Sealing method of compression padding with density gradient and compression padding produced according to method

A density gradient and density technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., to achieve the effect of uniform lateral force, low production cost, and uniform overall density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

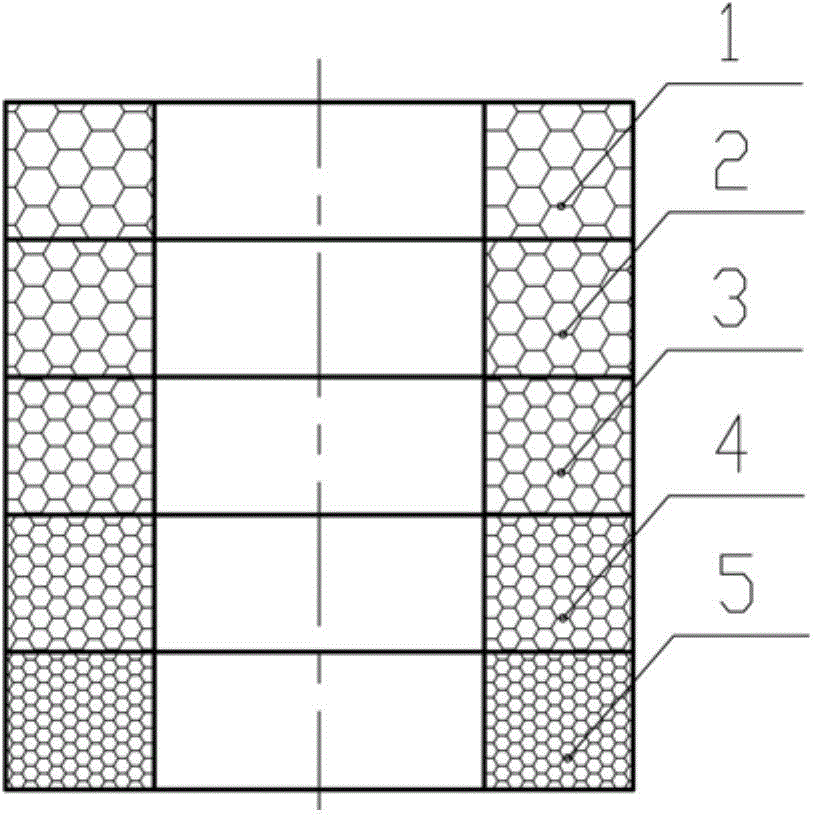

[0019] Further illustrate the present invention below in conjunction with accompanying drawing

[0020] Referring to the attached picture:

[0021] A sealing method for compressed packing with a density gradient, comprising the following steps:

[0022] Step 1, the strip filler is placed in the forming mold according to a certain weight and size (this strip filler can be the raw material used when the original process prepares the filler),

[0023] Step 2: Compress the annular packing ring with a press, and the forming height of the packing ring can be precisely controlled by a predetermined height of the gasket stopper during pressing, so as to obtain the packing ring with the required density;

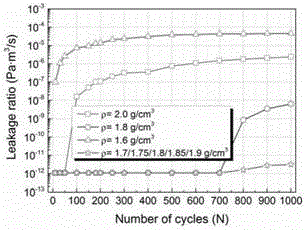

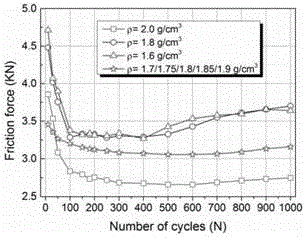

[0024] Step 3, stacking the packing rings along the stress direction, and along the force direction, the density of the packing rings increases one by one.

[0025] The compression packing produced according to the above method is characterized in that: it is composed of several pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com