Palladium alloy and preparation method thereof

An alloy, mass percentage technology, applied in the field of alloys, can solve the problems of low resistivity, low temperature coefficient of resistance, wear resistance, poor workability, and difficulty in mass production, and achieves improved wear resistance and oxidation resistance, improved ductility, less The effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

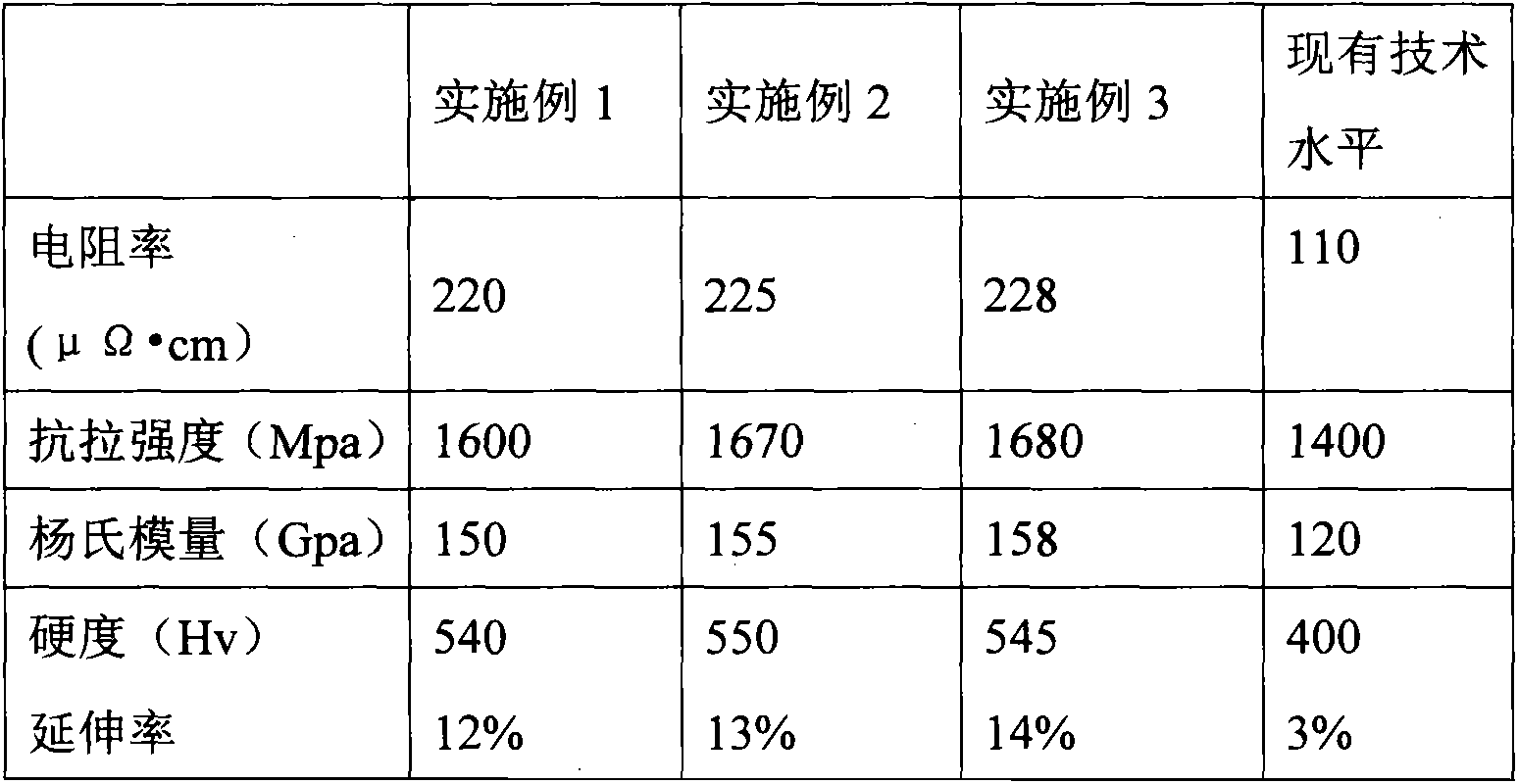

[0019] A palladium-based alloy, the palladium-based alloy is: 20% tungsten, 50% palladium, 20% tin, and 10% chromium by mass percentage; the hardness of the palladium-based alloy is 540Hv, the tensile strength reaches 1600MPa, and the elongation is 12%, Young's modulus is 150 GPa, and resistivity is 220 μΩ·cm.

Embodiment 2

[0021] A palladium-based alloy, the palladium-based alloy by mass percentage is: 22% tungsten, 48% palladium, 25% tin, 5% chromium; the hardness of the palladium-based alloy is 550Hv, the tensile strength reaches 1670MPa, and the elongation is 13%, Young's modulus is 155GPa, and resistivity is 225μΩ·cm.

Embodiment 3

[0023] A palladium-based alloy, the palladium-based alloy by mass percentage is: 25% tungsten, 45% palladium, 22% tin, 8% chromium; the hardness of the palladium-based alloy is 545Hv, the tensile strength reaches 1680MPa, and the elongation is 14%, Young's modulus is 158GPa, and resistivity is 228μΩ·cm.

[0024] Table 1: Performance Test Table

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com