High-friction and low-loss nylon composite material for castor of trolley luggage and preparation method of nylon composite material

A technology of nylon composite material and trolley case, which is applied in the field of chemical synthesis, can solve the problems of poor optimization of friction coefficient and friction loss, influence of caster noise and shock absorption experience, and inability to optimize rigidity and toughness, so as to solve the problem of processing Poor fluidity, increased contact surface energy and bond strength, and improved overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

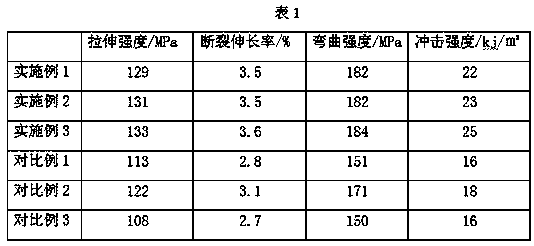

Examples

Embodiment 1

[0034] Preparation of PAR: mix bisphenol A, terephthalic acid, aliphatic dibasic acid and zinc acetate, pass through nitrogen, heat to 180°C, after the mixture is homogeneous, raise the temperature to 240°C for esterification reaction, After reacting for 2.5h, turbidity was obtained;

[0035] Add antimony trioxide to the turbidity, heat to 300°C under vacuum, and react for 0.2-1h to obtain a milky white polymer;

[0036] Extrude and purify the milky white polymer to obtain PAR.

[0037] Preparation of composite materials:

[0038] S1: put 10 parts of activated carbon fiber and 1 part of potassium permanganate into concentrated sulfuric acid, heat for 2 hours, then wash with distilled water until the pH value is 6.5, and then rinse with ethanol to obtain liquid-phase oxidized activated carbon fiber;

[0039] Ultrasonic dispersion of liquid-phase oxidized activated carbon fibers in ethanol, magnetic stirring, to obtain activation system A;

[0040] Ultrasonic dispersion of 1 ...

Embodiment 2

[0045] Preparation of PAR: mix bisphenol A, terephthalic acid, aliphatic dibasic acid and zinc acetate, pass through nitrogen, heat to 190°C, after the mixture is homogeneous, raise the temperature to 260°C for esterification reaction, After reacting for 2.5h, turbidity was obtained;

[0046] Add antimony trioxide to the turbidity, heat to 310°C under vacuum, and react for 0.2-1h to obtain a milky white polymer;

[0047] Extrude and purify the milky white polymer to obtain PAR.

[0048] Preparation of composite materials:

[0049] S1: Put 13 parts of activated carbon fiber and 2 parts of potassium permanganate into concentrated sulfuric acid, heat for 2~3h, then rinse with distilled water until the pH value is 7, and then rinse with ethanol to obtain liquid-phase oxidized activated carbon fiber;

[0050] Ultrasonic dispersion of liquid-phase oxidized activated carbon fibers in ethanol, magnetic stirring, to obtain activation system A;

[0051] Ultrasonic dispersion of 1.5 p...

Embodiment 3

[0056] Preparation of PAR: mix bisphenol A, terephthalic acid, aliphatic dibasic acid and zinc acetate, pass through nitrogen, heat to 200°C, after the mixture is homogeneous, raise the temperature to 280°C to carry out esterification reaction, After reacting for 2.5h, turbidity was obtained;

[0057] Add antimony trioxide to the turbidity, heat to 320°C under vacuum, and react for 0.2-1h to obtain a milky white polymer;

[0058] Extrude and purify the milky white polymer to obtain PAR.

[0059] Preparation of composite materials:

[0060] S1: put 15 parts of activated carbon fiber and 3 parts of potassium permanganate into concentrated sulfuric acid, heat for 2~3h, then rinse with distilled water until the pH value is 7.5, and then rinse with ethanol to obtain liquid-phase oxidized activated carbon fiber;

[0061] Ultrasonic dispersion of liquid-phase oxidized activated carbon fibers in ethanol, magnetic stirring, to obtain activation system A;

[0062] Ultrasonic dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com