloride to terminate the reaction: the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com