Novel alcohol-based fuel

An alcohol-based fuel, a new type of technology, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as unsatisfactory calorific value, achieve the effects of preventing stratification, increasing flash point, and promoting mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

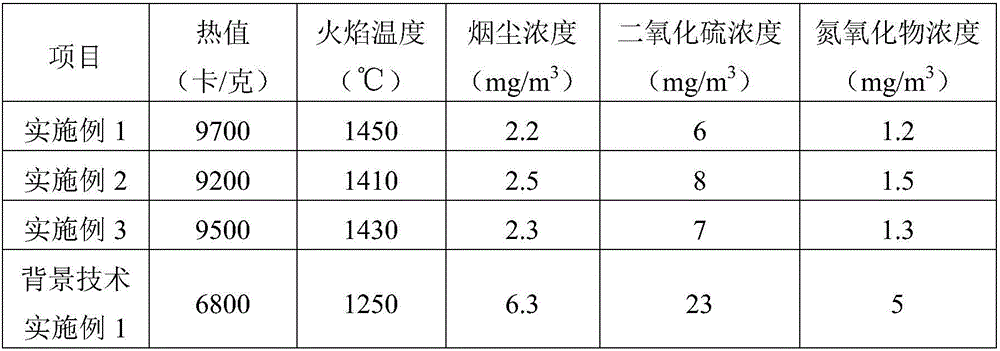

Examples

Embodiment 1

[0020] A new type of alcohol-based fuel, made from the following components by weight: 65 parts of methanol, 4 parts of ethanol, 3 parts of isobutanol, 2 parts of propylene glycol, 2 parts of isopropyl ether, di-tert-butyl peroxide 4 parts, 0.6 parts of glycerin, 0.03 parts of polyoxyethylene-polyoxypropylene copolymer, 0.4 parts of triethanolamine, 0.7 parts of nano-magnesium powder, and 0.4 parts of nano-iron oxide.

[0021] The particle diameter of described nano-magnesium powder, nano-iron oxide is 80nm, and process according to the following steps:

[0022] 1) Add the nanomaterials to ethanol, and place it on an ultrasonic machine with a frequency of 35KHz for 25 minutes, and set aside;

[0023] 2) Add silane coupling agent, sorbitan monostearate, and sodium lauryl sulfate to ethanol, and place it on an ultrasonic machine with a frequency of 35KHz for 20 minutes, and set aside;

[0024] 3) First mix the solution obtained in step 1) with the solution obtained in step 2), ...

Embodiment 2

[0028] A new type of alcohol-based fuel, made from the following components by weight: 60 parts of methanol, 3 parts of ethanol, 2 parts of isobutanol, 1 part of propylene glycol, 1 part of isopropyl ether, di-tert-butyl peroxide 3 parts, 0.4 parts of glycerin, 0.02 parts of polyoxyethylene-polyoxypropylene copolymer, 0.3 parts of triethanolamine, 0.5 parts of nano-magnesium powder, and 0.3 parts of nano-iron oxide.

[0029] The particle diameter of described nano-magnesium powder, nano-iron oxide is 60nm, and process according to the following steps:

[0030] 1) Add the nanomaterials to ethanol, and place it on an ultrasonic machine with a frequency of 30KHz for 20 minutes, and set aside;

[0031] 2) Add silane coupling agent, sorbitan monostearate, and sodium lauryl sulfate to ethanol, and place it on an ultrasonic machine with a frequency of 30KHz for 15 minutes, and set aside;

[0032] 3) First mix the solution obtained in step 1) with the solution obtained in step 2), an...

Embodiment 3

[0036] A new type of alcohol-based fuel, made from the following components by weight: 70 parts of methanol, 6 parts of ethanol, 4 parts of isobutanol, 4 parts of propylene glycol, 3 parts of isopropyl ether, di-tert-butyl peroxide 5 parts, 0.8 parts of glycerin, 0.04 parts of polyoxyethylene-polyoxypropylene copolymer, 0.5 parts of triethanolamine, 0.9 parts of nano-magnesium powder, and 0.5 parts of nano-iron oxide.

[0037] The particle diameter of described nano-magnesium powder, nano-iron oxide is 100nm, and process according to the following steps:

[0038] 1) Add the nanomaterials to ethanol, and place it on an ultrasonic machine with a frequency of 40KHz for 30 minutes, and set aside;

[0039] 2) Add silane coupling agent, sorbitan monostearate, and sodium lauryl sulfate to ethanol, and place it on an ultrasonic machine with a frequency of 40KHz for 25 minutes, and set aside;

[0040] 3) First mix the solution obtained in step 1) with the solution obtained in step 2),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com