Preparation method of photocatalyst with super-strong degradation effect

A photocatalyst and super-powerful technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low degradation efficiency and insufficient material degradation effect, and achieve surface Strong activity and the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

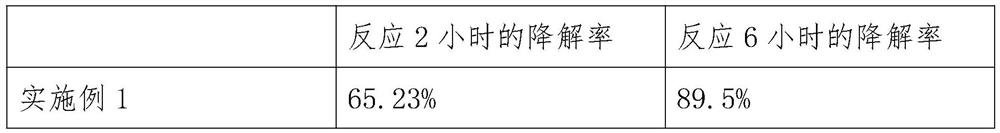

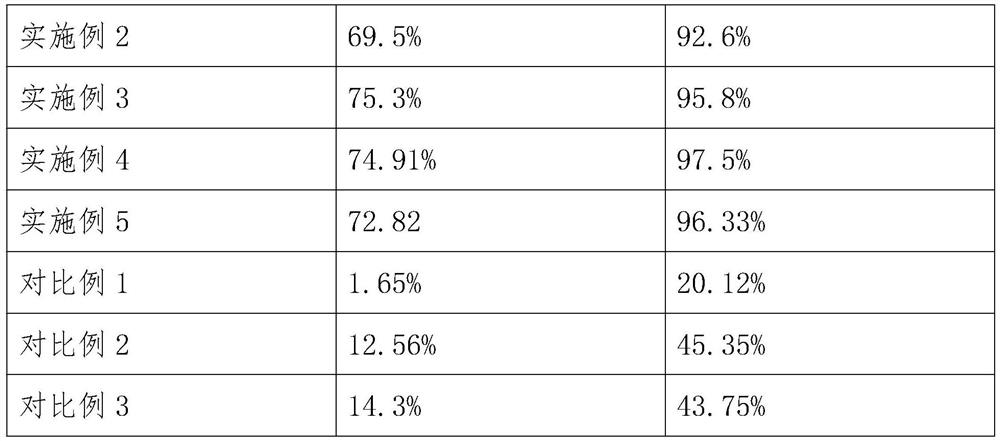

Examples

Embodiment 1

[0030] A preparation method of a photocatalyst with a super-strong degradation effect provided by the invention;

[0031] Including the following steps:

[0032] Titanium dioxide pretreatment:

[0033] S1: Calcining titanium dioxide in sections, the specific sections are as follows: continuous calcination at 100°C for 30 minutes, continuous calcination at 200°C for 30 minutes, continuous calcination at 400°C for 60 minutes, continuous calcination at 800°C for 60 minutes, and grinding and filtering after calcination to obtain Titanium dioxide powder;

[0034] S2: Take titanium dioxide powder and anhydrous toluene into a single-necked flask, and treat it under ultrasonic wave for 5-15 minutes to fully disperse;

[0035] S3: Then add an aqueous solution containing hydrogen fluoride and sodium fluoride to the single-necked flask. In the aqueous solution containing hydrogen fluoride and sodium fluoride, the mass percentage of hydrogen fluoride and sodium fluoride is 2:1, and reac...

Embodiment 2

[0041] A preparation method of a photocatalyst with a super-strong degradation effect provided by the invention;

[0042] Including the following steps:

[0043] Titanium dioxide pretreatment:

[0044] S1: Calcining titanium dioxide in sections, the specific sections are as follows: continuous calcination at 100°C for 30 minutes, continuous calcination at 200°C for 30 minutes, continuous calcination at 400°C for 60 minutes, continuous calcination at 800°C for 60 minutes, and grinding and filtering after calcination to obtain Titanium dioxide powder;

[0045] S2: Take titanium dioxide powder and anhydrous toluene into a single-necked flask, and treat it under ultrasonic wave for 5-15 minutes to fully disperse;

[0046] S3: Then add an aqueous solution containing hydrogen fluoride and sodium fluoride to the single-necked flask. In the aqueous solution containing hydrogen fluoride and sodium fluoride, the mass percentage of hydrogen fluoride and sodium fluoride is 2:1, and reac...

Embodiment 3

[0052] A preparation method of a photocatalyst with a super-strong degradation effect provided by the invention;

[0053] Including the following steps:

[0054] Titanium dioxide pretreatment:

[0055] S1: Calcining titanium dioxide in sections, the specific sections are as follows: continuous calcination at 100°C for 30 minutes, continuous calcination at 200°C for 30 minutes, continuous calcination at 400°C for 60 minutes, continuous calcination at 800°C for 60 minutes, and grinding and filtering after calcination to obtain Titanium dioxide powder;

[0056] S2: Take titanium dioxide powder and anhydrous toluene into a single-necked flask, and treat it under ultrasonic wave for 5-15 minutes to fully disperse;

[0057] S3: Then add an aqueous solution containing hydrogen fluoride and sodium fluoride to the single-necked flask. In the aqueous solution containing hydrogen fluoride and sodium fluoride, the mass percentage of hydrogen fluoride and sodium fluoride is 2:1, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com