Patents

Literature

31results about How to "The whole is dense and uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing flexible polyurethane foam plastic

Soft foamed polyurethane plastic is produced through a one-step reaction process with isocyanate component and low-unsaturation degree polyether polyol component in the presence of water as active foaming agent, catalyst(s), foam-stabilizing surfactant, optional foaming agent, coloring agent, stuffing, fire retardant and other conventional additives and assistants. It has high tensile strength, great elongation, very high tearing strength, improved machine performance and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

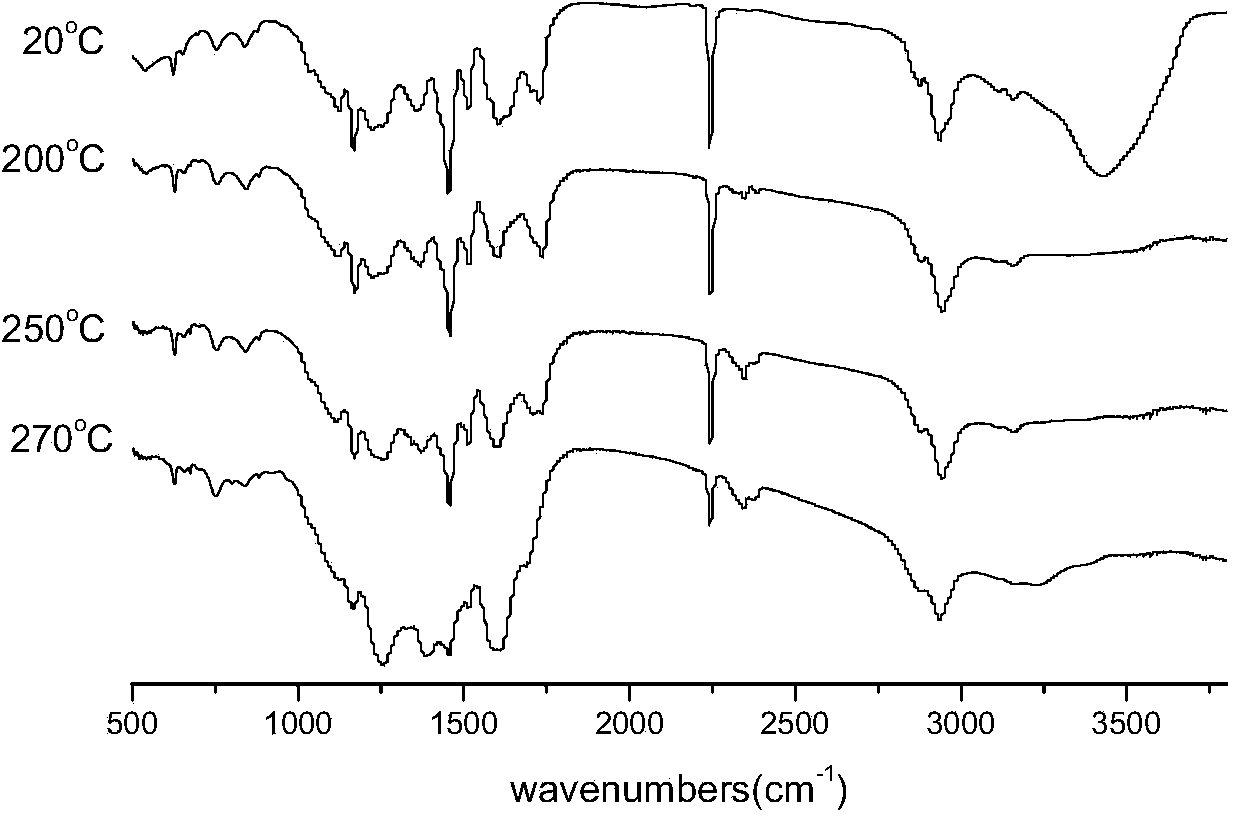

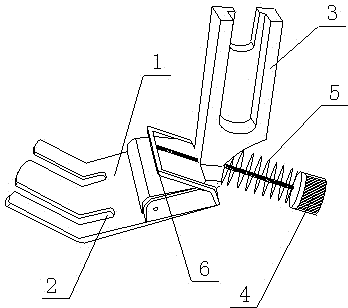

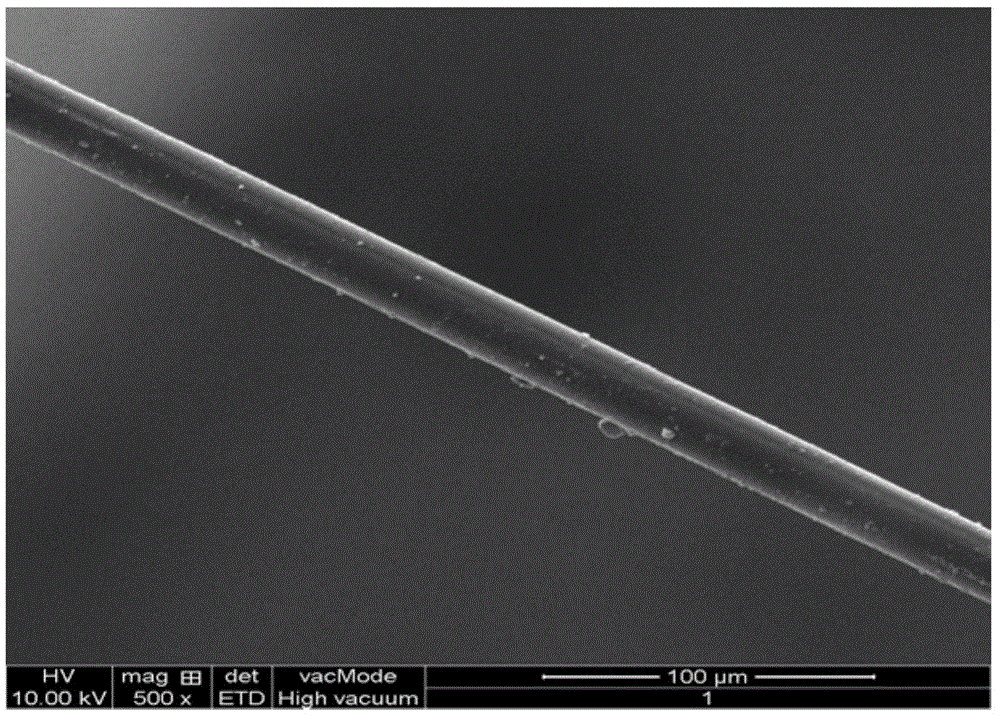

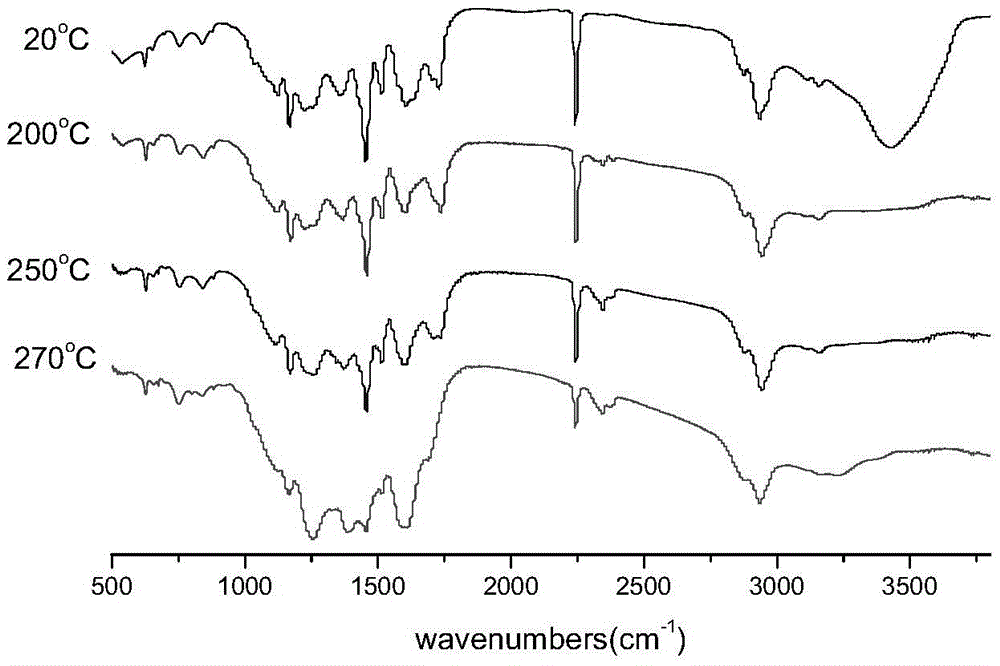

Method for improving pre-oxidation speed of polyacrylonitrile fiber through physical blending

ActiveCN103993382ASimple spinning processProcess is easy to controlFilament forming substance formingArtificial filament heat treatmentPlasticizerHydrogen bond

The invention relates to a method for improving pre-oxidation speed of polyacrylonitrile fiber through physical blending. The method comprises the following steps: performing vacuum drying on polyacrylonitrile, lignin and a plasticizer, and uniformly stirring and mixing, thus obtaining a mixed material; spinning, setting and winding to obtain a melt spun fiber, wherein a mass ratio of polyacrylonitrile to lignin to the plasticizer is (5-30):(10-30):(50-70); and performing water bath drawing on the melt spun fiber, and performing pre-oxidation to obtain the pre-oxidation polyacrylonitrile fiber. The raw material lignin is low in cost and slight in environmental pollution and is suitable for industrial production; lignin contains lots of hydroxyl groups which can achieve hydrogen-bond interaction with a polar group cyano on a polyacrylonitrile molecular chain, and lignin and polyacrylonitrile have high compatibility; moreover, the oxygen content in the lignin structure is high, the oxygen can be released in the pre-oxidation process, a uniform oxygen source is provided for an oxidation reaction of a polyacrylonitrile precursor, and a prepared pre-oxidation thread sheath-core is small in difference and dense and uniform in structure.

Owner:优聚新材料(浙江)有限公司

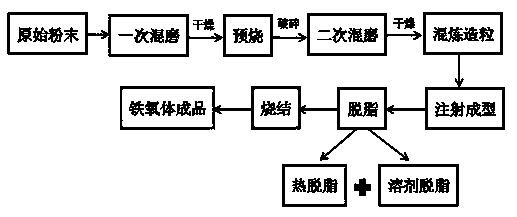

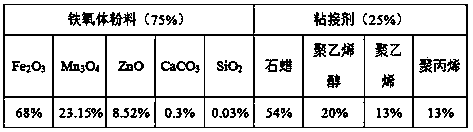

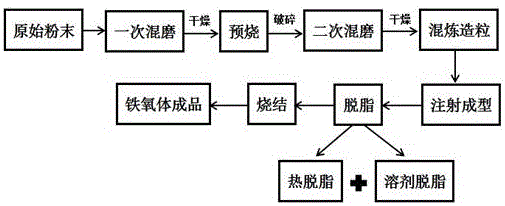

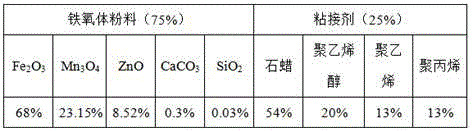

Injection forming method of soft magnetic ferrite material

ActiveCN104029281ASolve production and processing difficultiesHigh mechanical strengthCeramic shaping apparatusGrain treatmentsAdhesiveFerrite powder

The invention discloses an injection forming method of a soft magnetic ferrite material.The method comprises the following steps of: 1) powder preparation: mixing and milling ferrite powder at one time, after dryness, presintering the powder, crushing the presintered powder for secondary mixing and milling, and performing drying treatment, 2) mixing and granulation: uniformly mixing the powder obtained in Step 1) with an adhesive, mixing to form a mixture, crushing the mixture, 3) injection forming: heating the crushed mixture, injecting into a mold cavity under a pressure condition, opening a mold for cooling, then obtaining a forming body, 4) degreasing: putting the forming body in trichloro ethylene for degreasing, drying, and then performing heat degreasing, and 5) sintering: sintering the degreased forming body to form the soft magnetic ferrite material.The method is suitable for preparing middle and small high-precision ferrite core devices in complicated shapes, and the prepared soft magnetic ferrite material has the characteristics of large and uniform density, uniform internal structure, high mechanical strength and relatively low iron loss.

Owner:ZHEJIANG UNIV

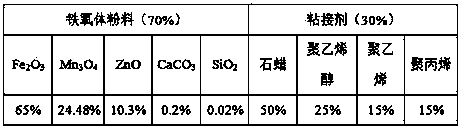

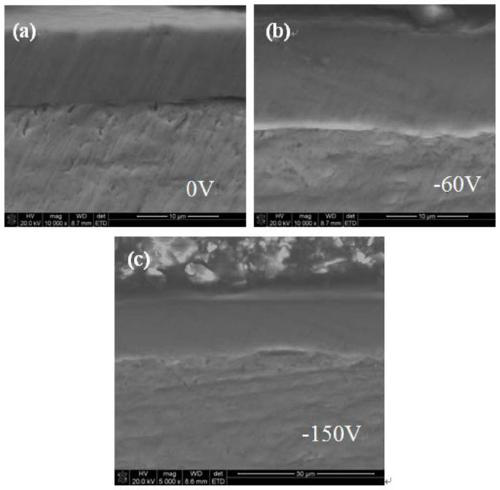

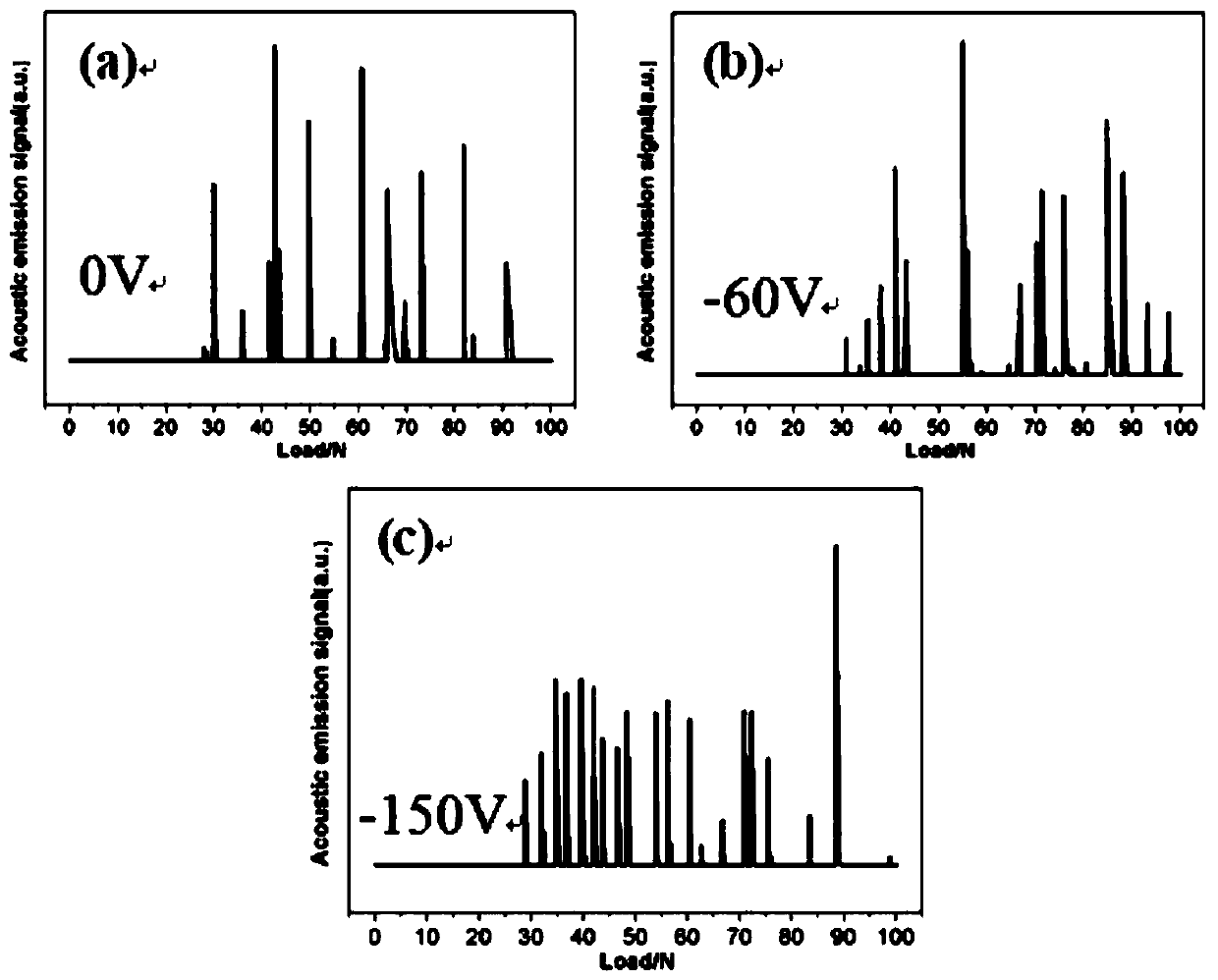

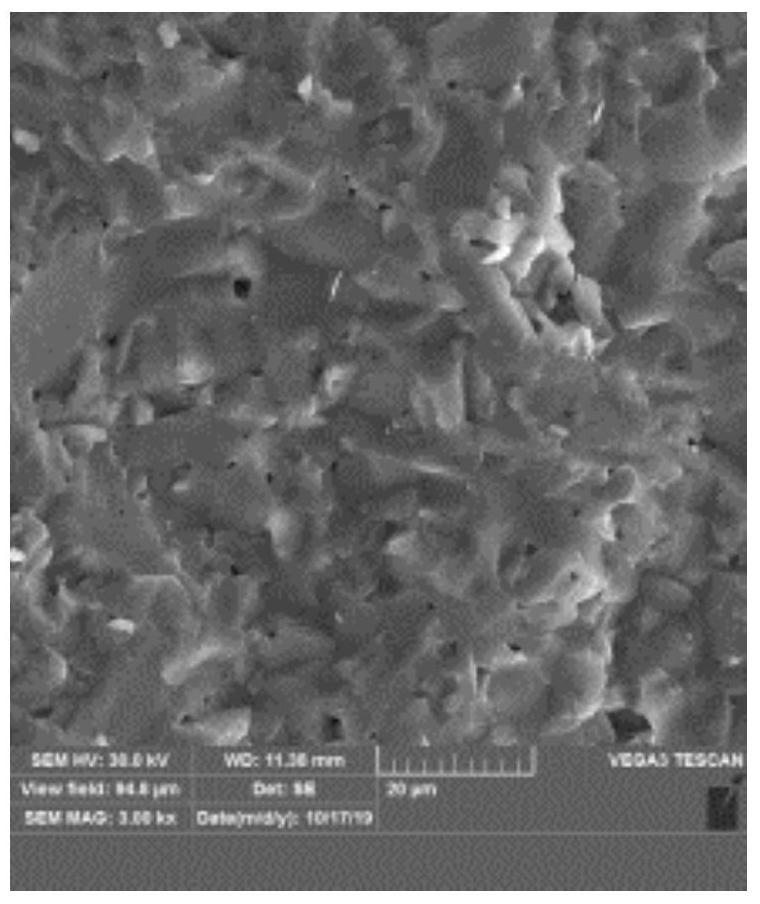

Preparation method for CrN coating on surface of nuclear zirconium alloy and product

ActiveCN109852943AStrengthen the bombardment effectImprove bindingVacuum evaporation coatingSputtering coatingZr alloyMaterials science

The invention discloses a preparation method for a CrN coating on a surface of a nuclear zirconium alloy and a product. The sputtering power, the matrix temperature and the bias voltage are adjusted by the multi-target magnetron sputtering technology; and the CrN coating is prepared on the surface of the Zr alloy matrix. According to the invention, the energy of deposited particles is increased byadjusting the bias voltage of the matrix, so the bombardment effect of the deposited particles on the surface of the Zr alloy matrix is enhanced, the bonding at the interface between the CrN coatingand the Zr alloy matrix is promoted, and then the bonding force of the CrN coating and the Zr alloy matrix is increased; the CrN coating with uniform compactness, excellent bonding performance and high thickness and deposited on the surface of the Zr alloy matrix is obtained; the CrN coating is of important scientific significance and engineering application value to a protective coating preparedon the surface of the zirconium alloy and meeting the engineering application thickness (above 10 microns).

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

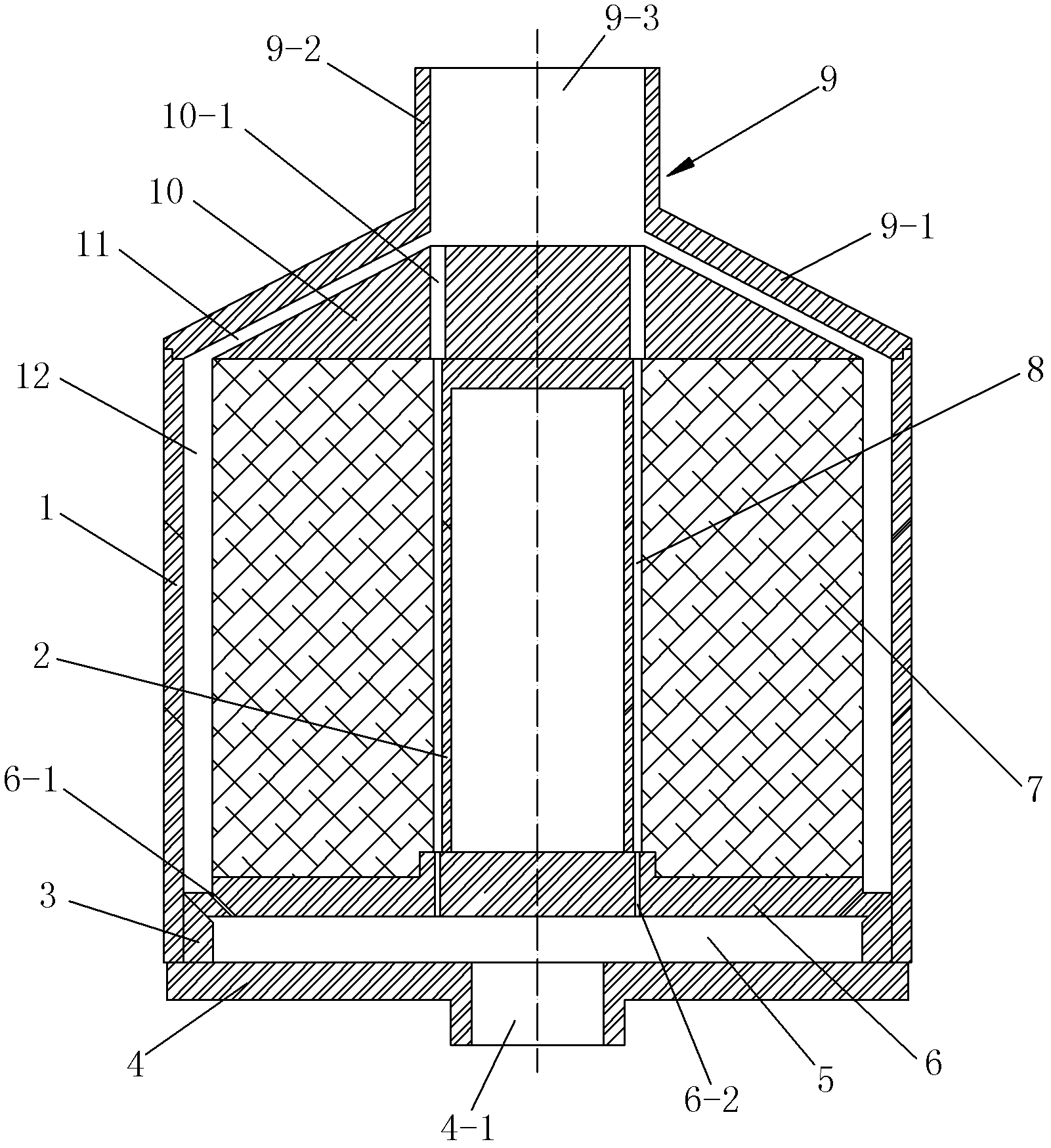

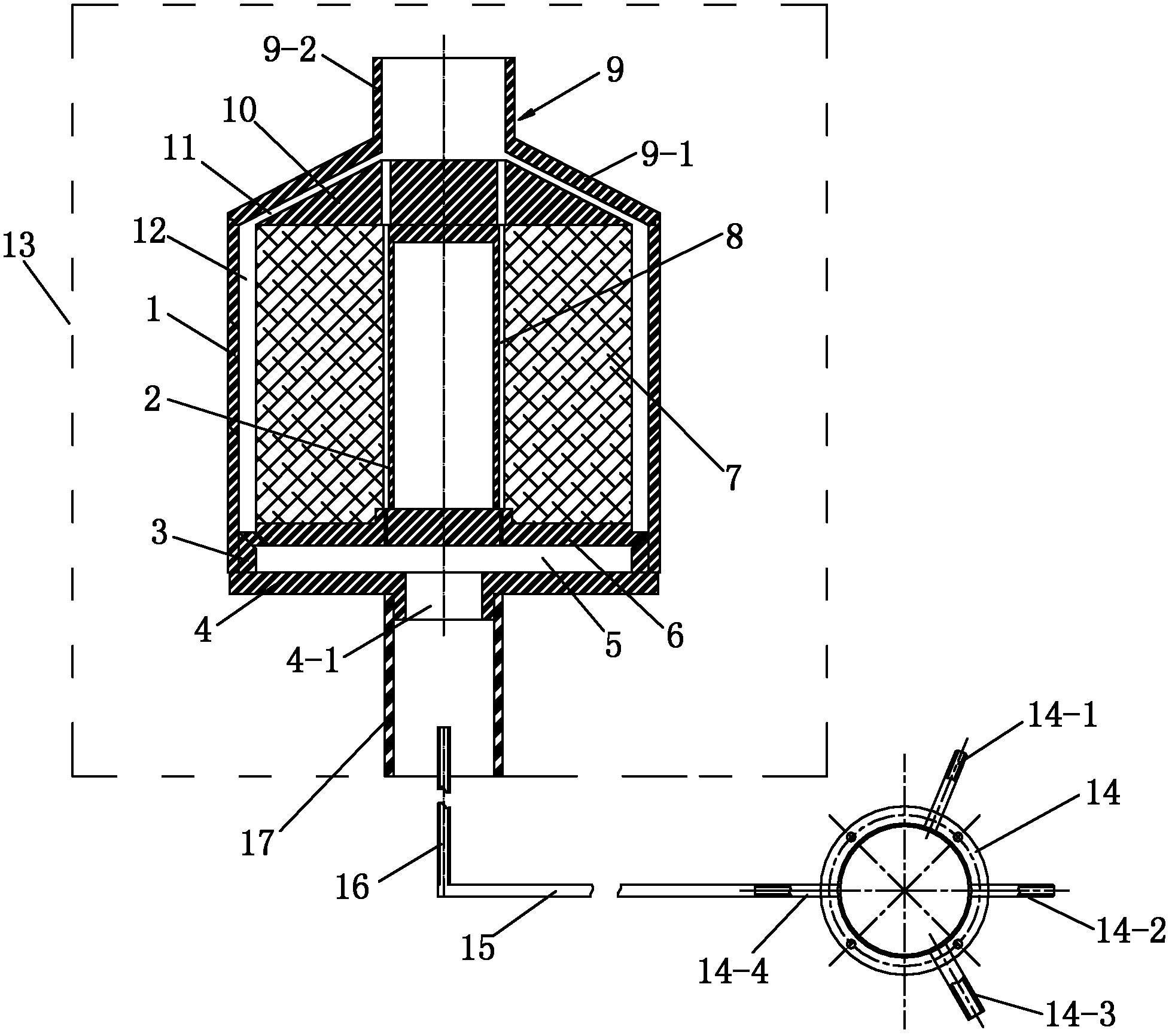

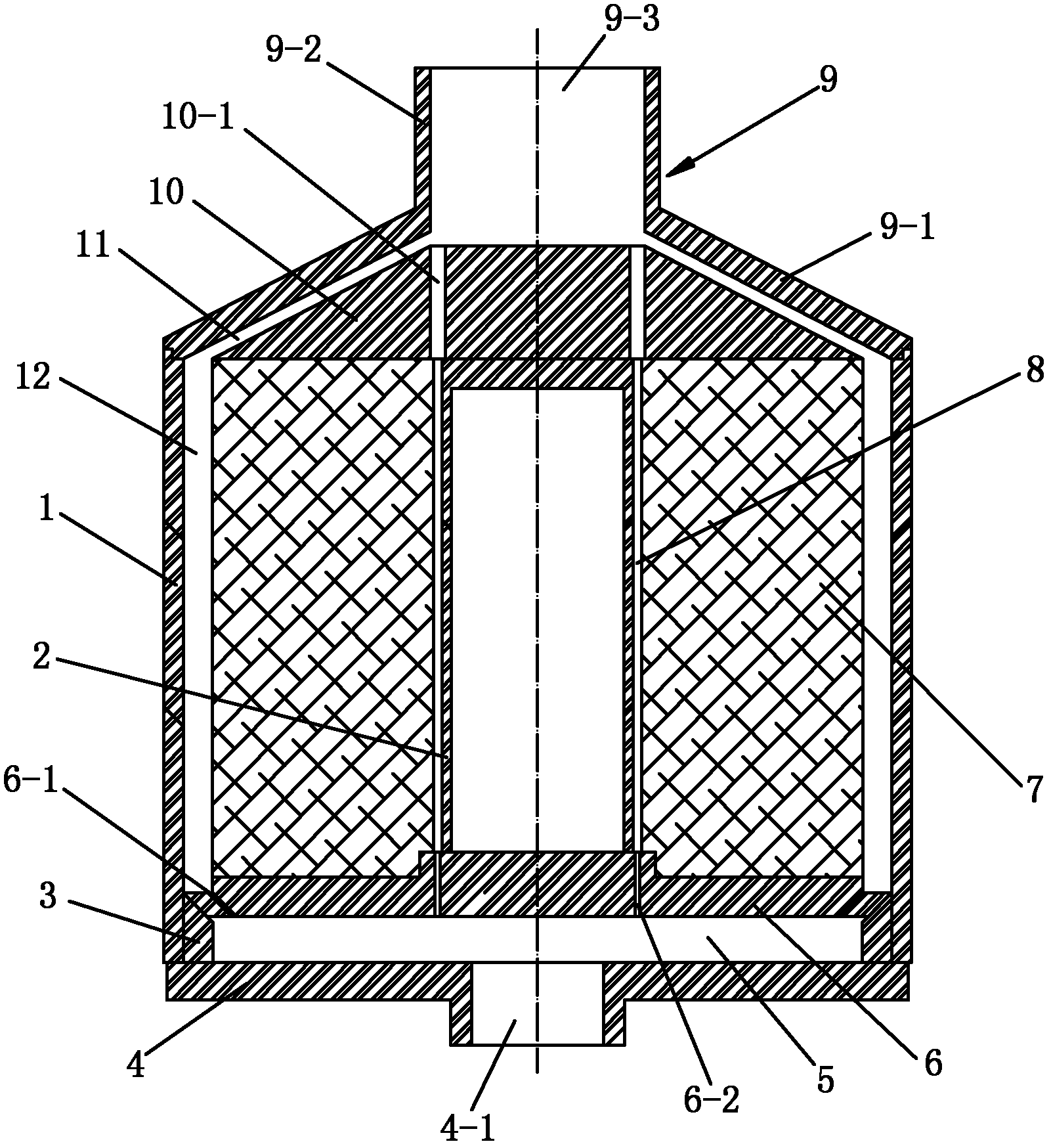

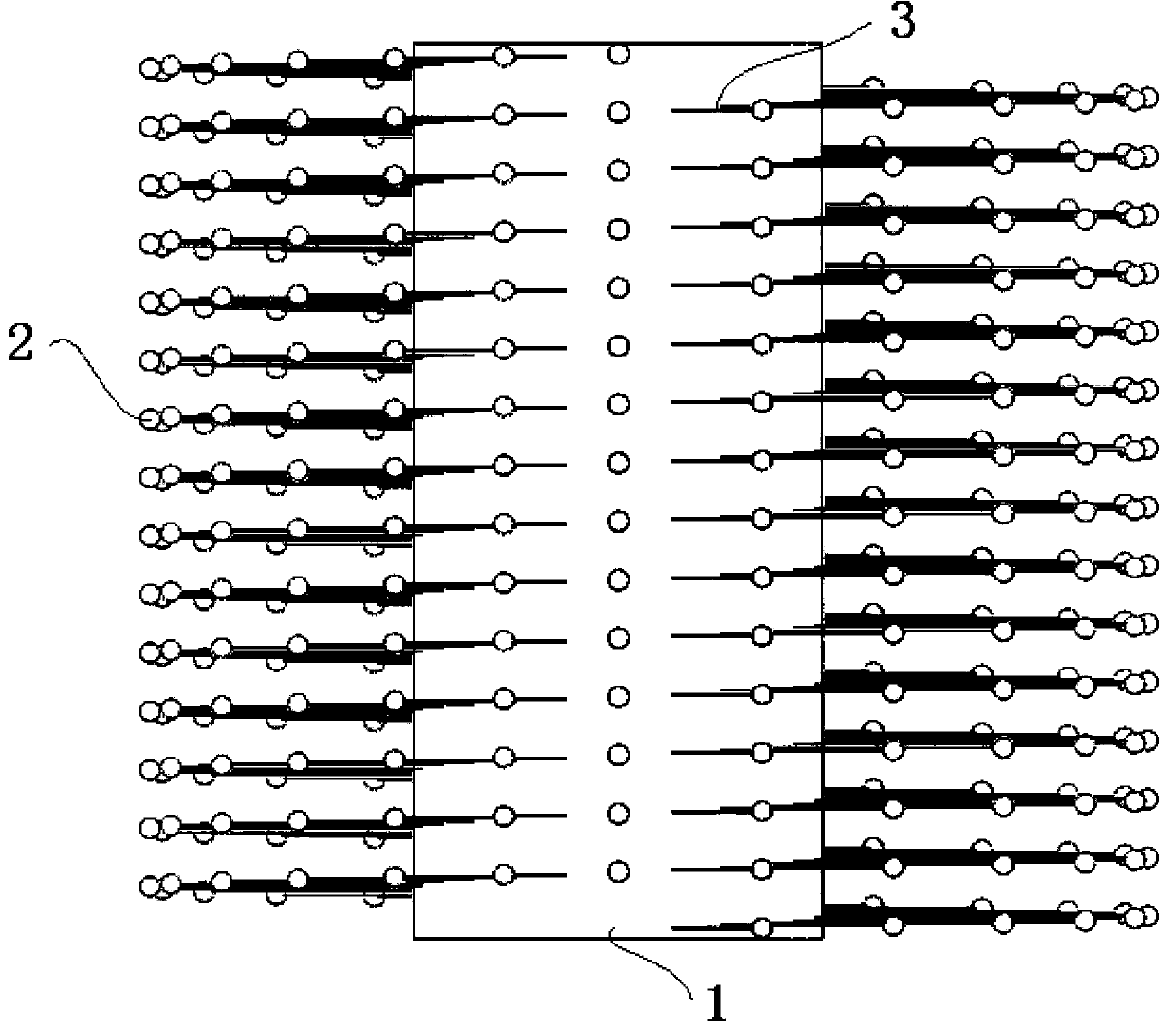

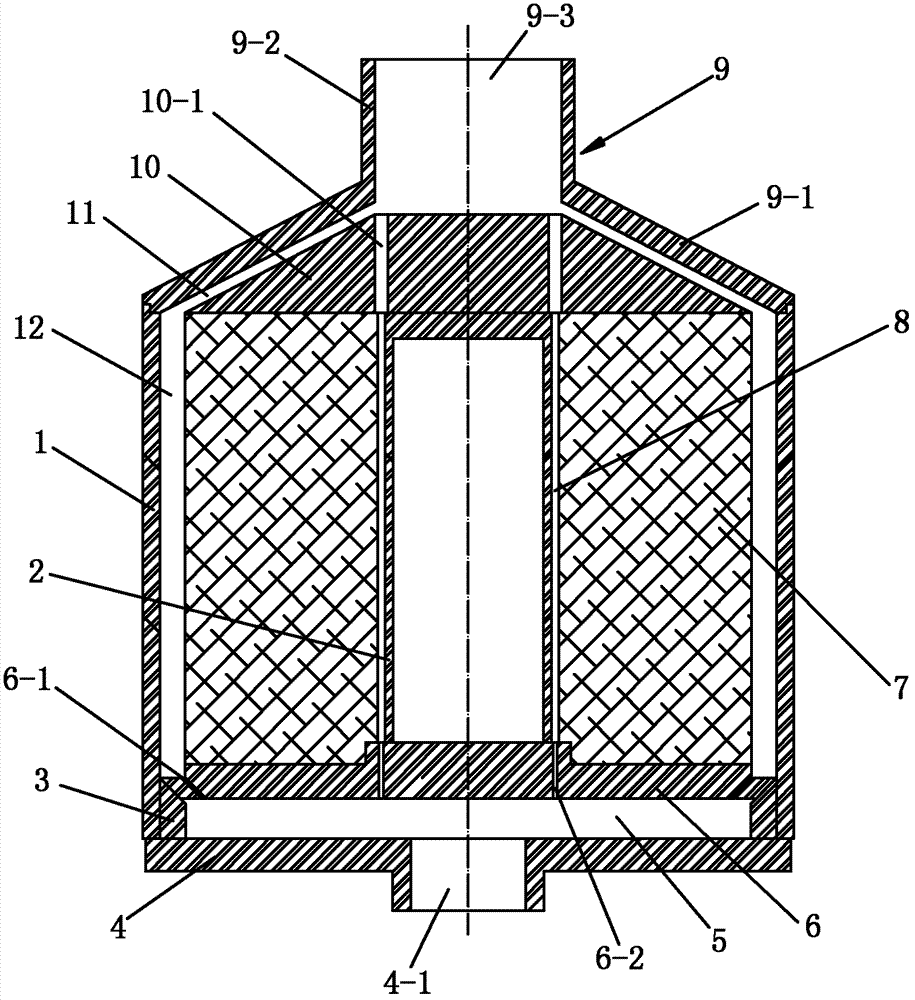

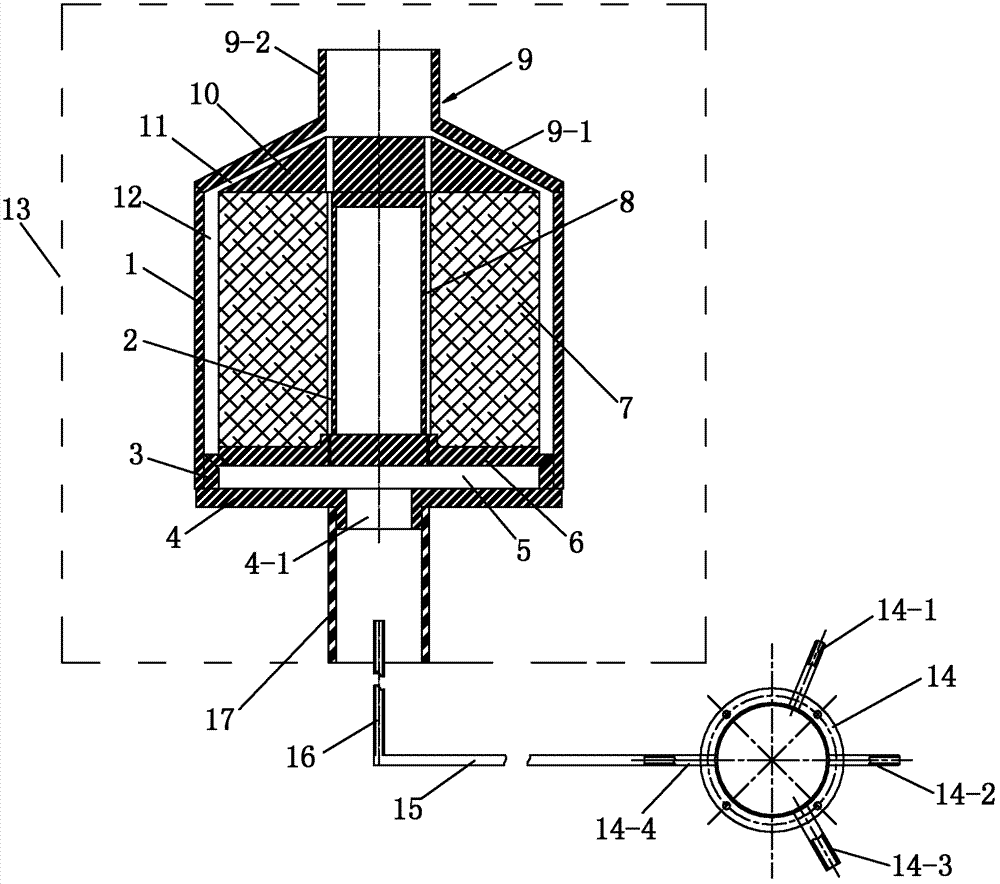

Tool for compacting thick-walled hollow carbon/carbon (C/C) composite product

ActiveCN102618851ASimple structureNovel and reasonable designChemical vapor deposition coatingRetention periodEngineering

The invention discloses a tool for compacting a thick-walled hollow carbon / carbon (C / C) composite product, which comprises an outer barrel, a gas inlet substrate and a gas guide device, wherein the interior of the outer barrel is provided with a gas inlet basal plate; a cavity I is formed between the gas inlet substrate and the gas inlet basal plate; the gas inlet substrate is provided with a gas inlet; the top face of the gas inlet basal plate is provided with an inner barrel; a to-be-compacted thick-walled hollow C / C composite preform is sheathed onto the inner barrel; a gap I for the circulation of gas is formed between the outer surface of the C / C composite preform and the inner surface of the outer barrel; a gap II for the circulation of the gas is formed between the inner surface of the C / C composite preform and the outer surface of the inner barrel; and the gas inlet basal plate is provided with a plurality of diversion passages II and diversion passages III, wherein the diversion passages II are used for communicating the cavity I with the gap I, and the diversion passages III are used for communicating the cavity I and the gap II. According to the tool for compacting the thick-walled hollow C / C composite product, gas diversion can be performed, and thereby, the retention period of pyrolysis gas in a depositing space is shortened, and the C / C composite preform is rapidly and evenly compacted.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

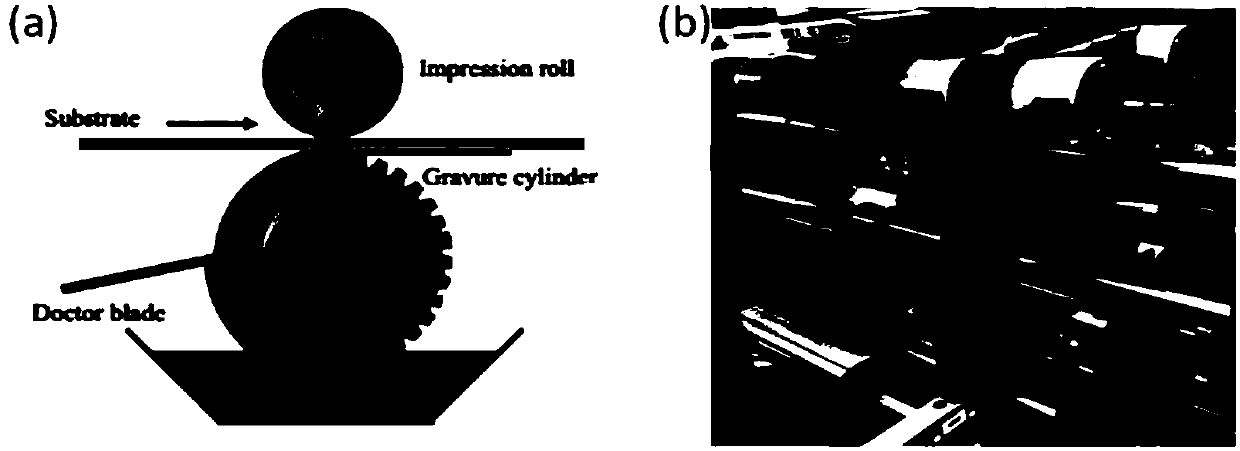

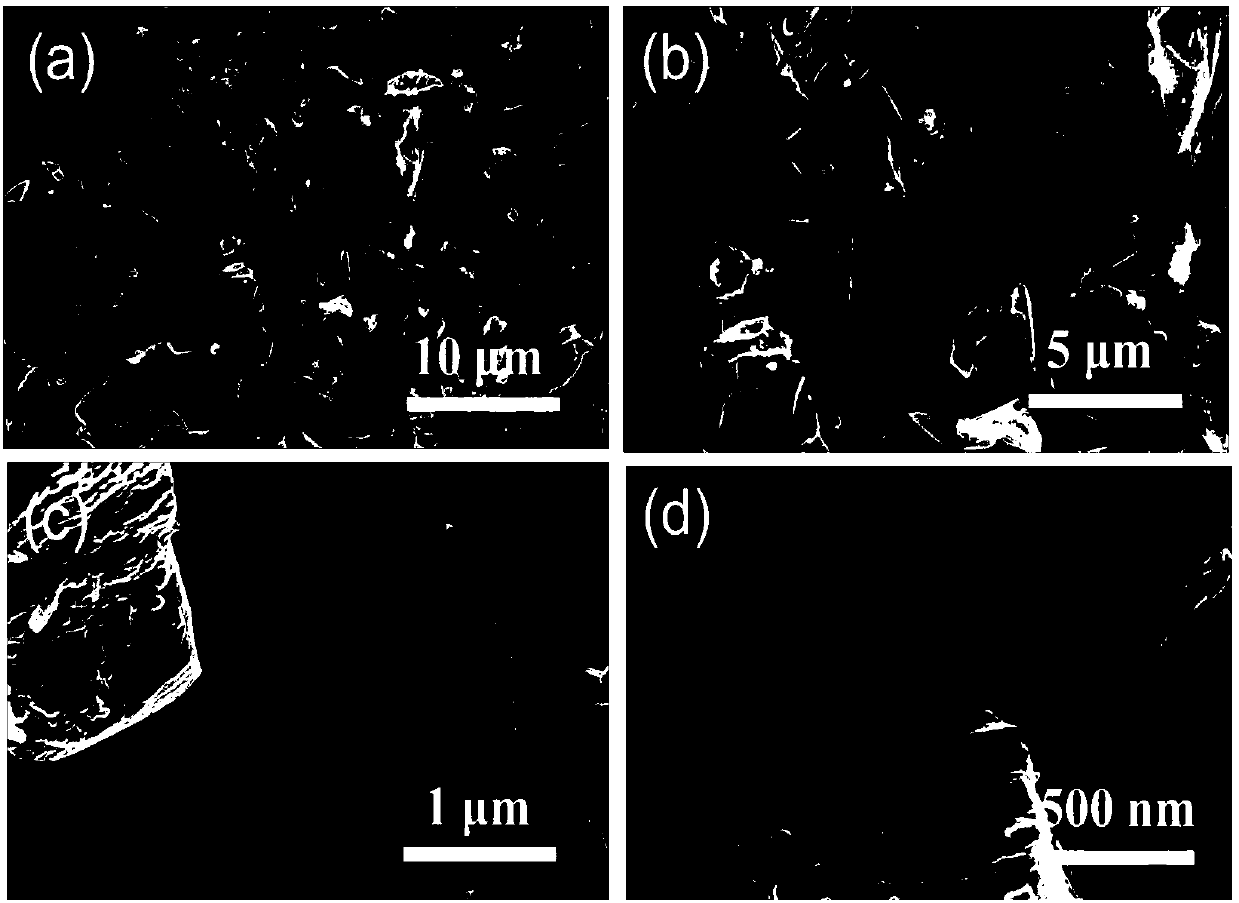

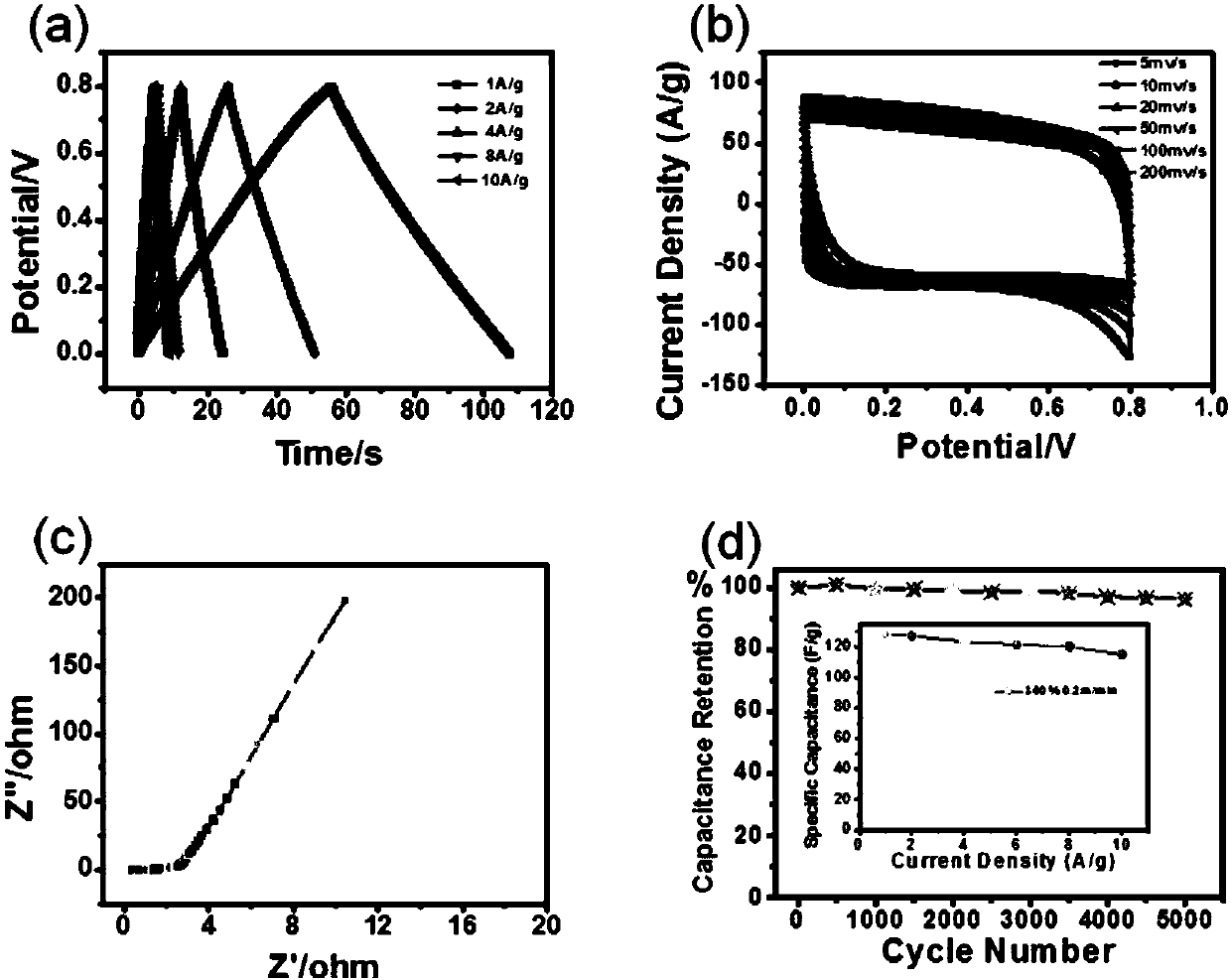

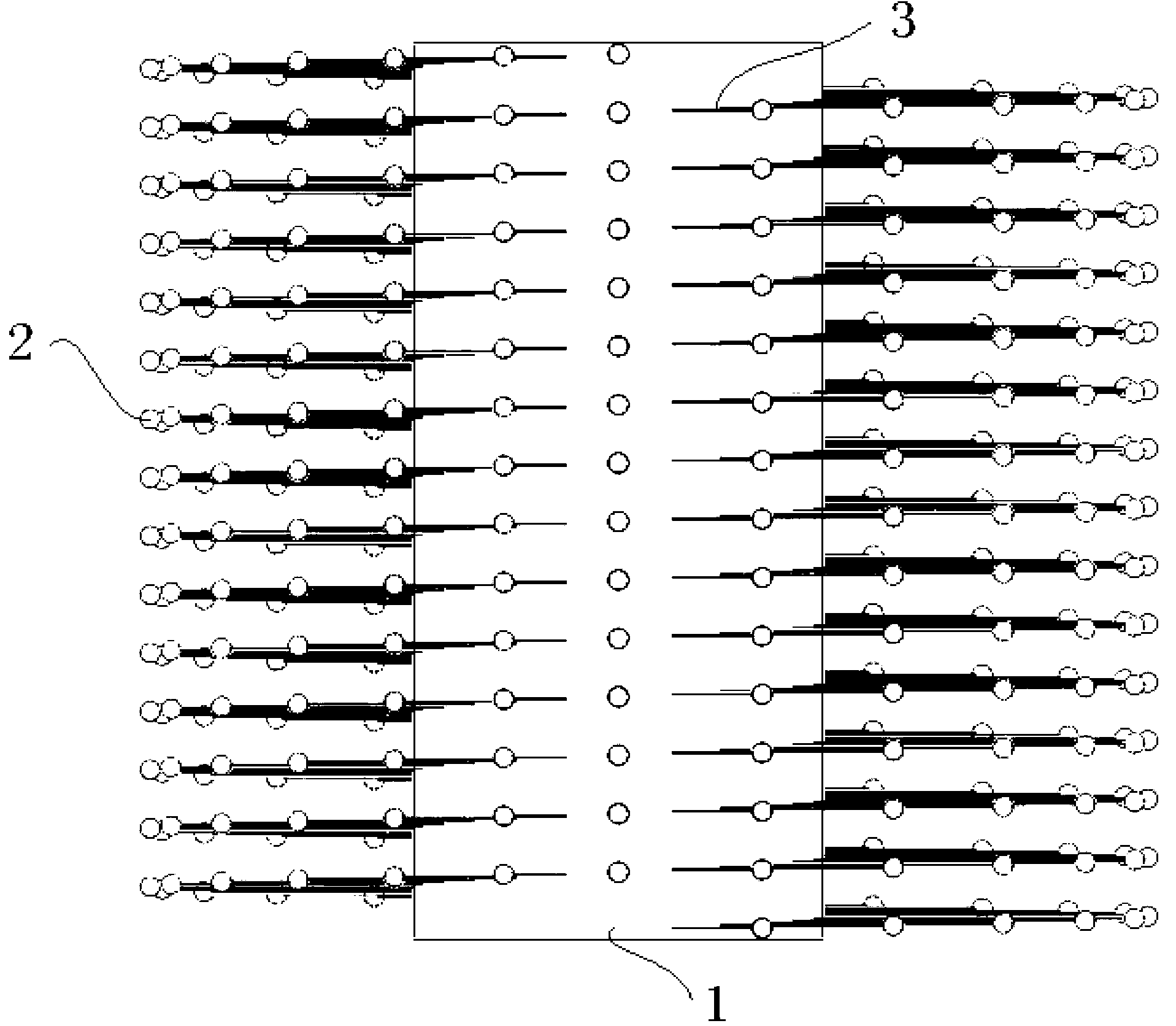

Method for preparing electrode of supercapacitor based on reel-to-reel printing technique

InactiveCN108039290AFully miscibleThe whole is dense and uniformHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorPole piece

The invention discloses a method for preparing an electrode of a supercapacitor based on a reel-to-reel printing technique. According to the method, by utilizing the reel-to-reel printing technique, asilver nano-wire is taken as a conductive agent and is mixed with a binder and active matters so as to form slurry, foamed nickel is used as a current collector for preparing an electrode pole piece,and the electrode pole piece is assembled with a diaphragm and electrolyte so as to form the supercapacitor. The method has the advantages of rapidness, high efficiency, excellent performance, good continuity and the like and has wide development prospects in industrial production and actual application, and the large-scale production can be realized.

Owner:湖南纳昇电子科技有限公司

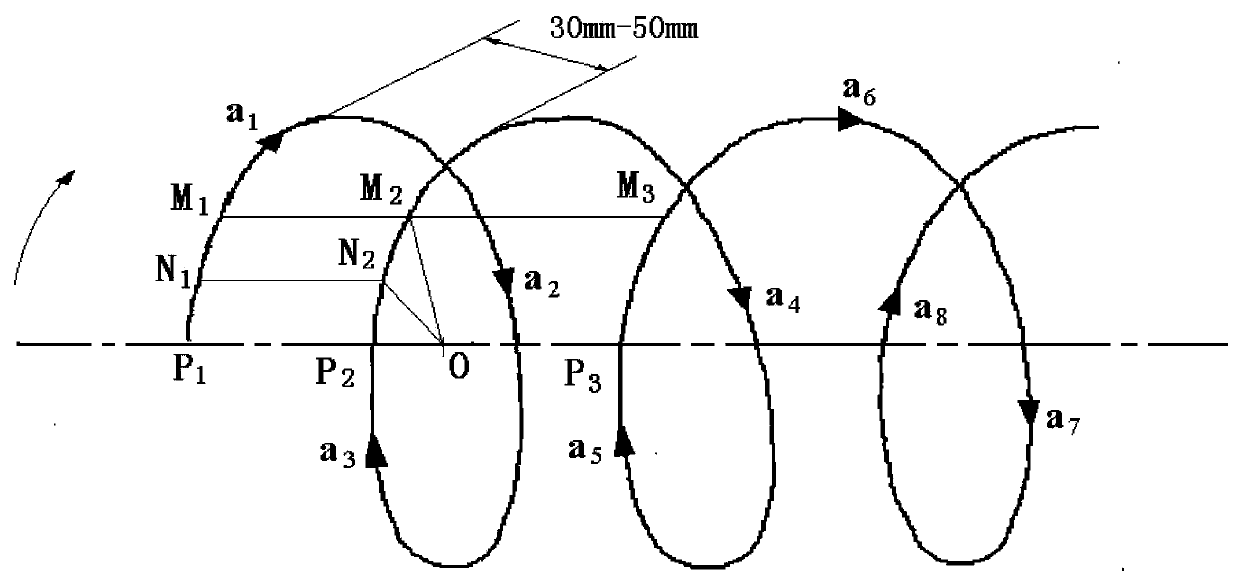

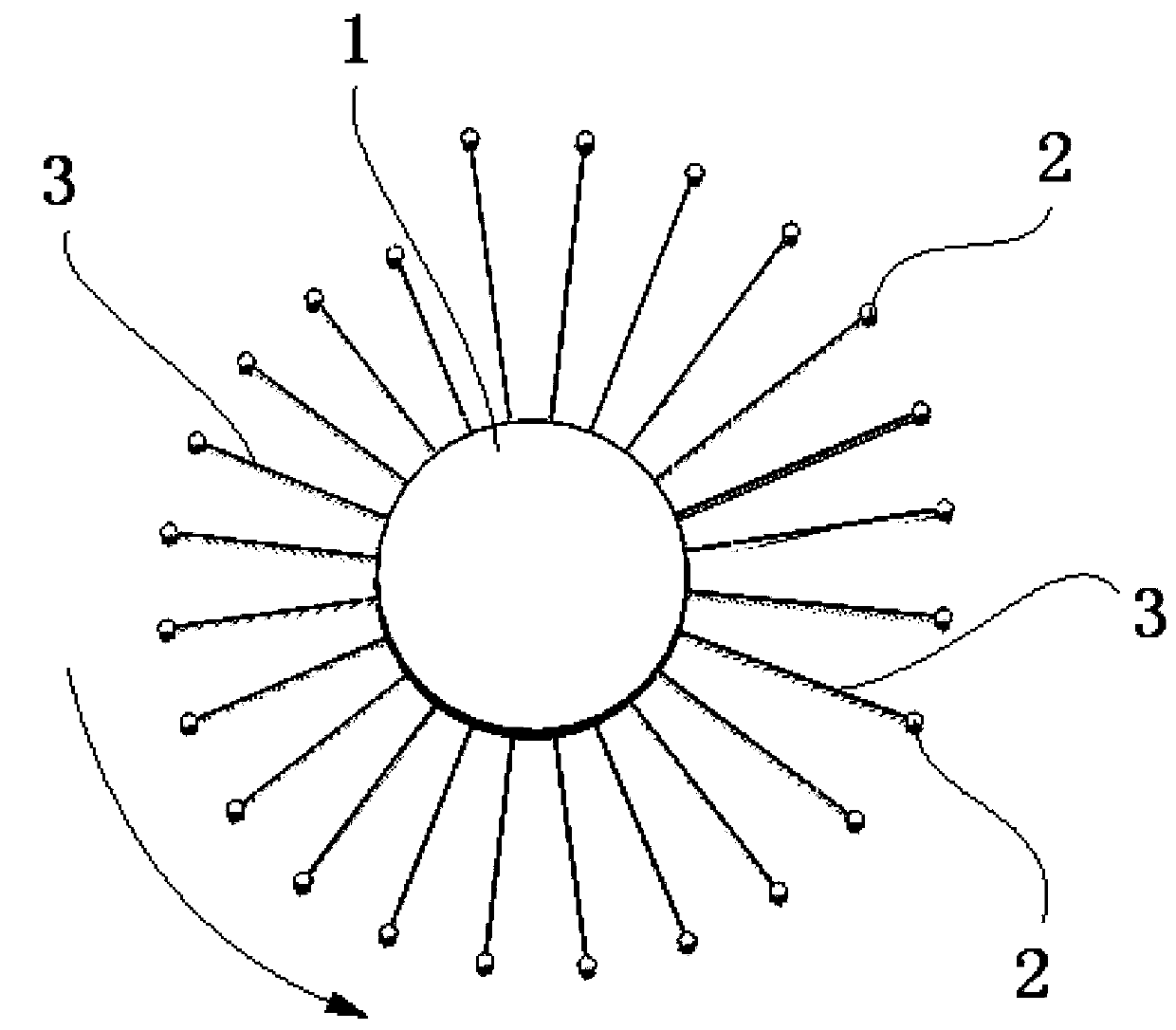

Spray deposition densifying device and application thereof

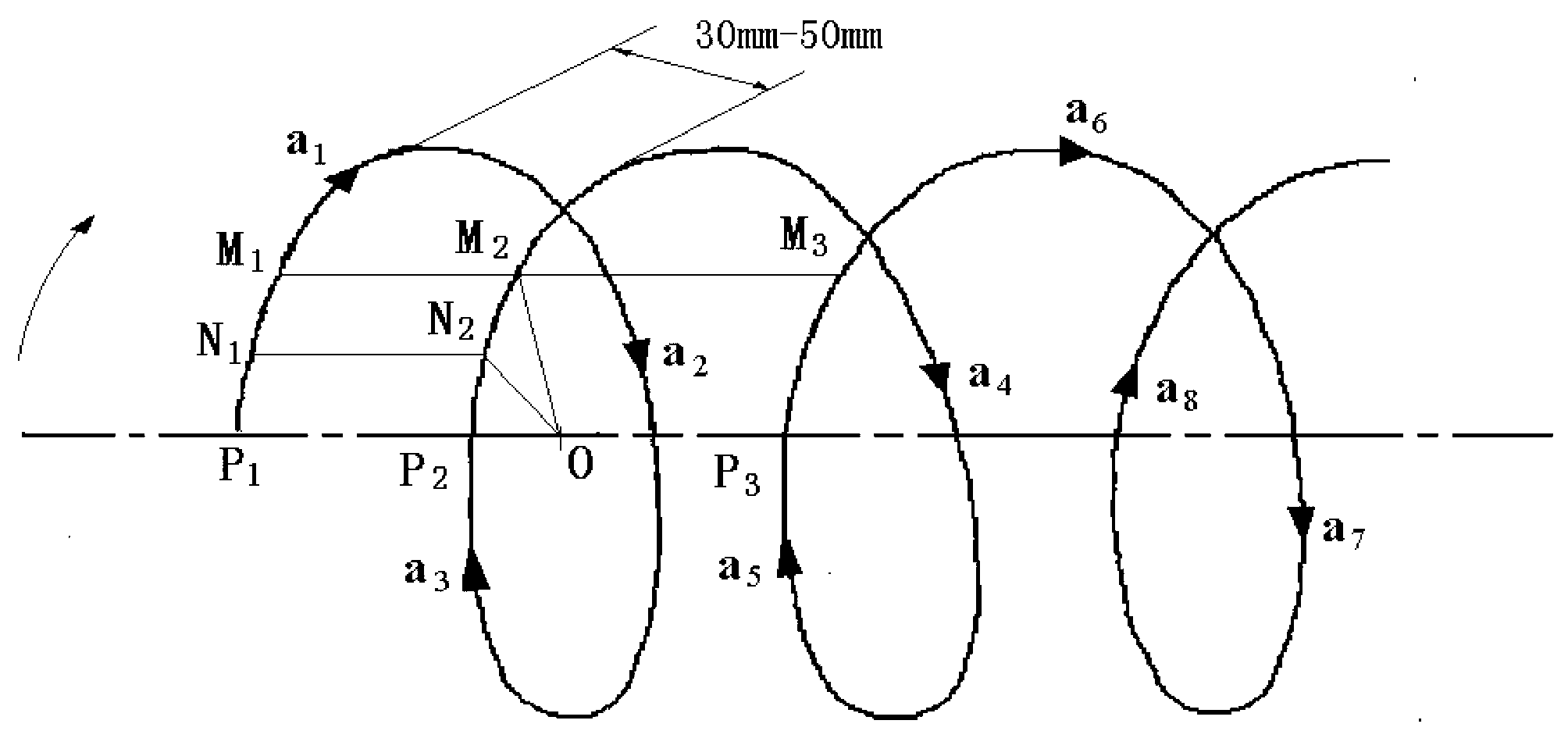

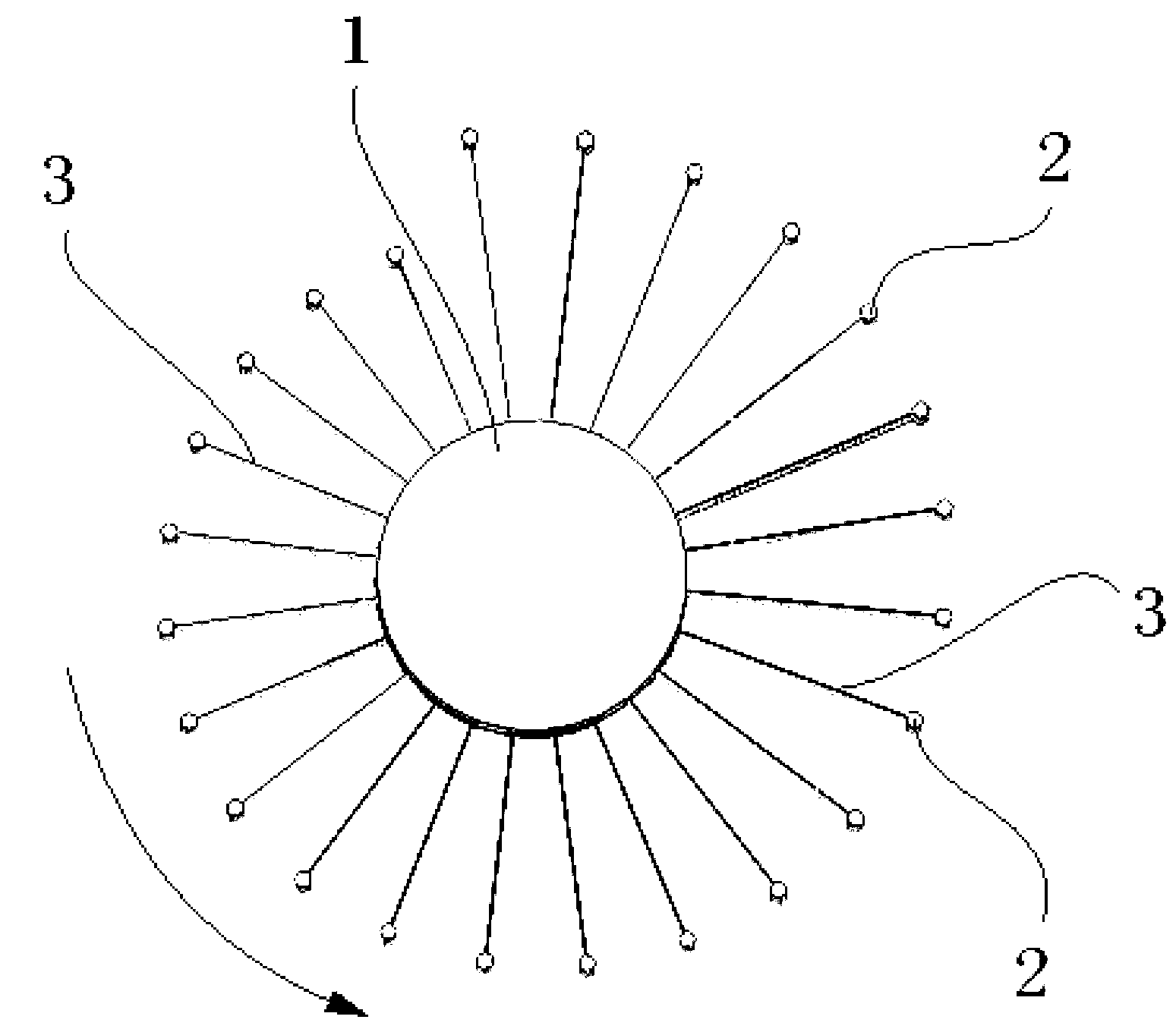

The invention discloses a spray deposition densifying device and the application thereof. The device disclosed by the invention includes a rotating shaft, wherein a plurality of rotating balls are fixed on the rotating shaft; each rotating ball is fixed on the rotating shaft through a flexible chain; during the rotation of the rotating shaft, the rotating balls are distributed in a spiral line around the rotating shaft, the extending direction of the spiral line is the same as the axial direction of the rotating shaft, and the length of the flexible chain in the direction the same as the rotating direction of the rotating shaft periodically changes along the spiral line; within each period, the length of the flexible chain is gradually increased in the direction the same as the rotating direction of the rotating shaft; the screw pitch of the spiral line is 30-50 mm; and the central angle of ball centers of the two adjacent rotating balls is 10-15 degrees. During the spray deposition, the rotating balls in the densifying device are used for impacting the surface of a deposition blank, metallurgical bonding is generated under the shearing action, the deposition blank is densified layer by layer through the rotation of a pipe blank during the spray deposition, the entire densification is realized in an accumulated manner, so that the pipe stock with high performance is obtained.

Owner:HUAIHAI INST OF TECH

High-toughness AlCrSc alloy powder for 3D printing and preparation method and application thereof

ActiveCN113512671AHigh tensile strengthHigh yield strengthAdditive manufacturing apparatusIncreasing energy efficiency3d printOxidation resistant

The invention relates to the technical field of aluminum alloy powder materials for 3D printing, in particular to high-toughness AlCrSc alloy powder for 3D printing and a preparation method and an application thereof. The aluminum alloy powder material for the 3D printing provided by the invention comprises the following alloy elements: 1.0 to 4.0 weight percent of Cr, 0.3 to 1.1 weight percent of Sc, 0.1 to 0.6 weight percent of Zr, 0.5 to 1.2 weight percent of Si, 0.1 to 0.7 weight percent of Mn, 0 to 6.0 weight percent of Mg, less than 0.1 weight percent of trace elements and the balance of Al; and the trace elements are one or more of Ti, Fe, Ni, Ce, Sr, Er and La. Research shows that according to the aluminum alloy powder obtained by controlling the conditions, a printed part formed by the 3D printing technology is high in density, strength and plasticity and good in corrosion resistance, yield ratio and fatigue performance, meanwhile, the problems of smoke dust and oxidation in the printing process are solved, and therefore the oxidation resistance and the fatigue resistance of the printed part are improved. The 3D printed part obtained through the method has great potential prospects in engineering application such as force bearing parts, light-weight integrated parts and heat exchangers and radiators.

Owner:CRRC IND INST CO LTD

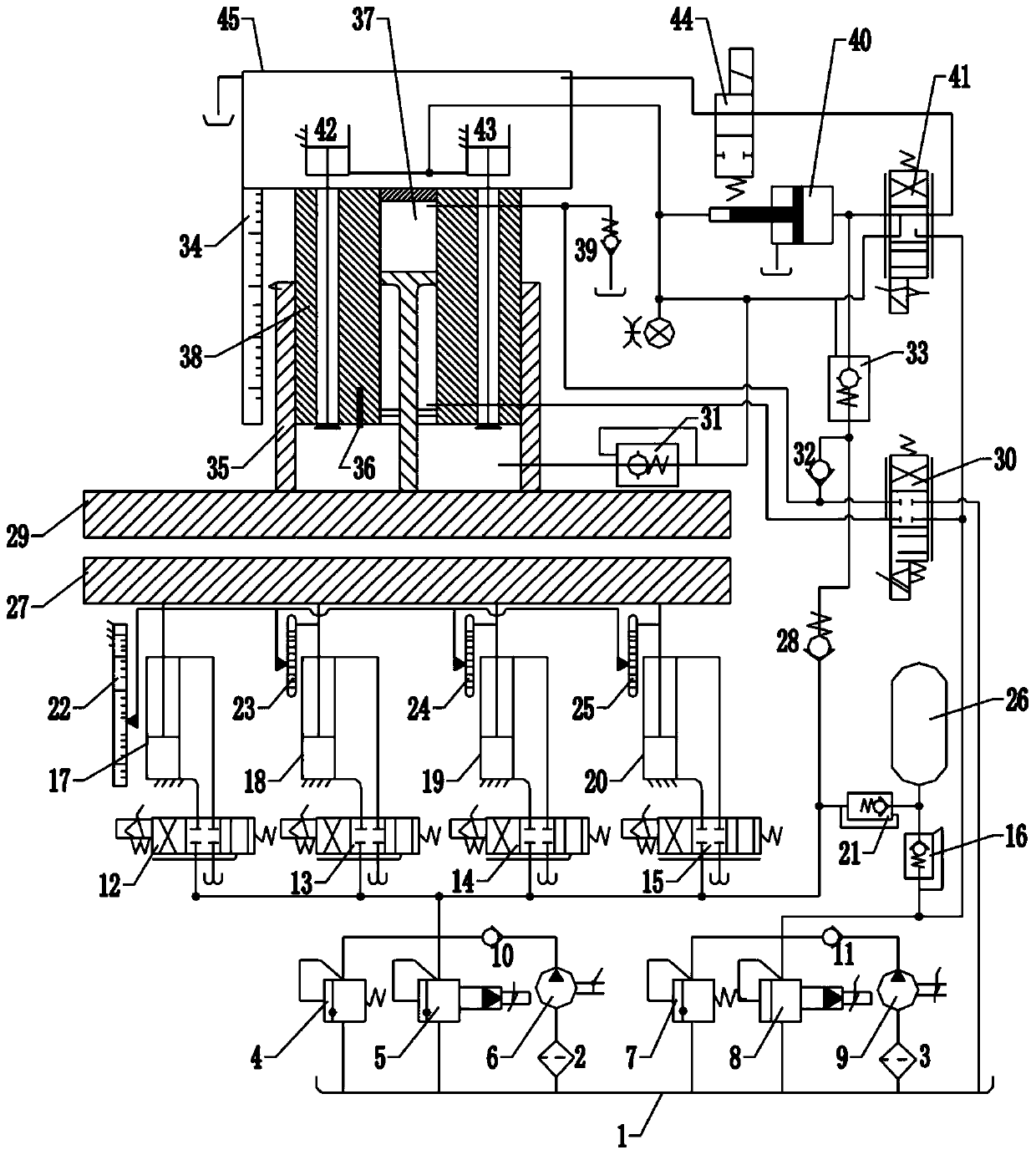

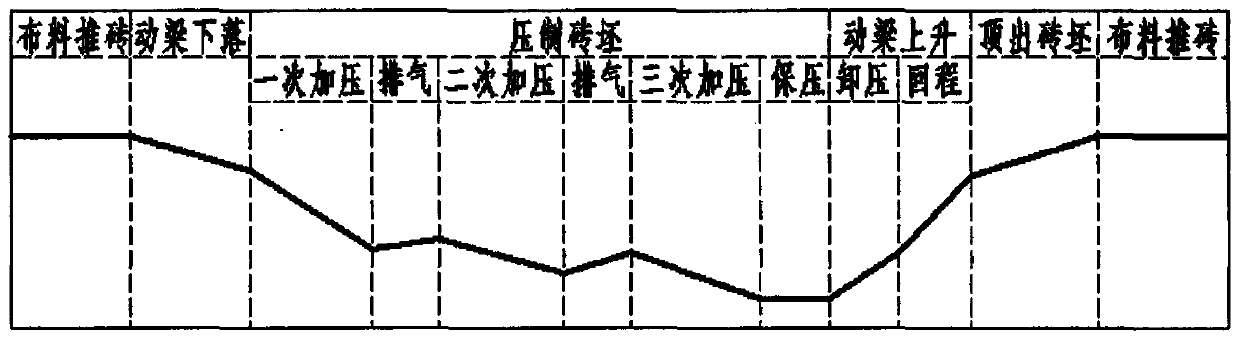

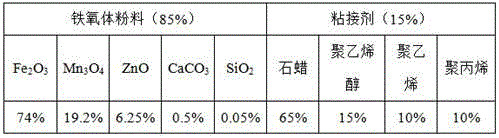

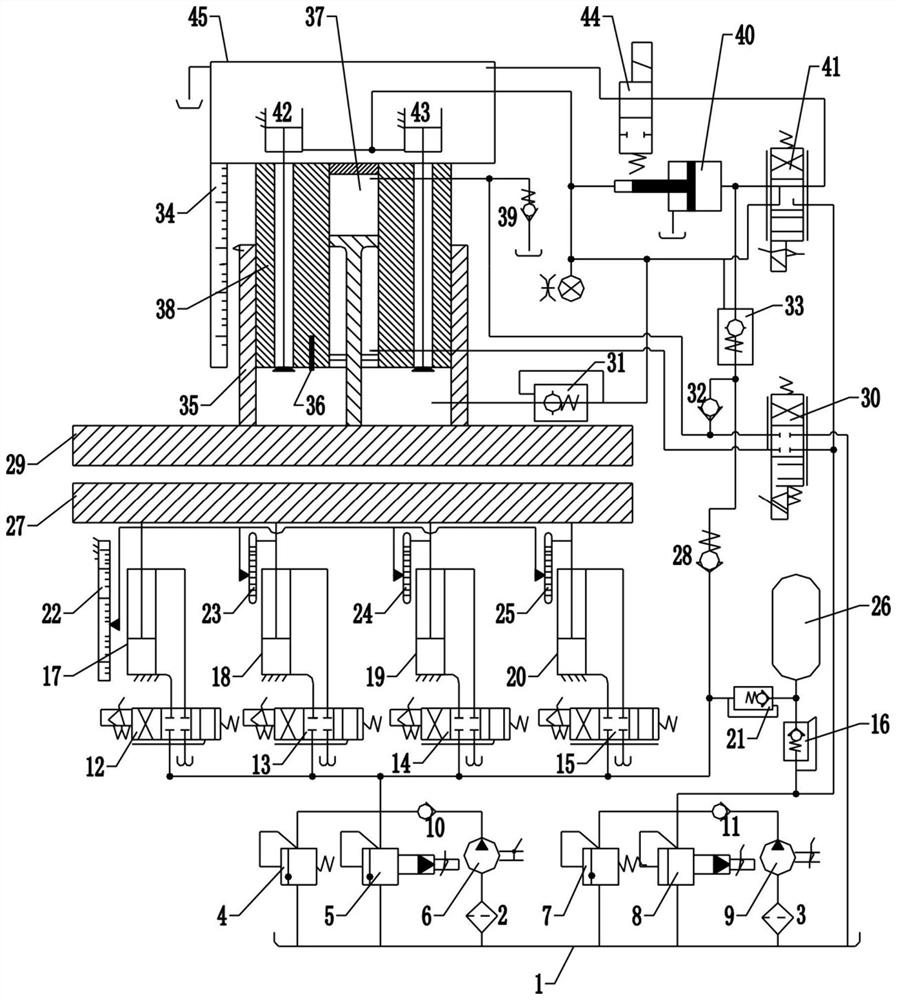

Hydraulic system of ceramic brick press and control method

ActiveCN111336139AThe whole is dense and uniformIncrease densityServomotor componentsAccumulator installationsHigh densityBrick

The invention provides a hydraulic system of a ceramic brick press and a control method, and relates to the technical field of brick press equipment. The hydraulic system comprises a pressure supply mechanism, a first control mechanism and a second control mechanism, wherein the first control mechanism and the second control mechanism are used for controlling a lower die moving beam and an upper die moving beam to move up and down respectively. According to the hydraulic system of the ceramic brick press, a green body is repeatedly pressurized and exhausted in the upper and lower directions, the repeatedly applied pressure is increased step by step, and finally, the green body has high density and is stressed uniformly. Besides, by improvement for a demoulding process, the condition of green body cracking caused by demoulding is greatly reduced.

Owner:XIAMEN UNIV OF TECH

Modified silanized metal surface pretreatment agent containing diphenylethyl diphenol polyoxyethylene ether and preparation method thereof

InactiveCN103451641AOvercome CorrosivityOvercome uniformity issuesMetallic material coating processesSilanesPhytic acid

The invention discloses a modified silanized metal surface pretreatment agent containing diphenylethyl diphenol polyoxyethylene ether. The pretreatment agent is prepared from the following raw materials in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of ethanol, 30-40 parts of gamma-chloropropyl triethoxysilane, 20-30 parts of gamma-glycidyloxypropyl trimethoxysilane, 1-2 parts of dicumyl peroxide, 0.002-0.003 part of perfluorooctyl sodium sulfonate, 0.3-0.5 part of wood ash, 4-6 parts of acrylic emulsion, 2-3 parts of sodium carboxymethyl cellulose, 0.4-1.0 part of Span80, 0.2-0.6 part of diphenylethyl diphenol polyoxyethylene ether, 0.005-0.01 part of lanthanum acetate and 0.1-0.3 part of phytic acid. A final product is obtained by modifying the coupling agent, compounding, adding auxiliaries and carrying out distribution, mixing and reaction. The modified silanized surface pretreatment agent has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane film, strong adhesion and good corrosion resistance.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

Silane treating agent and preparation method thereof

InactiveCN107326354AEasy to makeImprove performanceMetallic material coating processesMolybdateSilanes

The invention discloses a silane treating agent and a preparation method thereof. The silane treating agent comprises, by weight, 2-5 parts of a silane coupling agent, 2-5 parts of phytic acid, 8-14 parts of nitrate, 4-7 parts of molybdate and 70-100 parts of water. The silane treating agent prepared through the method has the beneficial effects of being stable in performance and free of poison and pollution. After the silane treating agent prepared through the method is utilized for treating a metal workpiece, a film layer formed on the metal surface has the beneficial effects of being excellent in adhesive force, compact, uniform and low in polarization current density. The defects of existing metal surface pretreatment are overcome, and therefore the silane treating agent can be applied to metal surface pretreatment better.

Owner:浙江裕辉新材料科技有限公司

Modified silanized metal surface pretreatment agent containing sodium carboxymethyl cellulose and preparation method thereof

The invention discloses a modified silanized metal surface pretreatment agent containing sodium carboxymethyl cellulose. The pretreatment agent is prepared from the following raw materials in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of propyl alcohol, 30-40 parts of silane coupling agent KH-171, 20-30 parts of silane coupling agent KH-560, 0.001-0.003 part of perfluorooctyl sodium sulfonate, 0.3-0.5 part of wood ash, 4-6 parts of polyvinyl acetate emulsion, 2-3 parts of sodium carboxymethyl cellulose, 0.4-1.0 part of phenylethyl phenylpropyl phenol polyoxyethylene ether, 0.2-0.8 part of sorbitan fatty acid ester, 0.005-0.01 part of lanthanum acetate and 0.1-0.3 part of phytic acid. A final product is obtained by modifying the coupling agent, compounding, adding auxiliaries and carrying out distribution, mixing and reaction. The modified silanized surface pretreatment agent has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane film, strong adhesion and good corrosion resistance.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

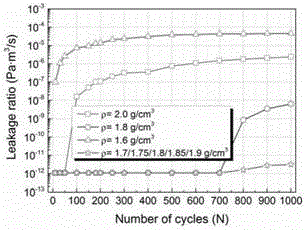

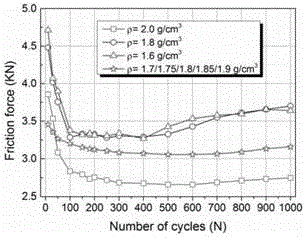

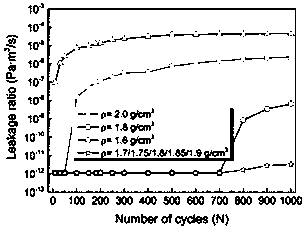

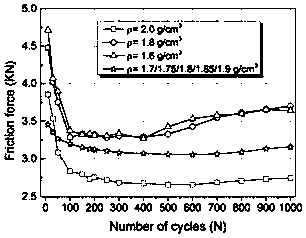

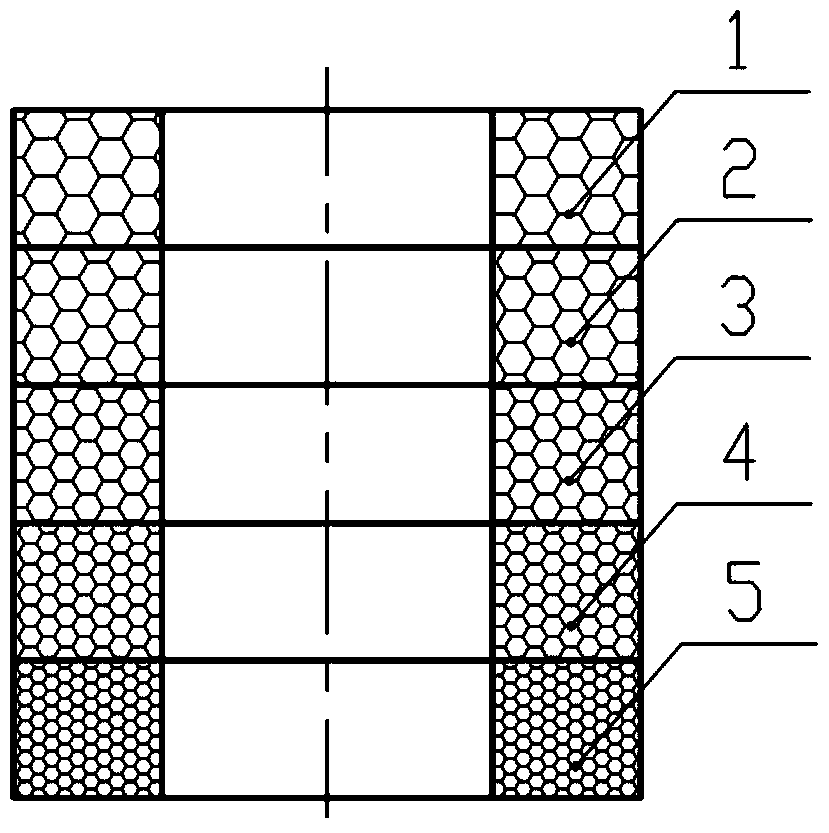

Sealing method of compression padding with density gradient and compression padding produced according to method

ActiveCN104154243AThe whole is dense and uniformUniform lateral forceEngine sealsEngineeringMechanical engineering

A sealing method of the compression padding with the density gradient comprises the first step of placing the strip-shaped padding in a forming mold according to a certain weight and a certain size, the second step of pressing the strip-shaped padding into annular padding rings through a press, wherein the forming height of the padding rings can be accurately controlled through a liner stop piece with the preset height in the pressing process so that the padding rings with the required densities can be obtained, and the third step of making the padding rings overlap in the force bearing direction, wherein the densities of the padding rings sequentially increase one by one in the force bearing direction. The invention further comprises the compression padding produced according to the method, wherein the compression padding is composed of the padding rings overlapping in the force bearing direction, and the densities of the padding rings sequentially increase one by one in the force bearing direction.

Owner:NINGBO TIANSHENG SEALING PACKING +2

Modified silanized metal surface pretreatment agent containing polyoxyethylene sorbitan monooleate and preparation method thereof

InactiveCN103450800AOvercome CorrosivityOvercome uniformity issuesAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

The invention discloses a modified silanized metal surface pretreatment agent containing polyoxyethylene sorbitan monooleate. The pretreatment agent is prepared from the following raw materials in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of propylene glycol, 30-40 parts of silane coupling agent KH-42, 20-30 parts of silane coupling agent KH-151, 1-2 parts of dicumyl peroxide, 0.002-0.003 part of perfluorooctyl sodium sulfonate, 0.3-0.5 part of wood ash, 4-6 parts of water-borne epoxy resin emulsion, 2-3 parts of sodium carboxymethyl cellulose, 0.4-1.0 part of polyoxyethylene sorbitan monooleate, 0.2-0.6 part of phenylethyl diphenol polyoxyethylene ether, 0.005-0.01 part of lanthanum acetate and 0.1-0.3 part of phytic acid. A final product is obtained by modifying the coupling agent, compounding, adding auxiliaries and carrying out distribution, mixing and reaction. The modified silanized surface pretreatment agent has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane film, strong adhesion and good corrosion resistance.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

Process for preparing flexible polyurethane foam plastic

Soft foamed polyurethane plastic is produced through a one-step reaction process with isocyanate component and low-unsaturation degree polyether polyol component in the presence of water as active foaming agent, catalyst(s), foam-stabilizing surfactant, optional foaming agent, coloring agent, stuffing, fire retardant and other conventional additives and assistants. It has high tensile strength, great elongation, very high tearing strength, improved machine performance and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

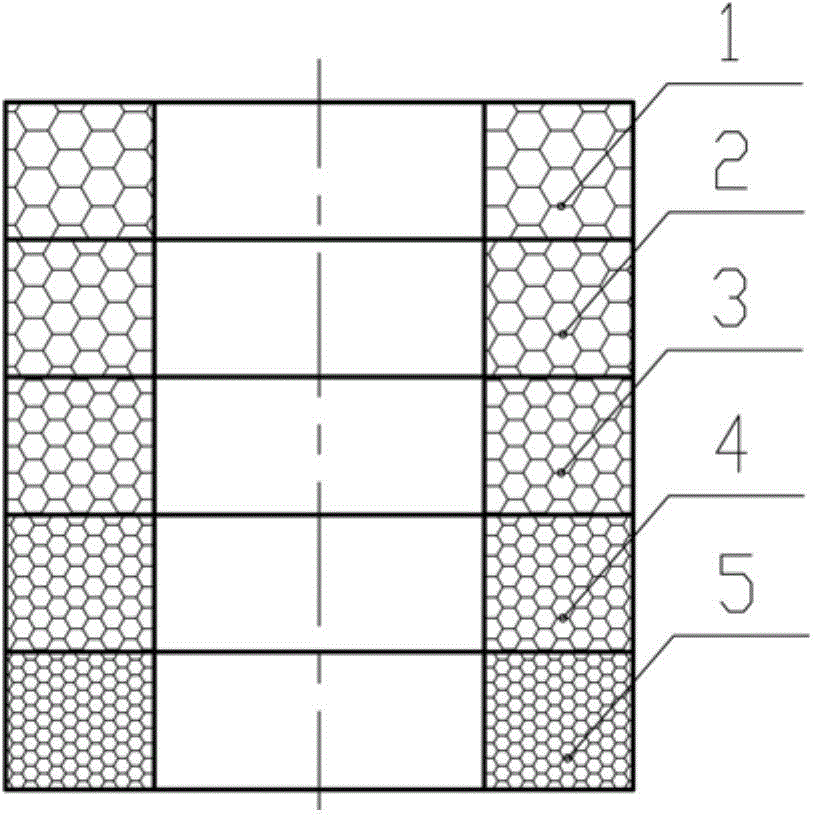

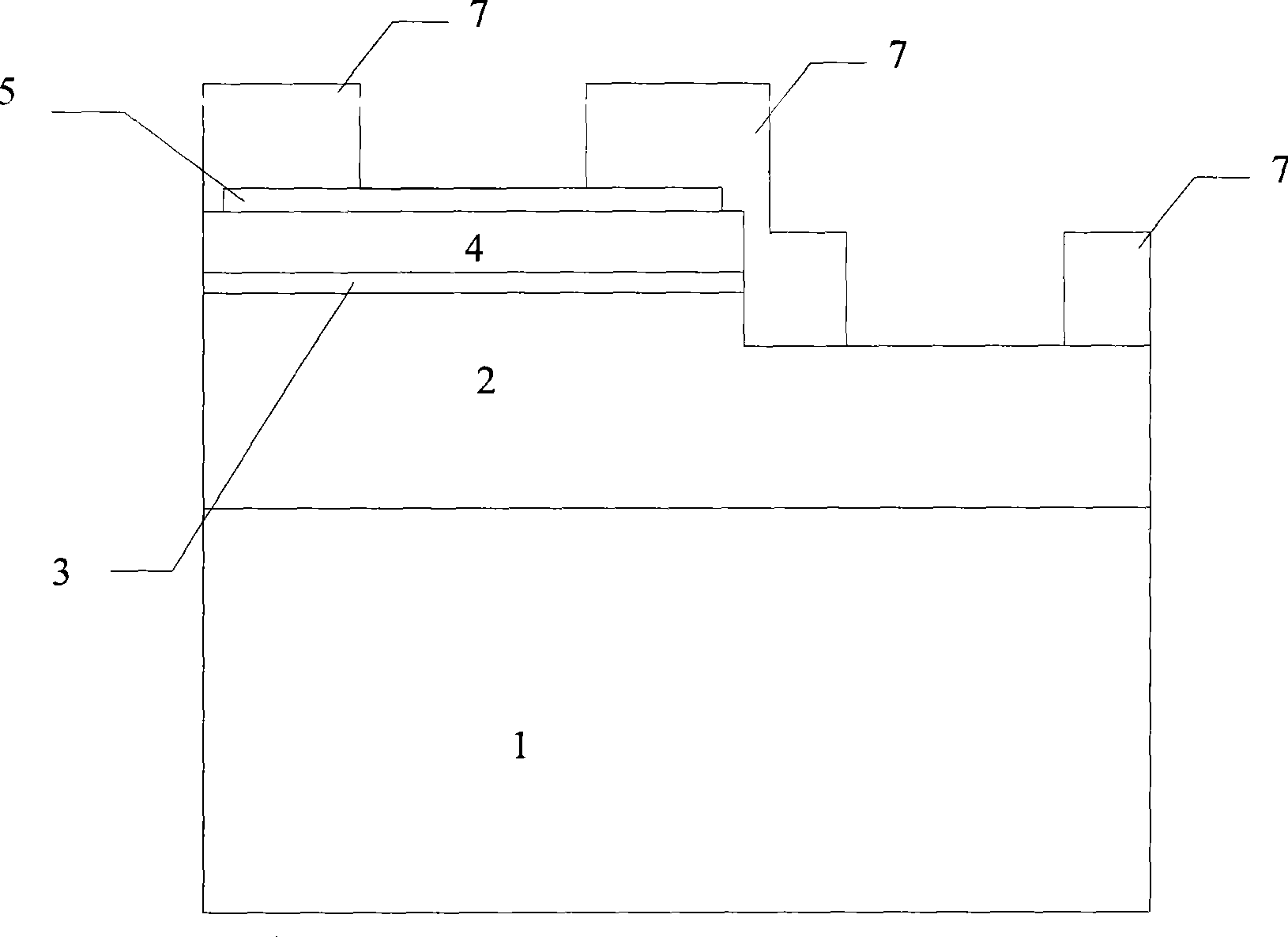

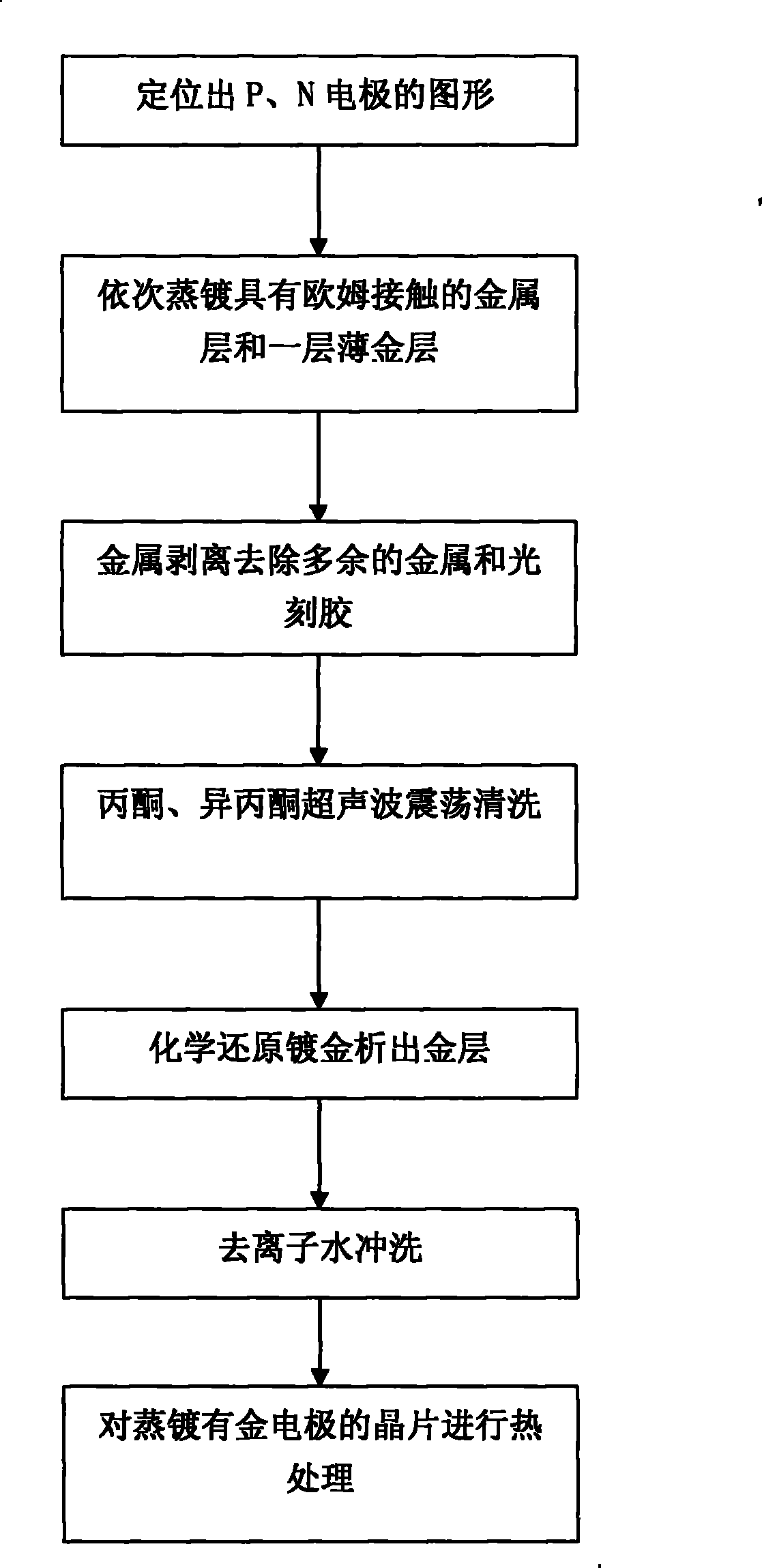

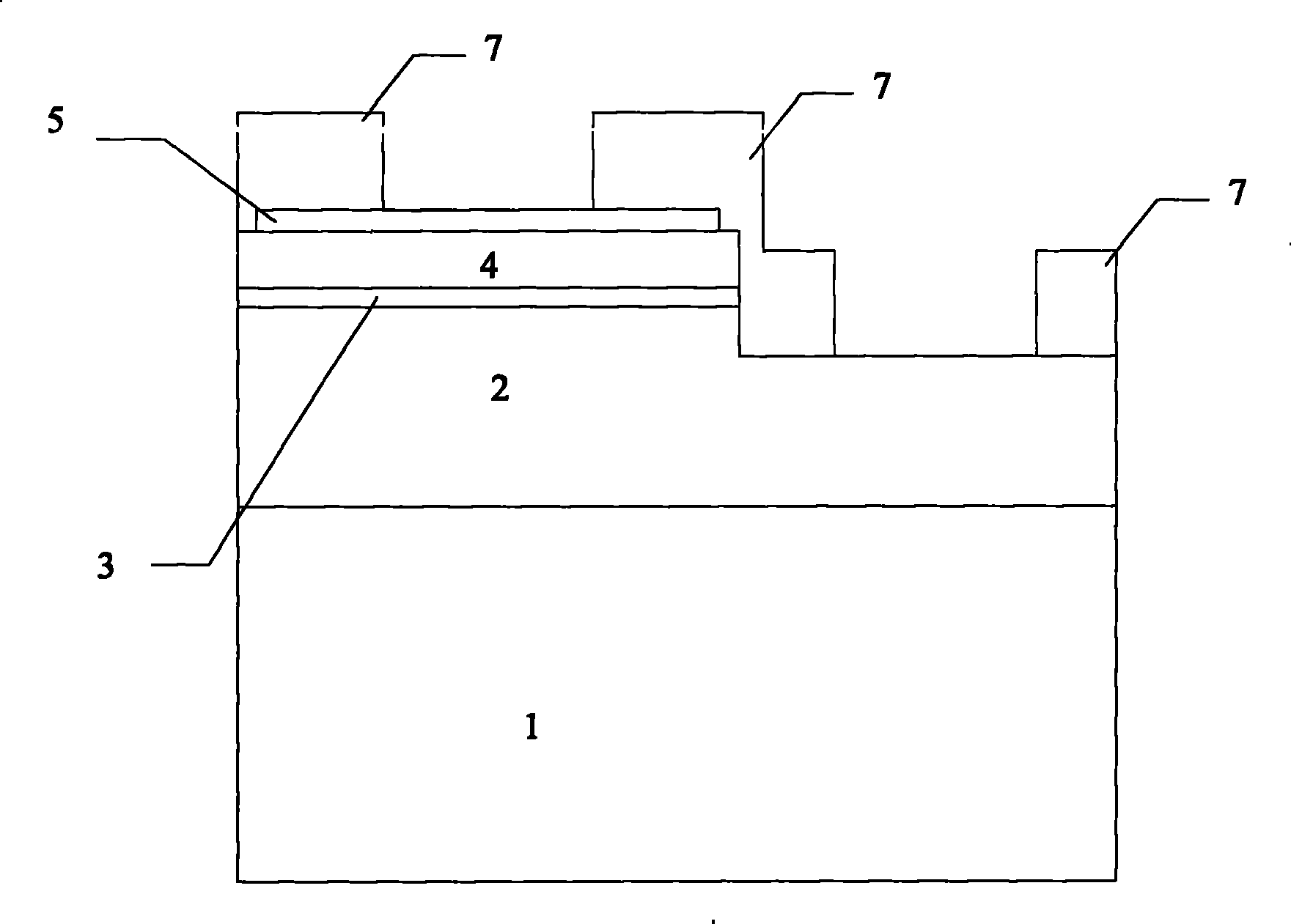

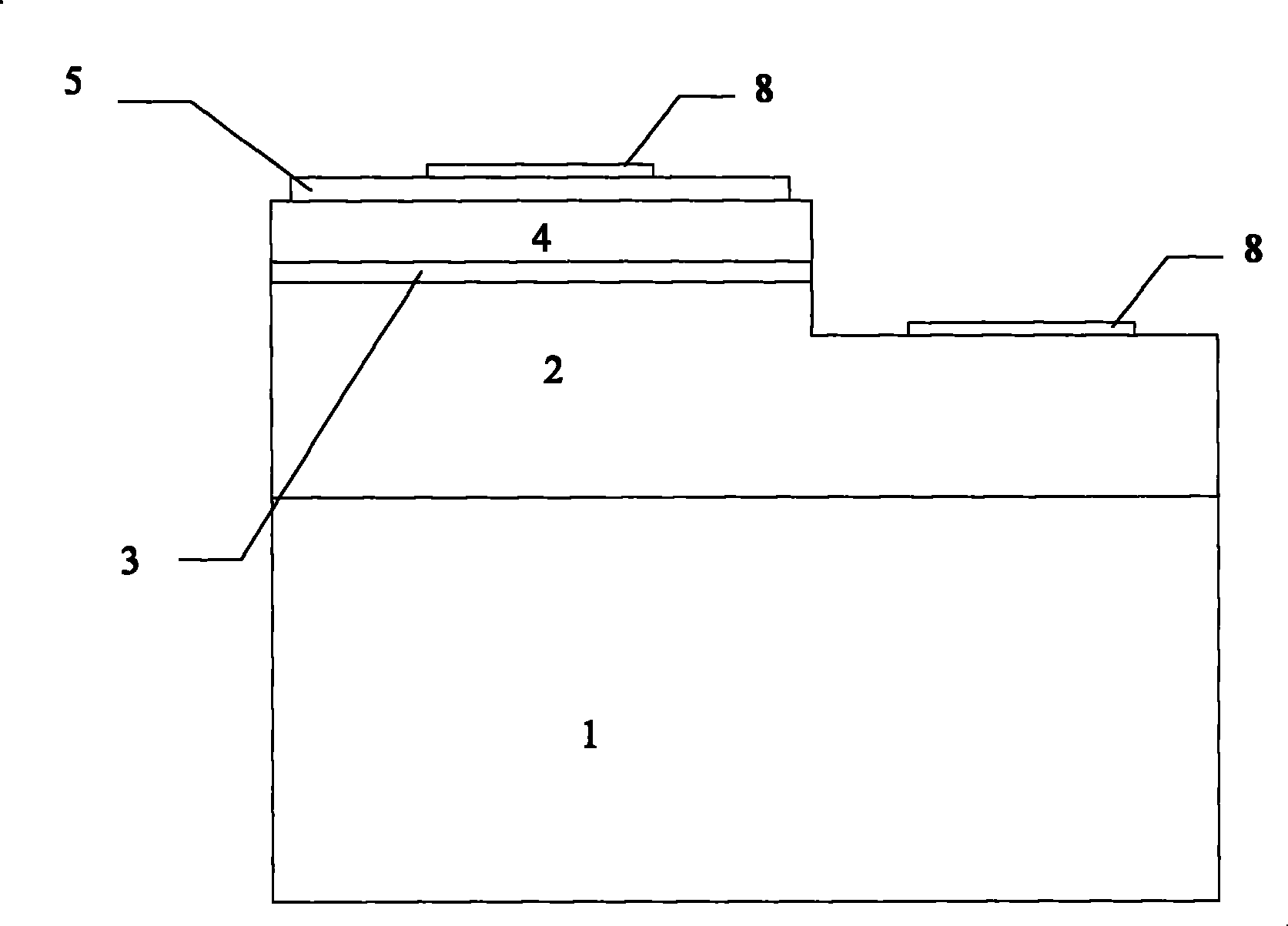

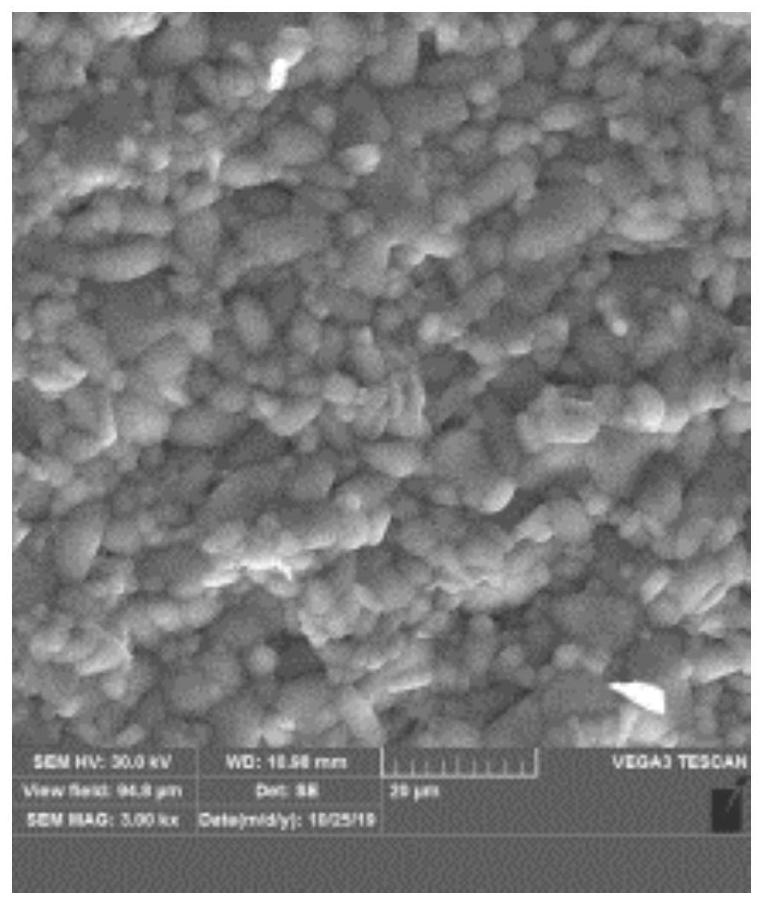

Production process for golden electrode for LED

The invention discloses a light-emitting diode gold electrode preparation method, which comprises the following steps: firstly, an ohmic-contact metal layer and a thin gold layer undergo vapour-deposition successively, and then the chemical reduction gold plating is adopted to precipitate a gold layer with a required thickness on the surface of the thin gold layer undergoing the vapour-deposition, so that the preparation of the light-emitting diode gold electrode is completed. The method adopts the chemical reduction gold plating method to prepare the gold electrode, so as to save significantly the consumption of gold, and lower the cost of raw material. The preparation method is simple in operation, and the storage of plating solution is stable. The prepared gold electrode has the advantages of high purity, smooth and bright surface, compactness and uniformity, has no pin-hole cracks or other defects, and is firmly combined.

Owner:ZHEJIANG INVENLUX TECH

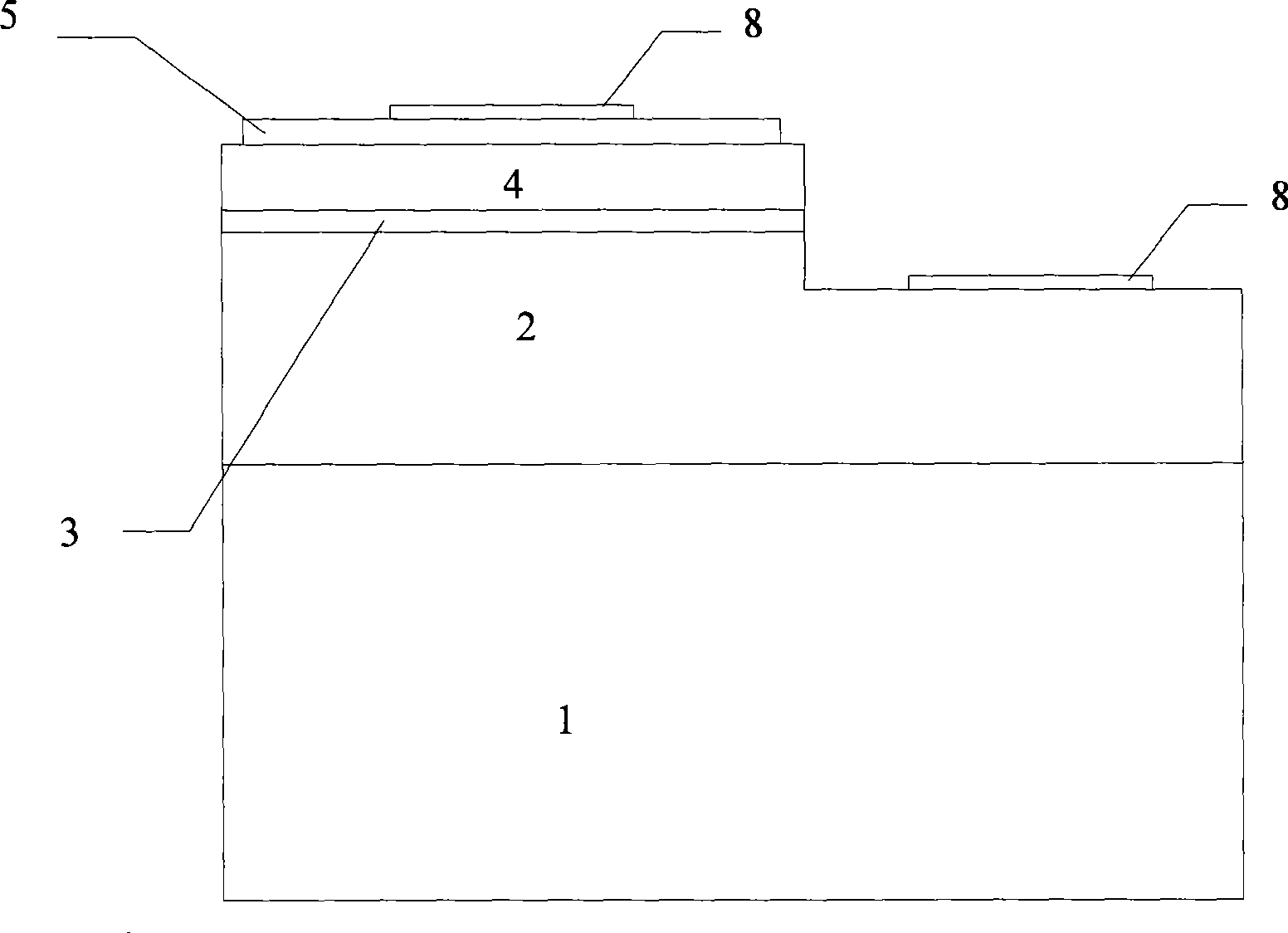

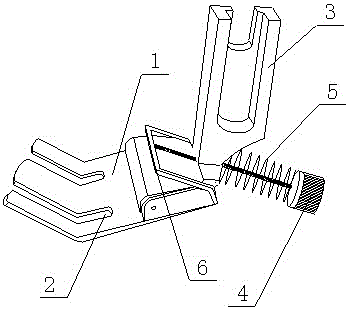

Manufacturing method and special tool for double-row down jacket ornament folds

The invention relates to down jacket manufacturing, in particular to a manufacturing method and special tool which are high in processing efficiency and quality and beneficial for producing double-row down jacket ornament folds in batches. The method includes the following steps of placing pleated fabric and down jacket surface fabric on an operation console of a double-needle machine in an overlapping mode, adjusting a bobbin case, a thread clamping device and the stitch length of the double-needle machine, rotating a screw shaft on a presser foot of the double-needle machine so that an included angle ranging from 20 degrees to 30 degrees can be formed between a bottom plate and the operation console, and finally conducting thread conveying. The presser foot used for achieving the method comprises the base and an installation part, wherein two grooves for needles to penetrate through are formed in the bottom plate, an adjustment part is arranged between the bottom plate and the installation part, and the adjustment part comprises the screw shaft, a spring and a pressing ord. Operation is easy, the garment quality is ensured, and the production efficiency is improved.

Owner:BOSIDENG DOWN WEAR

A method of improving the preoxidation speed of polyacrylonitrile fiber by physical blending

ActiveCN103993382BReduce usageReduce consumptionFilament forming substance formingArtificial filament heat treatmentWater bathsPlasticizer

The invention relates to a method for improving pre-oxidation speed of polyacrylonitrile fiber through physical blending. The method comprises the following steps: performing vacuum drying on polyacrylonitrile, lignin and a plasticizer, and uniformly stirring and mixing, thus obtaining a mixed material; spinning, setting and winding to obtain a melt spun fiber, wherein a mass ratio of polyacrylonitrile to lignin to the plasticizer is (5-30):(10-30):(50-70); and performing water bath drawing on the melt spun fiber, and performing pre-oxidation to obtain the pre-oxidation polyacrylonitrile fiber. The raw material lignin is low in cost and slight in environmental pollution and is suitable for industrial production; lignin contains lots of hydroxyl groups which can achieve hydrogen-bond interaction with a polar group cyano on a polyacrylonitrile molecular chain, and lignin and polyacrylonitrile have high compatibility; moreover, the oxygen content in the lignin structure is high, the oxygen can be released in the pre-oxidation process, a uniform oxygen source is provided for an oxidation reaction of a polyacrylonitrile precursor, and a prepared pre-oxidation thread sheath-core is small in difference and dense and uniform in structure.

Owner:优聚新材料(浙江)有限公司

Modified silanized metal surface pretreatment agent containing fatty alcohol-polyoxyethylene ether and preparation method thereof

InactiveCN103451642AOptimize the preparation processStrong corrosion resistanceMetallic material coating processesEmulsionChemistry

The invention discloses a modified silanized metal surface pretreatment agent containing fatty alcohol-polyoxyethylene ether. The pretreatment agent is prepared from the following raw materials in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of propyl alcohol, 30-40 parts of gamma-chloropropyl triethoxysilane, 20-30 parts of gamma-chloropropyl methyldimethoxysilane, 1-2 parts of dicumyl peroxide, 0.002-0.003 part of perfluorooctyl sodium sulfonate, 0.3-0.5 part of dioctyldilauryltin, 4-6 parts of epoxy resin emulsion, 2-3 parts of sodium carboxymethyl cellulose, 0.4-1.0 part of Span80, 0.2-0.6 part of fatty alcohol-polyoxyethylene ether, 0.005-0.01 part of lanthanum acetate and 0.1-0.3 part of phytic acid. A final product is obtained by modifying the coupling agent, compounding, adding auxiliaries and carrying out distribution, mixing and reaction. The modified silanized surface pretreatment agent has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane film, strong adhesion and good corrosion resistance.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

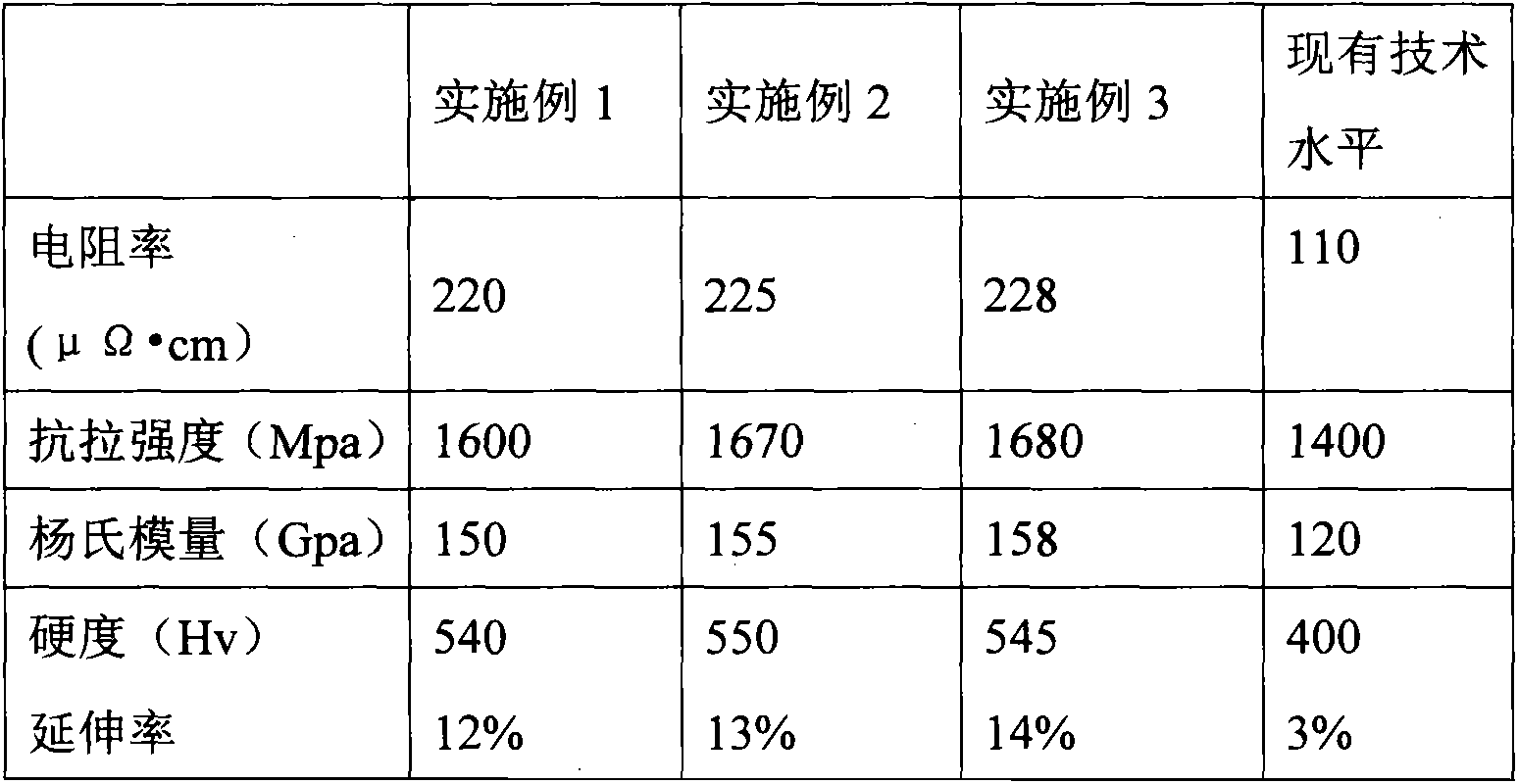

Palladium alloy and preparation method thereof

The invention relates to a palladium alloy which comprises the following components in percentage by mass: 20-25% of tungsten, 40-50% of palladium, 20-30% of tin and 5-10% of chromium. The hardness of the palladium alloy is 500-550Hv, the tensile strength is up to 1600-1700 MPa, the elongation percentage is 10-15%, the Young's modulus is 140-160 GPa, and the resistivity is 200-280 mu ohm.cm.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

A kind of injection molding method of ferrite soft magnetic material

ActiveCN104029281BSolve production and processing difficultiesHigh mechanical strengthCeramic shaping apparatusGrain treatmentsAdhesiveFerrite powder

Owner:ZHEJIANG UNIV

Hydraulic system and control method of a ceramic tile press

ActiveCN111336139BThe whole is dense and uniformIncrease densityServomotor componentsAccumulator installationsBrickHigh density

The invention provides a hydraulic system and a control method of a ceramic brick press, and relates to the technical field of brick press equipment. Wherein, the hydraulic system includes a pressure supply mechanism, a first control mechanism and a second control mechanism. The first control mechanism and the second control mechanism are respectively used to control the up and down movement of the movable beam of the lower mold and the movable beam of the upper mold. The hydraulic system of the ceramic tile press of the present invention pressurizes and exhausts the green body multiple times through the up and down directions, and the pressure applied multiple times is gradually increased, so that the green body has a high density and a uniform force. In addition, through the improvement of the demoulding process, the cracking of the green body caused by demoulding is greatly reduced.

Owner:XIAMEN UNIV OF TECH

Production process for golden electrode for LED

The invention discloses a light-emitting diode gold electrode preparation method, which comprises the following steps: firstly, an ohmic-contact metal layer and a thin gold layer undergo vapour-deposition successively, and then the chemical reduction gold plating is adopted to precipitate a gold layer with a required thickness on the surface of the thin gold layer undergoing the vapour-deposition, so that the preparation of the light-emitting diode gold electrode is completed. The method adopts the chemical reduction gold plating method to prepare the gold electrode, so as to save significantly the consumption of gold, and lower the cost of raw material. The preparation method is simple in operation, and the storage of plating solution is stable. The prepared gold electrode has the advantages of high purity, smooth and bright surface, compactness and uniformity, has no pin-hole cracks or other defects, and is firmly combined.

Owner:ZHEJIANG INVENLUX TECH

A kind of high strength and toughness alcrsc alloy powder for 3d printing and its preparation method and application

ActiveCN113512671BHigh tensile strengthHigh yield strengthAdditive manufacturing apparatusIncreasing energy efficiency3d printHigh density

The invention relates to the technical field of aluminum alloy powder materials for 3D printing, in particular to a high-strength and tough AlCrSc alloy powder for 3D printing and its preparation method and application. The alloying elements of the aluminum alloy powder material for 3D printing provided by the present invention include: Cr: 1.0-4.0wt%, Sc: 0.3-1.1wt%, Zr: 0.1-0.6wt%, Si: 0.5-1.2wt%, Mn : 0.1~0.7wt%, Mg: 0~6.0wt%, trace element: <0.1wt%, the balance is Al; the trace element is one of Ti, Fe, Ni, Ce, Sr, Er, La or several. Studies have shown that the aluminum alloy powder obtained by controlling the above conditions, the printed parts formed by 3D printing technology have high density, strength, plasticity, corrosion resistance, yield strength ratio and fatigue performance, and at the same time solve the problem of the printing process. Soot and oxidation problems, thereby improving the anti-oxidation and anti-fatigue properties of printed parts. The 3D printed parts obtained by the present invention have great potential prospects in engineering applications such as load-bearing parts, lightweight integrated parts, and radiator replacements.

Owner:CRRC IND INST CO LTD

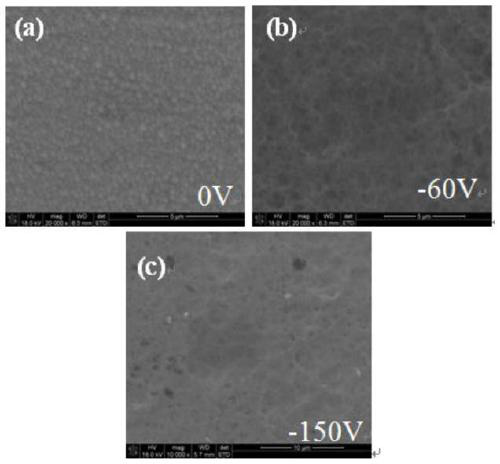

Granules of microwave dielectric material for injection molding, and manufacturing method of microwave dielectric device

The invention relates to granules of a microwave dielectric material for injection molding, and a manufacturing method of a microwave dielectric device. The granules comprise, by weight, 70-90% of a microwave dielectric material and 10-30% of a binder, wherein the microwave dielectric material comprises 60-70% of titanium dioxide, 25-35% of magnesium oxide, 2-8% of calcium carbonate, 2-8% of barium carbonate, 0.1-1% of niobium pentoxide, and 0.1-1% of bismuth trioxide, and the binder comprises 70-90% of polyformaldehyde, 2-15% of polymethyl methacrylate, 2-15% of polypropylene, 2-15% of an ethylene-vinyl acetate copolymer, 2-10% of wax, 1-3% of dioctyl phthalate, 1-3% of dibutyl phthalate and 1-5% of stearic acid. According to the invention, the relative dielectric constant epsilon r, theQ*f value and the resonant frequency temperature coefficient tau f of the microwave dielectric device manufactured by the method are better than those of a traditional method, and crystal grains of asample are compact, fine and uniform.

Owner:SHENZHEN SUNLORD ELECTRONICS

Manufacturing method and special tools for double-row down jacket decorative pleats

The invention relates to down jacket manufacturing, in particular to a manufacturing method and special tool which are high in processing efficiency and quality and beneficial for producing double-row down jacket ornament folds in batches. The method includes the following steps of placing pleated fabric and down jacket surface fabric on an operation console of a double-needle machine in an overlapping mode, adjusting a bobbin case, a thread clamping device and the stitch length of the double-needle machine, rotating a screw shaft on a presser foot of the double-needle machine so that an included angle ranging from 20 degrees to 30 degrees can be formed between a bottom plate and the operation console, and finally conducting thread conveying. The presser foot used for achieving the method comprises the base and an installation part, wherein two grooves for needles to penetrate through are formed in the bottom plate, an adjustment part is arranged between the bottom plate and the installation part, and the adjustment part comprises the screw shaft, a spring and a pressing ord. Operation is easy, the garment quality is ensured, and the production efficiency is improved.

Owner:BOSIDENG DOWN WEAR

Sealing method of compression packing with density gradient and compression packing thereof

ActiveCN104154243BThe whole is dense and uniformUniform lateral forceEngine sealsEngineeringMechanical engineering

A sealing method of the compression padding with the density gradient comprises the first step of placing the strip-shaped padding in a forming mold according to a certain weight and a certain size, the second step of pressing the strip-shaped padding into annular padding rings through a press, wherein the forming height of the padding rings can be accurately controlled through a liner stop piece with the preset height in the pressing process so that the padding rings with the required densities can be obtained, and the third step of making the padding rings overlap in the force bearing direction, wherein the densities of the padding rings sequentially increase one by one in the force bearing direction. The invention further comprises the compression padding produced according to the method, wherein the compression padding is composed of the padding rings overlapping in the force bearing direction, and the densities of the padding rings sequentially increase one by one in the force bearing direction.

Owner:NINGBO TIANSHENG SEALING PACKING +2

Spray deposition densifying device and application thereof

ActiveCN103302293BAvoid dense unevennessThe whole is dense and uniformEngineeringMechanical engineering

The invention discloses a spray deposition densifying device and the application thereof. The device disclosed by the invention includes a rotating shaft, wherein a plurality of rotating balls are fixed on the rotating shaft; each rotating ball is fixed on the rotating shaft through a flexible chain; during the rotation of the rotating shaft, the rotating balls are distributed in a spiral line around the rotating shaft, the extending direction of the spiral line is the same as the axial direction of the rotating shaft, and the length of the flexible chain in the direction the same as the rotating direction of the rotating shaft periodically changes along the spiral line; within each period, the length of the flexible chain is gradually increased in the direction the same as the rotating direction of the rotating shaft; the screw pitch of the spiral line is 30-50 mm; and the central angle of ball centers of the two adjacent rotating balls is 10-15 degrees. During the spray deposition, the rotating balls in the densifying device are used for impacting the surface of a deposition blank, metallurgical bonding is generated under the shearing action, the deposition blank is densified layer by layer through the rotation of a pipe blank during the spray deposition, the entire densification is realized in an accumulated manner, so that the pipe stock with high performance is obtained.

Owner:HUAIHAI INST OF TECH

Tool for compacting thick-walled hollow carbon/carbon (C/C) composite product

ActiveCN102618851BSimple structureNovel and reasonable designChemical vapor deposition coatingRetention periodEngineering

The invention discloses a tool for compacting a thick-walled hollow carbon / carbon (C / C) composite product, which comprises an outer barrel, a gas inlet substrate and a gas guide device, wherein the interior of the outer barrel is provided with a gas inlet basal plate; a cavity I is formed between the gas inlet substrate and the gas inlet basal plate; the gas inlet substrate is provided with a gas inlet; the top face of the gas inlet basal plate is provided with an inner barrel; a to-be-compacted thick-walled hollow C / C composite preform is sheathed onto the inner barrel; a gap I for the circulation of gas is formed between the outer surface of the C / C composite preform and the inner surface of the outer barrel; a gap II for the circulation of the gas is formed between the inner surface of the C / C composite preform and the outer surface of the inner barrel; and the gas inlet basal plate is provided with a plurality of diversion passages II and diversion passages III, wherein the diversion passages II are used for communicating the cavity I with the gap I, and the diversion passages III are used for communicating the cavity I and the gap II. According to the tool for compacting the thick-walled hollow C / C composite product, gas diversion can be performed, and thereby, the retention period of pyrolysis gas in a depositing space is shortened, and the C / C composite preform is rapidly and evenly compacted.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

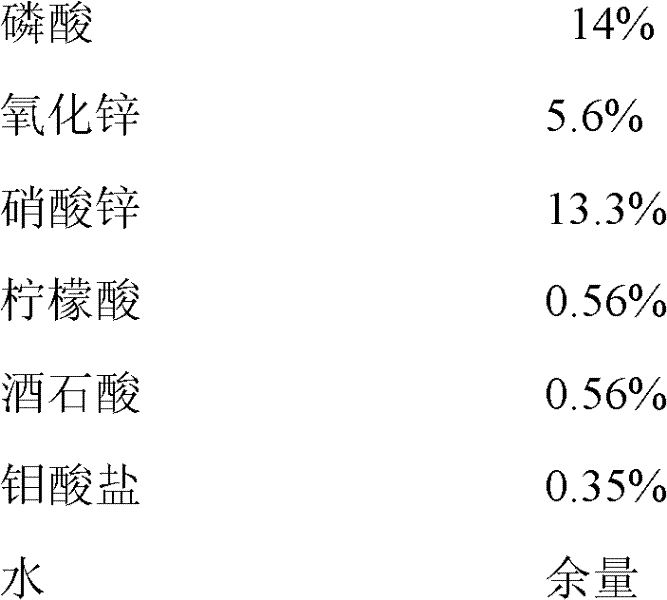

Zinc-iron metal alramenting liquid capable of being recycled at normal temperature

InactiveCN101935832BLow investment costReduce energy consumptionMetallic material coating processesSlagPhosphoric acid

The invention relates to a zinc-iron metal alramenting liquid capable of being recycled at normal temperature. The invention is characterized in that the alramenting liquid is prepared by the following raw materials by weight percent: 14-28% of phosphoric acid, 3.5-7% of zinc oxide, 12.6-17.5% of zinc nitrate, 0.14-0.56% of citric acid, 0.14-0.7% of tartaric acid and 0.14-0.84% of molybdate, and balance of water.In the invention, phosphorization is carried out in one process after oil removing and rust removing are carried out, the processes of neutralizing, surface conditioning, passivating and washing are eliminated, and a compact and uniform phosphorization membrane with strong adhesive force is rapidly formed on the surface of ferrous metal. The process greatly reduces operation procedure, the phosphorization process produces no slag, thus reducing pollution to the environment and greatly improving utilization factor of material; and energy consumption at normal temperature is reduced and water is saved. The invention has the advantages of wide application range, less investment, high efficiency and high safety, and bath solution has good stability, no deterioration or volatilization is caused, and maintenance is easy, thus being beneficial to follow-up spraying processes.

Owner:NANJING YOUWEI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com