Samarium-cobalt permanent magnet material and preparation method thereof

A permanent magnet material, samarium cobalt technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems that need to be further improved, and achieve the effect of reducing oxygen content, reducing oxidation, and improving the ability of demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Raw materials: Samarium, Cobalt, Iron, Copper, Zirconium, Erbium.

[0022] The above-mentioned raw materials are batched in mass percentage, wherein 25.5% of samarium, 49.1% of cobalt, 15% of iron, 7% of copper, 2.8% of zirconium and 0.6% of erbium.

[0023] The samarium cobalt permanent magnet material of the present invention comprises the following steps:

[0024] (1) Compounding samarium, cobalt, iron, copper, zirconium and erbium according to mass percentage.

[0025] (2) Put the prepared raw materials into a vacuum intermediate frequency induction furnace for smelting, and after they are completely melted, keep them warm for 5 minutes at a temperature of 1430-1450°C for alloy refining. After refining, pour them into a water-cooled copper mold to obtain samarium cobalt alloy.

[0026] (3) Put the samarium-cobalt alloy into a tube-type vacuum sintering furnace, feed hydrogen gas, make the hydrogen pressure reach 1MPa, raise the temperature to 150° C. and keep it w...

Embodiment 2

[0032] Raw materials: Samarium, Cobalt, Iron, Copper, Zirconium, Erbium.

[0033] The above-mentioned raw materials are compounded in mass percentage, including 25.2% of samarium, 48.3% of cobalt, 16.2% of iron, 5.9% of copper, 3.2% of zirconium and 1.2% of erbium.

[0034] The preparation method of the samarium cobalt permanent magnet material of the present invention is the same as that of embodiment 1.

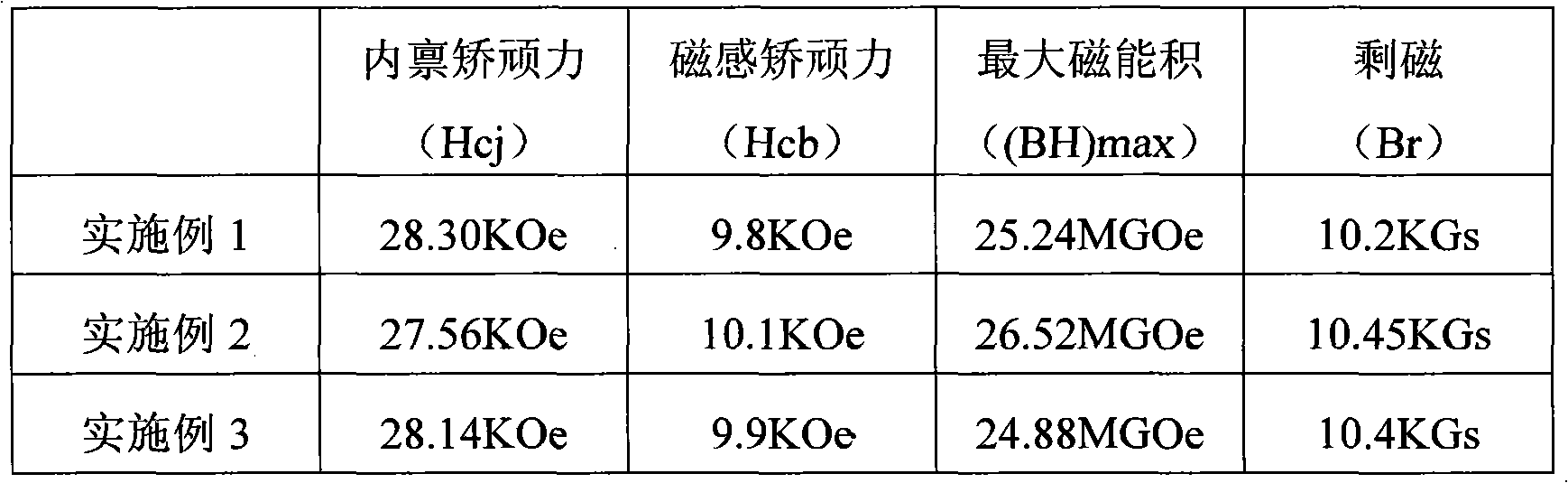

[0035] The relevant magnetic performance parameters of the obtained samarium-cobalt magnets were tested, as shown in Table 1.

Embodiment 3

[0037] Raw materials: Samarium, Cobalt, Iron, Copper, Zirconium, Erbium.

[0038] The above-mentioned raw materials are batched in mass percentage, including 25.6% of samarium, 49.6% of cobalt, 13.5% of iron, 6.8% of copper, 2.9% of zirconium and 1.6% of erbium.

[0039] The preparation method of the samarium cobalt permanent magnet material of the present invention is the same as that of embodiment 1.

[0040] The relevant magnetic performance parameters of the obtained samarium-cobalt magnets were tested, as shown in Table 1.

[0041] Table 1

[0042]

[0043] The magnetic performance test parameters of each embodiment in Table 1 show that the samarium cobalt permanent magnet material prepared by the present invention has high coercive force, and has a higher ability to resist external reverse magnetic fields or other demagnetization effects than in the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com